Patents

Literature

67results about How to "Increase opening width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

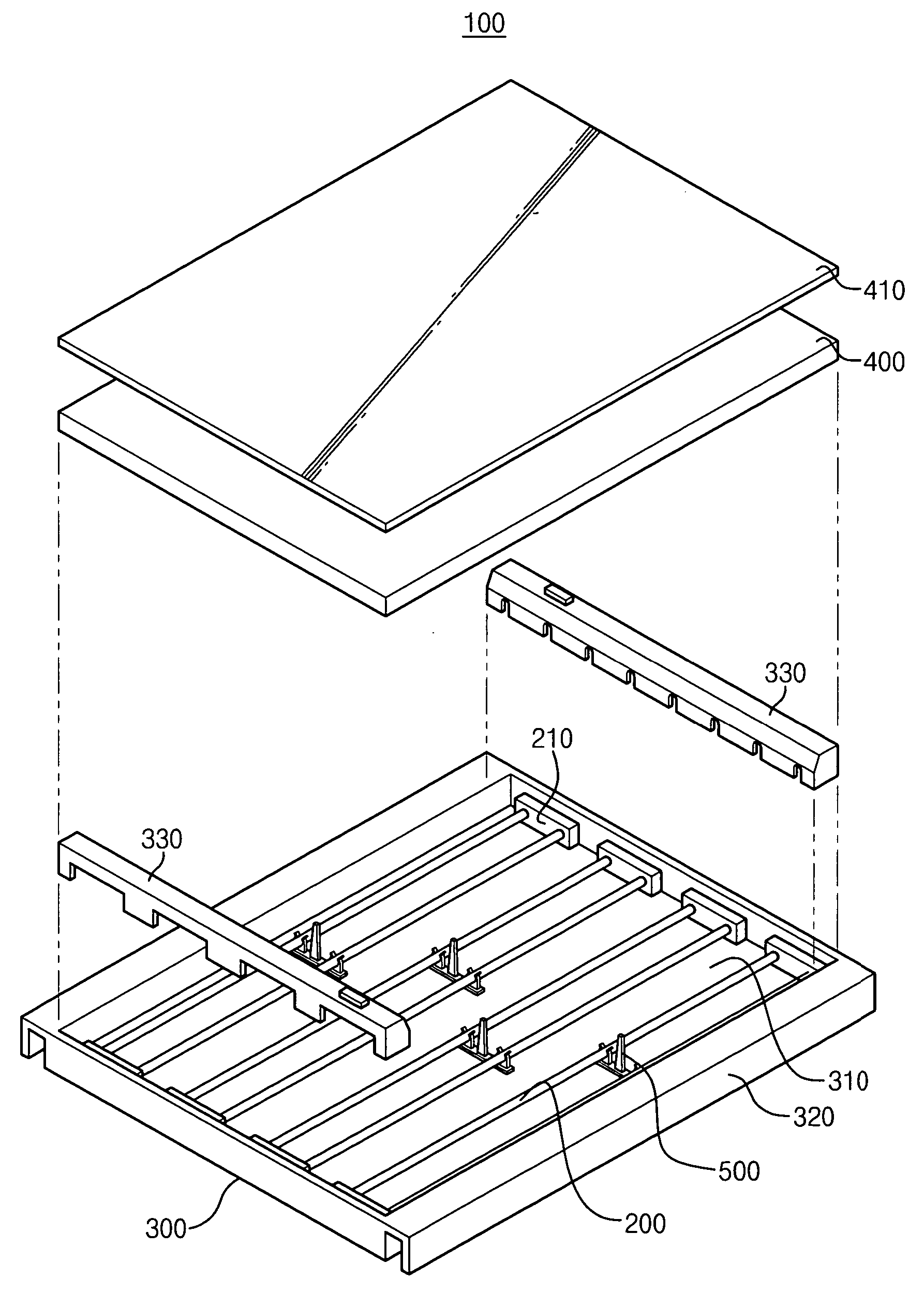

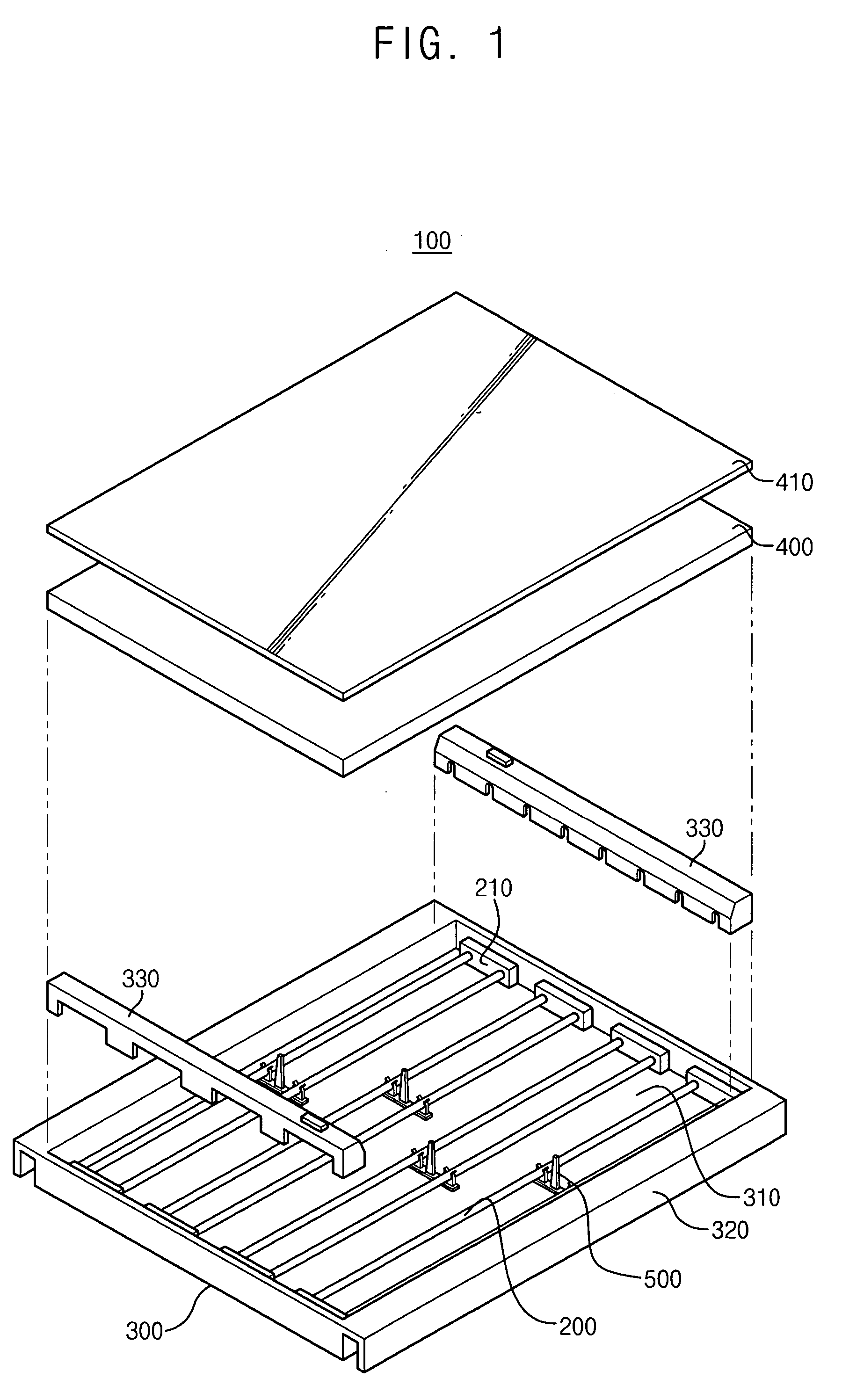

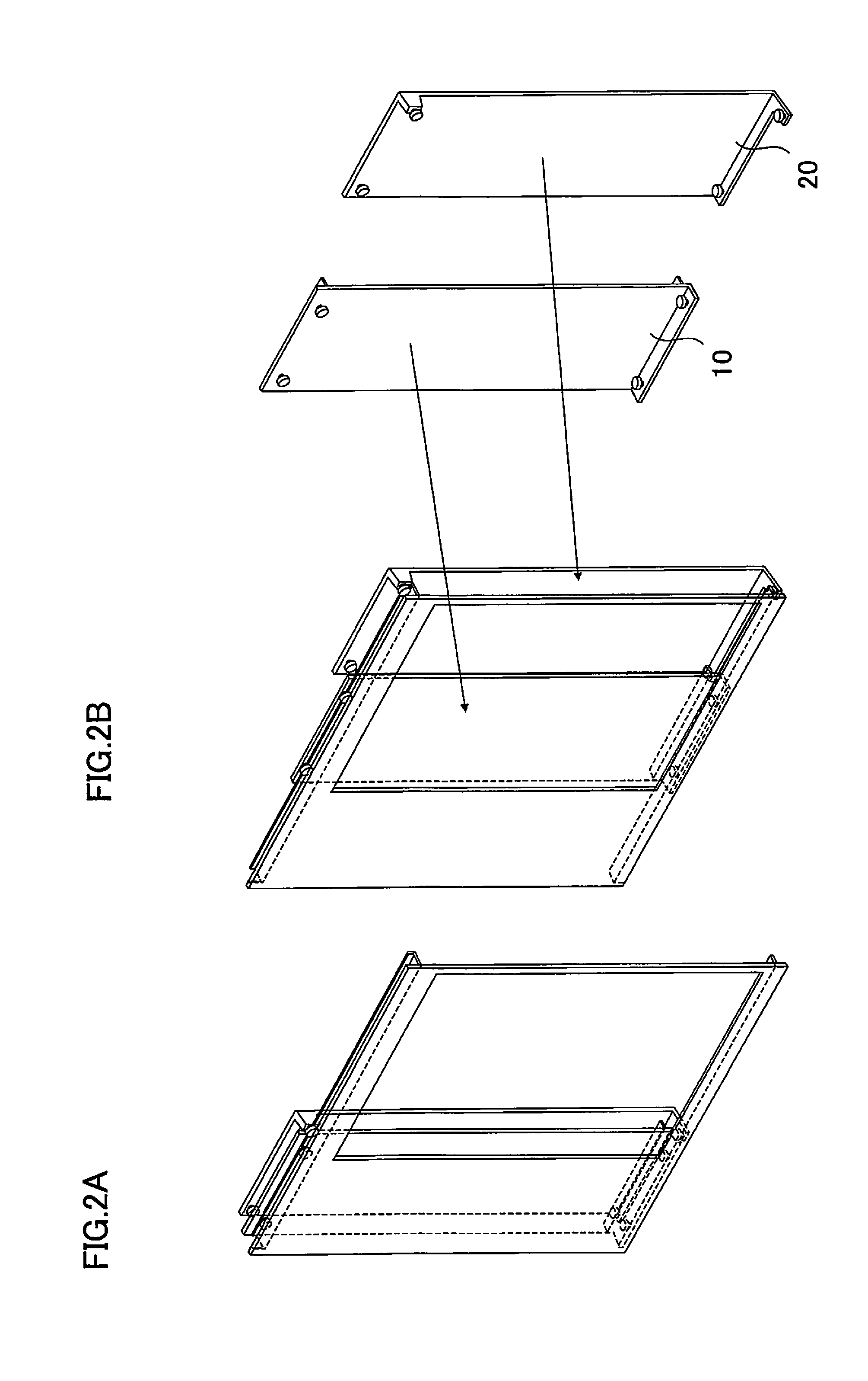

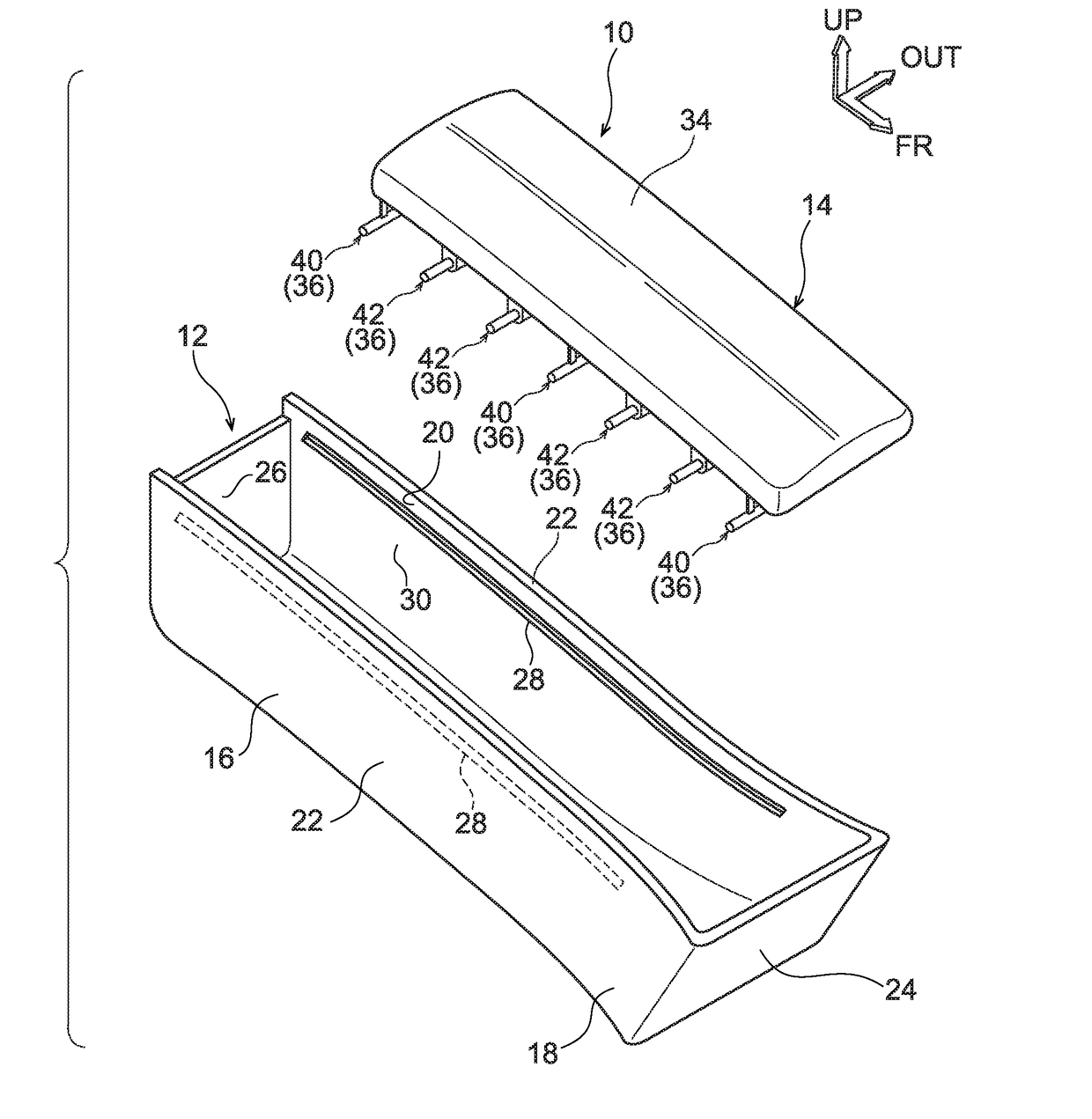

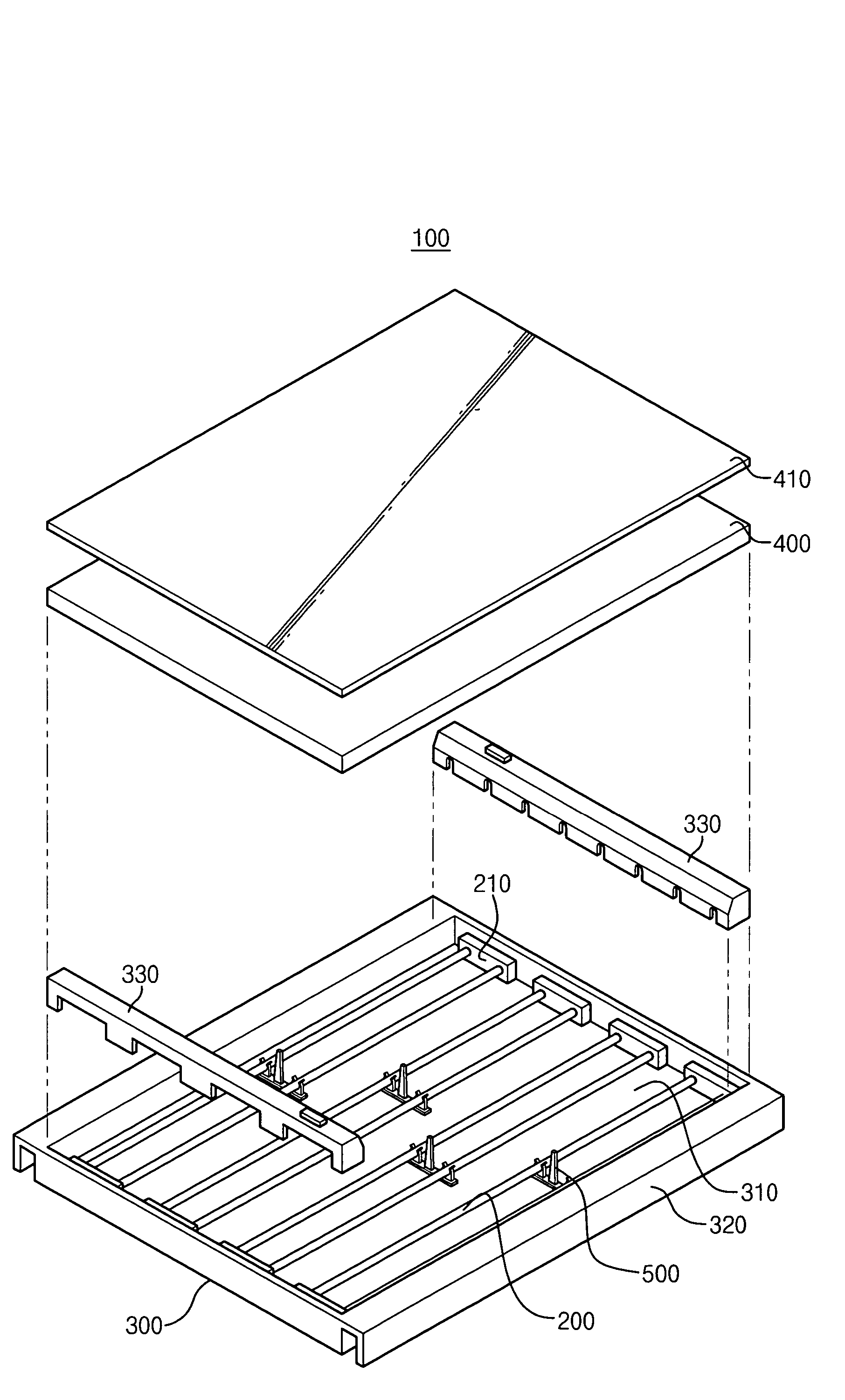

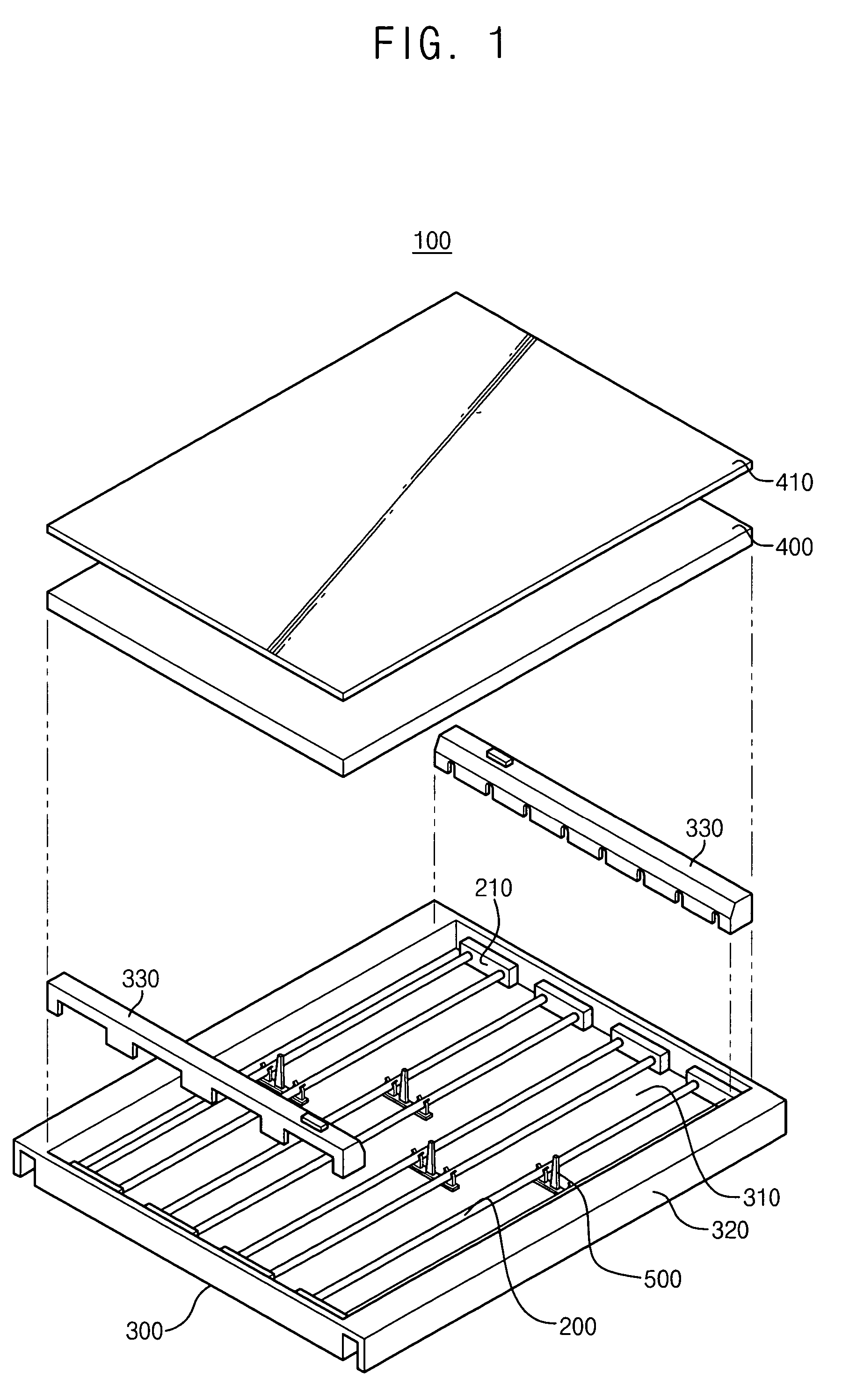

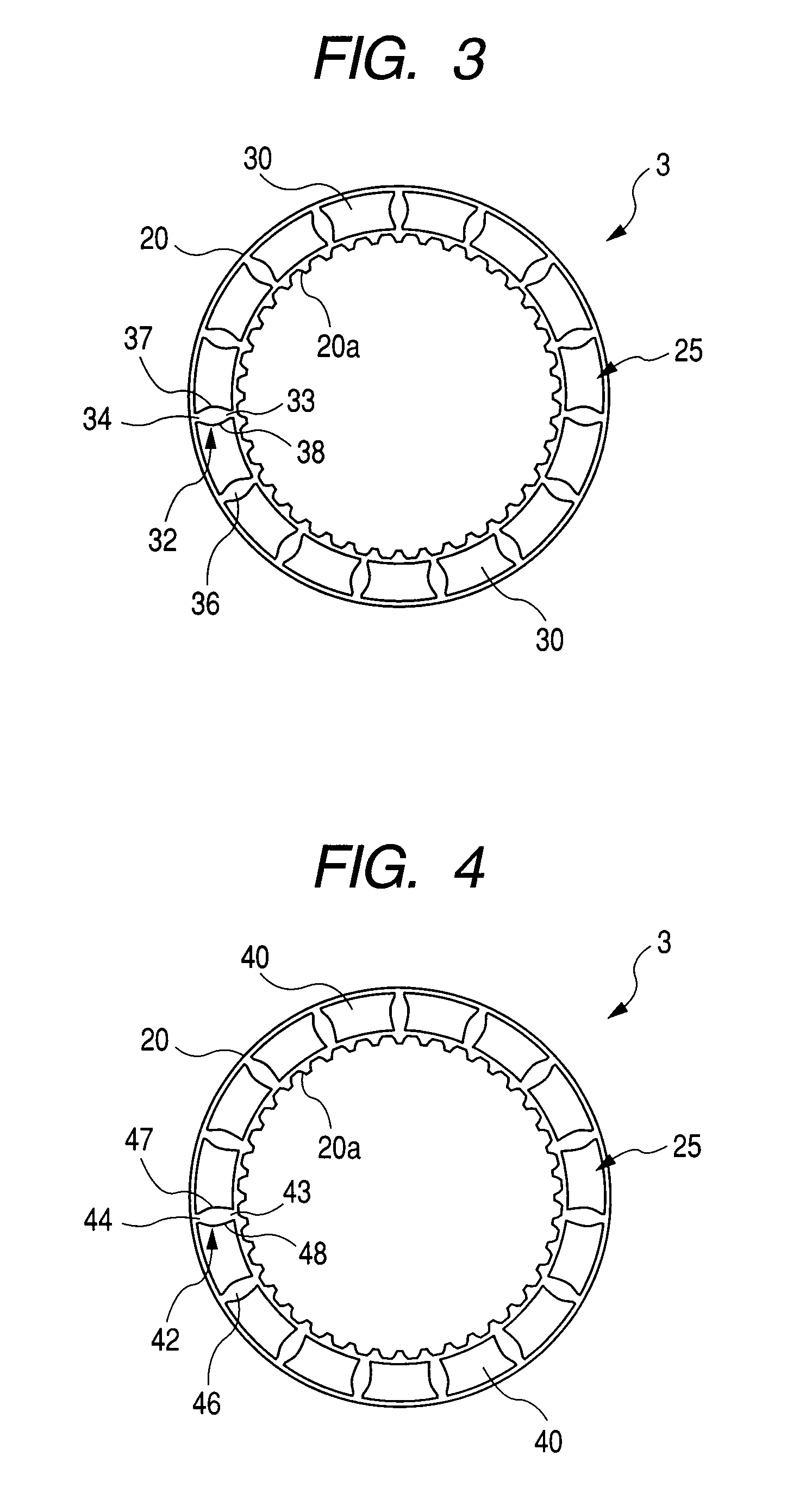

Backlight assembly and liquid crystal display apparatus having the same

InactiveUS20060018130A1Avoid breakingEasy to assembleElectric discharge tubesElectric discharge lampsLiquid-crystal displayEngineering

A backlight assembly includes a plurality of lamps, a receiving container, a diffuser plate and a plurality of holding members. The lamps generate a light. The receiving container receives the lamps. The receiving container includes a bottom portion and a side portion protruded from a side of the bottom portion. The diffuser plate is over the lamps