Patents

Literature

30results about How to "Not easy to restore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

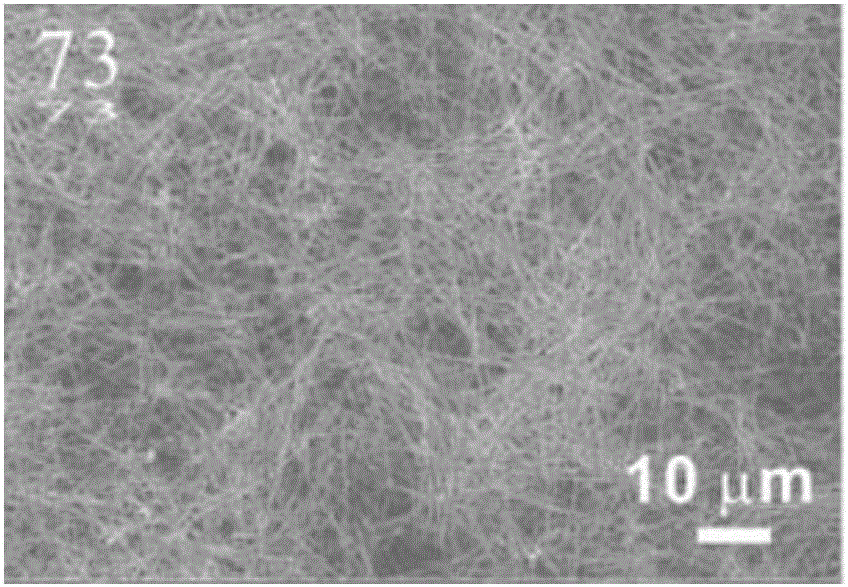

Metal nanowire-antioxidation material composite transparent conductive film and preparation thereof

InactiveCN106297966ARich sourcesEasy to manufactureConductive layers on insulating-supportsOxide conductorsTransmittanceOxidation resistant

The invention relates to the technical field of transparent electrodes, and specifically discloses a metal nanowire-antioxidation material composite transparent conductive film. The conductive film comprises a high-conductivity transparent metal nanowire and an antioxidation material continuous film which covers the outer side of a metal nanowire grid and used for isolating the air. The antioxidation material is graphene or conductive nanocrystalline metal oxide. The conductive film provided by the invention belongs to a transparent conductive film of a new generation, is abundant in material resources, is relatively easy to prepare, is low in cost, is high in cost performance, is good in flexibility, is poisonless, is resistant to environment, is good in chemical stability, is not easy to reduce, and has the best square resistance, light transmittance and flexibility.

Owner:GUANGDONG NANOLUTION SCI & TECH CO LTD

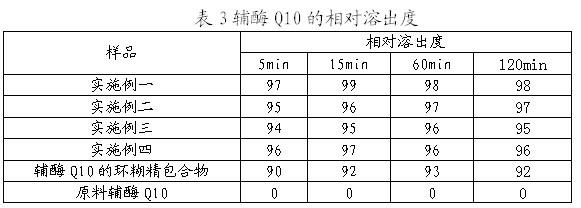

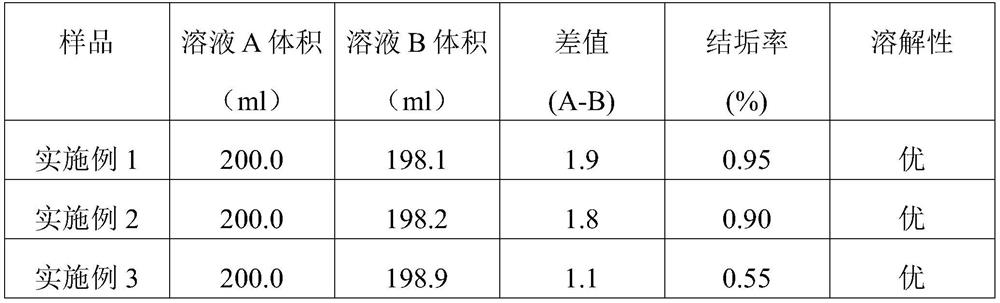

Water-soluble coenzyme Q10 combination and preparation method thereof

InactiveCN101940564AEasy to getImprove solubilityEther/acetal active ingredientsMacromolecular non-active ingredientsFructoseCarrageenan

The invention relates to a coenzyme Q10 combination and a preparation method thereof and provides a water-soluble coenzyme Q10 combination, which contains the following raw materials in parts by weight: 5-15 parts of coenzyme Q10, 10-120 parts of water-soluble carrier and 0.5-40 parts of emulsifier; the water-soluble carrier is one or more of maltodextrin, CMC, purity gum, soluble starch, lactose, fructose, sorbierite, mannite, Arabic gum, carrageenan, microcrystalline cellulose and sodium carboxymethyl starch; and the emulsifier is non-ionic surfactant. The invention also provides the preparation method of the water-soluble coenzyme Q10 combination. Fat-soluble coenzyme Q10, the water-soluble carrier and the amphoteric emulsifier are mixed and prepared into the water-soluble coenzyme Q10 combination, and the method synthesizes the advantages of an inclusion technique and a solid dispersion technique and solves the problems that the fat-soluble coenzyme Q10 is difficult to dissolve in water and has low bioavailability, and a number of experiments prove that the water-soluble coenzyme Q10 combination has good water solubility, fast dissolution rate, good stability and high content of effective substances.

Owner:杭州华东医药集团康润制药有限公司

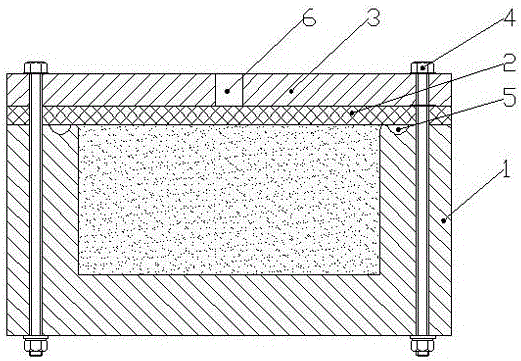

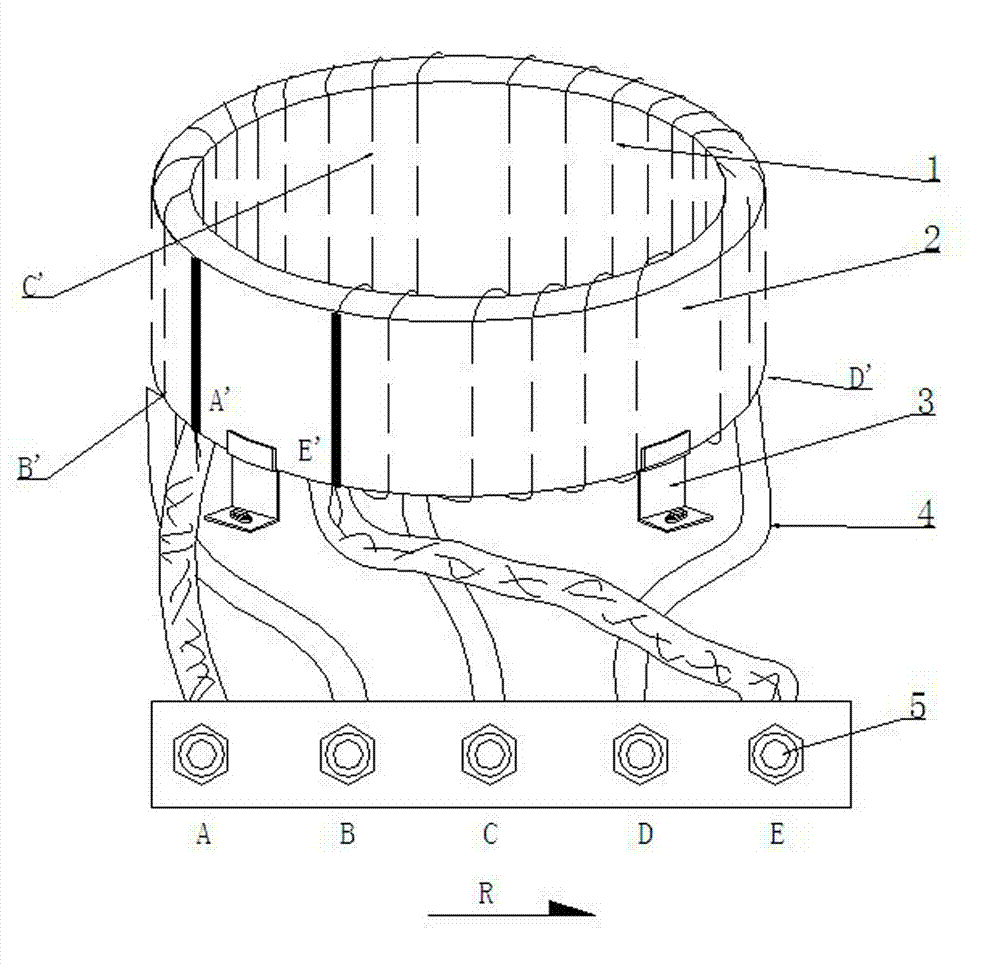

Preparation method of large-size and fine-grain molybdenum tantalum alloy sputtering target material

ActiveCN105714253AEvenly distributedAvoid defectsVacuum evaporation coatingSputtering coatingSputteringLarge size

A preparation method of a large-size and fine-grain molybdenum tantalum alloy sputtering target material comprises steps of cold isostatic pressing molding through combination of a steel mold with a rubber plate, sintering, levelling and reshaping, hot isostatic pressing treatment, rolling and machining. The grain size of the produced target material is smaller than 50 microns, the change of the grain size is maintained within 20%, and grains are evenly distributed in the plane direction and the thickness direction of the target material; the relative density of the target material is higher than 97%; besides, the large-size sputtering target material with the length being about 2 m and the width being about 1.3 m can be produced.

Owner:ACHEMETAL TUNGSTEN & MOLYBDENUM

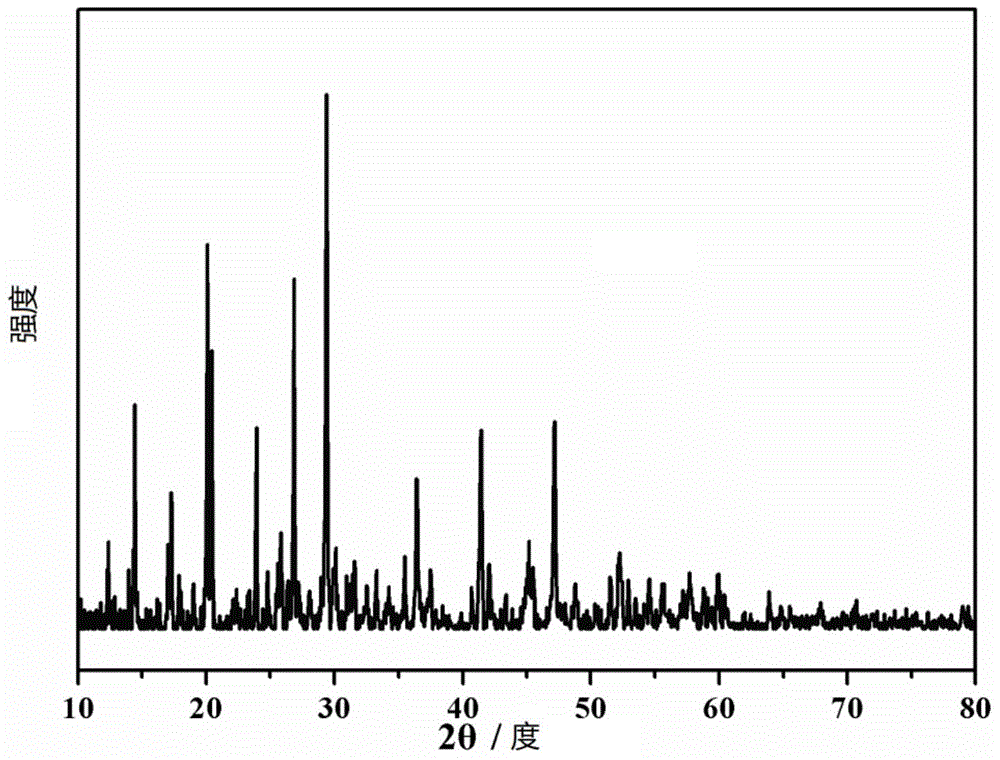

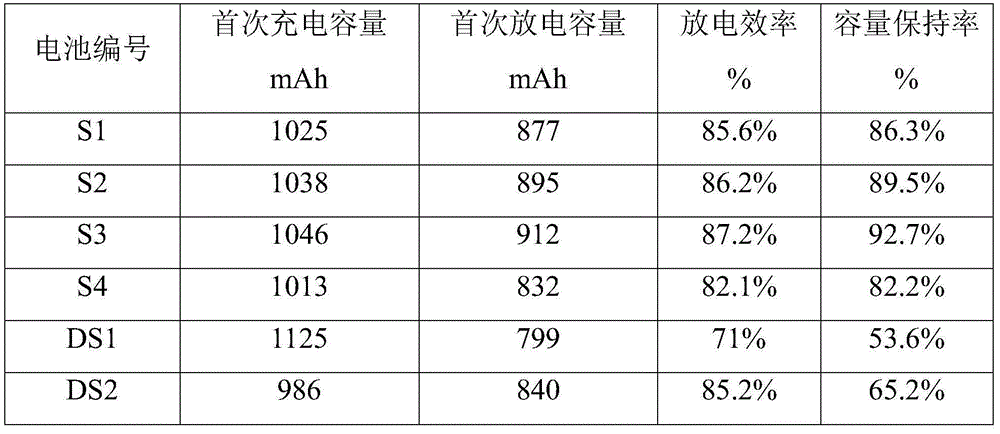

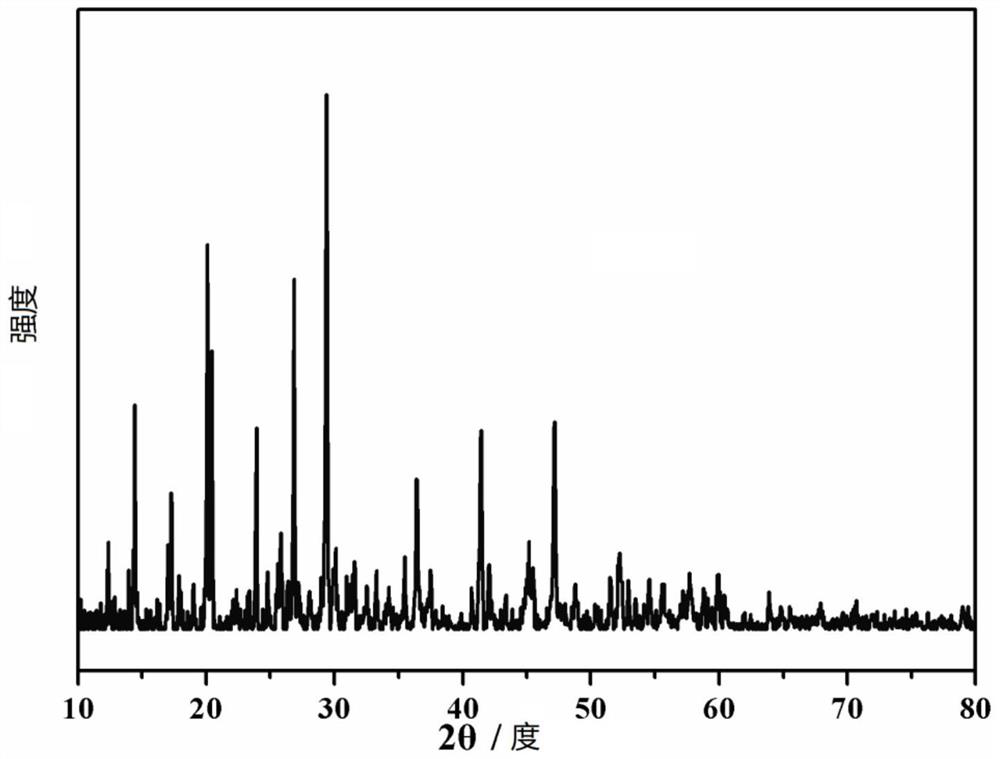

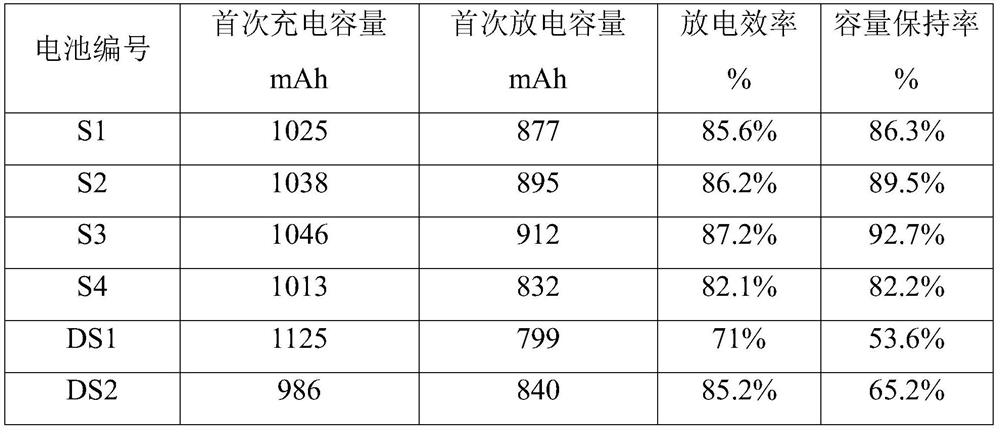

Solid electrolyte material and preparation method therefor, solid electrolyte and battery

ActiveCN106611871AEasy to makeImprove ionic conductivitySolid electrolytesFinal product manufactureElectrolysisMetal

The invention relates to a solid electrolyte material. The solid electrolyte material comprises a crystalline state inorganic solid electrolyte and an amorphous state inorganic solid electrolyte, wherein the crystalline state inorganic solid electrolyte is one or more of crystalline state inorganic solid electrolytes expressed by a formula of Li<10 plus or minus 1>AB<2>X<12>; and the amorphous state inorganic solid electrolyte is one or more of amorphous state inorganic solid electrolytes expressed by a formula of <y>Li<2>X<-(100-y)>P<2>X<5>. The invention also provides a preparation method for the solid electrolyte material, a solid electrolyte comprising the solid electrolyte material, and a battery comprising the solid electrolyte. The solid electrolyte material provided by the invention is simple in preparation process, excellent in ionic conductivity, particularly not reduced by a metal negative electrode easily, and relatively high in stability; and the prepared electrolyte has longer cycle life, so that the battery is more durable.

