Soldering flux

A technology of flux and weight ratio, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems that solder paste is difficult to pass the probe test, etc., to improve the welding performance and improve the probe The effect of test pass rate

Active Publication Date: 2012-12-26

DONGGUAN YONGAN TECH

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In view of this, the present invention aims at the deficiencies in the prior art, and its main purpose is to provide a solder paste and its flux and their manufacturing method, which can effectively solve the problem that the existing solder paste is difficult or even impossible to pass the probe test. question

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0056] Example 2

Embodiment 2

[0058] Example 3

Embodiment 3

[0060] Example 4

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

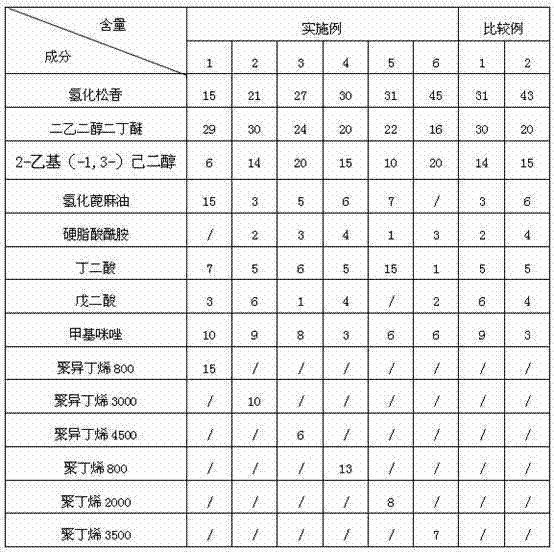

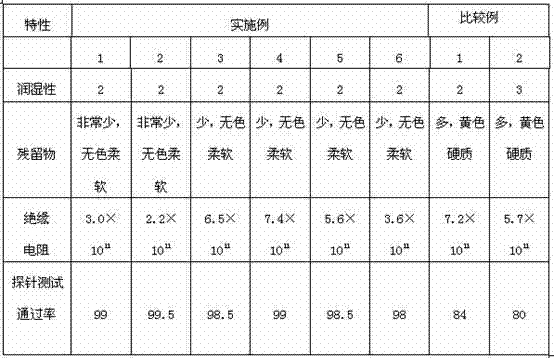

The invention discloses soldering paste and a soldering flux thereof, and preparation methods thereof. The soldering paste comprises lead-free soldering powder and the soldering flux, wherein the soldering flux comprises the following raw materials in percentage by weight: 6-15 percent of polyisobutene or polybutylene, 3-10 percent of imidazoles compound, 15-45 percent of rosin, 3-15 percent of thixotropic agent, 3-15 percent of active agent and the balance of solvent; therefore, through adding at least one of polyisobutene or polybutylene and replacing partial rosin with the polyisobutene or polybutylene, on the one hand, the consumption of the rosin can be reduced so that yellow rosin residuals are reduced, on the other hand, the polyisobutene or polybutylene residuals are both colorless and transparent viscous fluid and can soften the harder rosin residuals so that soldering paste residuals are soft, colorless and transparent substances, therefore, the probe test passing rate is greatly improved, and an effective guarantee is provided for the welding quality of electronic products.

Description

Technical field [0001] The invention involves welded technology, especially a welding paste and its welding agent and their manufacturing methods. Background technique [0002] Welding paste is widely used in high -precision electronic components. The use of welded paste can be used to isolate the air from oxidation.To a big role. [0003] At present, with the rapid development of science and technology, people's requirements for the welding quality of electronic products are getting higher and higher. Therefore, more and more electronic products use probe to test their welding performance after welding.But the existing patented welded paste has the following defects: [0004] After use, there is a lot of rosin residues on the welded joints, and the residues are harder. The probe cannot pierce the residue to touch the solder joints, so that the probe test is difficult or even pass. The quality of the welding operation cannot be obtained.Effective guarantee.In response to this iss...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K35/363B23K35/40

Inventor 吴国齐宣英男

Owner DONGGUAN YONGAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com