to diffuse the light generated from the lamps. The holding members are engaged with the bottom portion. Each of the holding members has a lamp holding portion that holds one of the lamps. 10 The lamp holding portion has an opening for receiving the lamp. The opening is inclined by a first angle with respect to a normal line of the bottom portion. Therefore, the lamps are securely combined with the lamp holding portion, and the lamps are easily assembled to protect the lamps from an externally provided impact.

Owner:SAMSUNG DISPLAY CO LTD

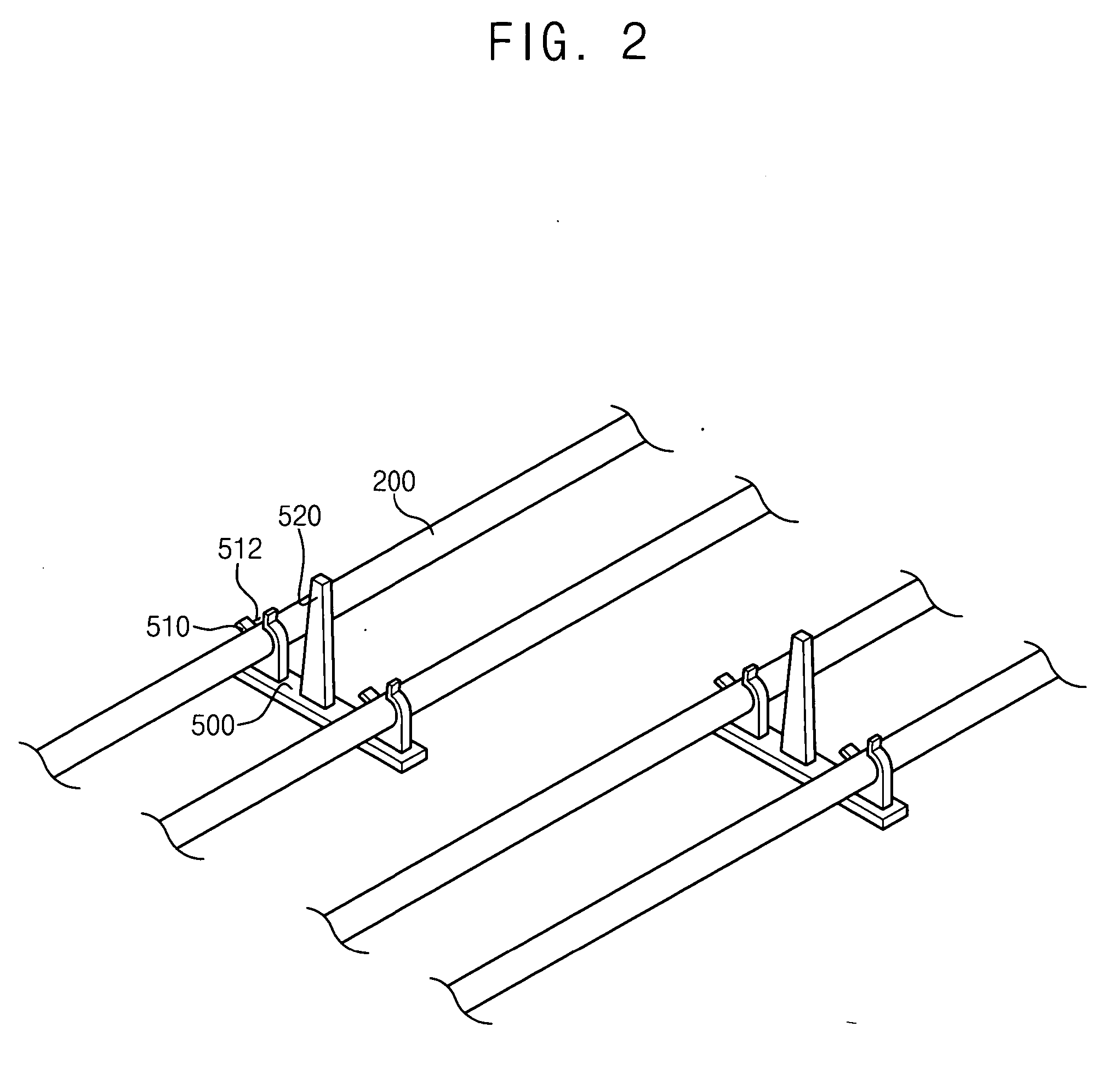

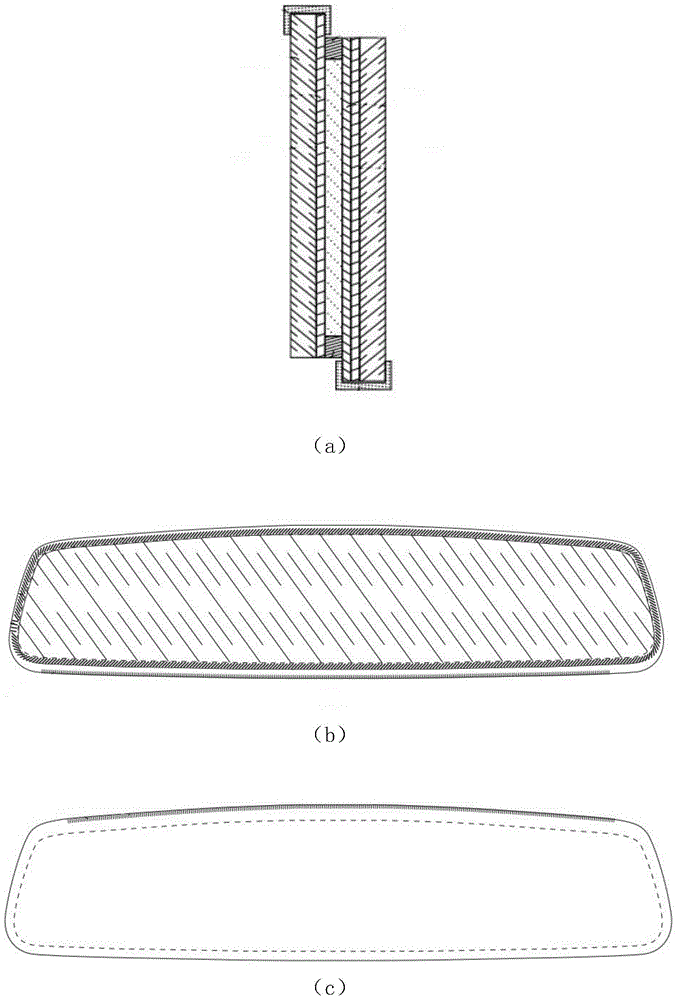

Manufacturing packaging method of electrochromic anti-dazzle device for vehicle

The invention relates to a packaging method of an electrochromic anti-dazzle device, and in particular relates to a packaging manufacturing method for edging and chamfering in a conduction region, where an electrode needs to be imported, of the conductive layer of the glass substrate of the electrochromic anti-dazzle device so as to increase the sectional area of a conductive silver adhesive; according to the requirements of reduce the package and the electrode leading-out region of the electrochromic anti-dazzle device and increasing the thermochromic device structure of a visible range, the packaging of the electrochromic anti-dazzle device is completed by use of the techniques of etching, vacuum electrochromic material pouring, sealant box hot pressing, silver adhesive pouring, heat treatment and the like. Compared with the traditional packaging of the electrochromic anti-dazzle device, the electrical conductivity of the silver adhesive after heat treatment is improved, the width of the conductive sealant is reduced and the production process and the equipment are simplified; the packaging method has obvious advantages; the height of the visual range of the electrochromic anti-dazzle device package is increased by 2-3mm.

