Method for processing crease lines of flexible flat cable (FFC) material and crimping machine implementing method

A working and cylinder technology, applied in the field of discount machines, can solve problems such as difficult control of processing strength, difficulty in restoring the original shape, broken wires, etc., to achieve the effect of reducing product defect rate, reducing production cost, and improving discount quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

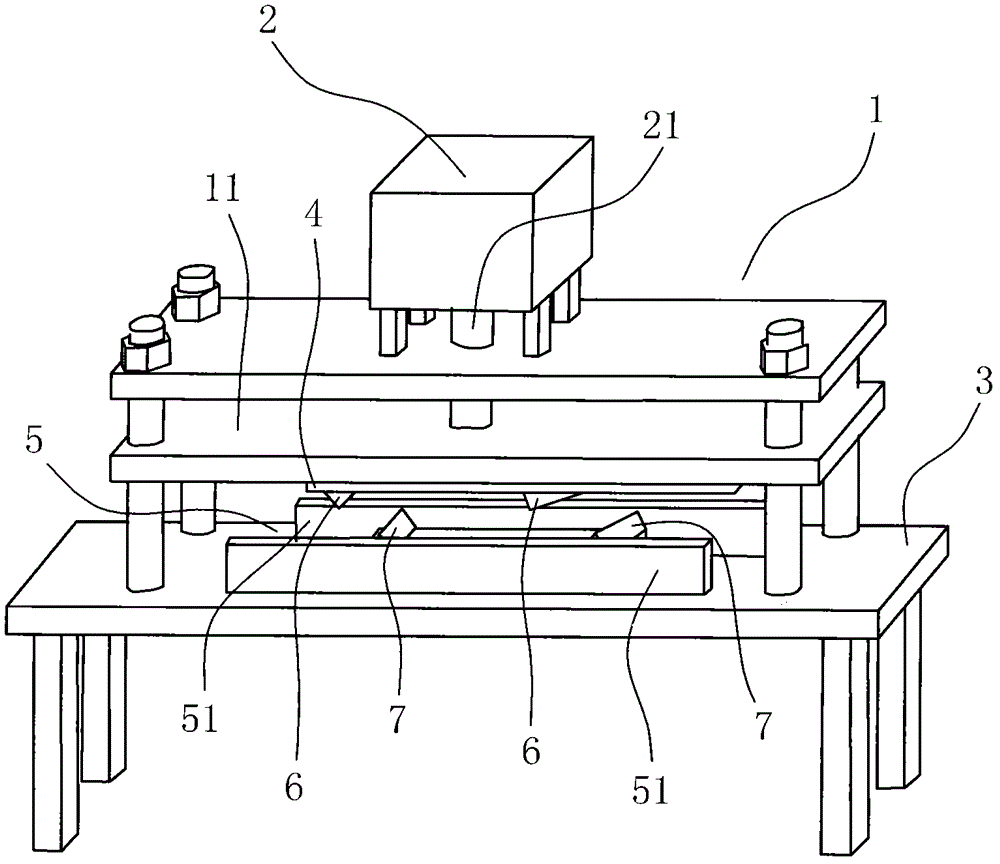

[0026] Example: see figure 1 , a kind of method that the present invention carries out crease processing to FFC material, it comprises the following steps:

[0027] (1) A cylinder 2 output shaft 21 is fixed downward on a machine platform 3 through a bracket 1, and a stamping die fixing plate 4 is fixed at the end of the output shaft 21;

[0028] (2) An FFC material is set on the machine platform 3 to pass through the track 5, and the distance between the two side walls 51 of the track 5 is greater than the width of the stamping die fixed plate 4;

[0029] (3) On the bottom surface of the stamping die fixing plate 4, a number of upper stamping dies 6 are set according to the number of creases and directions required by the FFC material;

[0030] (4) A control system is set, and the control system includes an induction module for sensing the conductor position of the FFC material and a control module for controlling the work of the cylinder 2;

[0031] (5) Set the working rang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com