Owner:BYD CO LTD

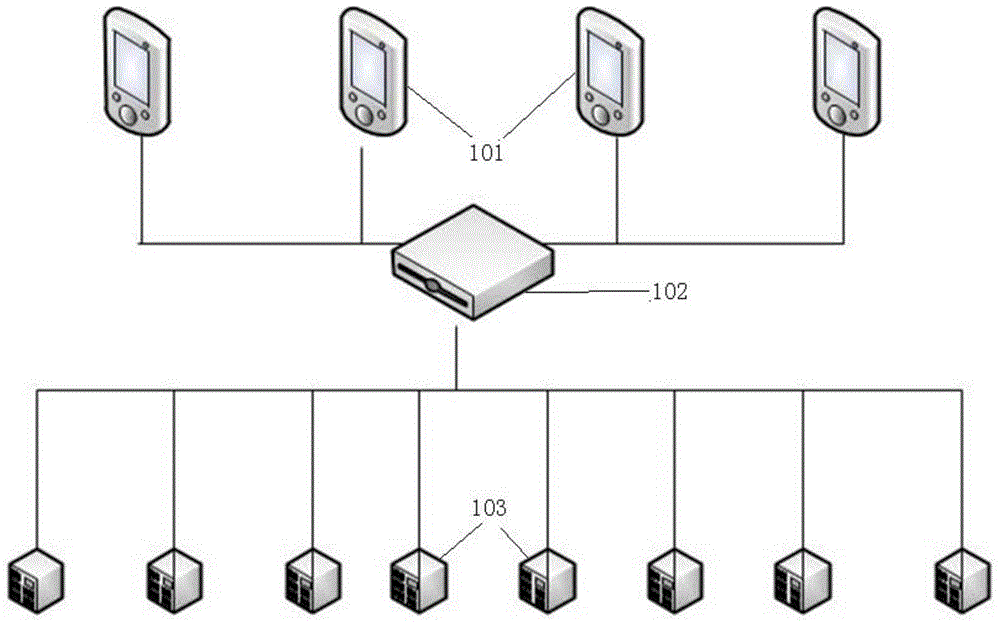

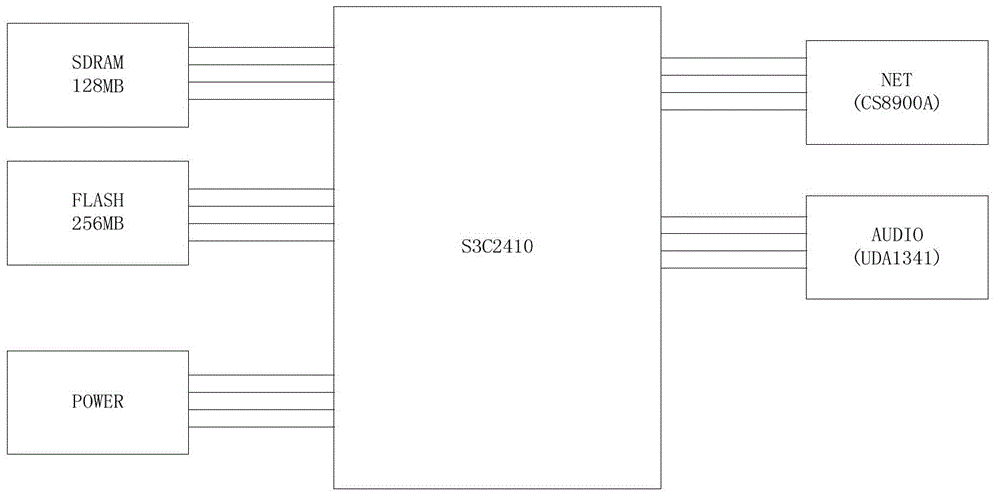

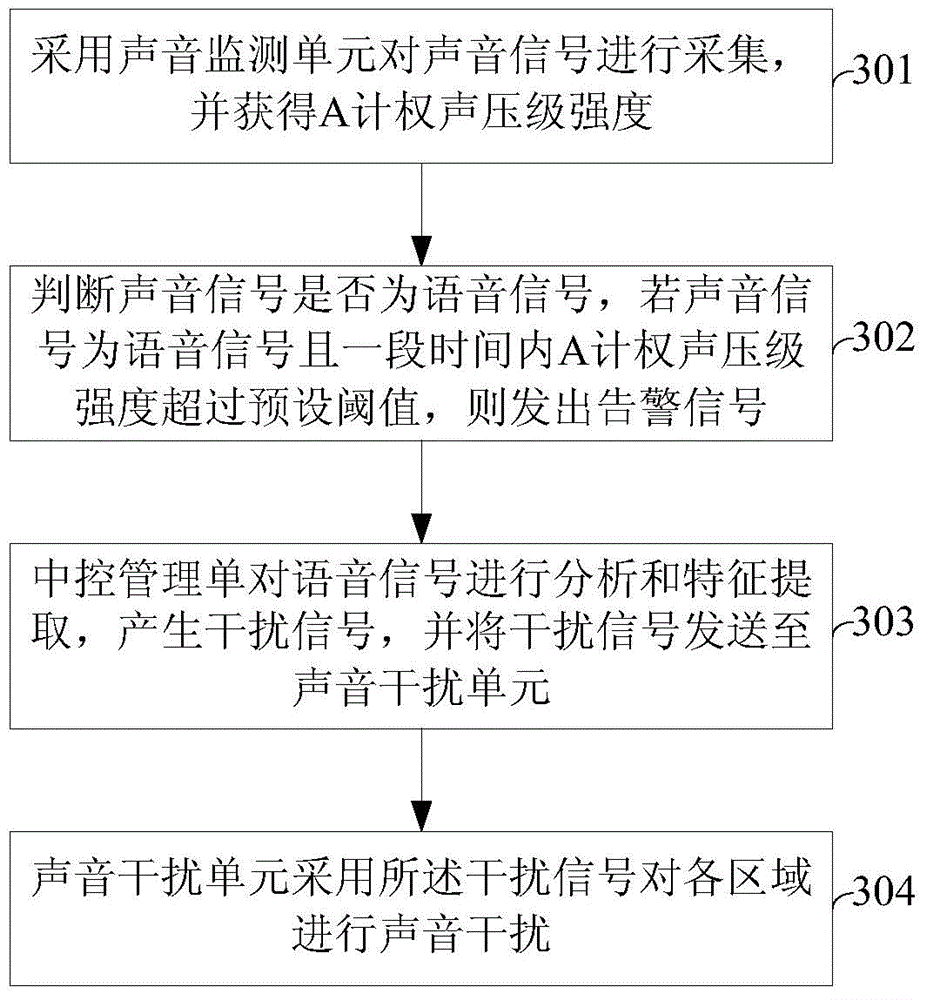

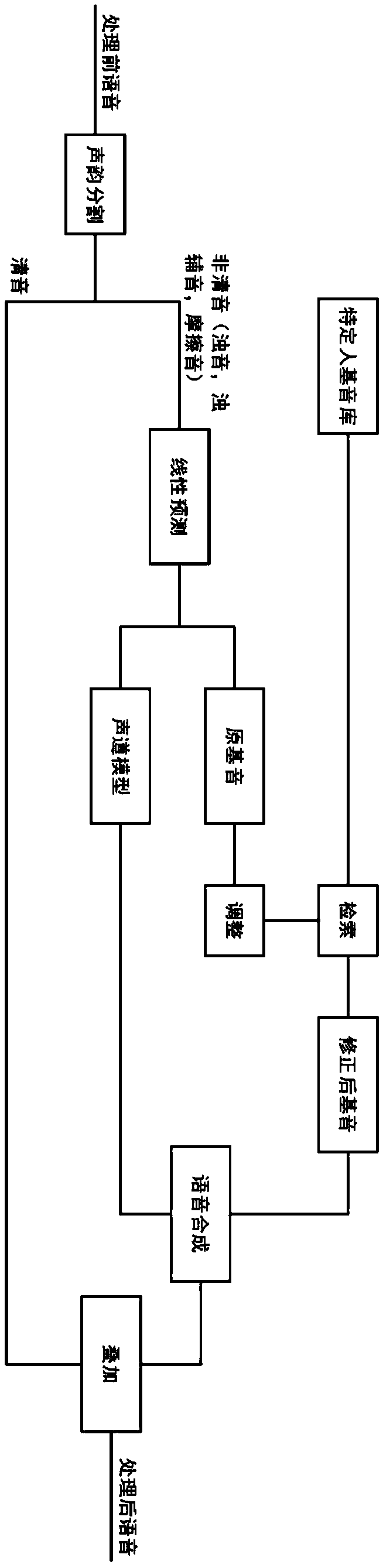

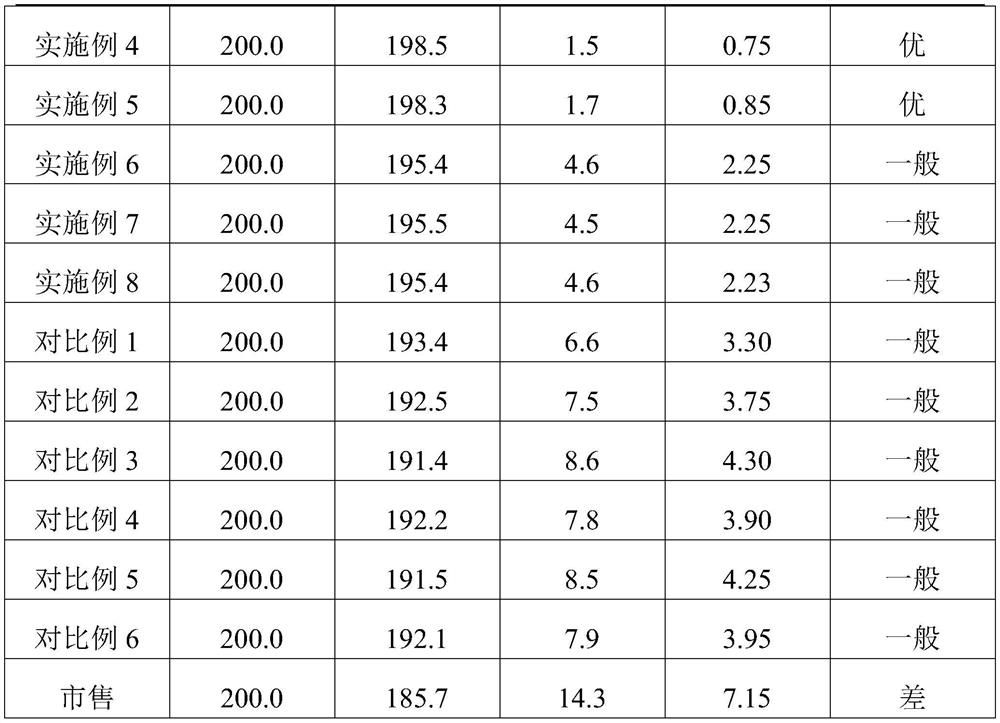

Sound leakage protection method and system based on sound masking principle

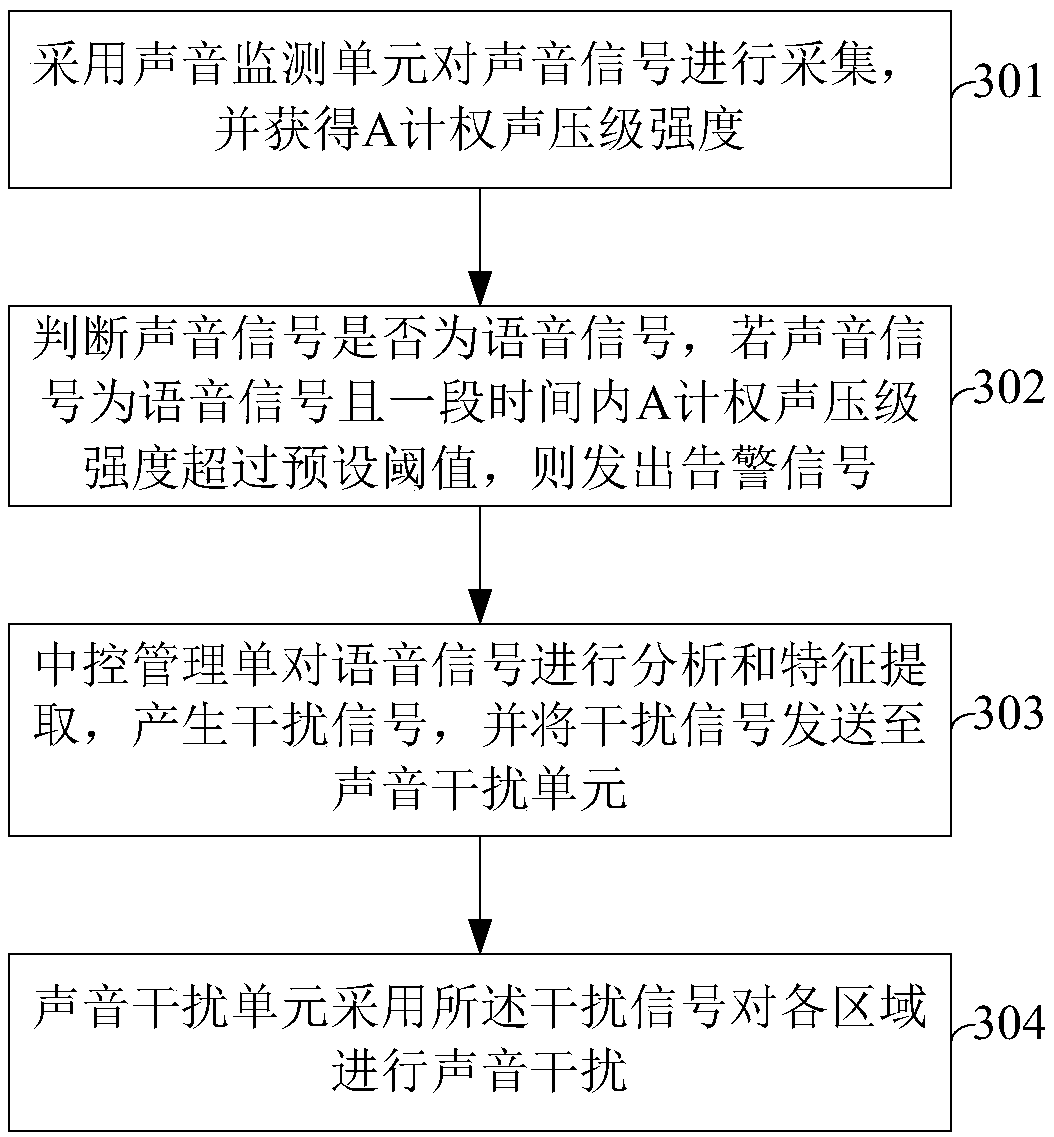

ActiveCN104575486ASimple reductionGood masking effectSound producing devicesManagement unitFeature extraction

The invention provides a sound leakage protection system based on the sound masking principle. The system comprises a sound monitoring unit, a sound disturbing unit and a center control management unit. The invention further provides a sound leakage protection method based on the sound masking principle. The method comprises steps as follows: the sound monitoring unit is adopted to collect a sound signal, and A-weighting sound pressure level intensity is obtained; whether the sound signal is a voice signal is judged, if the sound signal is the voice signal and the A-weighting sound pressure level intensity exceeds a preset threshold value in a period, a warning signal is emitted; the center control management unit performs analysis and feature extraction on the voice signal, generates a disturbing signal and sends the disturbing signal to the sound disturbing unit; the sound disturbing unit adopts the disturbing signal to perform sound disturbing on each area. According to the method and the system, a masking signal processed in real time has higher relevance with a target voice, the masking effect is better, and general privacy can be protected better.

Owner:INST OF INFORMATION ENG CAS

High-temperature-resistant emerald ceramic pigment and preparation method thereof

InactiveCN102775187ASolve the instability problem of darkening hair color toneStrong color development abilityAlkaline earth metalEmerald

The invention discloses a high-temperature-resistant emerald ceramic pigment and a preparation method thereof. The high-temperature-resistant emerald ceramic pigment comprises the following steps of: (1) uniformly mixing chromium oxide green with alumina according to a mole ratio of (0.48-0.54):(0.5-0.6); (2) adding alkaline earth metal halide which accounts for 3-5 percent of total weight of the mixed mixture and uniformly mixing again; (3) feeding the mixture in a resistance furnace for calcining under the calcining condition that the heat is preserved for 3-4 hours at the temperature of 1250-1280DEG C and naturally cooling; and (4) grinding, washing, drying and screening the cooled calcined material to obtain the high-temperature-resistant emerald ceramic pigment. According to the high-temperature-resistant emerald ceramic pigment disclosed by the invention, by doping other materials, a high-temperature-resistant solid solution of corundum alumina and chromium oxide green is formed by high-temperature synthesis; and when the high-temperature-resistant emerald ceramic pigment is used at high temperature, chromium ions can be stably maintained to Cr<3+> and the problem that chromium oxide green solution and CaO, Ba, Na2O, ZnO and the like in a glaze react is solved, and thus the effect of stability at high temperature is achieved.

Owner:佛山市南海万兴材料科技有限公司

Lithium ion battery, preparation method thereof and electric vehicle

ActiveCN110858660AImprove Interface StabilityReduce the problem of internal micro-short circuitSolid electrolytesFinal product manufactureSolid state electrolyteElectrolysis

The invention provides a lithium ion battery, a preparation method and an electric vehicle. The lithium ion battery comprises a positive electrode, a negative electrode and a composite solid electrolyte layer positioned between the positive electrode and the negative electrode, wherein the composite solid electrolyte layer comprises a positive electrode side solid electrolyte layer, a negative electrode side solid electrolyte layer and an intermediate layer solid electrolyte layer clamped between the positive electrode side solid electrolyte layer and the negative electrode side solid electrolyte layer; the positive electrode side solid electrolyte layer, the negative electrode side solid electrolyte layer and the intermediate layer solid electrolyte layer all contain first inorganic solidelectrolyte; the intermediate solid electrolyte layer further comprises second inorganic solid electrolyte. The composite solid electrolyte can delay the problem that lithium dendrites penetrate through the electrolyte layer to cause micro short circuit in the battery, and can avoid the problem that the electrolyte layer is reduced by the lithium dendrites to fail, so that the cycle performance and the safety performance of the whole battery are greatly improved.