Owner:CHANGZHOU YAPU NEW MATERIALS CO LTD

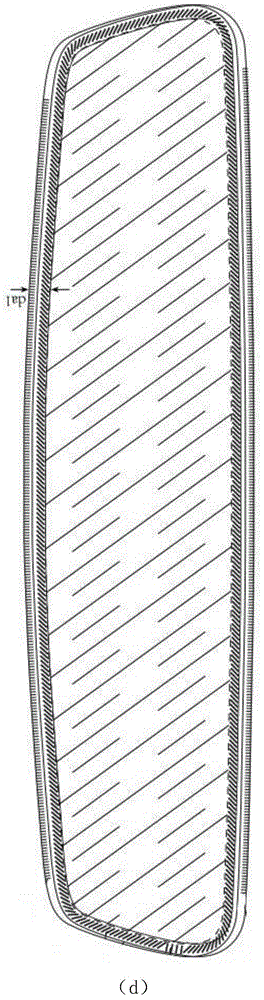

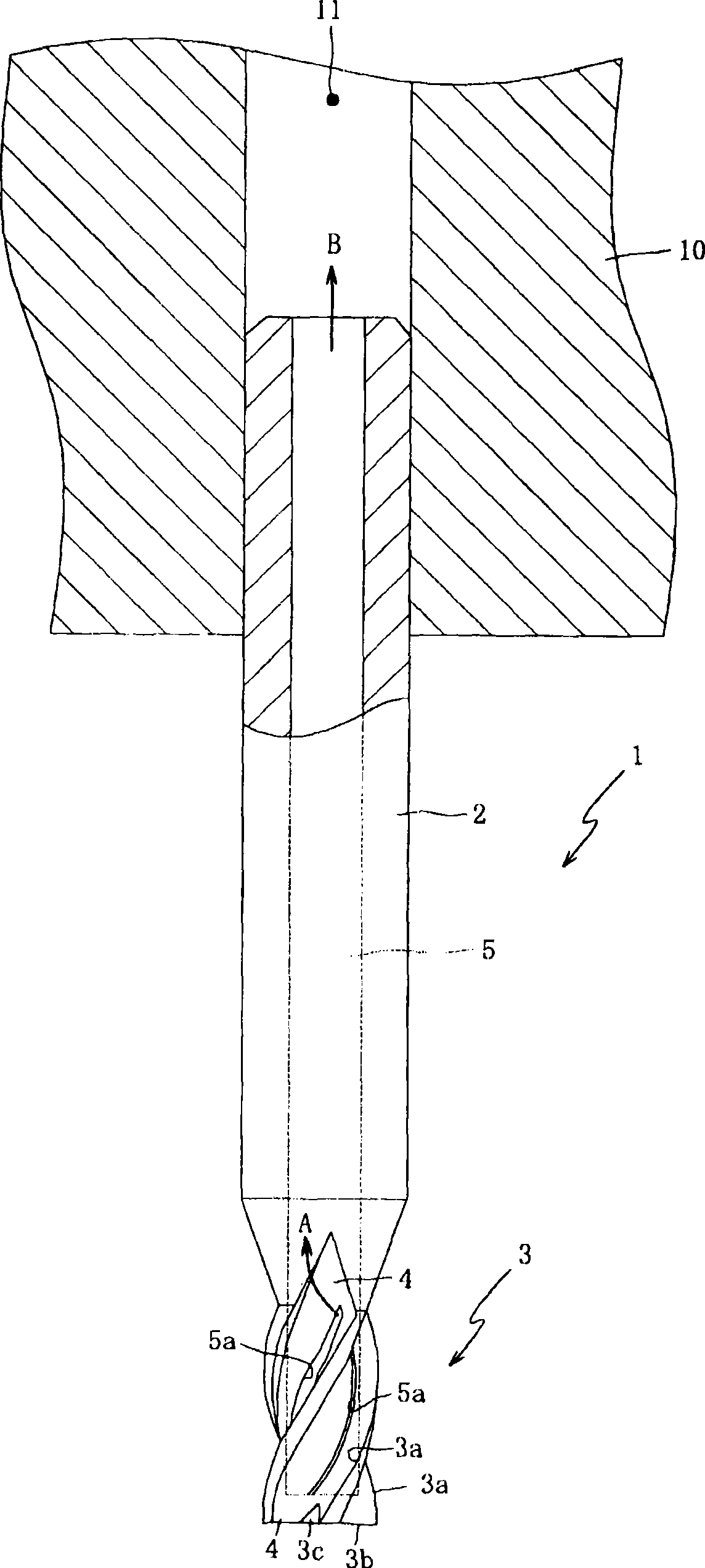

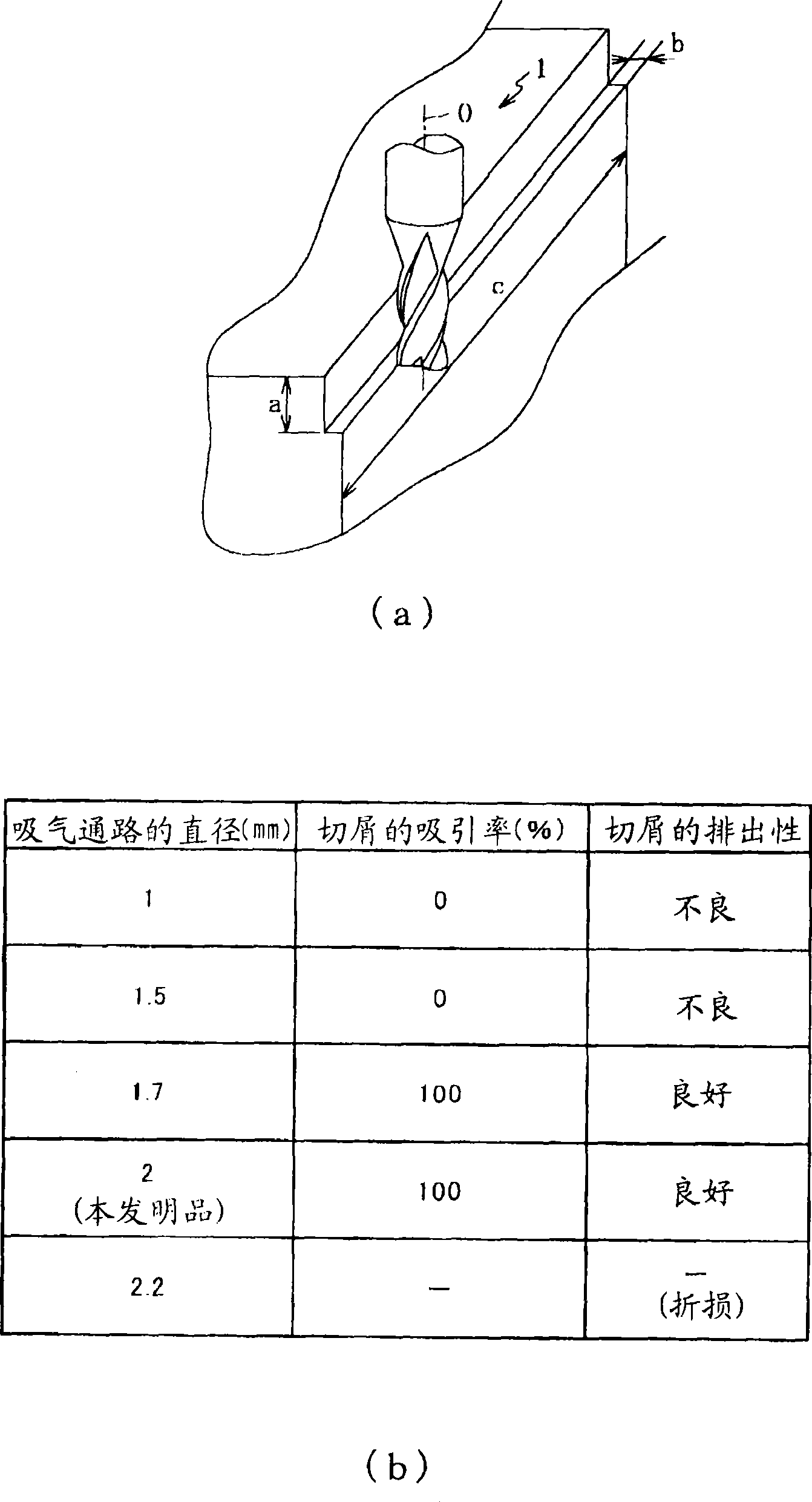

End milling tool

InactiveCN101394962AProhibition of useReduce recycling costsMilling cuttersShaping cuttersFluteMilling cutter

An end mill that realizes prevention of environmental pollution. End mill (1) has aperture (5a) resulting from opening forming along helical flute (4). The aperture (5a) is so structured as to communicate via air suction channel (5) with an opening of the rear end face of shank (2). Accordingly, by air suction through the air suction channel (5), chips generated at cutting processing can be forcibly suctioned from the aperture (5a), and the suctioned chips can be discharged outside from the opening of the rear end face of shank (2). As a result, as compared with conventional products, the use of cutting liquid for eliminating of chips can be suppressed (or rendered unnecessary) to thereby attain prevention of environmental pollution.

