An environment-friendly, energy-saving, high-conversion rare earth catalyst and preparation method thereof

A rare earth catalyst, high conversion rate technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high cost of tail gas treatment and high wear rate , to achieve the effect of solving the exhaust emission problem, prolonging the service life and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

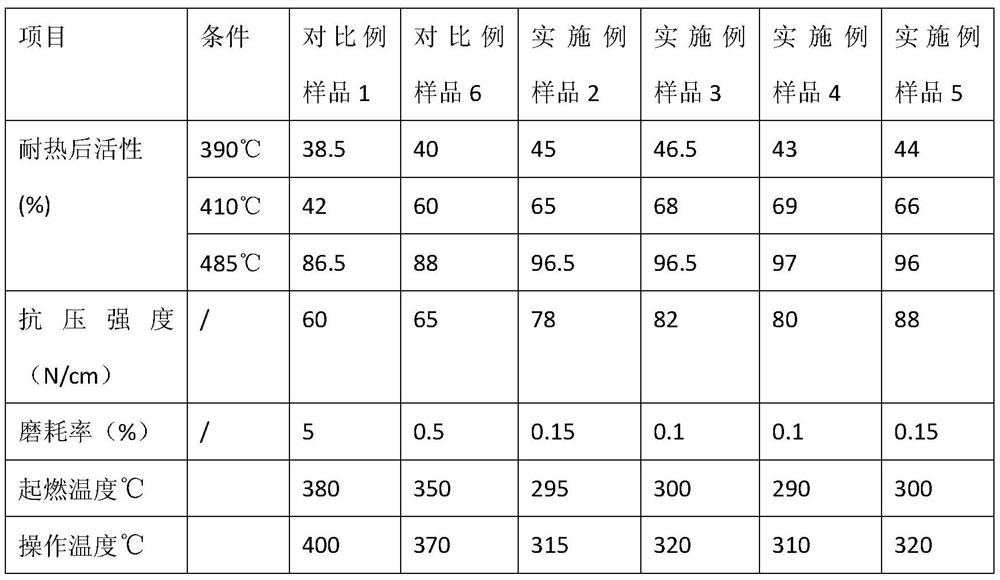

Examples

Embodiment 1

[0037] Weigh 2.5gLa(NO 3 ) 3 ﹒ 6H 2 O, 2.5gCe(NO 3 ) 3 ﹒ 6H 2 O, 2.5gNd(NO 3 ) 3 ﹒ 6H 2 O, 2.5gPr(NO 3 ) 3 ﹒ 6H 2 Add O to 400mL distilled water, add 150g of refined diatomaceous earth after completely dissolving, stir for 30min, dry in vacuum at 60°C for 12h, and roast at 400°C for 4h to obtain material b; 2 o 5 , 10gKOH is fully dissolved in the same reaction tank, after mixing evenly, add 2.5g organic polymer compound (polyethylene glycol 8000) and 2.5g surfactant (hexadecyltrimethylammonium bromide), fully react to obtain KVO 3 or NaVO 3 Solution, take 200mL, add 60mL dilute sulfuric acid (mass concentration 25%), join in the material b after reaction forms uniform solution, and and 10gCs 2 SO 4 , 2.5g thiosulfate, 2.5g sodium bicarbonate, 2.5mL phosphoric acid (mass concentration is 85%), and 7.5% sulfur (fineness 20 orders) are metered into the roller and fully mixed and milled for 0.5 hour. The mixed and milled material is mechanically shaped, then dr...

Embodiment 2

[0039] Weigh 5gLa(NO 3 ) 3 ﹒ 6H 2 O, 5gCe(NO 3 ) 3 ﹒ 6H 2 O, 5gNd(NO 3 ) 3 ﹒ 6H 2 O, 5gPr(NO 3 ) 3 ﹒ 6H 2 Add O to 400mL distilled water, add 150g of refined diatomaceous earth after completely dissolving, stir for 30min, dry in vacuum at 60°C for 12h, and roast at 400°C for 4h to obtain material b; 2 o 5 , 10gKOH is fully dissolved in the same reaction tank, after mixing evenly, add 2.5g organic polymer compound (polyvinylpyrrolidone PVPK15) and 2.5g surfactant (hexadecyltrimethylammonium chloride), fully react to obtain KVO 3 or NaVO 3 Solution, take 200mL, add 60mL dilute sulfuric acid (mass concentration 25%), join in the material b after reaction forms uniform solution, and and 10gCs 2 SO 4 , 2.5g thiosulfate, 2.5g sodium bicarbonate, 2.5mL phosphoric acid (mass concentration is 85%), and 7.5% sulfur (fineness 20 orders) are metered into the roller and fully mixed and milled for 0.5 hour. The mixed and milled material is mechanically shaped, then dried ...

Embodiment 3

[0041] Weigh 7.5gLa(NO 3 ) 3 ﹒ 6H 2 O, 7.5gCe(NO 3 ) 3 ﹒ 6H 2 O, 7.5gNd(NO 3 ) 3 ﹒ 6H 2 O, 7.5gPr(NO 3 ) 3 ﹒ 6H 2 Add O to 400mL distilled water, add 150g of refined diatomaceous earth after completely dissolving, stir for 30min, dry in vacuum at 60°C for 12h, and roast at 400°C for 4h to obtain material b; 2 o 5 , 10gKOH is fully dissolved in the same reaction tank, after mixing evenly, add 2.5g organic polymer compound (polystyrene GH-660) and 2.5g surfactant (sodium dodecylbenzenesulfonate), fully react to obtain KVO 3 or NaVO 3 Solution, take 200mL, add 60mL dilute sulfuric acid (mass concentration 25%), join in the material b after reaction forms uniform solution, and and 10gCs 2 SO 4 , 2.5g thiosulfate, 2.5g sodium bicarbonate, 2.5mL phosphoric acid (mass concentration is 85%), and 7.5% sulfur (fineness 20 orders) are metered into the roller and fully mixed and milled for 0.5 hour. The mixed and milled material is mechanically shaped, then dried at 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com