A kind of alkane dehydrogenation heating aid, its preparation method and application

A heating aid and alkane dehydrogenation technology, which is applied in propane dehydrogenation and petrochemical fields, can solve the problems of poor hydrothermal performance and difficult reduction, and achieve high calorific value, cost saving and good hydrothermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of an alkane dehydrogenation heating aid, comprising the following steps:

[0030] S1: Calcium oxide or calcium hydroxide or a mixture of both, CuO or copper hydroxide or copper carbonate or basic copper carbonate or a mixture of at least two, Al 2 o 3 Or aluminum hydroxide or a mixture of the two, add water to knead evenly to obtain a kneaded product;

[0031] S2: Drying and calcining the kneaded product in sequence;

[0032] Preferably, the kneaded product can be extruded into strips or pelletized before drying, preferably extruded into strips; then dried and calcined in sequence, the drying temperature is 80-110°C, preferably 100°C, and the calcining temperature is 900°C -1200°C, preferably 1100°C, the calcination time is 3-4 hours, preferably 4 hours.

[0033] The exothermic additive for alkane dehydrogenation can be used as an exothermic additive in the dehydrogenation process of low-carbon alkanes.

Embodiment 1

[0055] Pseudoboehmite (containing 0.07 kg of alumina), calcium hydroxide (containing 0.68 kg of calcium oxide), and 0.25 kg of copper oxide were placed in a kneader and mixed evenly, and kneaded by adding water. After the kneading is completed, it is placed in an extruder to extrude, and the extruded sample is dried at 100° C. for 4 hours. The dried sample was then baked at 1100°C for 3 hours. The sample was named REZEL-1. The heat release before and after hydrothermal treatment is shown in Table 1.

[0056] REZEL-1 was aged at 800°C and 100% hydrothermal for 48 hours, and the sample was named Steam REZEL-1.