Owner:OSG

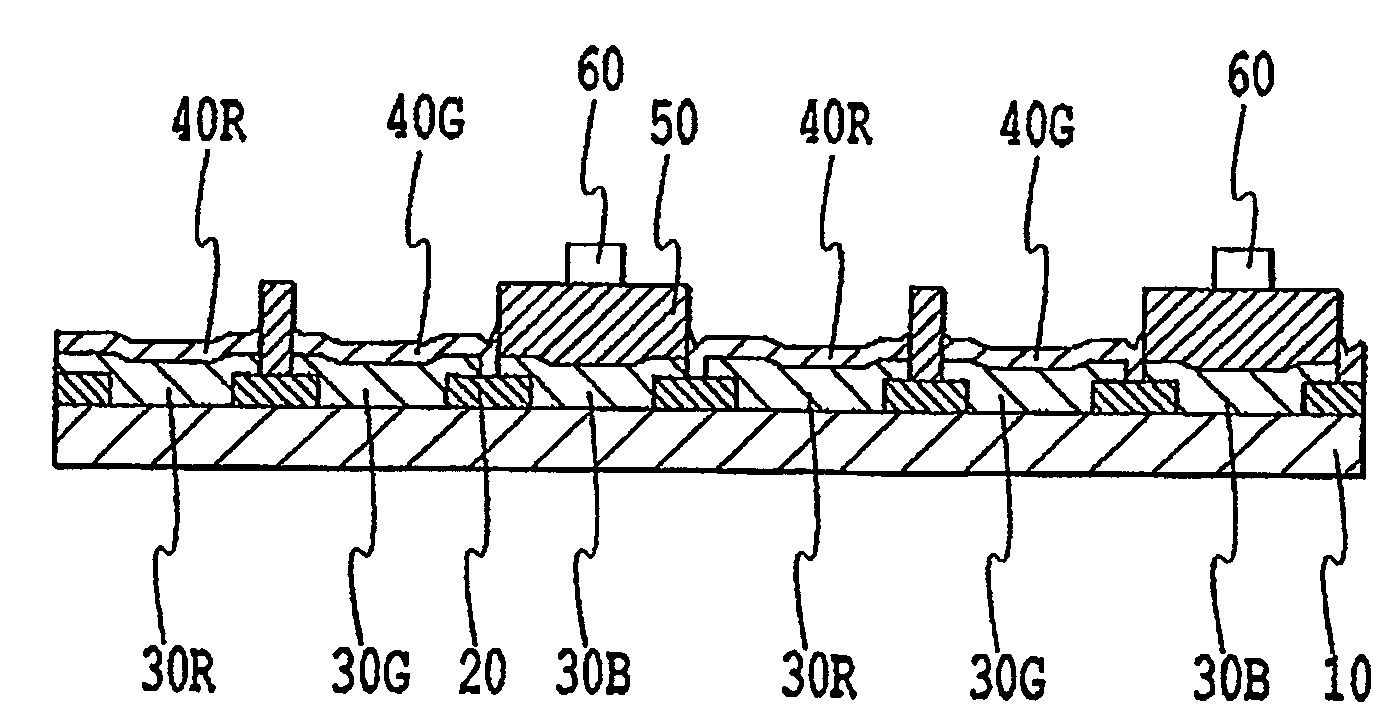

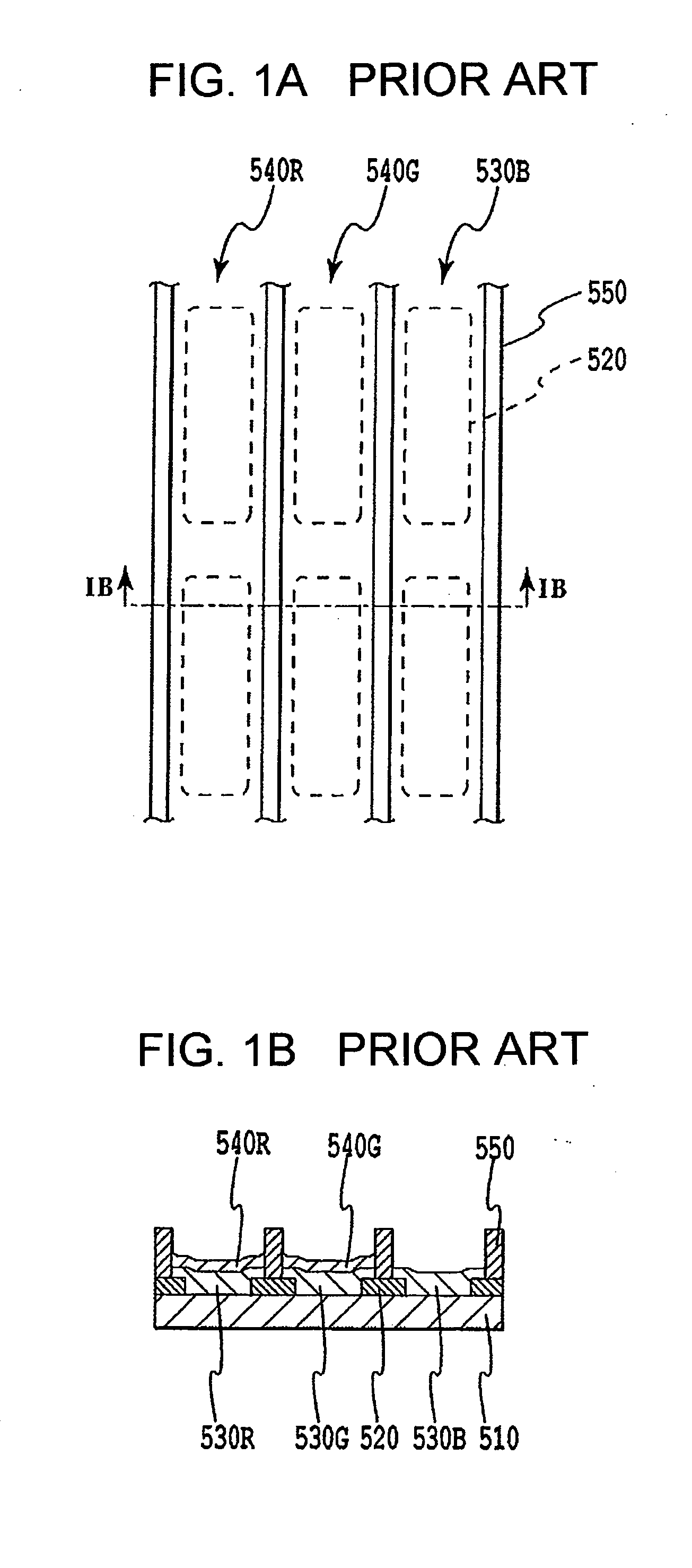

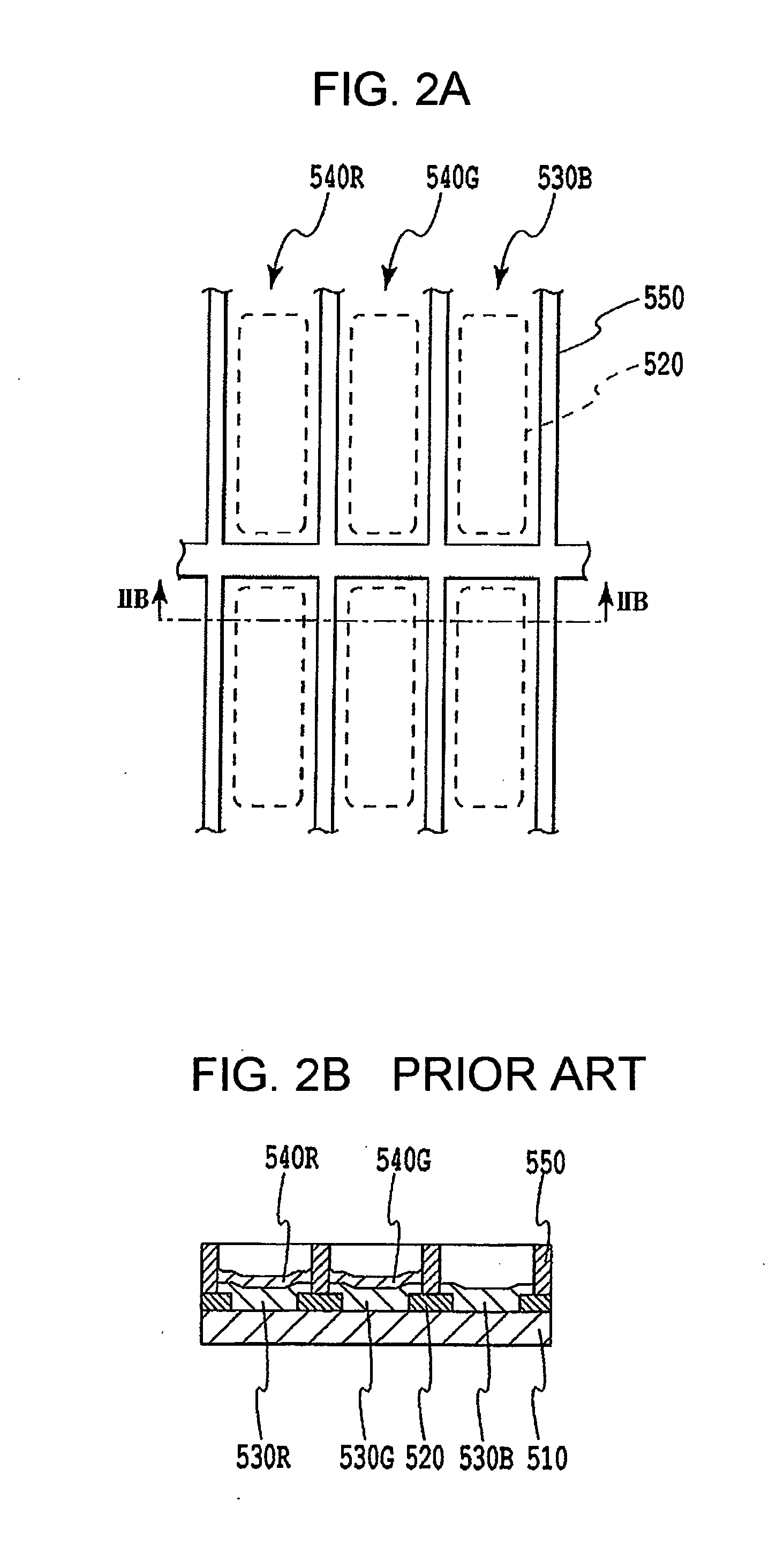

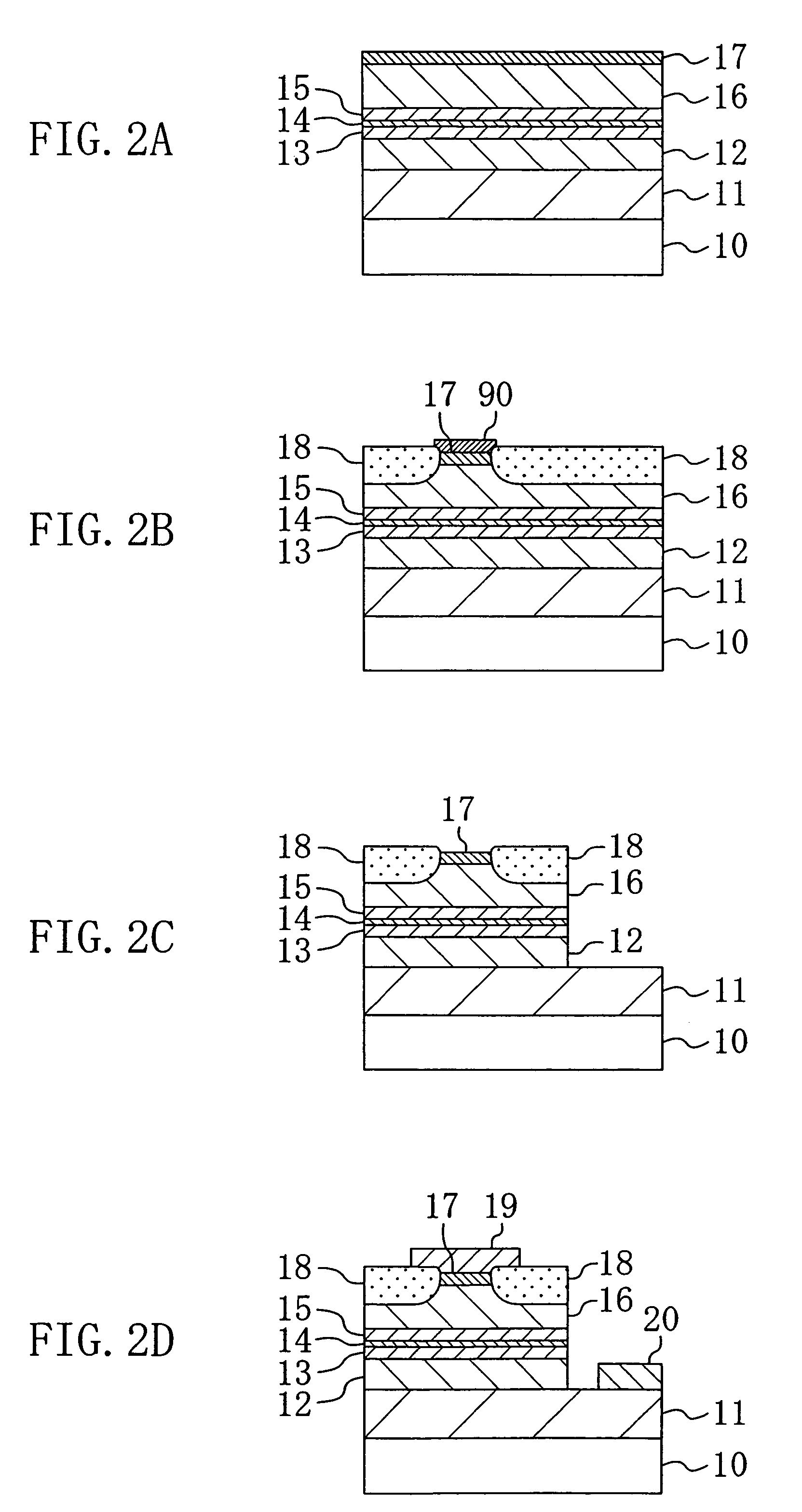

Flat panel display, intermediate manufactured product and method of manufacturing same

InactiveUS20120098414A1Improve finenessShorten production timeIncadescent screens/filtersDischarge tube luminescnet screensDisplay deviceFineness

The present invention aims at providing a structure, manufacturing method, and an intermediate manufactured product enabling the low-cost manufacture of a flat panel display with high fineness. In a flat panel display of the invention, by decentering the opening portions formed by a bank in red and green subpixels to the blue subpixel side, color conversion layers with higher fineness can be formed even when using conventional apparatuses and materials. Moreover, decentering of the opening portions of the bank enables reductions in manufacturing time and manufacturing cost.