Owner:BYD CO LTD

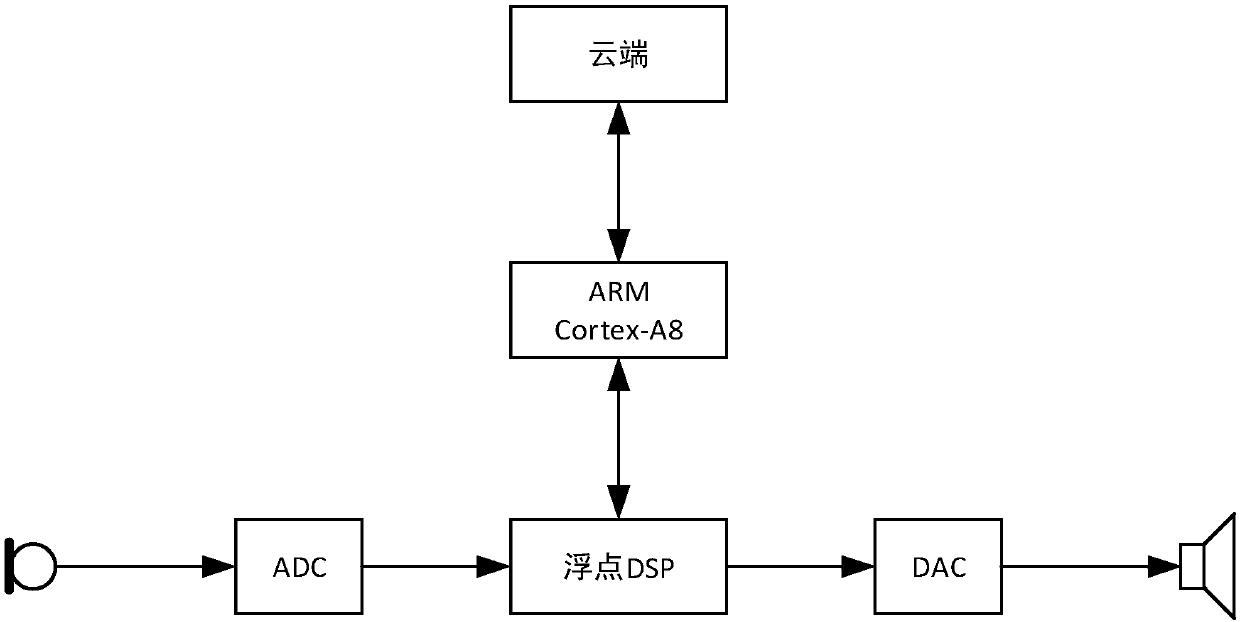

Real-time digital voice changing method

ActiveCN109616131AGuaranteed natural voiceGuaranteed intelligibilitySpeech analysisSuperimpositionConfidentiality

The invention discloses a real-time digital voice changing method which comprises the following steps: adjusting and analyzing a non-unvoiced sound part of original voice, extracting a signal from a specific person fundamental tone base to replace an original fundamental tone according to a comparison result, and further performing synthesis and superimposition, so as to obtain a voice changing signal. According to the method, the voice changing effect has the characteristics of being high in naturalness and intelligibility; the change d voice is not recovered easily, so that the method is high in confidentiality; meanwhile, the method has the characteristics of being low in delay and complexity.

Owner:南京南大电子智慧型服务机器人研究院有限公司 +2

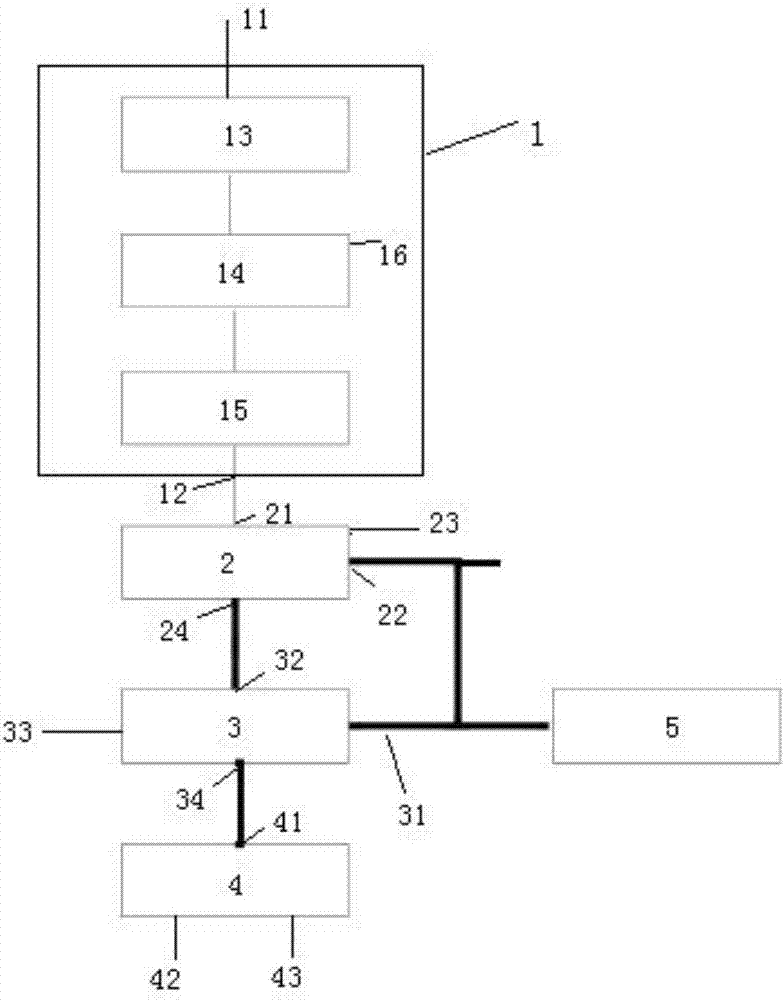

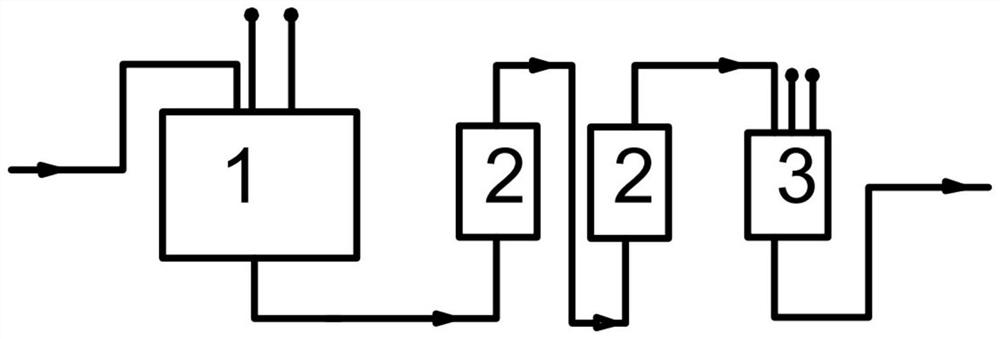

Smelting system and smelting method for mother liquid of stainless steel

InactiveCN107099659ALow costProportion adjustmentElectric furnaceProcess efficiency improvementThermal stateSlag

The invention relates to a smelting system and a smelting method for a mother liquid of stainless steel. The smelting system includes a mixing and pelletizing unit, a drying apparatus, a rotary hearth furnace, and an electric furnace. The mixing and pelletizing unit includes a raw material inlet and a pellet outlet; the drying apparatus includes a pellet inlet, a drying gas inlet, a flue gas outlet, and a dried pellet outlet; the pellet inlet is connected to the pellet outlet; the rotary hearth furnace includes a flue, a material distributing mouth, a burning nozzle, and a pre-reduced pellet outlet; the material distributing mouth is connected to the dried pellet outlet; the electric furnace includes a pre-reduced pellet inlet, an iron outlet and a slag outlet; the pre-reduced pellet inlet is connected to the pre-reduced pellet outlet. By means of the system and the method, ratio of chromite ore powder and iron ore is easy to control, and metallization ratio of thermal-state metallized pellet is high. So that a mother liquid of stainless steel, which includes required components, can be smelted in one step; the pellets are hot-delivered to the electric furnace with non-coke coal resource and hot delivery method which are low in cost, thus reducing cost and energy consumption.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

