Coal mining machine fluid-driven crusher

A technology for coal shearers and crushers, applied in the direction of slitting machinery, cutting machinery, driving devices, etc., can solve the problems of high failure rate and poor impact resistance, and achieve high-efficiency crushing, high impact resistance, and overload capacity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

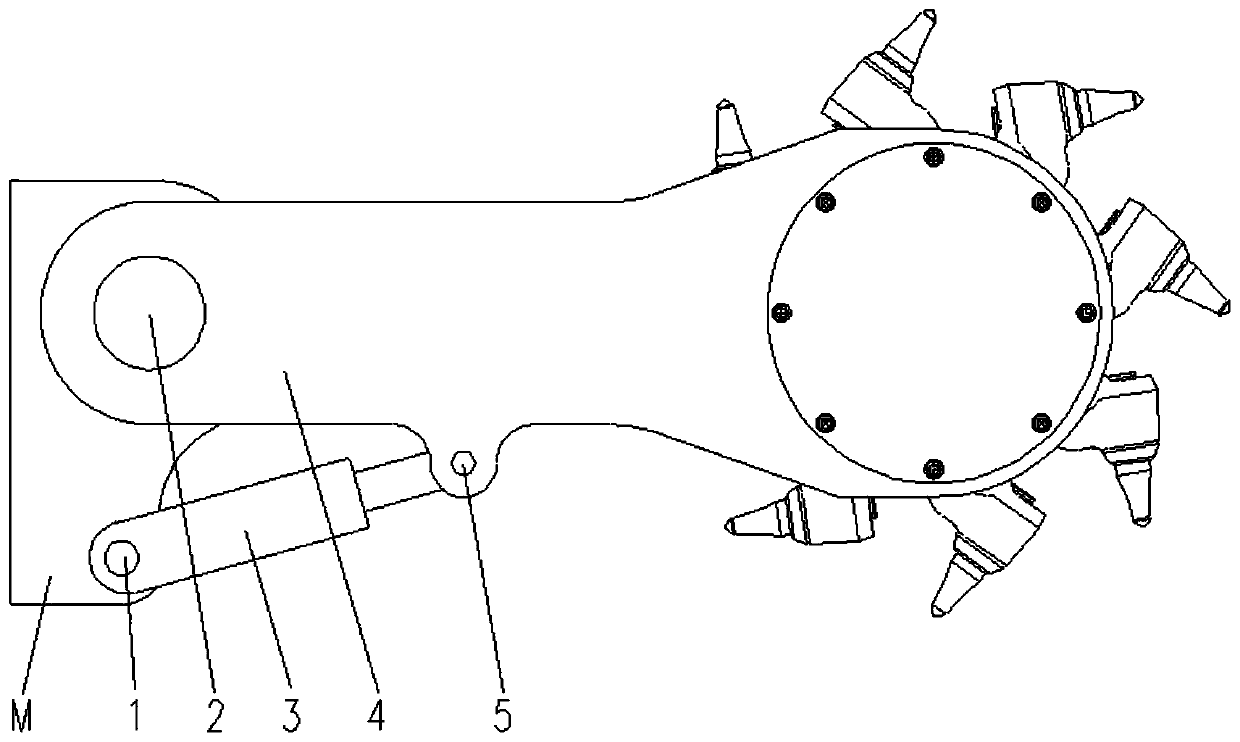

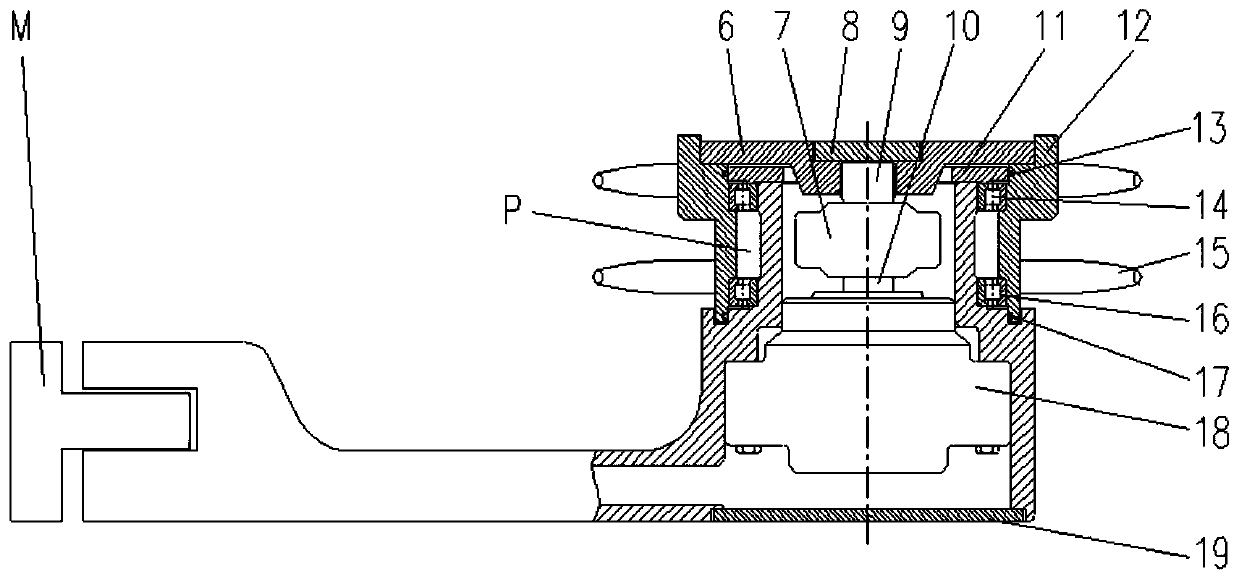

[0024] The invention discloses a shearer hydraulic breaker, such as figure 1 , 2 As shown, it includes a boom 4, a drum 12, a hydraulic motor 18 and an end cover 6. The boom includes a cylinder and an arm, and the axis of the cylinder is front and rear (corresponding to figure 2 up and down) extension, arms left and right (corresponding to figure 2 The left and right) extend and one end is connected to the rear of the cylinder. The coaxial rotating support of the drum is installed outside the front part of the cylinder. The end cover is coaxially fixed on the front end of the drum, and the drum and the end cover can rotate continuously around the axis of the cylinder of the jib as a whole. The hydraulic motor is fixedly installed in the barrel, that is, the housing of the hydraulic motor is relatively fixed to the barrel, and the output shaft of the hydraulic motor is coaxially connected with the end cover. The hydraulic motor is used to provide rotational power for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com