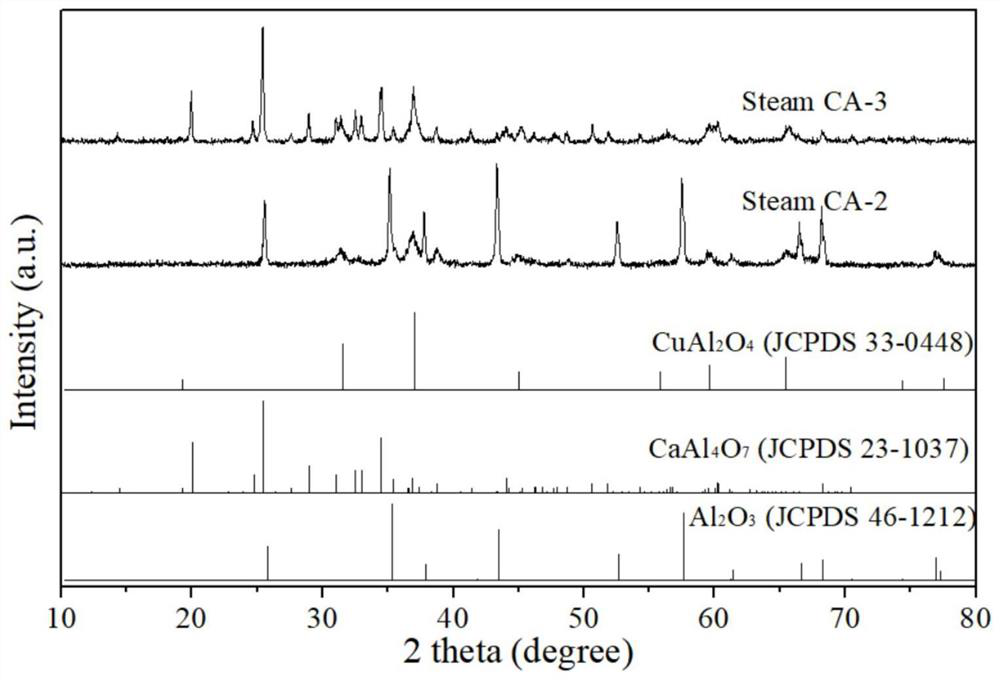

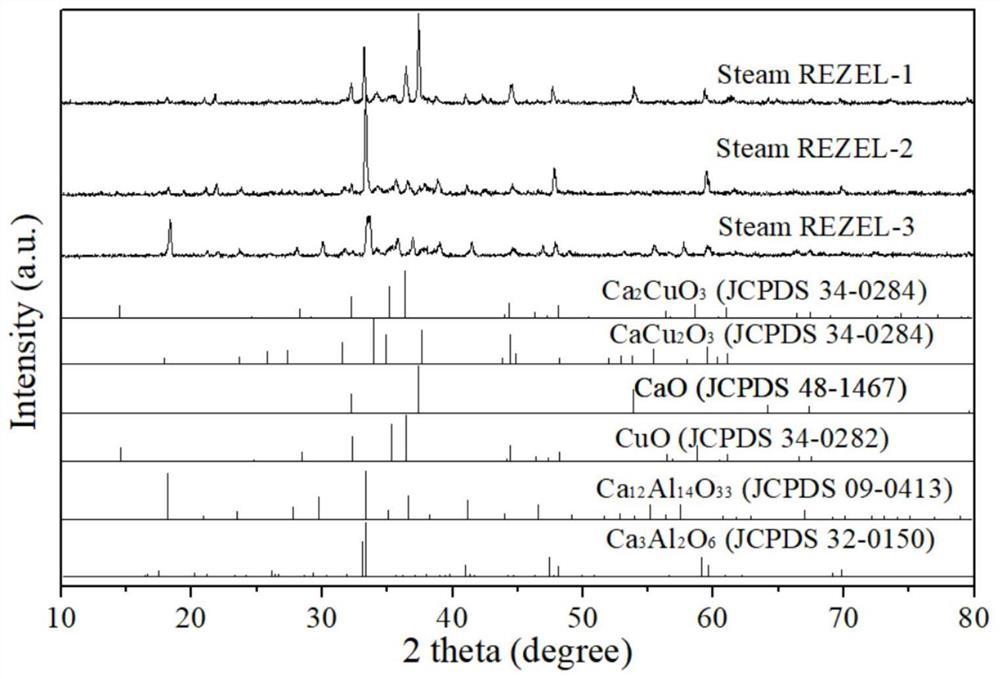

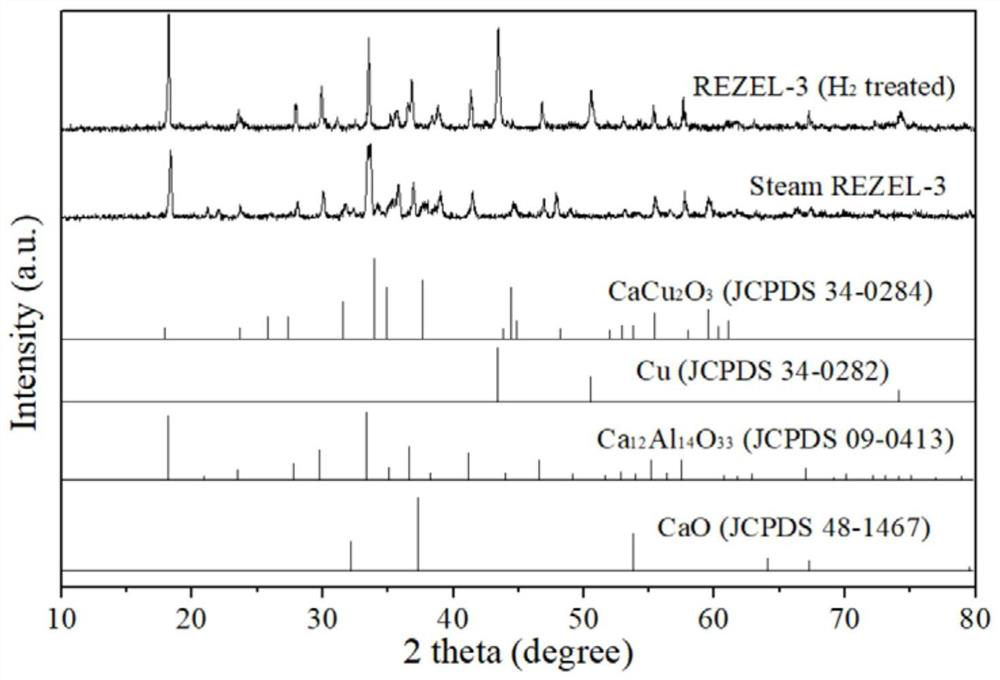

[0057] For the XRD pattern of Steam REZEL-1, see figure 2 , Steam REZEL-1 is black, see the DSC curve of REZEL-1 before and after hydrothermal aging Figure 4 .

Embodiment 2

[0059] Pseudo-boehmite (containing 0.16 kg of alumina), 0.53 kg of calcium oxide, and 0.25 kg of copper oxide are placed in a kneader and mixed evenly, and kneaded by adding water. After the kneading is completed, it is placed in an extruder to extrude, and the extruded sample is dried at 110° C. for 4 hours. The dried sample was then baked at 900°C for 4 hours. The sample was named REZEL-2. The heat release before and after hydrothermal treatment is shown in Table 1.

[0060] REZEL-2 was aged at 800°C and 100% hydrothermal for 48 hours, and the sample was named Steam REZEL-2.

[0061] See the XRD pattern of Steam REZEL-2 figure 2 , Steam REZEL-2 is black, see the DSC curve of REZEL-2 before and after hydrothermal aging Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com