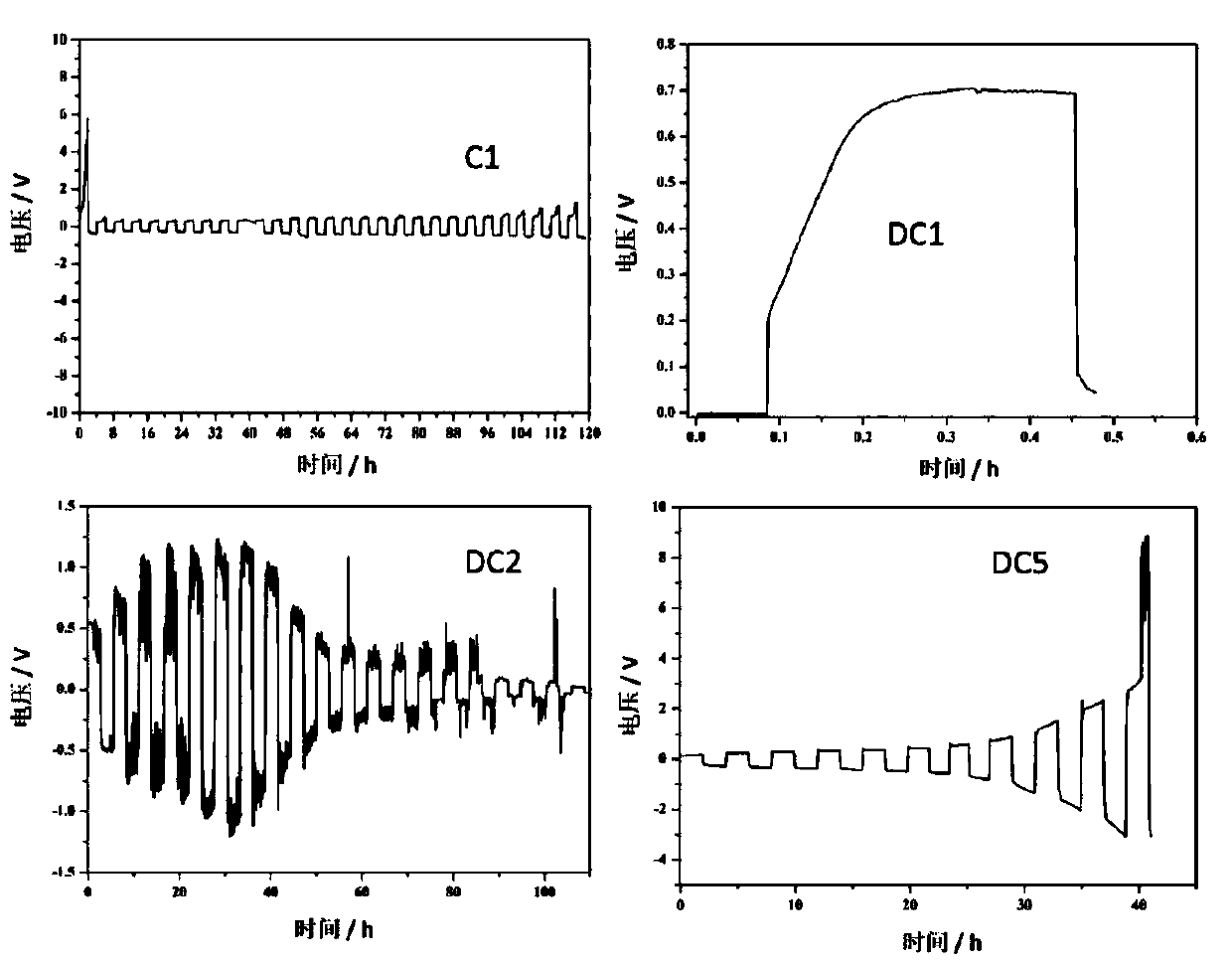

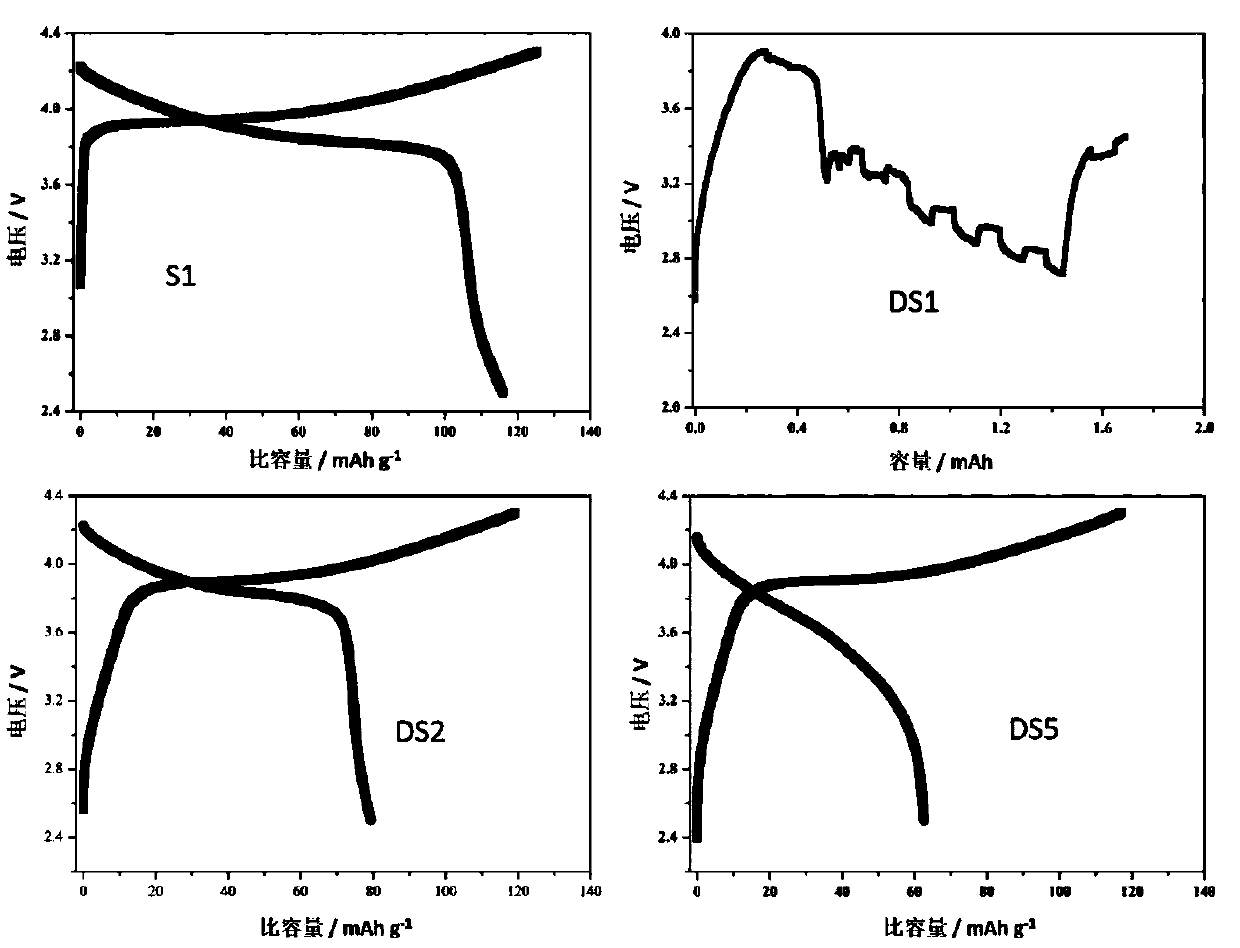

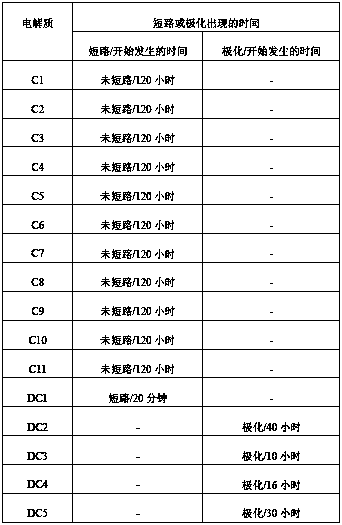

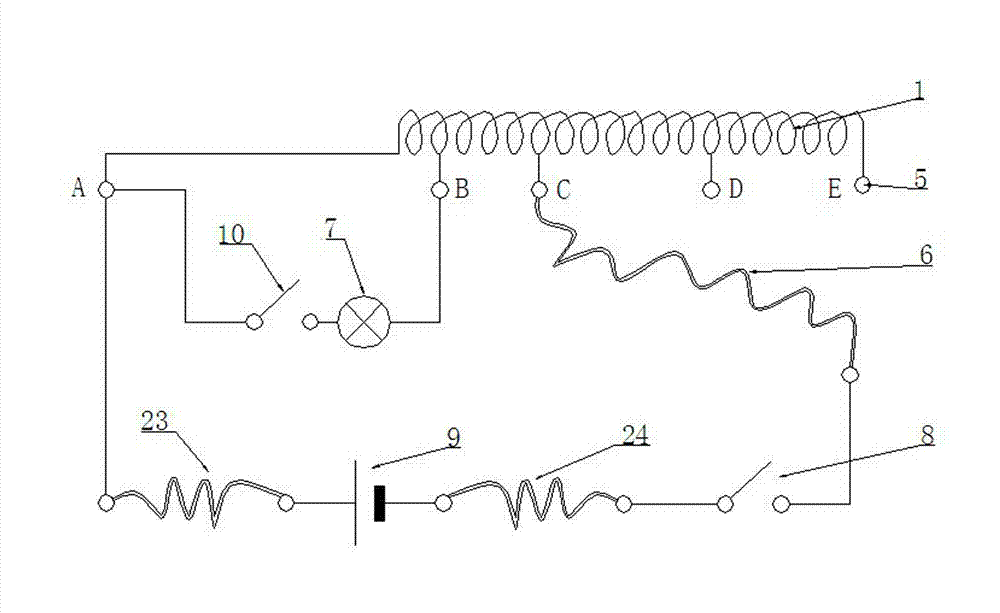

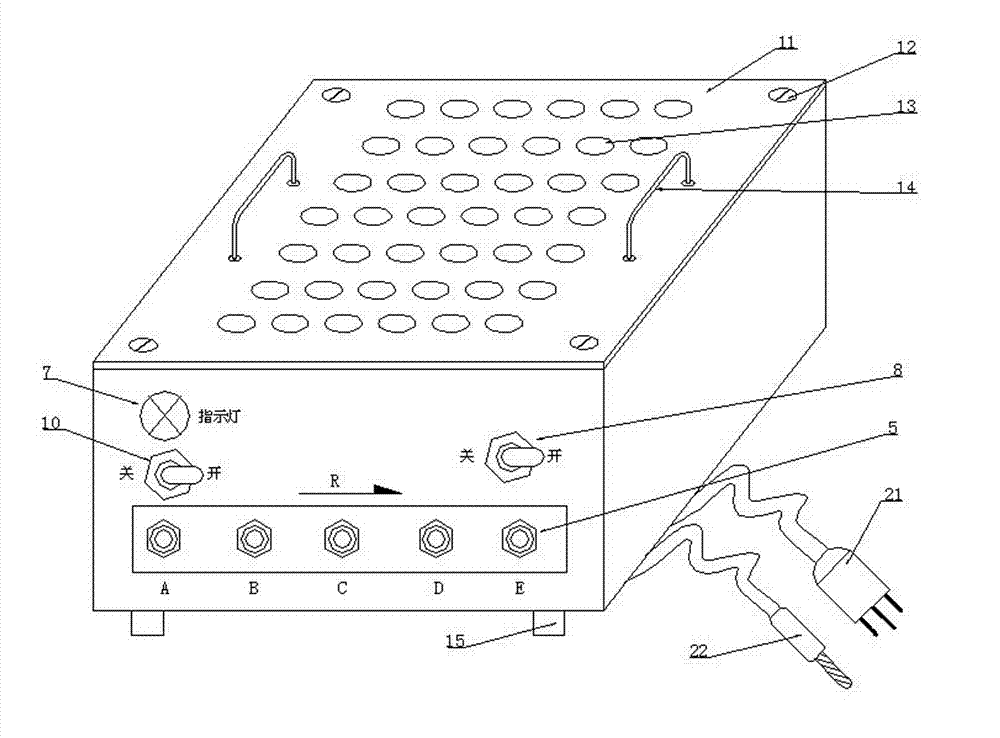

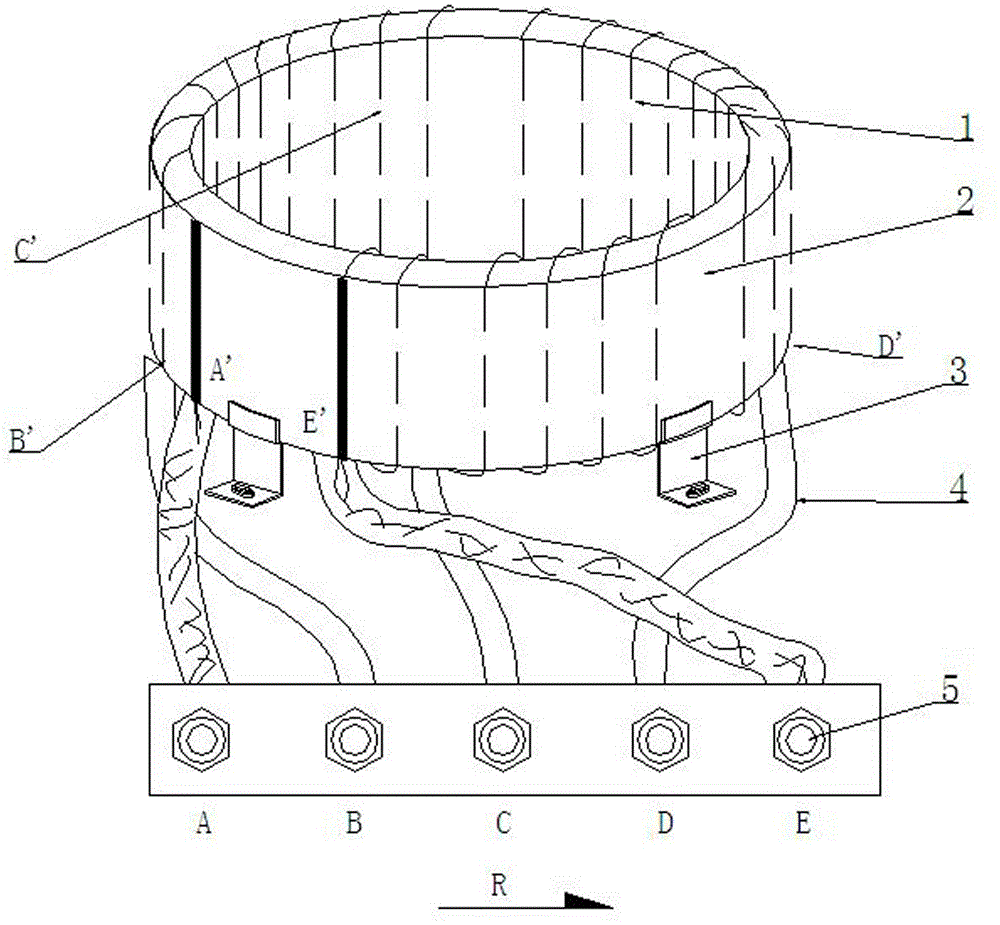

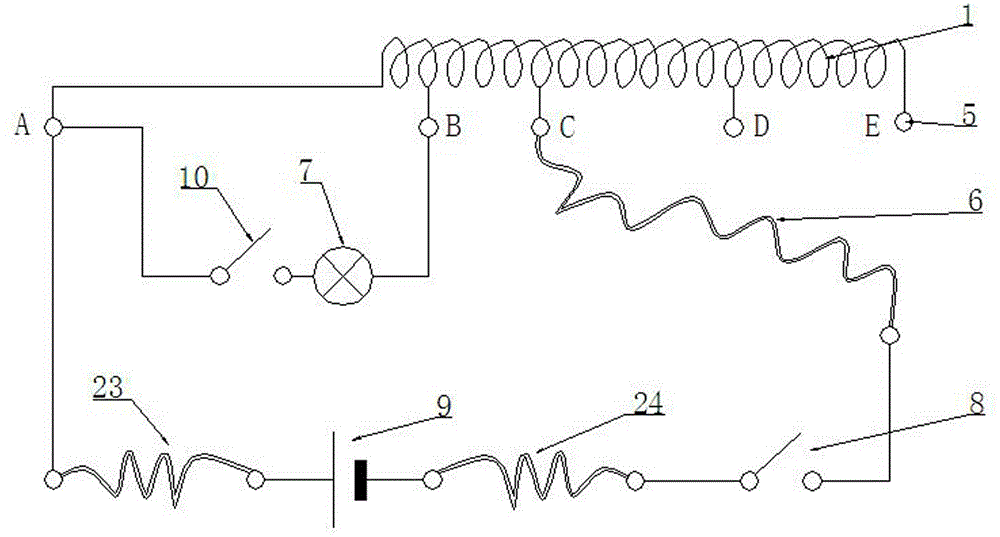

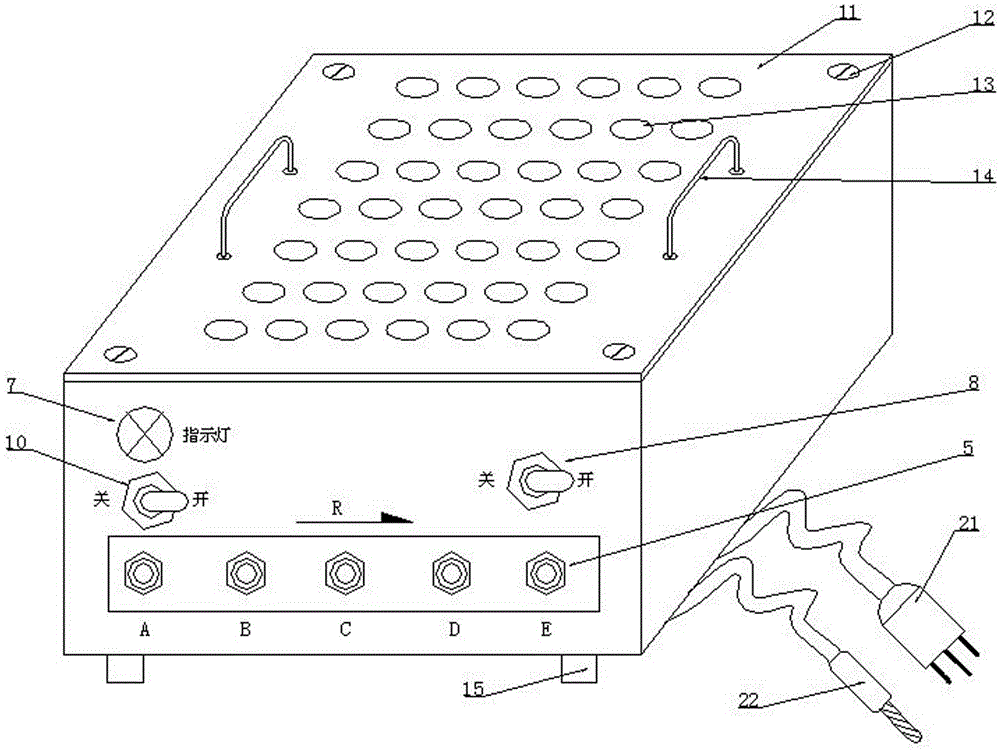

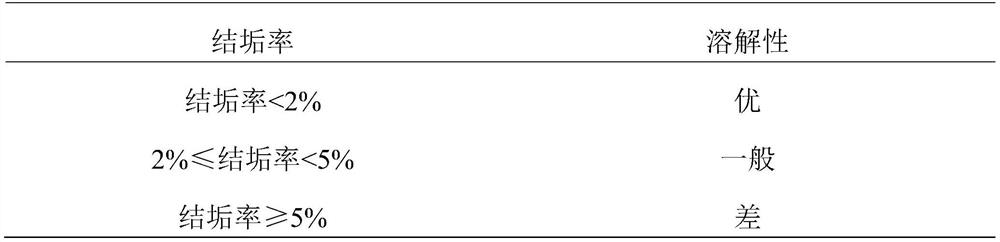

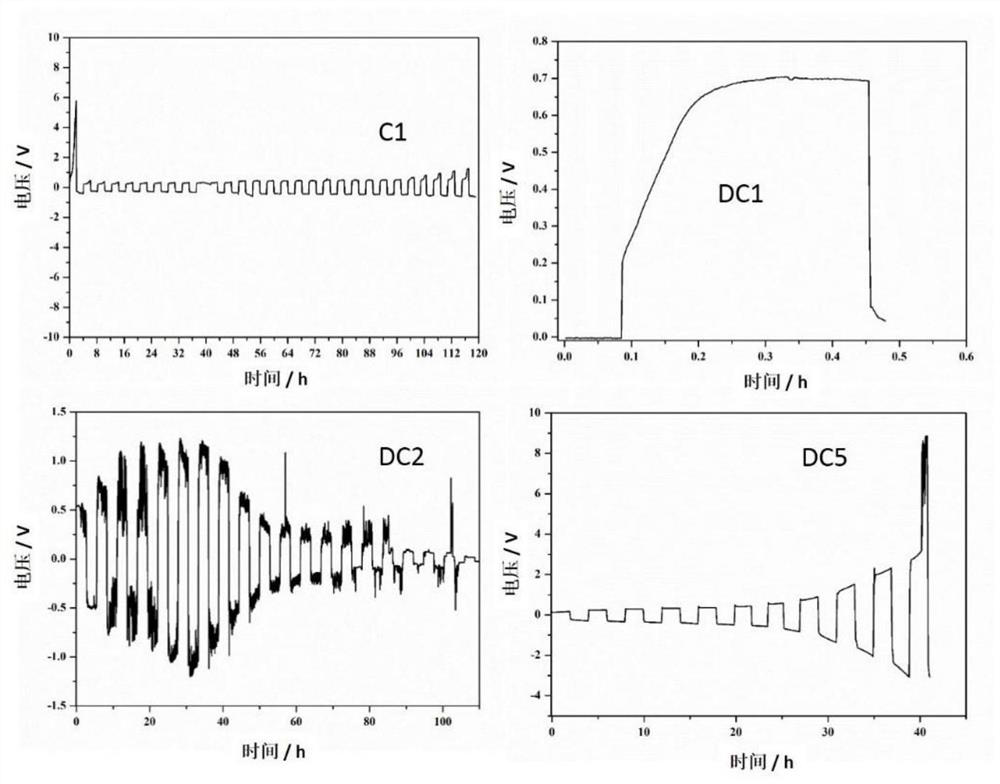

Lead storage battery regeneration apparatus and regeneration method thereof

InactiveCN104332671APrevent dehydrationInhibitory activityWaste accumulators reclaimingBattery recyclingElectrical batteryProcess engineering

The invention relates to the electrical energy storage field, and concretely relates to a lead storage battery regeneration apparatus and a regeneration method thereof. The apparatus adopts a resistance-variable resistance wire provided with an indicating lamp, and the resistance can be changed as needed to completely discharge a lead battery and can effectively avoid the generation of large granule lead sulfate caused by difficult reduction of large granule lead dioxide to lead sulfate due to small discharge current in the later stage of discharge; and the discharge depth can be momentarily observed through the indicating lamp to effectively avoid the sulfate formation of the lead battery and greatly prolong the life of the processed lead battery. The lead storage battery regeneration method has the advantages of non-strict operating conditions, simplicity, use convenience, and realization of good regeneration ability and multiplied service life of the processed lead battery.

Owner:NANYANG NORMAL UNIV

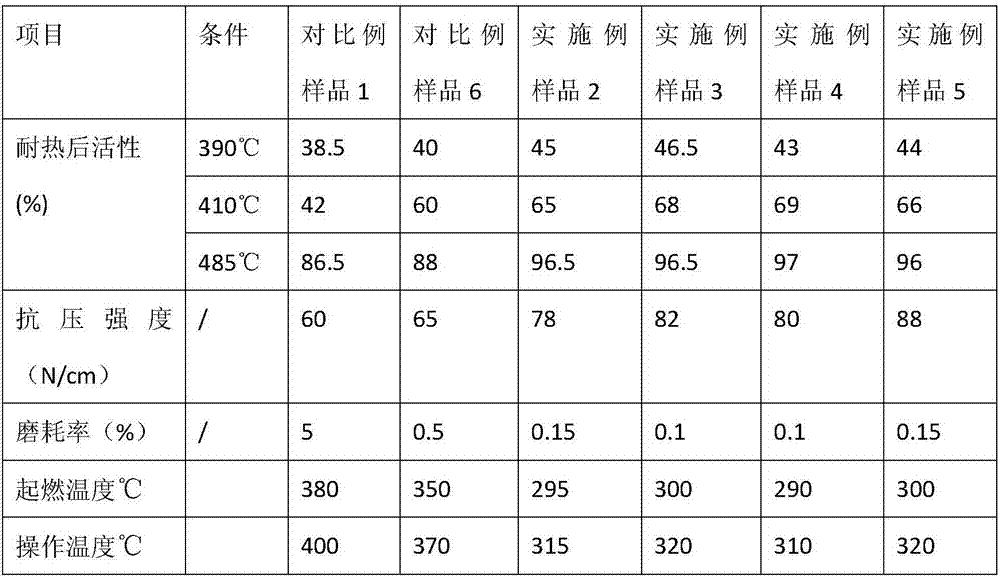

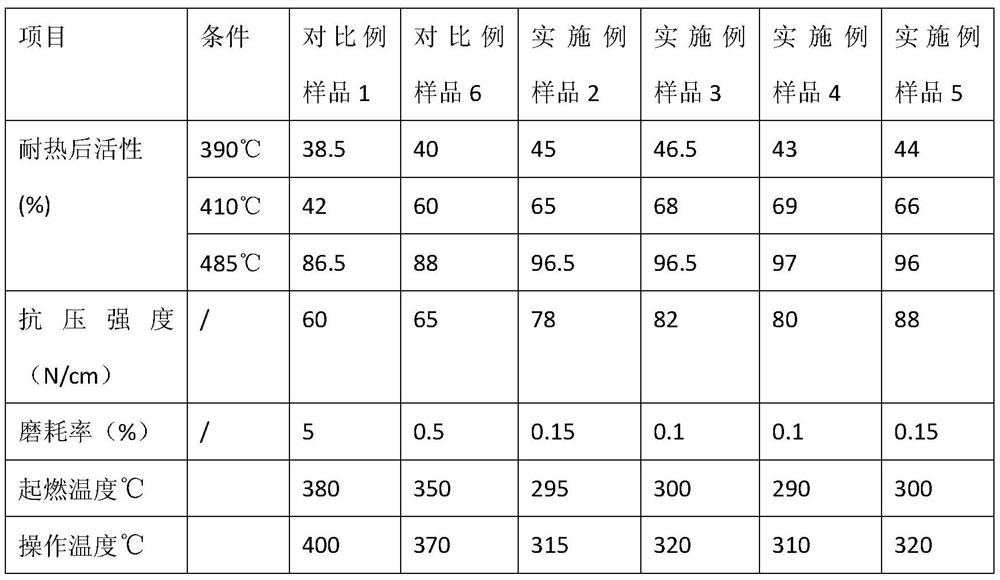

Environment-friendly energy-saving high-conversion-ratio rare-earth catalyst and preparation method thereof

ActiveCN107970911AImprove stabilityExtended service lifeHeterogenous catalyst chemical elementsDispersed particle separationChemistryLanthanum

The invention discloses an environment-friendly energy-saving high-conversion-ratio rare-earth catalyst and a preparation method thereof. The environment-friendly energy-saving high-conversion-ratio rare-earth catalyst is prepared from the following raw materials in percentage by mass: 0.01-10% of a lanthanum-containing compound, 0.01-10% of a cerium-containing compound, 0.01-10% of a neodymium-containing compound, 0.01-10% of a praseodymium-containing compound, 3-15% of V2O5, 1-3% of thiosulfate, 1-15% of a caesium-containing compound, 1-5% of a surfactant, 1-5% of an organic high-molecular compound, 1-30% of hydroxide, 5-30% of diluted sulphuric acid, 0.1-10% of anhydrous sodium sulphate, 0.1-7% of phosphoric acid, 1-15% of sulfur and the balance of diatomite. The material components cooperatively act, so that the stability of the catalyst is improved, and the service life of the catalyst is remarkably prolonged, and an ignition temperature is remarkably reduced.