Owner:FUJI ELECTRIC CO LTD

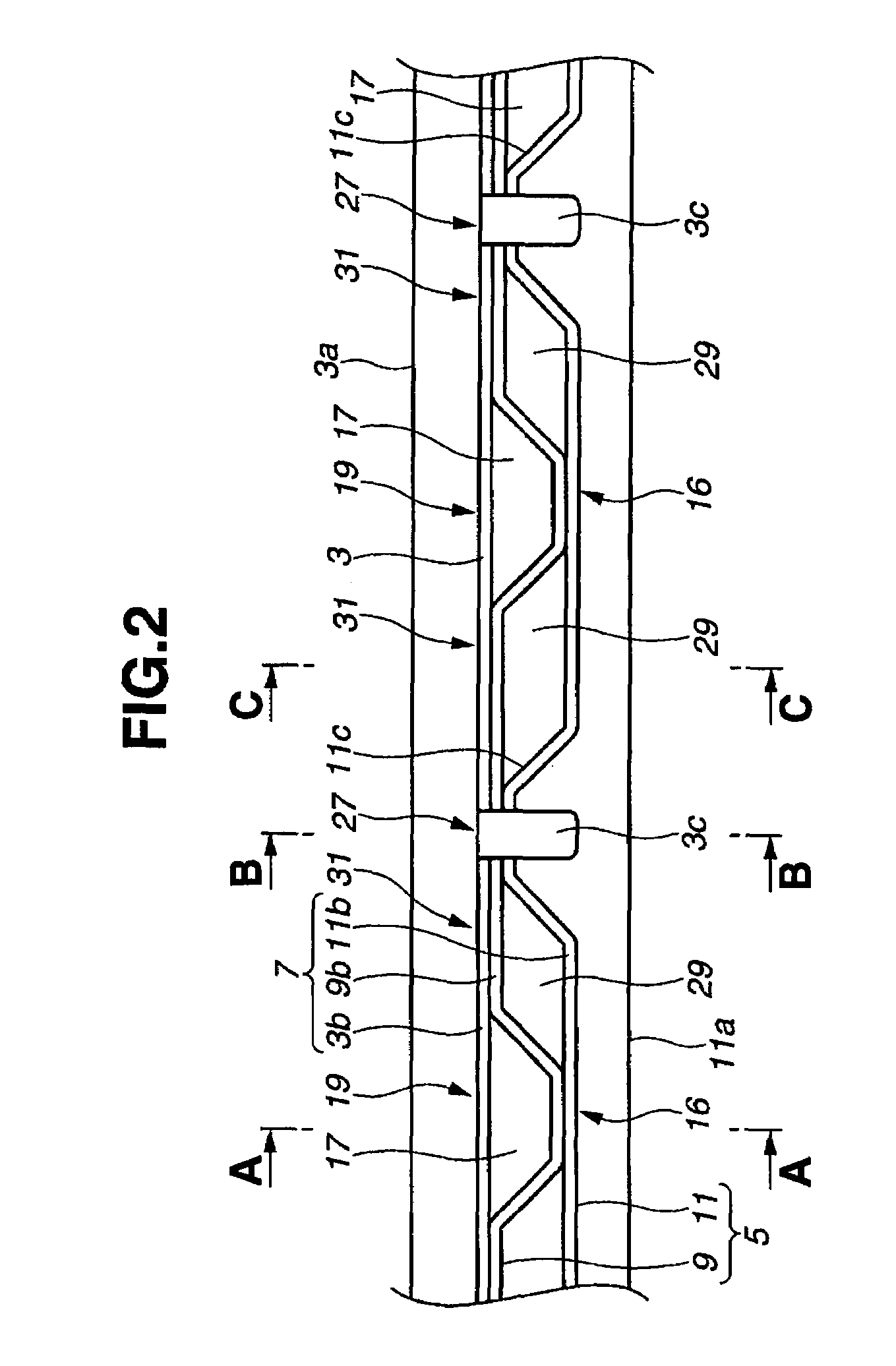

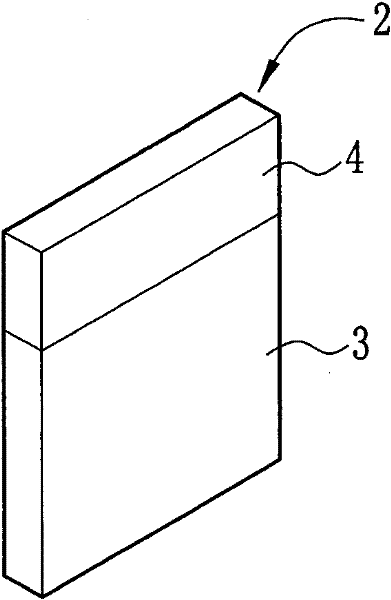

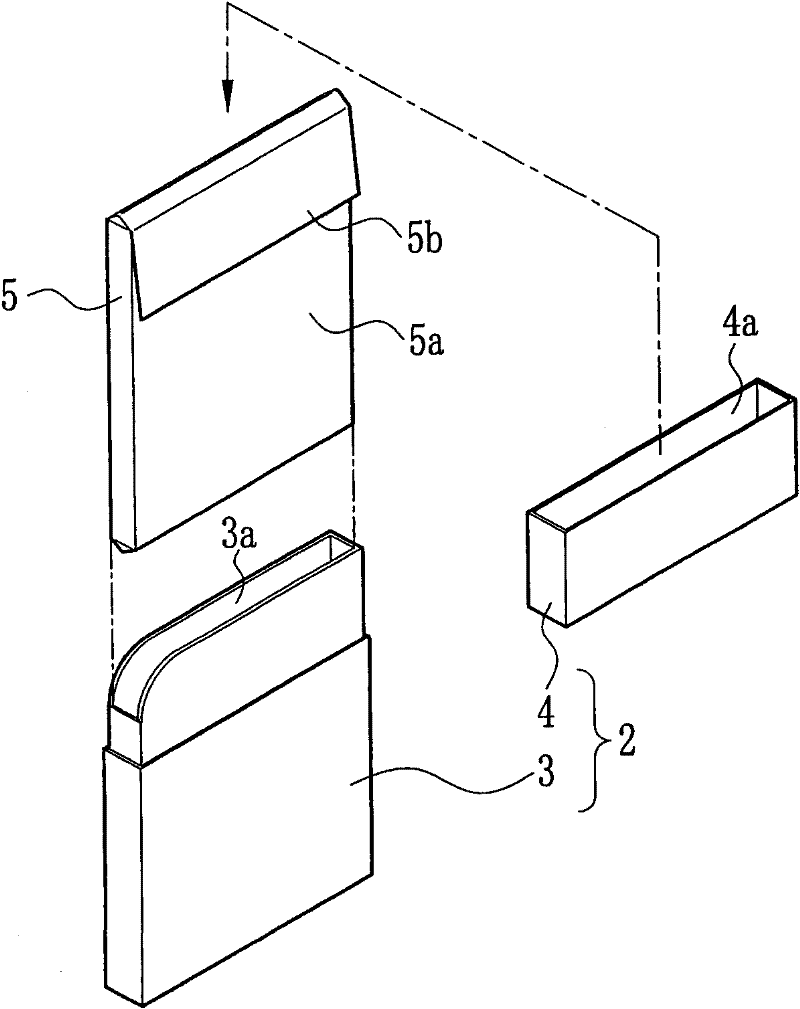

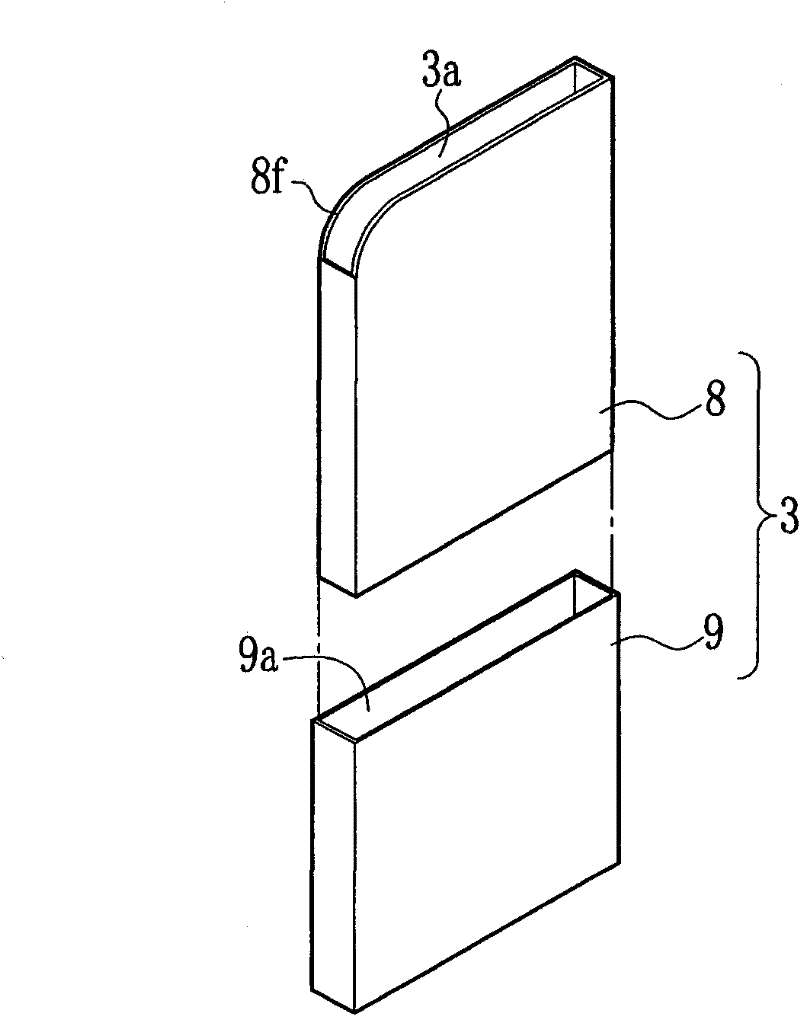

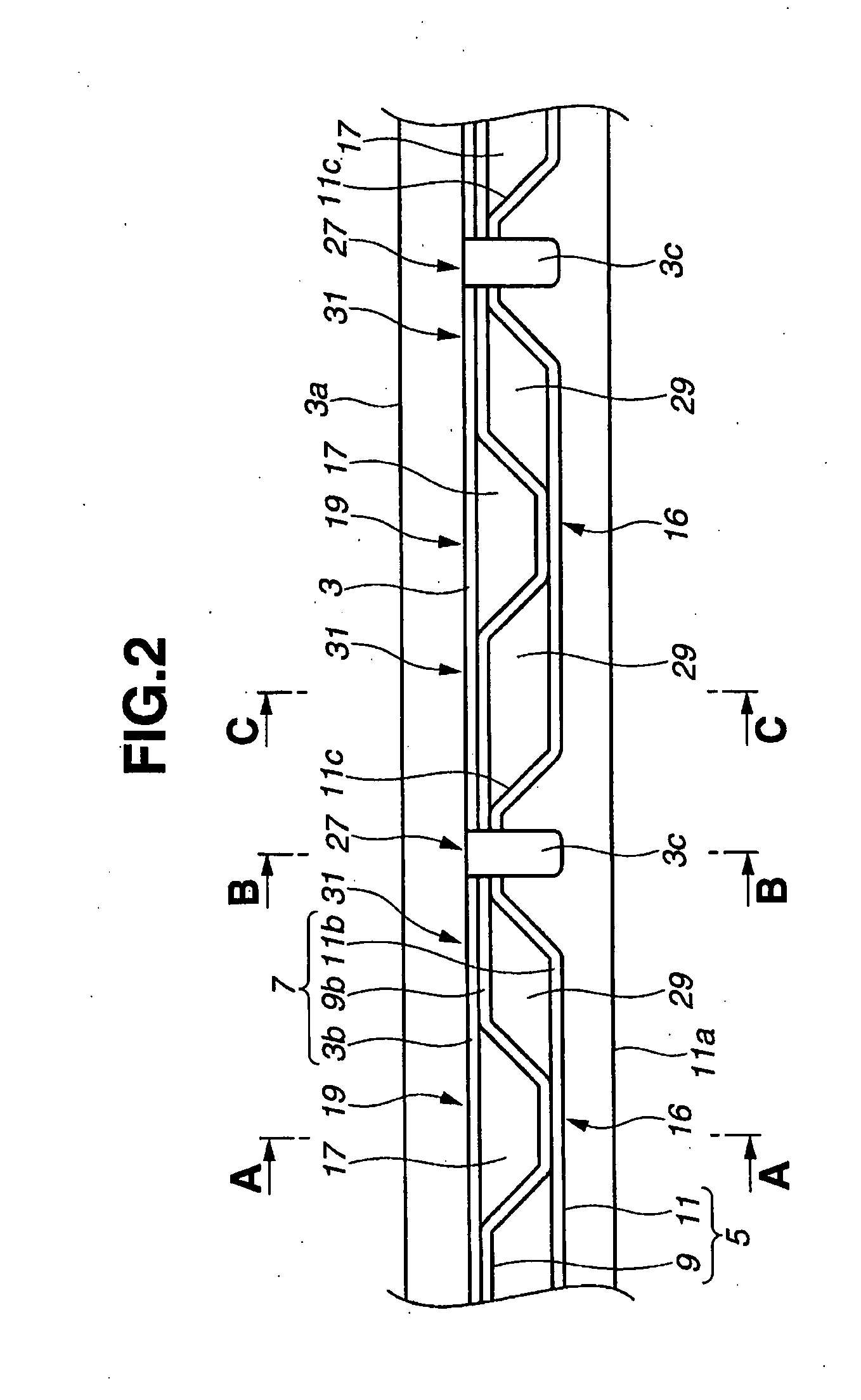

Door panel structure and method of producing the same

ActiveUS7637555B2Maintain accuracyEliminate connectionVehicle sealing arrangementsMonocoque constructionsEngineeringFace sheet

A door panel structure including a door panel and a door waist reinforcement connected to the door panel. The door waist reinforcement includes an inner reinforcement and an outer reinforcement. The door panel and the door waist reinforcement have respective upper end portions which form a waist flange to which a weather strip is fitted. The waist flange includes a plurality of connecting portions at which the upper end portion of the door panel and the upper end portion of the door waist reinforcement are connected to each other, and at least one spaced portion at which the upper end portion of the door panel and the upper end portion of the door waist reinforcement are spaced from each other.

