Lithium ion battery, preparation method thereof and electric vehicle

A lithium-ion battery and electrolytic layer technology, applied in the field of lithium-ion batteries and electric vehicles, can solve the problems of increasing battery cost, reducing energy density of battery system, high price, etc. The effect of reducing internal micro-short circuit and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the above-mentioned lithium ion battery, the method comprising: coating the first solid electrolyte slurry on a support, and drying to obtain a positive electrode side solid electrolyte layer or a negative electrode side solid electrolyte layer; Coating the second solid electrolyte slurry on the surface of the solid electrolyte layer on the positive side or the solid electrolyte layer on the negative side to obtain an intermediate solid electrolyte layer, coating the third solid electrolyte slurry on the surface of the intermediate solid electrolyte layer, and drying The composite solid electrolyte is obtained, and then the positive electrode, the composite solid electrolyte, and the negative electrode are pressed into shape to obtain the lithium ion battery.

[0036] For the above preparation method, the solid electrolyte layer on the positive electrode side can be prepared first, or the solid electrolyte layer ...

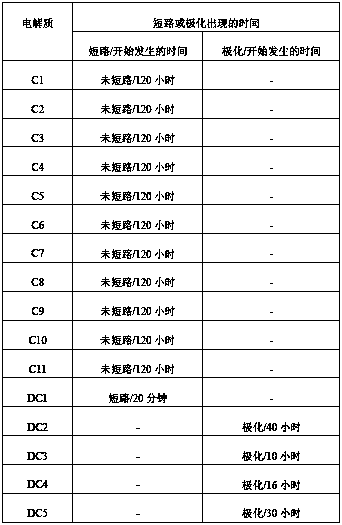

Embodiment 1

[0054] Fabrication of positive side solid electrolyte layer:

[0055] 4.85g 70Li 2 S-30P 2 S 5 Sulfide solid electrolyte (the preparation method refers to Chinese invention patent CN201510695407.5) and 0.15g styrene-butadiene rubber (SBR) are added to 6.0 g anhydrous n-heptane, and then stirred in a vacuum mixer to form a stable and uniform first solid state Electrolyte slurry: the first solid electrolyte slurry was evenly and intermittently coated on the PET film, dried at ~80°C, and rolled to obtain a solid electrolyte layer on the positive electrode side, with a coating thickness of 10 μm.

[0056] Fabrication of the middle layer solid electrolyte layer:

[0057] 2.85g sulfide solid electrolyte 70Li 2 S-30P 2 S 5 , 2.0g Li 10 SnP 2 S 12 Electrolyte and 0.15g of SBR were added to 6.0g of anhydrous n-heptane, and then stirred in a vacuum mixer to form a stable and uniform second solid electrolyte slurry; the second solid electrolyte slurry was evenly and intermittent...

Embodiment 2

[0067] Composite electrolyte C2 and button cell S2 are prepared according to the method of Example 1, the difference is that, in making the middle layer solid electrolyte layer, glassy Li 3 PO 3.6 N 0.4 Replace Li 10 SnP 2 S 12 electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com