Owner:南京云高新型材料有限公司

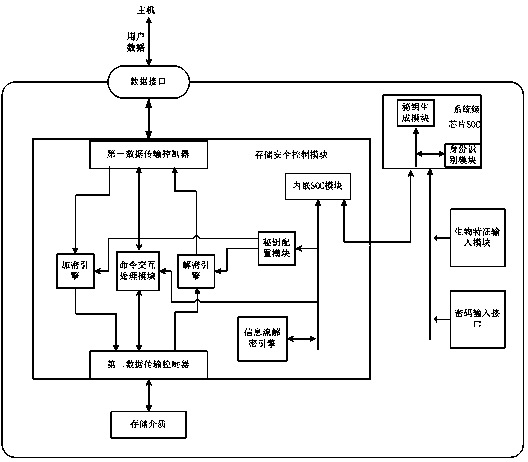

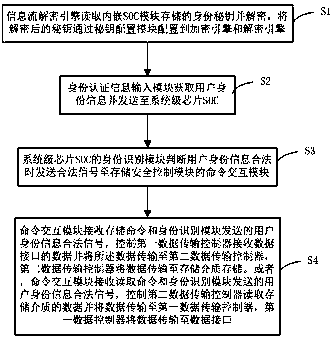

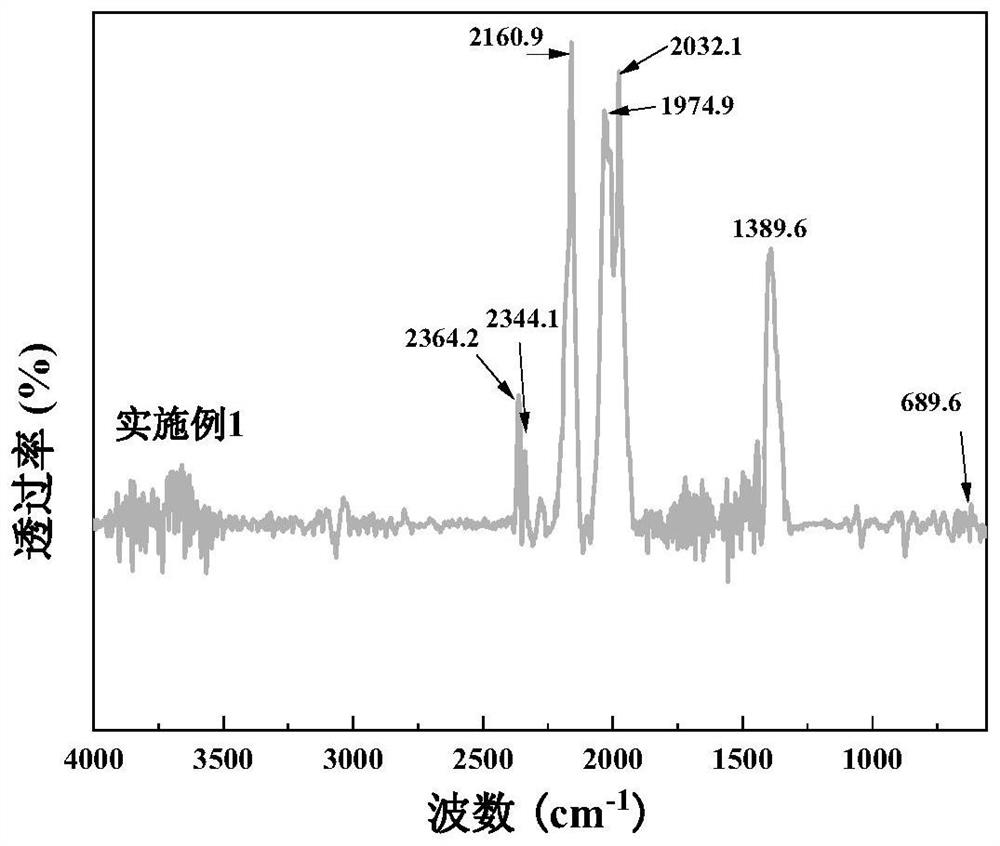

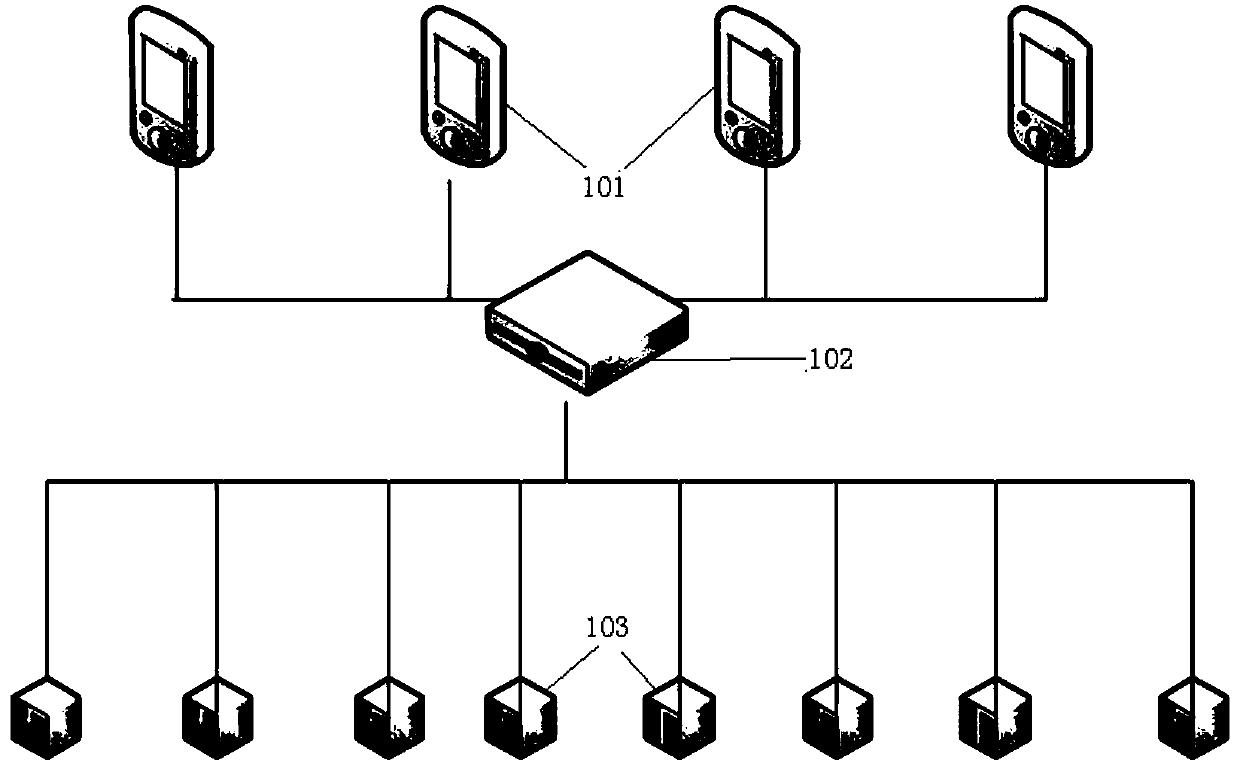

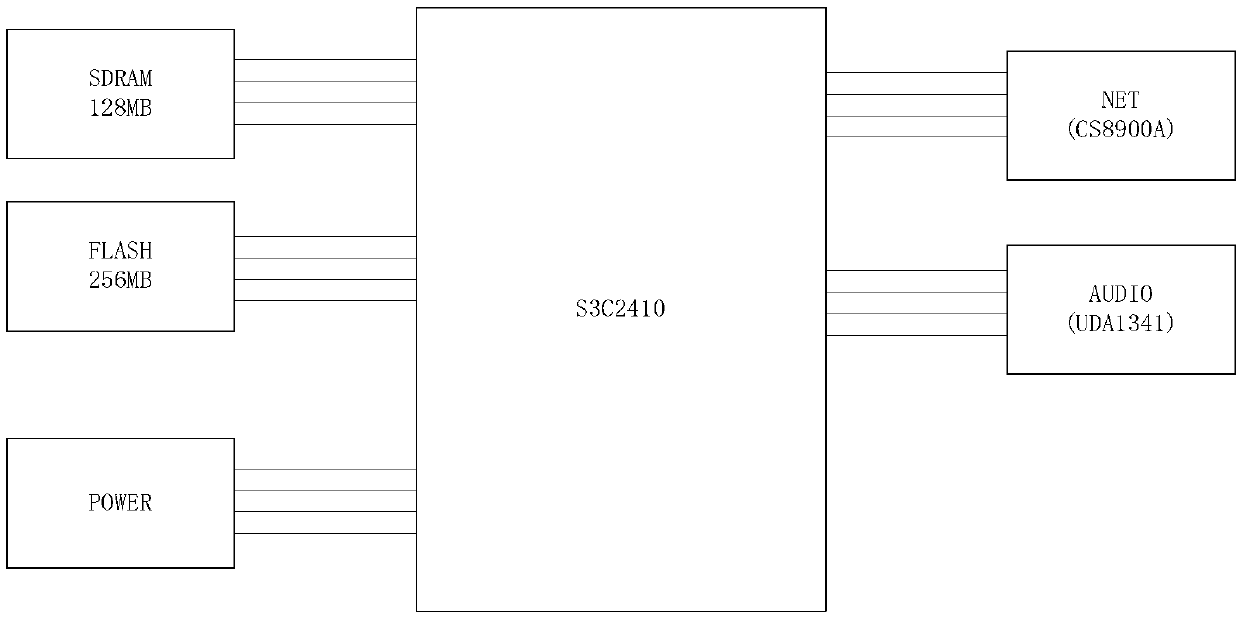

Data storage device and method

PendingCN110727931ASimple reductionWith data security and confidentiality measuresDigital data protectionInternal/peripheral component protectionStorage securityEngineering

The invention provides a data storage device and method. The data storage device comprises a storage medium, a storage security control module. A system-on-chip SOC and an identity authentication information input module, an identity key is stored in the storage security control module, the identity key is generated by encrypting an encryption key and user identity information through an encryption algorithm, and the identity key is configured to an encryption engine and a decryption engine. When data is stored and read in a storage medium, user identity information must be verified, the stored data is encrypted, and the read data is decrypted. Therefore, the device has a data security and secrecy measure, a security protection measure has dual protection of identity authentication and a secret key and is not easy to crack and attack, and the data is not easy to restore when the storage medium is lost.

Owner:QINGDAO HISENSE ELECTRONICS EQUIP

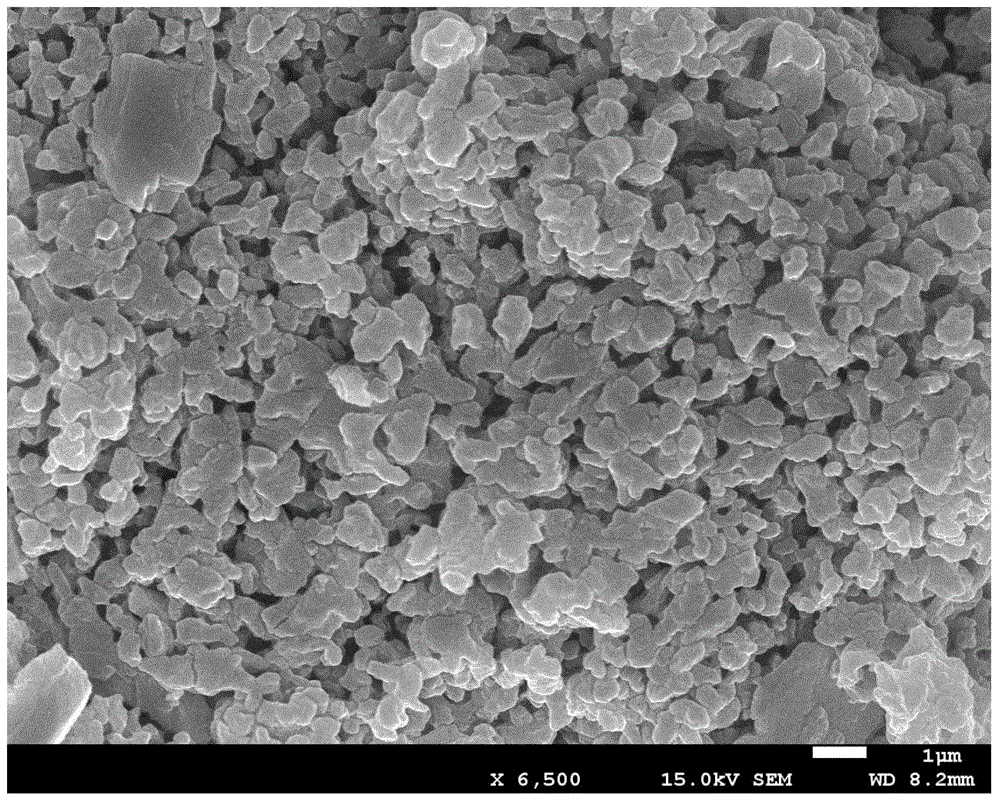

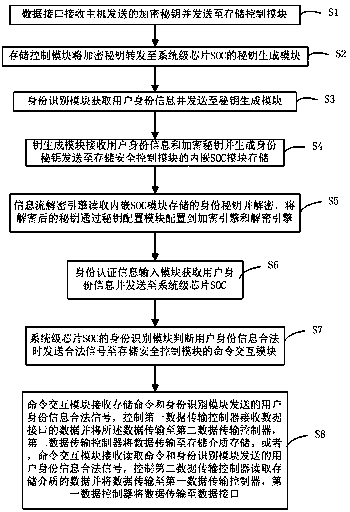

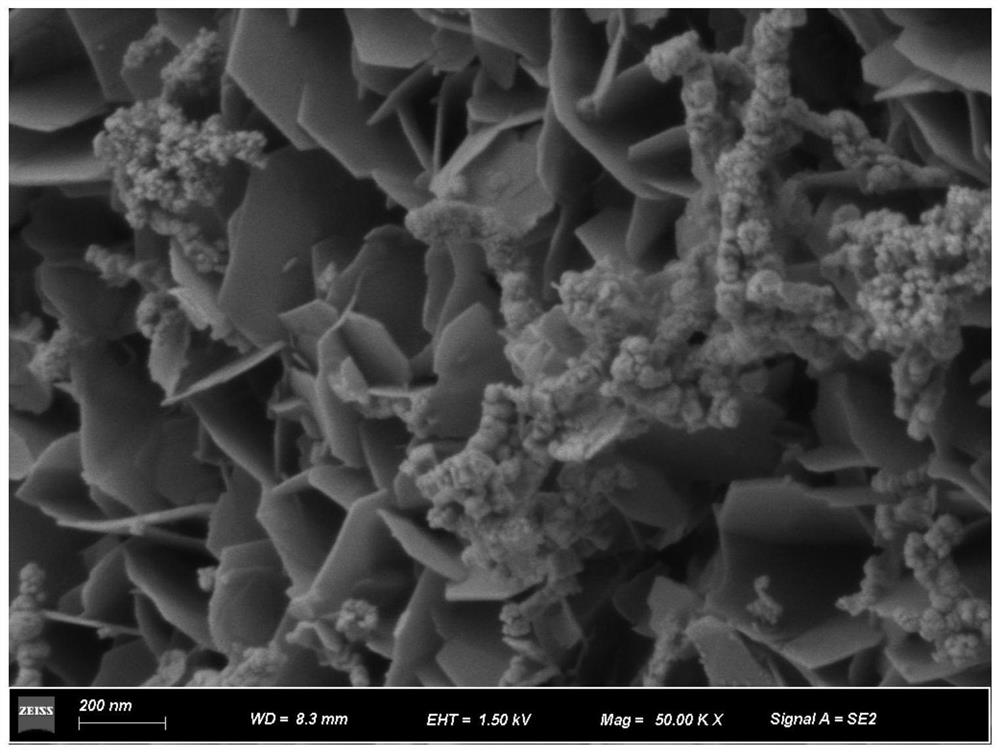

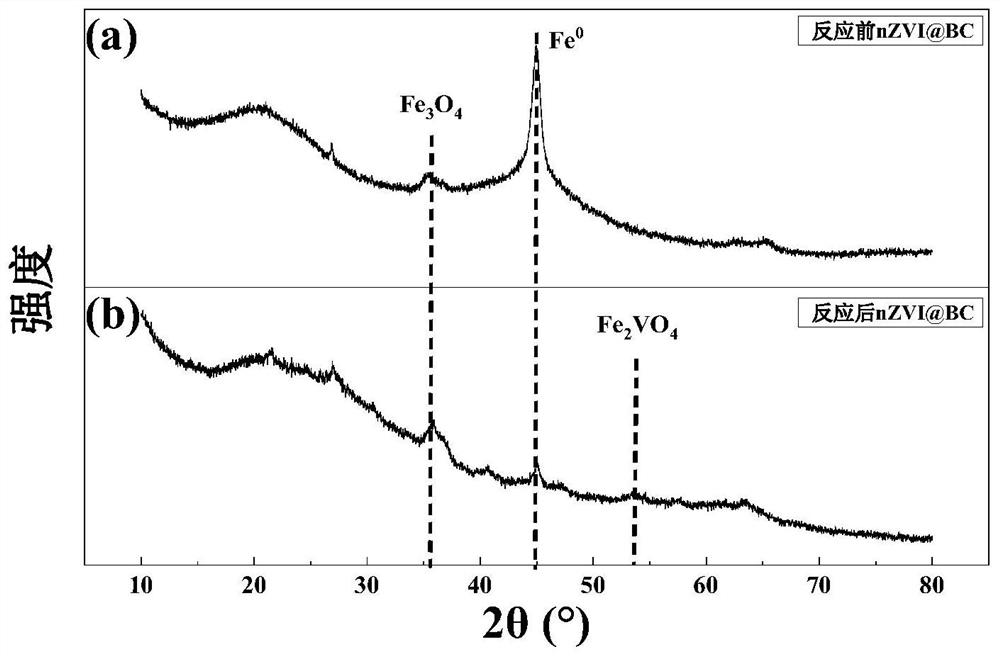

Preparation and application of metal vanadium efficient adsorption-reduction material taking waste green tea residues as raw material

PendingCN113893824APromote reductionNot easy to restoreOther chemical processesWater contaminantsFiberCrude fibre

The invention provides preparation and application of a metal vanadium efficient adsorption-reduction material taking waste green tea residues as a raw material. The green tea residues are composed of 17%-28% of crude protein, 16%-35% of crude fiber, 2%-3% of free amino acid, 1%-2% of tea polyphenol, 0.1%-0.3% of caffeine and the like. After the green tea residues are pyrolyzed into biochar, the variety and number of functional groups of unsaturated bonds on the surface are large, and the original vanadium adsorption capacity is obviously superior to that of other biochar. Zero-valent iron modification is carried out on the surface and pore channels of the green tea residue biochar, the pore channel structure of the biochar is optimized, the reducing capacity of the biochar is enhanced, the vanadium adsorption capacity is improved, and efficient adsorption-reduction of vanadium is achieved. After modification, the adsorption capacity is improved by 3.48-11.28 times, the adsorption rate is improved by 20-36 times, pentavalent vanadium is reduced into tetravalent vanadium with low toxicity, and the toxicity is reduced by 70% or above. The material is simple and convenient in synthesis method and excellent in repairing effect, can be applied to scenes such as a permeable reactive barrier technology or vanadium pollution emergency treatment, remarkably reduces the early-stage investment and operation cost of a project, and has a good practical application prospect.