Owner:NISSAN MOTOR CO LTD

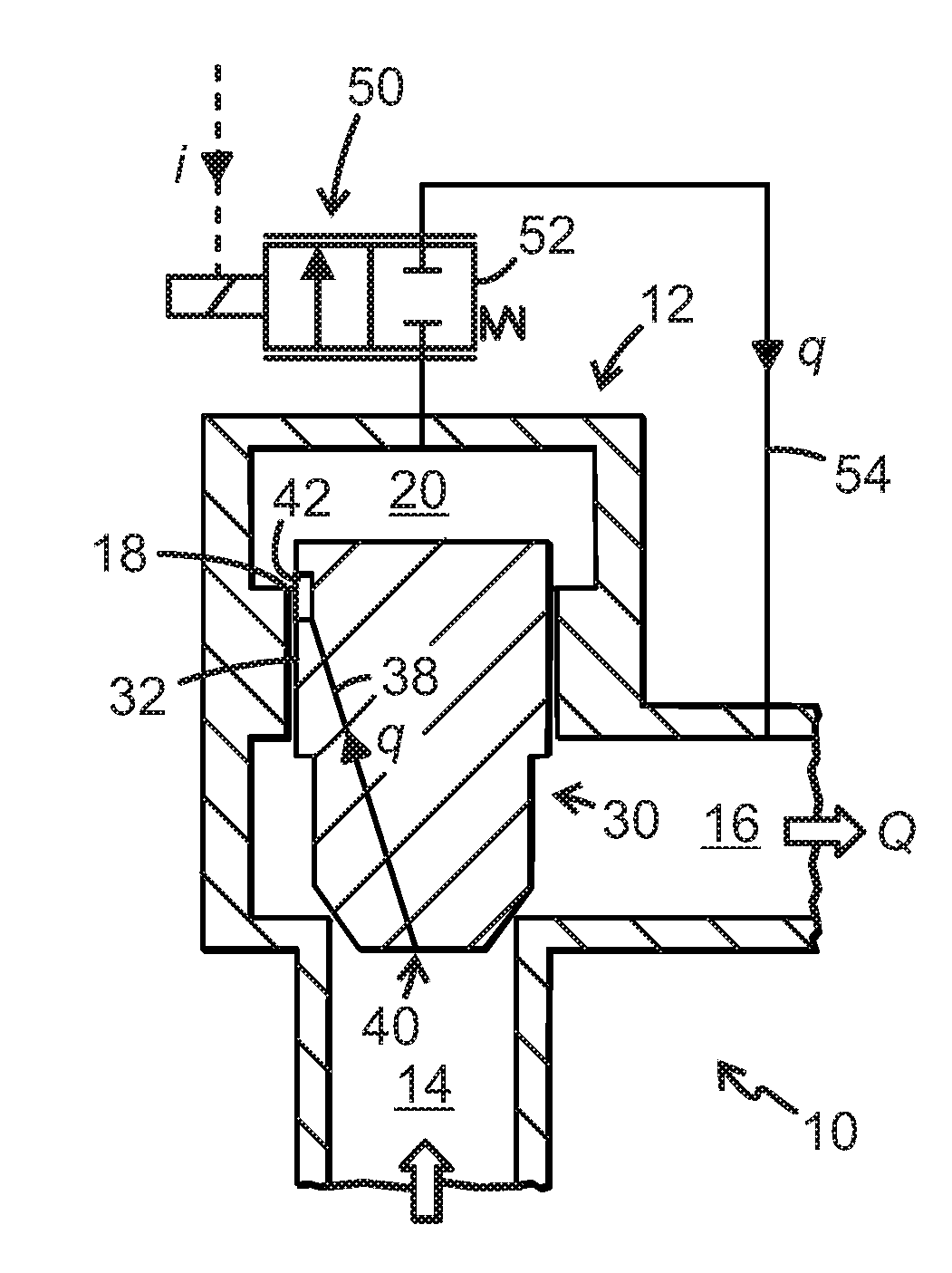

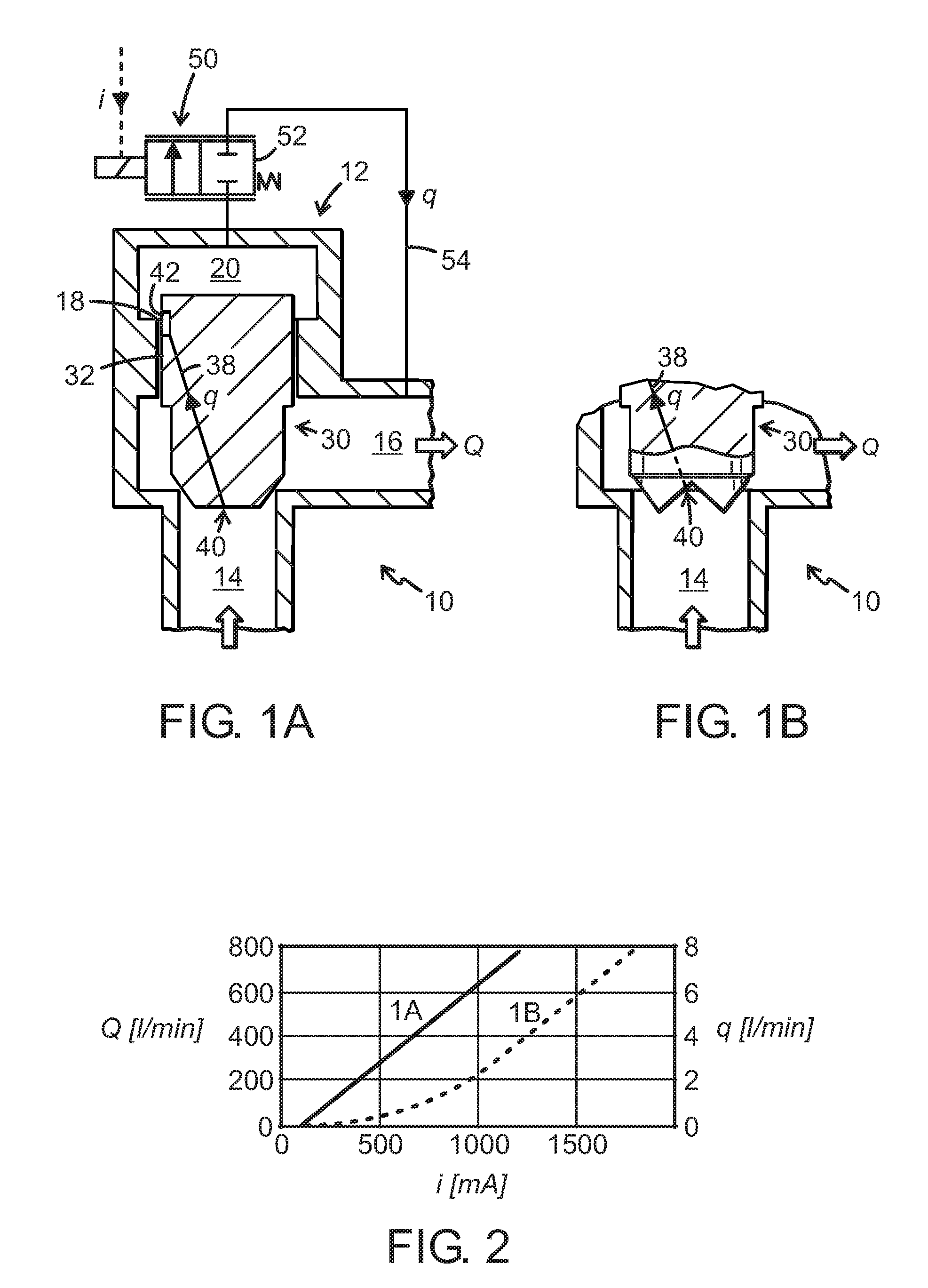

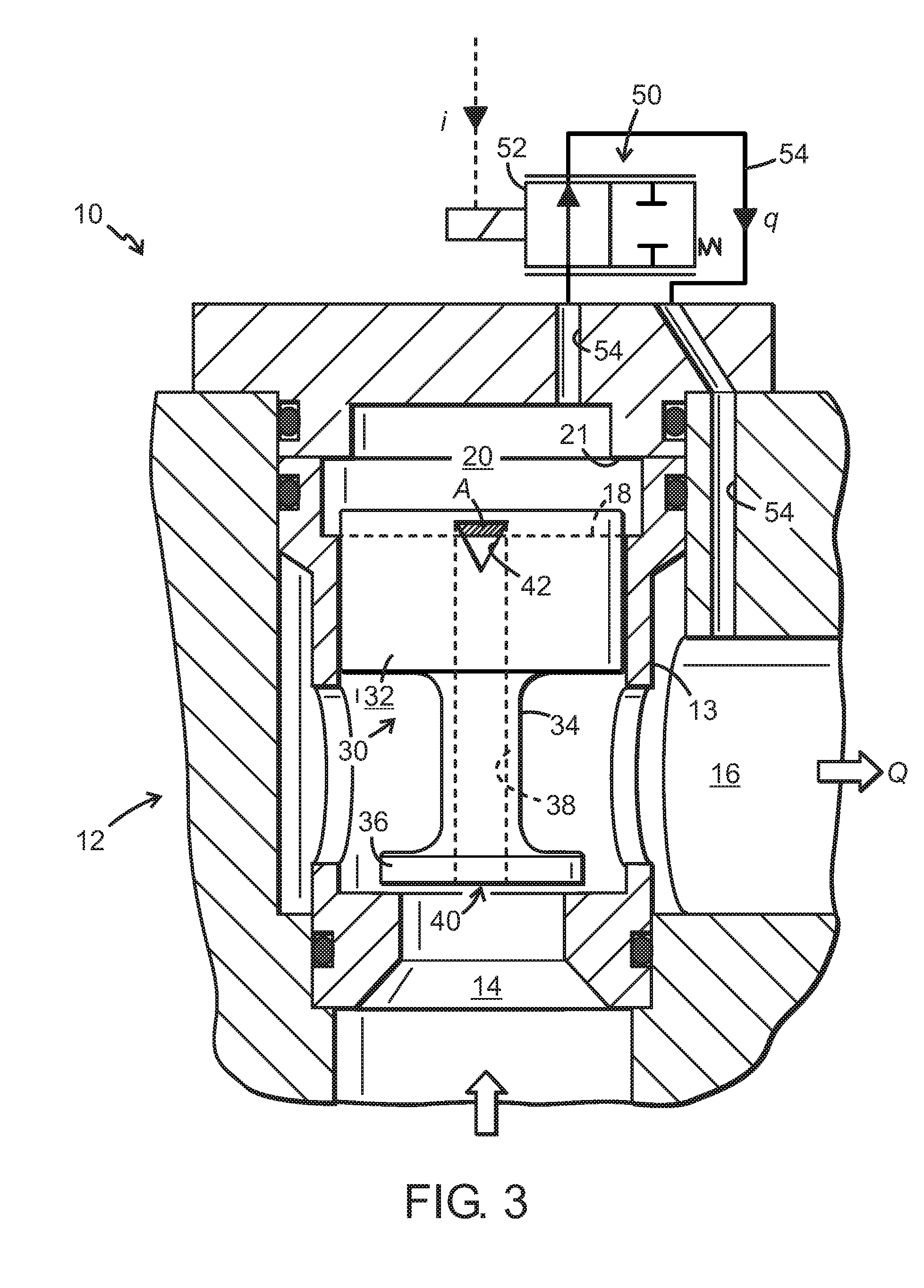

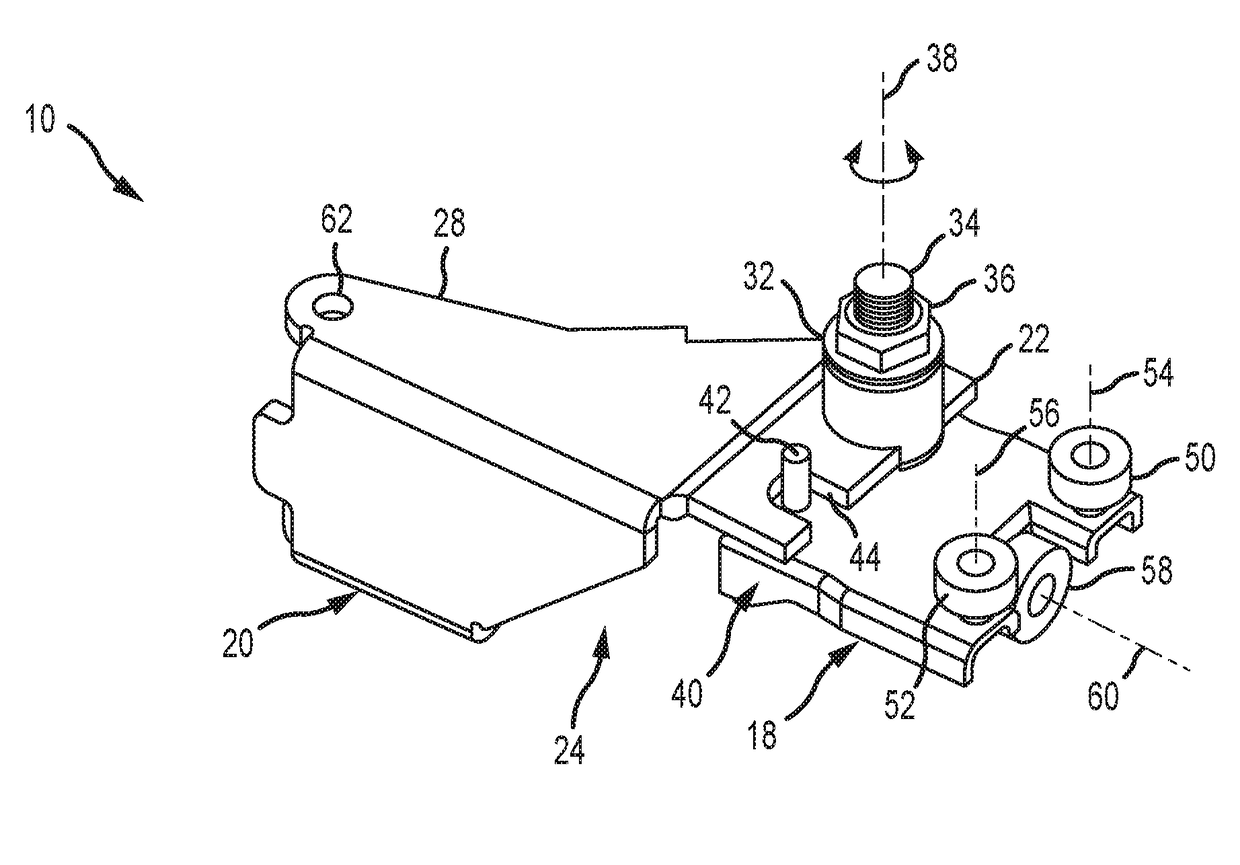

Fluid control valve and valve body

InactiveUS20090302245A1Easy to implementDecrease derivativeOperating means/releasing devices for valvesFluid controlControl room

A fluid control valve (10) comprising a valve housing (12), a valve body (30) having a peripheral surface (32) slidably supported for movement in an axial direction in the valve housing and a feedback circuit duct (38) in the valve body. The feedback circuit duct has a first end (40) communicating with a flow port (14) in