Box jogged method and apparatus and manufacturing system of packaging box

A technology of inserting device and conveying device, which is applied in the direction of carton/carton manufacturing machinery, packaging, transportation and packaging, etc., which can solve the problems of increasing the manufacturing cost of packaging boxes, achieve the effect of high operation reliability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

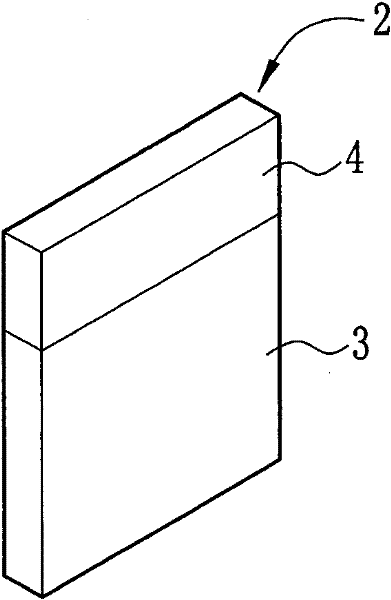

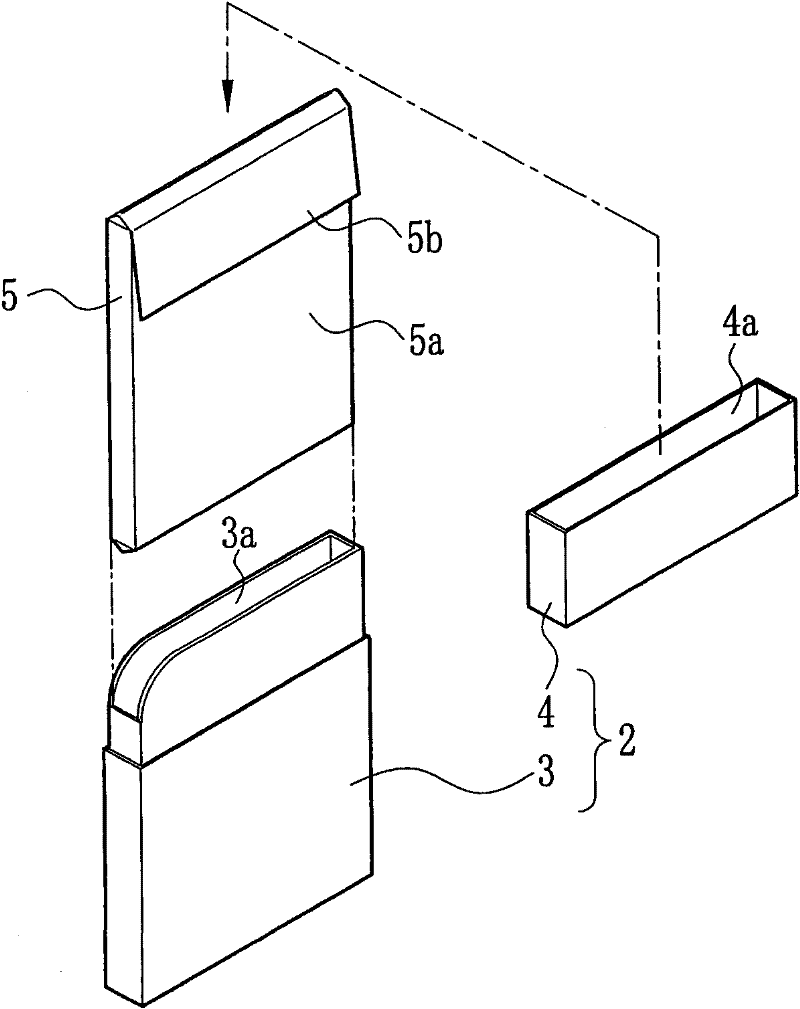

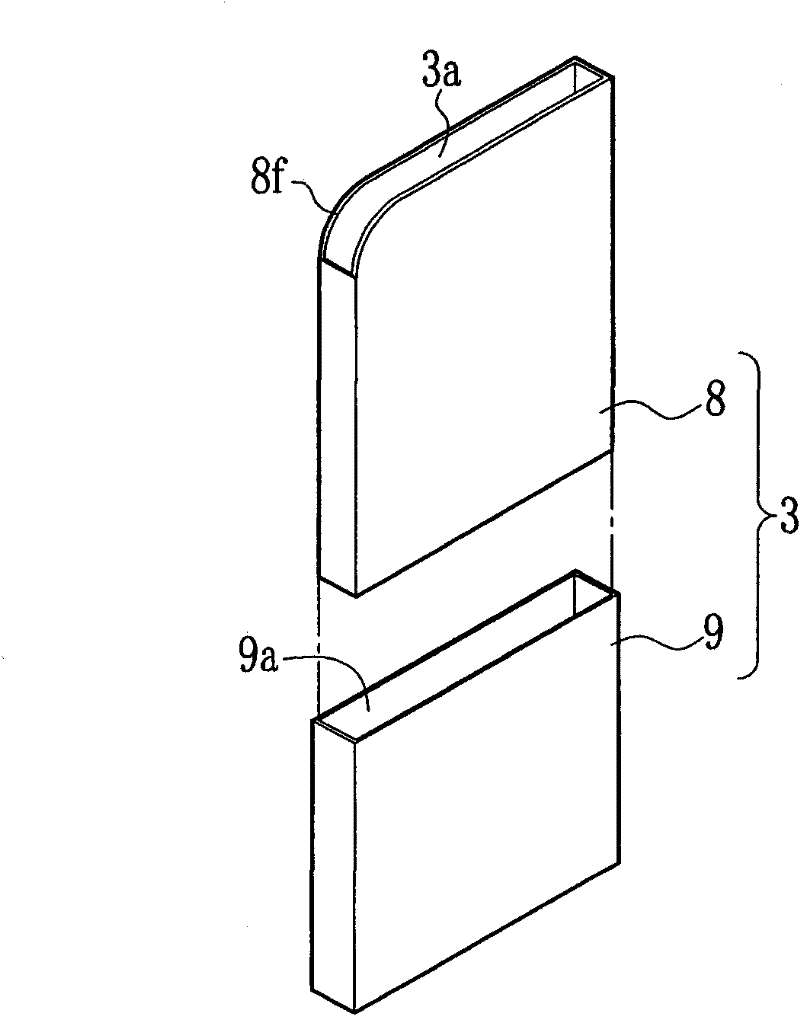

[0071] like figure 1 As shown, the packaging box 2 is composed of a vertical box body 3 and a cover box 4 detachably fitted to the upper portion of the box body 3 . like figure 2 As shown, the upper surface of the box body 3 is provided with an opening 3a. From the opening 3a, the bag-packaged product 5 in which the article is accommodated in the packaging bag 5a is inserted into the box body 3. As shown in FIG. The lower surface of the cover box 4 is provided with an opening 4a which is fitted into the upper part of the box body 3 . In this embodiment, the article to be packaged is an X-ray film, and a plurality of X-ray films are stacked and stored in the packaging bag 5a.

[0072] The packaging bag 5a is made of a packaging board having light-shielding and moisture-proof properties. A plurality of X-ray films are placed on the packaging board in an enclosed manner. After folding each side of the packaging plate so as to enclose a plurality of X-ray films, the sides we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com