Owner:BEIJING UNIV OF CHEM TECH

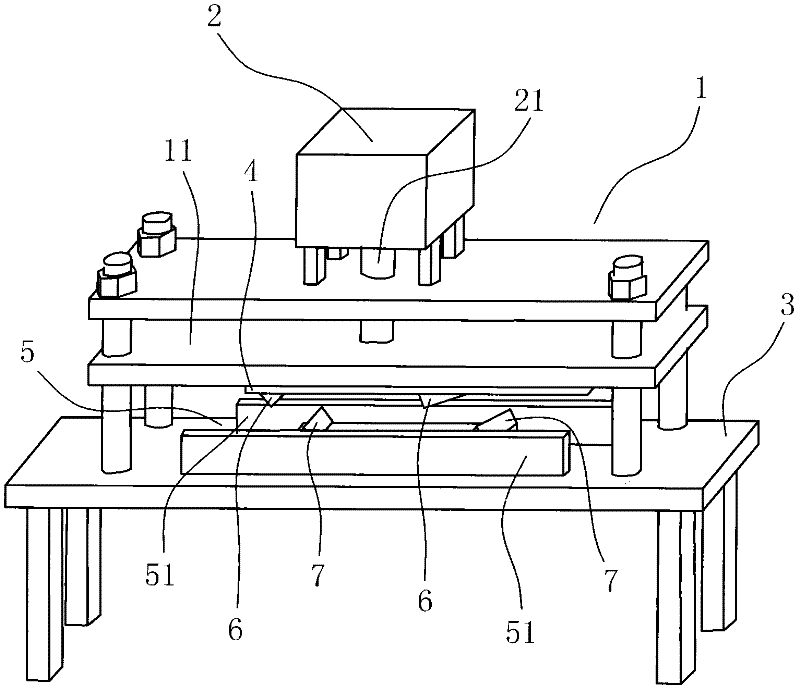

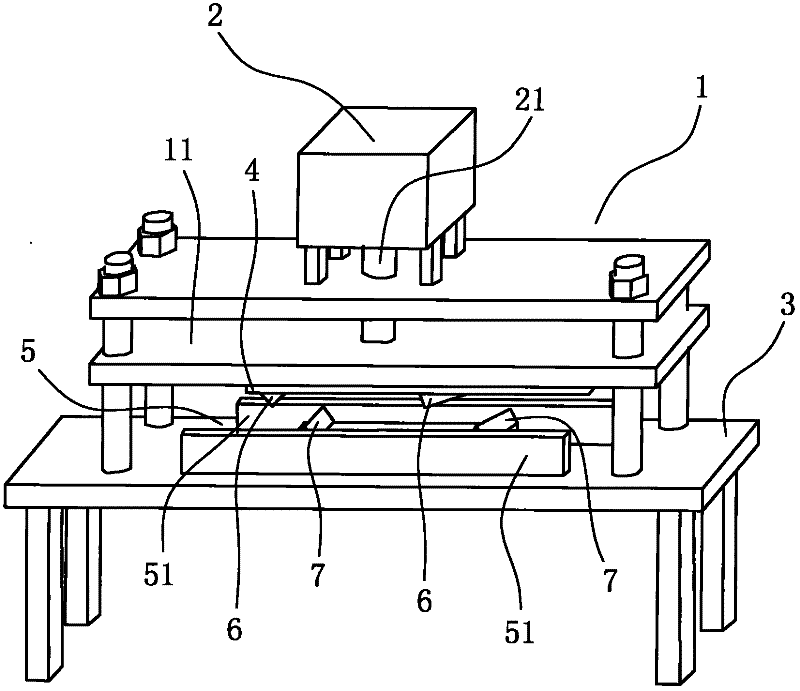

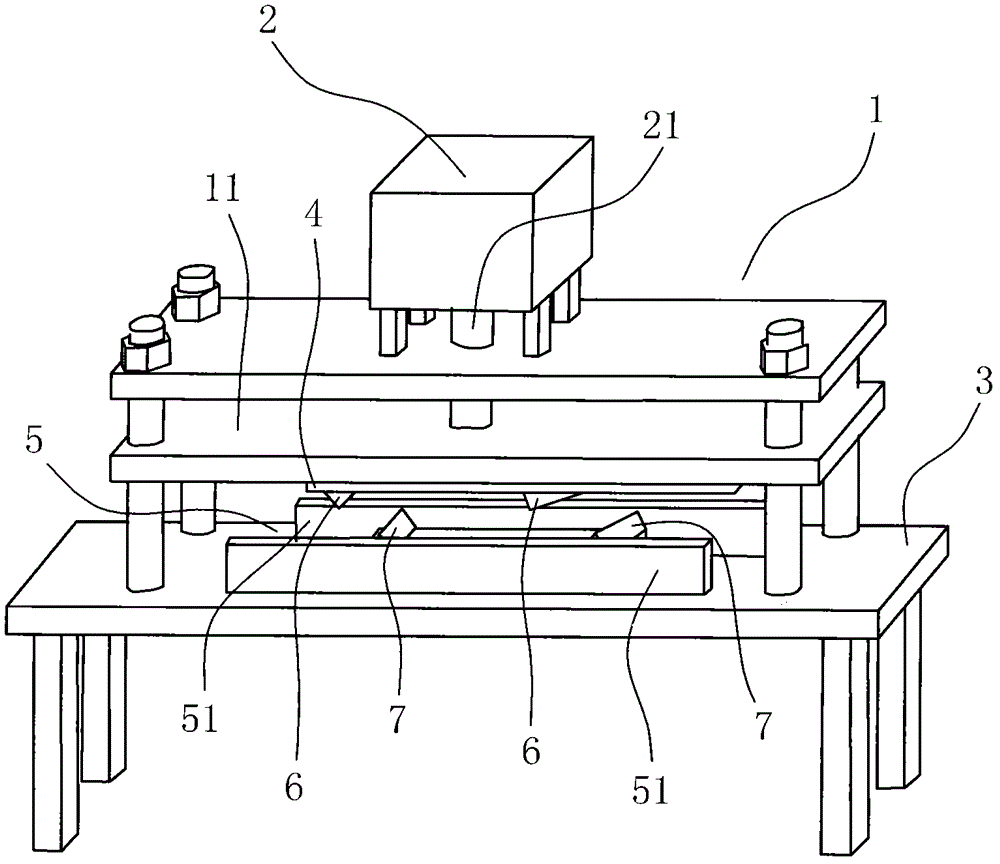

Method for processing crease lines of flexible flat cable (FFC) material and crimping machine implementing method

The invention discloses a method for processing crease lines of a flexible flat cable (FFC) material, which comprises the following steps of: (1) fixing an output shaft of a cylinder downwards to a table; (2) arranging an FFC material passing rail on the table; (3) arranging a plurality of upper stamping dies on the bottom surface of a stamping die fixing plate; (4) arranging a control system which comprises an induction module for inducing a conductor position of the FFC material and a control module for controlling the work of the cylinder; (5) setting the operating range of the cylinder according to the thickness of an insulating layer of the FFC material needing crease line processing; and (6) making the FFC material automatically pass through the rail, and when the induction module in a control system induces a fact that the FFC material passes through the rail, making the cylinder work and driving the upper stamping dies to press down by using the output shaft, so that the upperstamping dies process the crease lines facilitating bending the FFC material on the FFC material, and the output shaft quickly retreats for the next processing. By the method, workers required by thetraditional processing method are reduced, and the production cost is greatly reduced.

Owner:东莞市锐升电线电缆有限公司

Funeral and interment method

The invention discloses a funeral and interment method. The funeral and interment method comprises the following steps: uniformly mixing grey bones and fragments after cremation of remains and lime powder, and encoffining into a ceramic coffin; air in the ceramic coffin is completely pumped out, an end opening of the ceramic coffin is fully pressed with the mixed ointment in a vacuum environment, the ceramic coffin is sleeved with a soft metal sealing ring, and then an end cover is screwed for sealing; a metal tomb nameplate formed by compression molding of a copper sheet is clamped on the sealed ceramic coffin, and an image and all information of the departed are printed on the metal tomb nameplate by using a laser instrument; concave-convex spots are pressed by a mold, and a lead external port is arranged, so that the specific burial position of the ceramic coffin of the departed can be found by using a scanner in the future; drilling a grave to the depth of 1.5-2m, filling part of lime to the bottom, burying the sealed ceramic coffin into the grave, and pouring lime slurry to completely bury the ceramic coffin; after the lime slurry is solidified, the graves are filled with soil; flowers and plants and trees can be planted on the ground of the grave in the cemetery area; in a non-cemetery area, crops can still be planted on the ground of the grave, and farming is not affected.

Owner:姜玉亮

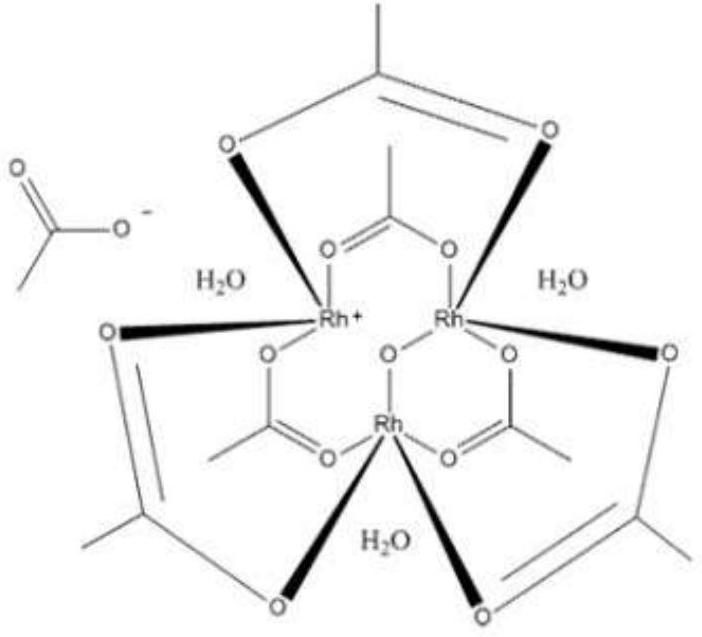

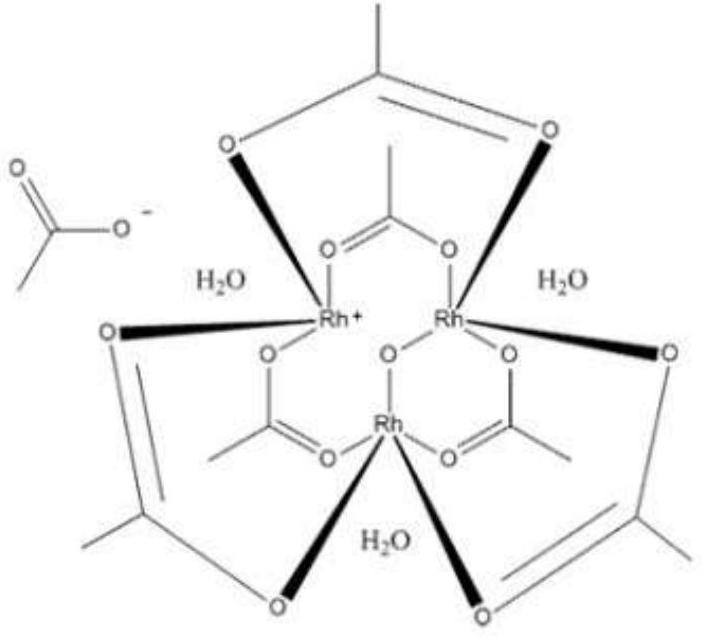

A kind of preparation method of trivalent rhodium acetate trimer

The invention relates to the technical field of inorganic synthesis and discloses a preparation method of rhodium trivalent acetate trimer, which includes the following steps: (1) After mixing rhodium powder and potassium chloride, chlorine gas is introduced for reaction; (2) The product obtained in step (1) is dissolved in water, filtered, potassium hydroxide is added to the filtrate for reaction, and rhodium hydroxide is obtained after filtering and washing; (3) water, nitric acid and glacial acetic acid are added to the rhodium hydroxide. The reaction is carried out. After the reaction is completed, the solution is evaporated to dryness. After the nitrate is driven out with glacial acetic acid, the acid is driven out with water to obtain rhodium trivalent acetate trimer. The present invention uses nitric acid and glacial acetic acid to dissolve rhodium hydroxide, and then uses glacial acetic acid to drive out the nitrate, which can significantly speed up the reaction and thereby increase the yield of rhodium trivalent acetate trimer.

Owner:浙江微通催化新材料有限公司

A kind of regeneration device and regeneration method of lead storage battery

InactiveCN104332671BRestore usabilityDischarge fullyWaste accumulators reclaimingBattery recyclingElectrical batteryProcess engineering

Owner:NANYANG NORMAL UNIV

Water-soluble coenzyme Q10 beverage and production method thereof

PendingCN111700197AGood water solubilitySolve problems that are difficult to apply in beveragesFood ingredient as clouding agentOligosaccharide food ingredientsBiotechnologyIsomaltooligosaccharide

The invention provides a water-soluble coenzyme Q10 beverage and a production method thereof. The water-soluble coenzyme Q10 beverage comprises the following raw materials in parts by weight: 5-30 parts of a coenzyme Q10, 0.3-11 parts of an emulsifier, 1-8 parts of a stabilizer, 1-10 parts of oligomeric isomaltose, 3-6 parts of vitamin B2 and 2-4 parts of piperonylic acid. A specific emulsification mean and the specific production method are adopted, the dissolving-out speed is high, neither suspension nor sedimentation happens, and the coenzyme Q10 is not liable to be reduced to a reduced coenzyme, so that the stability is high, and the solubility is good.

Owner:HAINAN DABAI KANGJIAN PHARMA CO LTD

Sound leakage protection method and system based on sound masking principle

ActiveCN104575486BNot easy to restoreGood masking effectSound producing devicesFeature extractionManagement unit

The invention provides a sound leakage protection system based on the sound masking principle. The system comprises a sound monitoring unit, a sound disturbing unit and a center control management unit. The invention further provides a sound leakage protection method based on the sound masking principle. The method comprises steps as follows: the sound monitoring unit is adopted to collect a sound signal, and A-weighting sound pressure level intensity is obtained; whether the sound signal is a voice signal is judged, if the sound signal is the voice signal and the A-weighting sound pressure level intensity exceeds a preset threshold value in a period, a warning signal is emitted; the center control management unit performs analysis and feature extraction on the voice signal, generates a disturbing signal and sends the disturbing signal to the sound disturbing unit; the sound disturbing unit adopts the disturbing signal to perform sound disturbing on each area. According to the method and the system, a masking signal processed in real time has higher relevance with a target voice, the masking effect is better, and general privacy can be protected better.

Owner:INST OF INFORMATION ENG CHINESE ACAD OF SCI

Method for processing crease lines of flexible flat cable (FFC) material and crimping machine implementing method

The invention discloses a method for processing crease lines of a flexible flat cable (FFC) material, which comprises the following steps of: (1) fixing an output shaft of a cylinder downwards to a table; (2) arranging an FFC material passing rail on the table; (3) arranging a plurality of upper stamping dies on the bottom surface of a stamping die fixing plate; (4) arranging a control system which comprises an induction module for inducing a conductor position of the FFC material and a control module for controlling the work of the cylinder; (5) setting the operating range of the cylinder according to the thickness of an insulating layer of the FFC material needing crease line processing; and (6) making the FFC material automatically pass through the rail, and when the induction module in a control system induces a fact that the FFC material passes through the rail, making the cylinder work and driving the upper stamping dies to press down by using the output shaft, so that the upperstamping dies process the crease lines facilitating bending the FFC material on the FFC material, and the output shaft quickly retreats for the next processing. By the method, workers required by thetraditional processing method are reduced, and the production cost is greatly reduced.

Owner:东莞市锐升电线电缆有限公司

A kind of alkane dehydrogenation heating aid, its preparation method and application

ActiveCN113388376BHigh bulk densityHigh calorific valueHydrocarbonsHeat-exchange elementsAlkaneDehydrogenation

Owner:润和科华催化剂上海有限公司

Preparation method of large-size, fine-grained molybdenum-tantalum alloy sputtering target

ActiveCN105714253BEvenly distributedAvoid defectsVacuum evaporation coatingSputtering coatingSputteringVolumetric Mass Density

A preparation method of a large-size and fine-grain molybdenum tantalum alloy sputtering target material comprises steps of cold isostatic pressing molding through combination of a steel mold with a rubber plate, sintering, levelling and reshaping, hot isostatic pressing treatment, rolling and machining. The grain size of the produced target material is smaller than 50 microns, the change of the grain size is maintained within 20%, and grains are evenly distributed in the plane direction and the thickness direction of the target material; the relative density of the target material is higher than 97%; besides, the large-size sputtering target material with the length being about 2 m and the width being about 1.3 m can be produced.

Owner:ACHEMETAL TUNGSTEN & MOLYBDENUM

Preparation method of trivalent rhodium acetate tripolymer

The invention relates to the technical field of inorganic synthesis, and discloses a preparation method of a trivalent rhodium acetate tripolymer, which comprises the following steps: (1) mixing rhodium powder and potassium chloride, and introducing chlorine for reaction; (2) dissolving the product obtained in the step (1) in water, filtering, adding potassium hydroxide into the filtrate for reaction, filtering and washing to obtain rhodium hydroxide; and (3) adding water, nitric acid and glacial acetic acid into rhodium hydroxide for reaction, after the reaction is completed, evaporating the solution to dryness, performing nitrate removal with glacial acetic acid, and performing acid removal with water to obtain the trivalent rhodium acetate tripolymer. The nitric acid and the glacial acetic acid are adopted to dissolve rhodium hydroxide, and then the glacial acetic acid is used for removing nitrate, so that the reaction can be obviously accelerated, and the yield of the trivalent rhodium acetate tripolymer is improved.

Owner:浙江微通催化新材料有限公司

Lithium-ion battery and its preparation method and electric vehicle

ActiveCN110858660BImprove Interface StabilityReduce the problem of internal micro-short circuitSolid electrolytesFinal product manufactureSolid state electrolyteElectrolysis

The application provides a lithium-ion battery, a preparation method and an electric vehicle, the lithium-ion battery includes a positive electrode, a negative electrode, and a composite solid electrolyte layer between the positive electrode and the negative electrode, and the composite solid electrolyte layer includes a positive electrode side solid electrolyte layer , the negative electrode side solid electrolyte layer and the intermediate layer solid electrolyte layer sandwiched between the positive electrode side solid electrolyte layer and the negative electrode side solid electrolyte layer; the positive electrode side solid electrolyte layer, the negative electrode side solid electrolyte layer and the intermediate layer solid electrolyte Each layer contains a first inorganic solid electrolyte, and the intermediate solid electrolyte layer also includes a second inorganic solid electrolyte. The composite solid electrolyte can delay the problem of lithium dendrites penetrating through the electrolyte layer and cause micro-short circuits inside the battery, and can avoid electrolyte The layer is reduced and failed by lithium dendrites, which greatly improves the cycle performance and safety performance of the entire battery.

Owner:BYD CO LTD

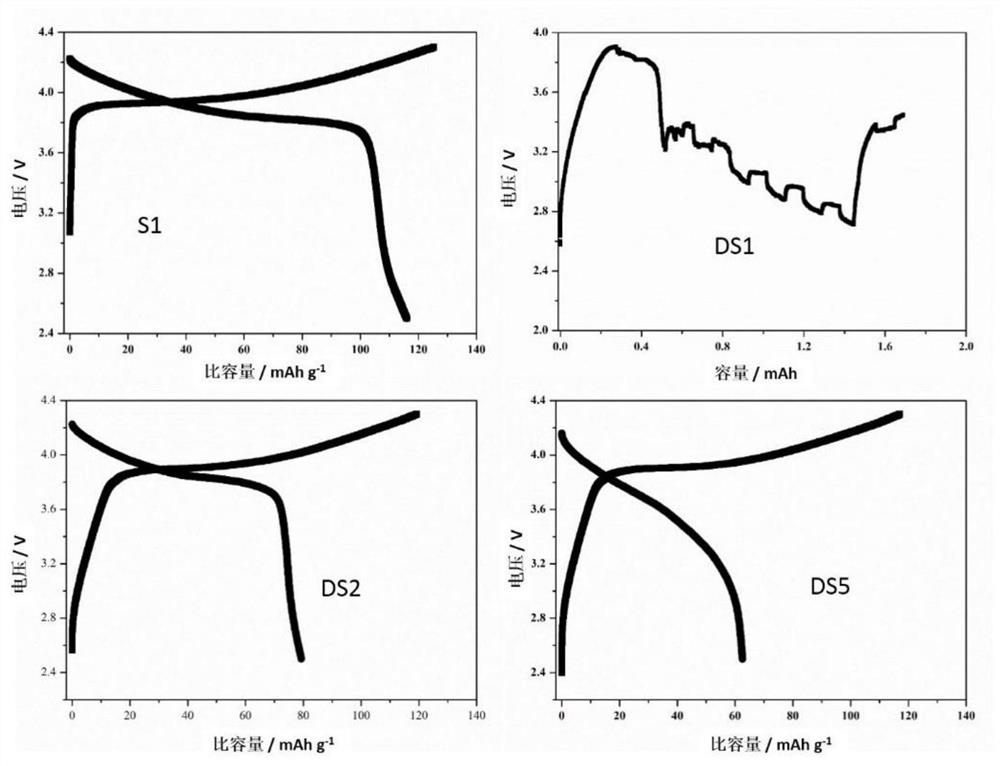

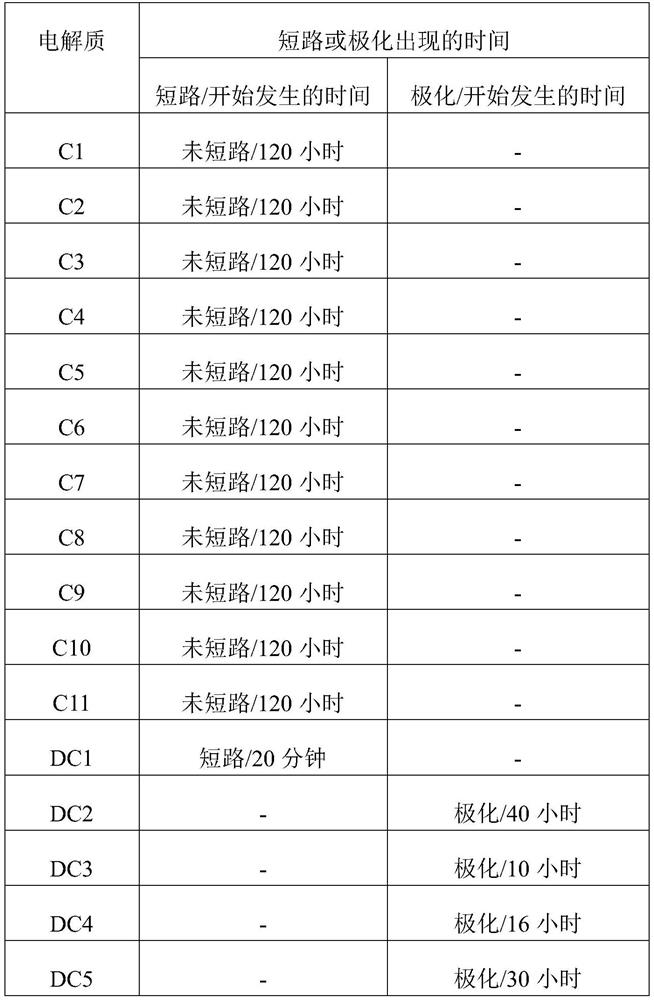

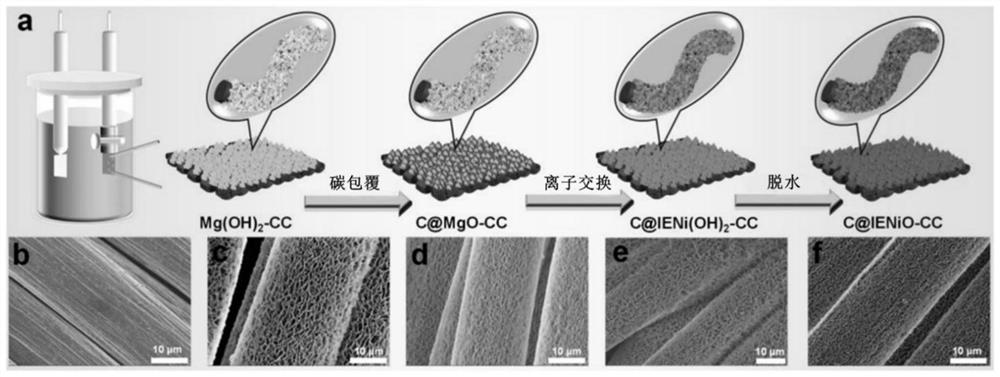

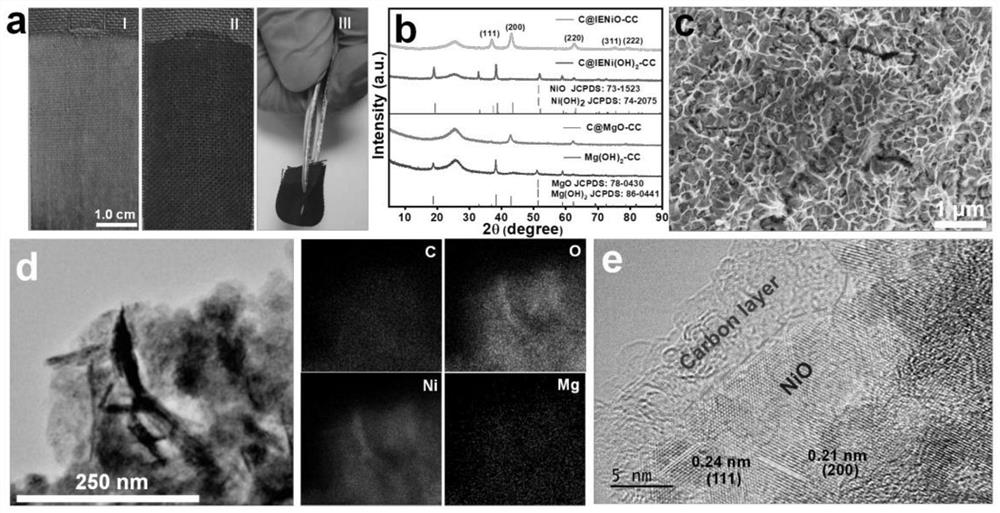

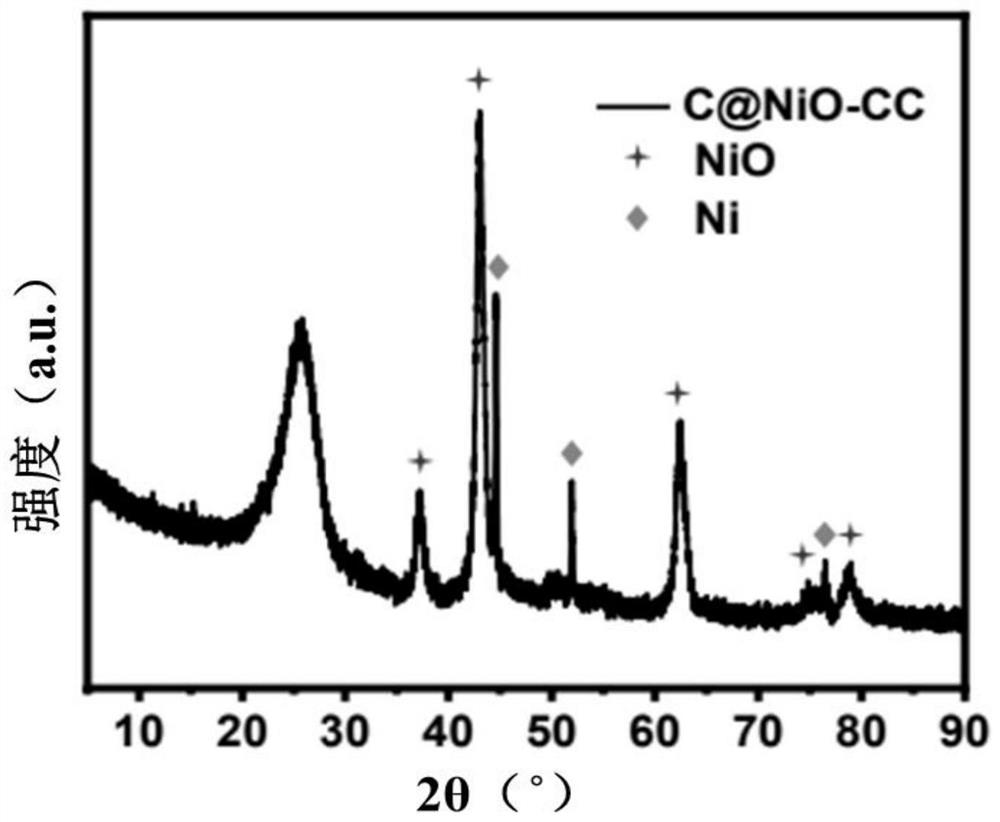

Preparation method of lithium-free flexible electrode by using ion exchange method

PendingCN113346073AIncrease capacityIncrease loadSecondary cellsPositive electrodesCarbon coatingElectrical battery

The invention provides a preparation method of a lithium-free flexible electrode by using an ion exchange method. The preparation method comprises the following steps of: depositing magnesium hydroxide on carbon cloth by adopting an electrochemical deposition method to prepare a magnesium hydroxide-carbon cloth compound; taking glucose as a carbon source, forming a carbon coating layer through hydrothermal treatment and high-temperature carbonization treatment, and dehydrating the magnesium hydroxide into magnesium oxide through high-temperature carbonization treatment to obtain a carbon-coated magnesium oxide-carbon cloth compound; and carrying out ion exchange reaction and dehydration treatment on the carbon-coated magnesium oxide-carbon cloth compound to convert the carbon-coated magnesium oxide-carbon cloth compound into a carbon-coated nickel oxide-carbon cloth compound, thereby acquiring the flexible electrode material with high capacity. In the mode, the loading capacity of active substances on the surface of the carbon cloth can be improved while a lossless and compact carbon coating layer is formed, and the influence of a high-temperature carbonization process on nickel oxide is effectively avoided, so that the prepared flexible electrode has relatively high conductivity and specific capacity and has important significance on the design of a high-capacity flexible battery system.

Owner:HUAZHONG UNIV OF SCI & TECH

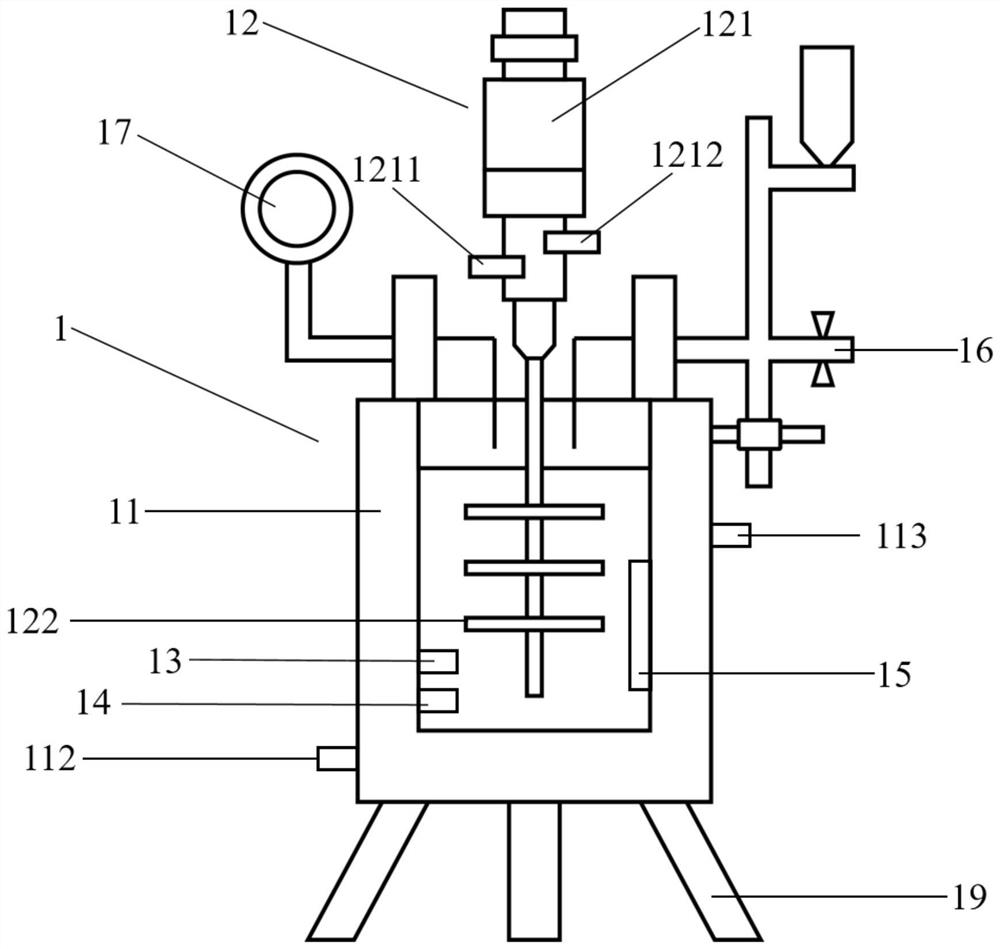

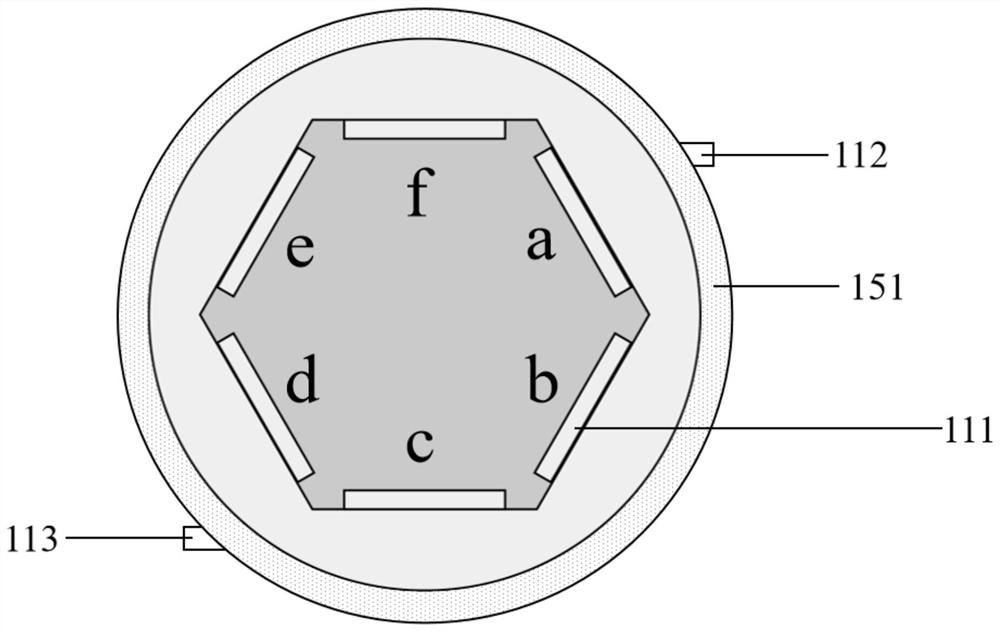

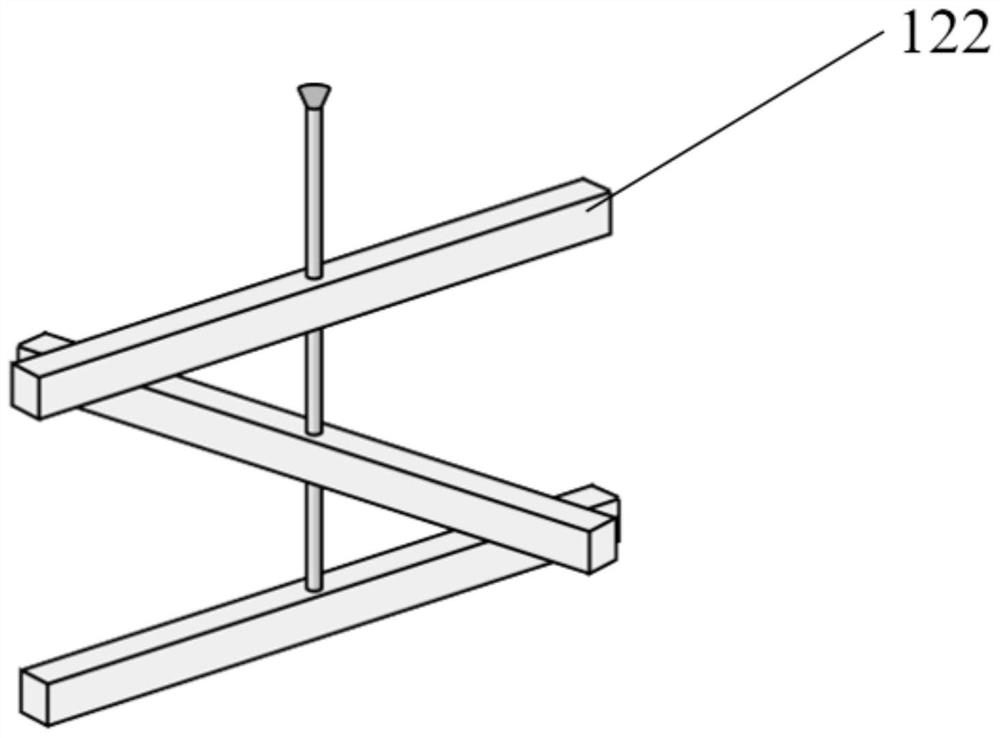

Continuous reactor for synthesizing high-crystallinity nanoscale solid electrolyte precursor and synthesis method

PendingCN114432994AMonitor temperature in real timeReal-time pH monitoringSecondary cellsChemical/physical/physico-chemical stationary reactorsContinuous reactorReaction temperature

The invention relates to a continuous reactor for synthesizing a high-crystallinity nanoscale solid electrolyte precursor and a synthesis method. The continuous reactor comprises a reaction kettle body, and a stirring device, a heating device and a feeding controller are arranged on the reaction kettle body; the stirring device is used for stirring reaction materials; the heating device is used for changing the reaction temperature; the feeding controller is used for adding reaction materials; the reaction kettle body further comprises a temperature sensor and a pH sensor, and the temperature sensor is arranged in the reaction kettle body, connected with the heating device and used for detecting the reaction temperature and controlling starting and stopping of the heating device; the pH sensor is arranged in the reaction kettle body, is connected with the feeding controller, and is used for detecting a reaction pH value and controlling the feeding controller to start and stop. The continuous reactor can monitor the temperature and the pH value of a reaction system in real time and transmit signals to the heating device and the feeding controller, so that the temperature and the pH value in the reaction process are automatically and accurately adjusted, and the reaction is smoothly carried out.

Owner:瑟瑞米(洛阳)新能源科技有限公司

Healthy energy water generating device

PendingCN112850854AImprove economyIncrease costWater treatment parameter controlSpecific water treatment objectivesElectrolysisMedicine

The invention discloses a healthy energy water generating device which comprises an electrolysis device connected with a water inlet and outlet pipeline, the electrolysis device is connected with a power supply, and the healthy energy water generating device is characterized in that a microbattery device is arranged on the water inlet and outlet pipeline, the microbattery device is made of a negative potential alloy material, and a micro-electrolysis device is arranged on the water inlet and outlet pipeline. The healthy energy water treated by the method provided by the invention still has higher negative potential and alkalinity at higher temperature such as 40 DEG C, contains beneficial minerals, and has a better health-care effect.

Owner:佛山市先洋水科技发展有限公司

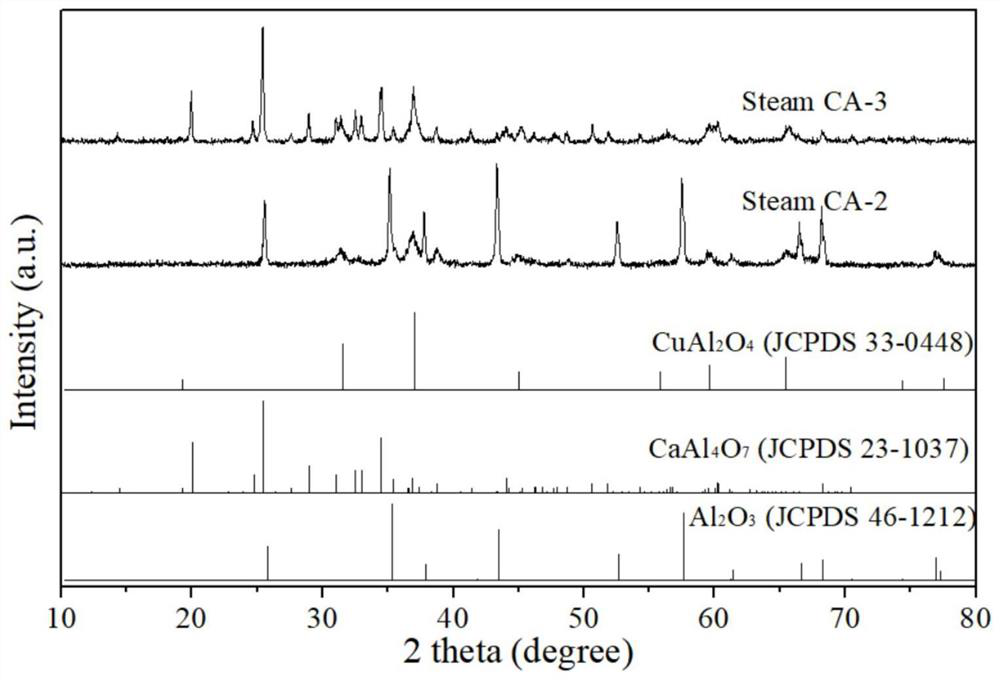

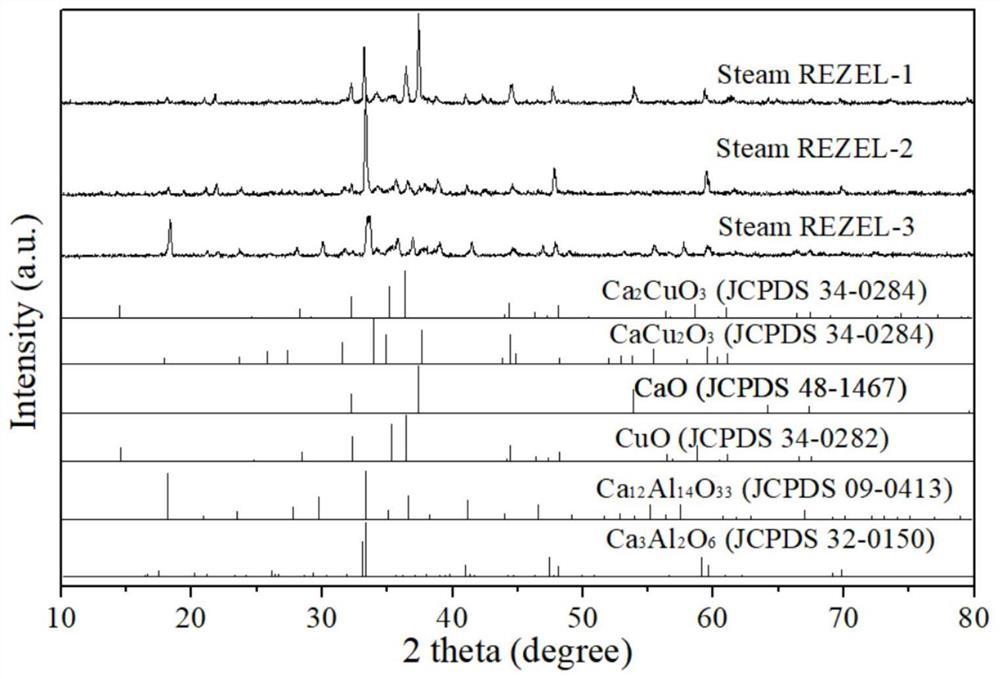

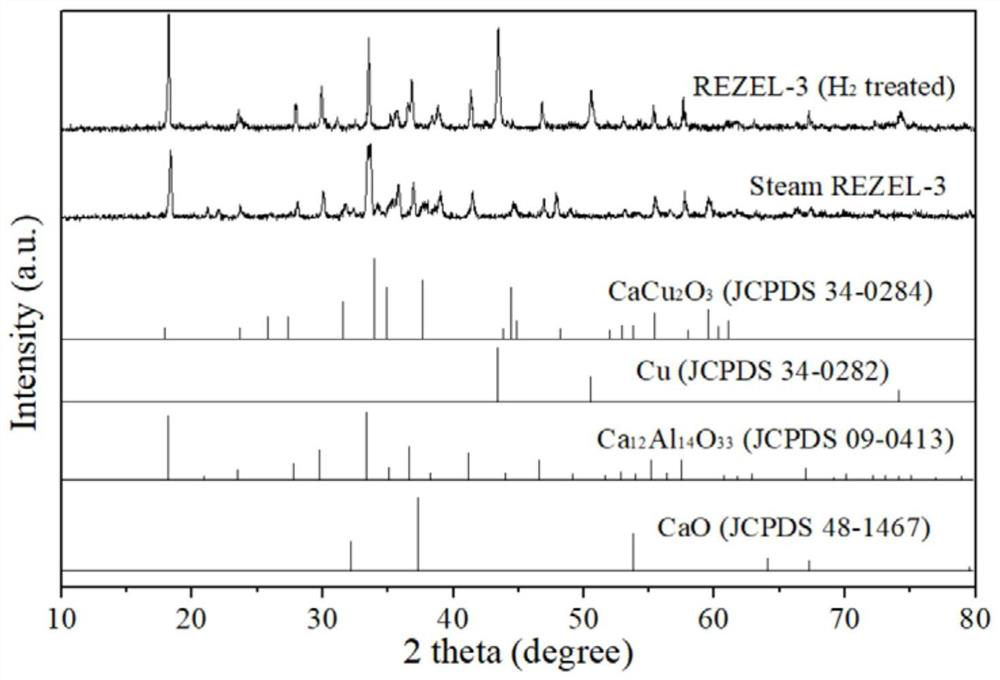

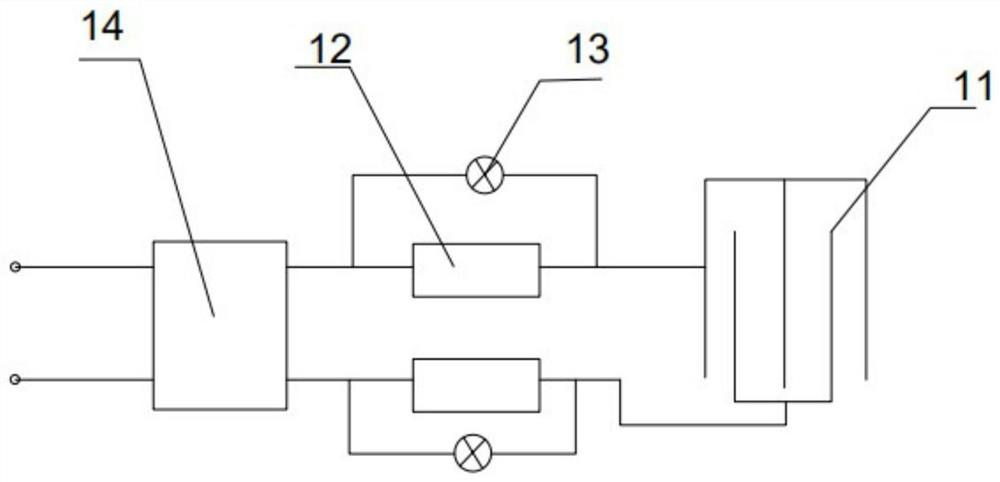

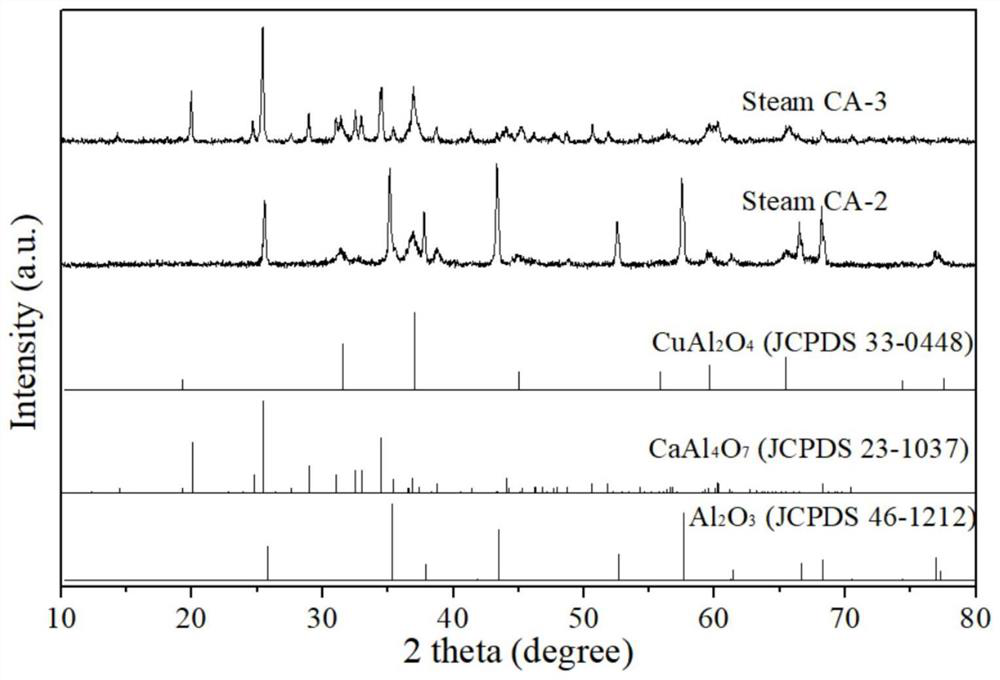

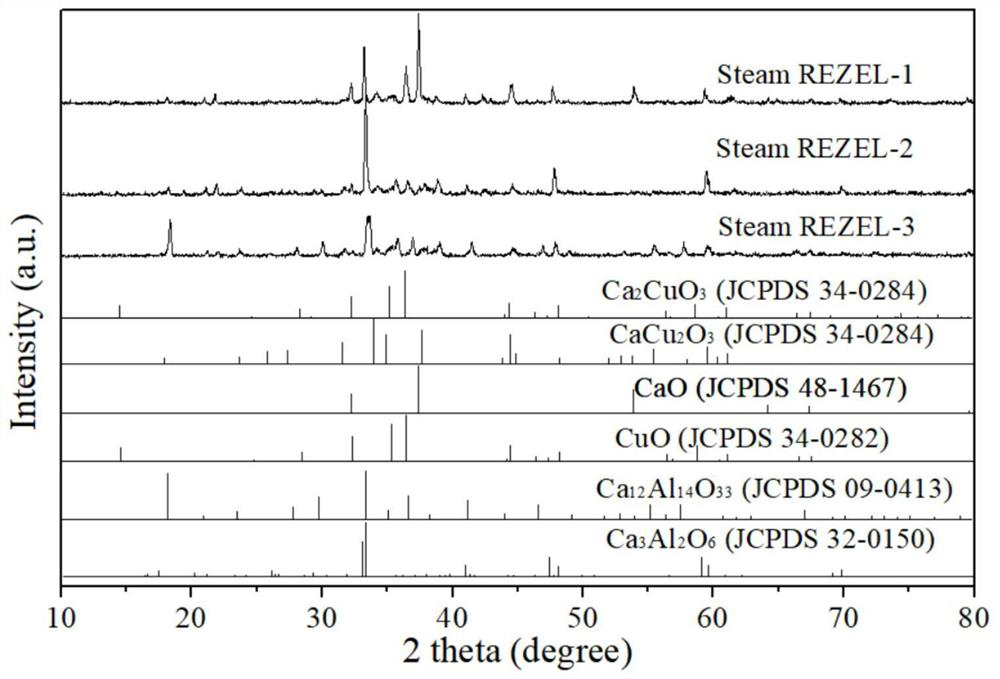

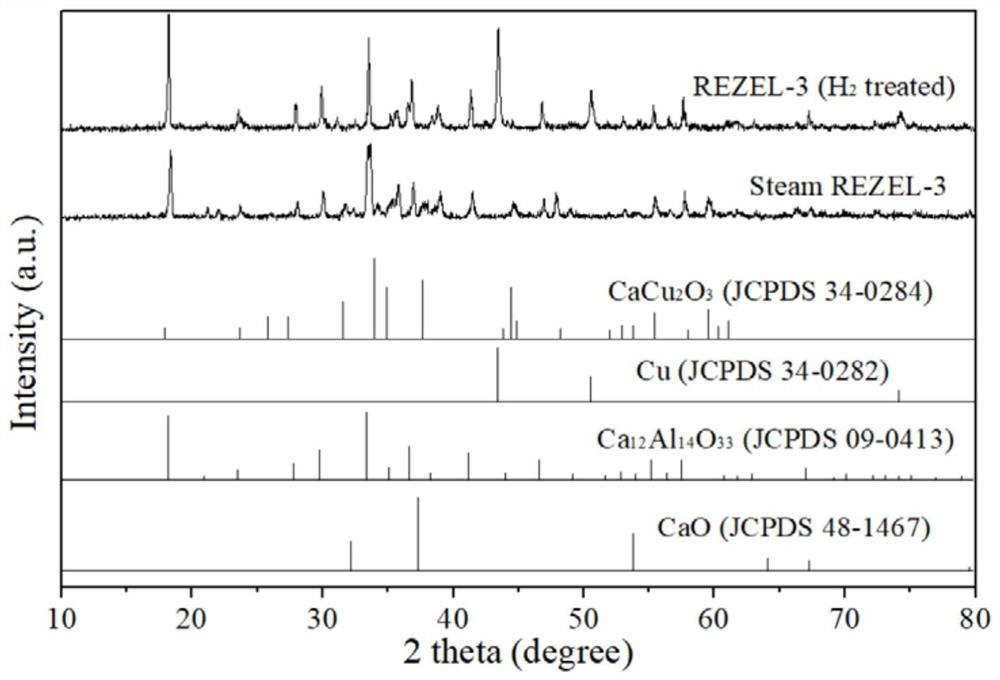

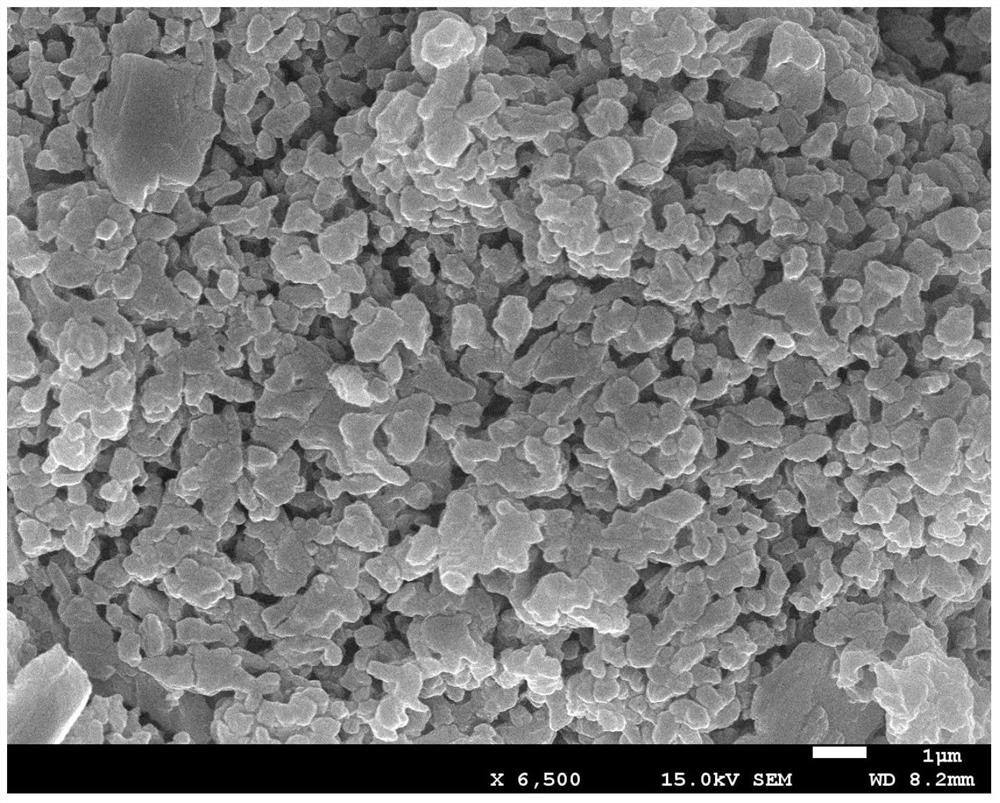

Alkane dehydrogenation heating auxiliary agent, preparation method and application thereof

ActiveCN113388376AHigh bulk densityHigh calorific valueHydrocarbonsHeat-exchange elementsAlkaneDehydrogenation

The invention discloses an alkane dehydrogenation heating auxiliary agent, a preparation method and application thereof, wherein the alkane dehydrogenation heating auxiliary agent is mainly prepared from the following components in parts by weight: 35-90 parts of CaO, 10-40 parts of CuO and 5-40 parts of Al2O3, the element Cu in the alkane dehydrogenation heating auxiliary agent mainly exists in the forms of CaCu2O3 and Ca2CuO3, and the ratio of the number of Ca atoms to the number of Al atoms is larger than or equal to 6 / 7; and the alkane dehydrogenation heating auxiliary agent does not contain an aluminum oxide phase. According to the invention, aluminum oxide and calcium oxide are converted into high-calcium calcium aluminate (the Ca / Al atom number ratio is larger than or equal to 6 / 7), so that the situation that CuO and the aluminum oxide react to produce the aluminum-copper spinel can be avoided; and the high-calcium calcium aluminate serves as a framework, so that the adhesion phenomenon caused by sintering of the carrier under the condition is avoided.

Owner:润和科华催化剂上海有限公司

Solid electrolyte material and preparation method thereof, solid electrolyte and battery

ActiveCN106611871BEasy to makeImprove ionic conductivitySolid electrolytesFinal product manufactureElectrical batteryIonic conductivity

The invention relates to a solid electrolyte material, which contains a crystalline inorganic solid electrolyte and an amorphous inorganic solid electrolyte, and the crystalline inorganic solid electrolyte is of the formula Li 10±1 AB 2 x 12 One or more of the crystalline inorganic solid electrolytes represented, the amorphous inorganic solid electrolyte is of the formula yLi 2 X‑(100‑y)P 2 x 5 One or more of the indicated amorphous inorganic solid electrolytes. The present invention also provides a preparation method of the above-mentioned solid electrolyte material, a solid electrolyte containing the solid electrolyte material and a battery containing the above-mentioned solid electrolyte. The preparation process of the solid electrolyte material provided by the invention is simple, and has excellent ionic conductivity, especially is not easy to be reduced by the metal negative electrode, has good stability, and the electrolyte prepared by it has a longer cycle life, so that the battery is also more efficient. durable.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com