the housing and a second end (42) opening at the peripheral surface (32). The second end is capable of exposing a variable opening area (A) to a control chamber (20) in the housing and thereby subjecting the valve body to said movement by a resulting difference between pressure dependent forces acting on opposite surfaces of the valve body. According to the invention, the second end comprises an aperture (42) having a peripheral width (w) that varies at least over a portion proximate to the control chamber of an axial length of the aperture exposable to the control chamber.

Owner:INAB AUTOMATION

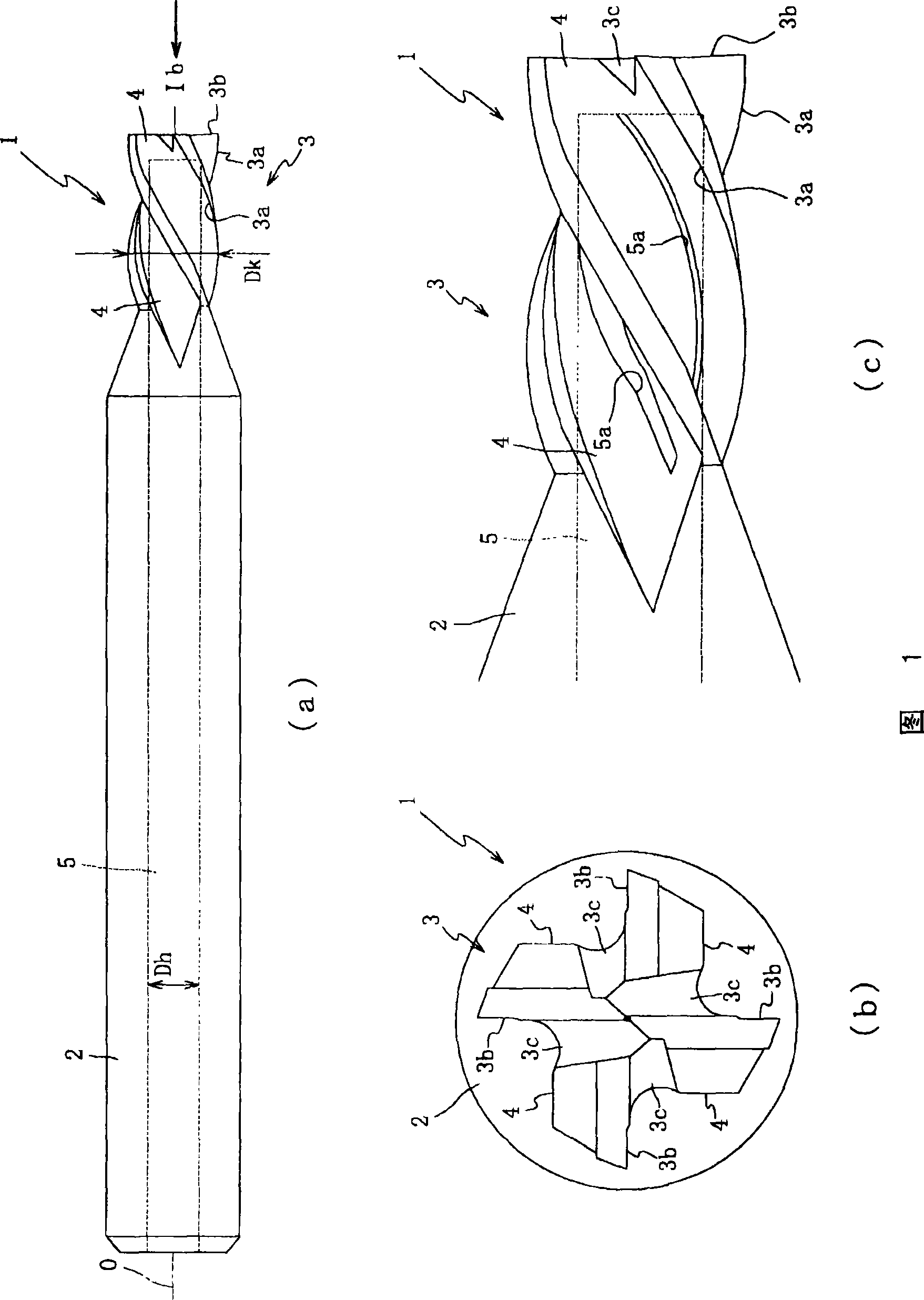

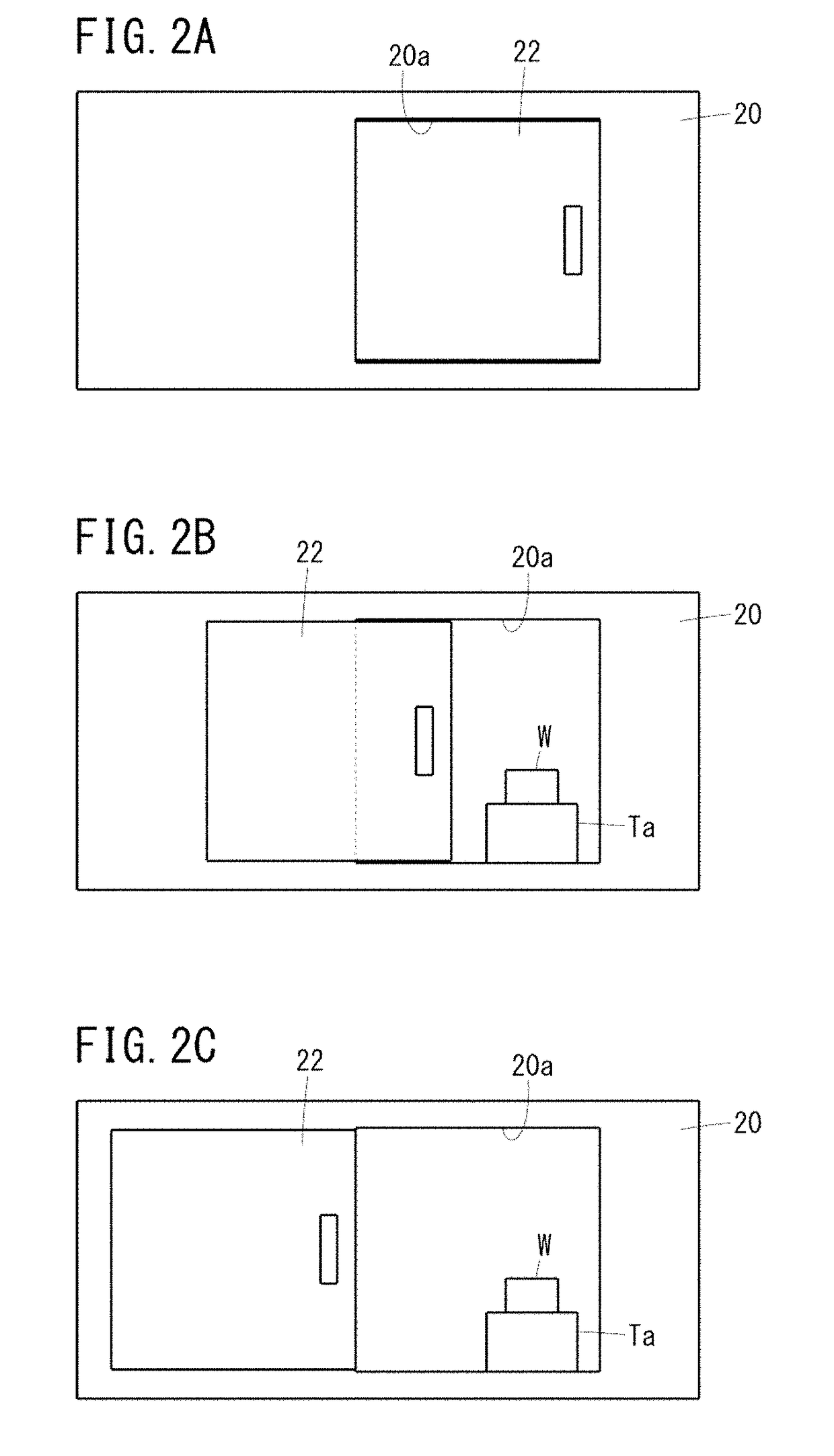

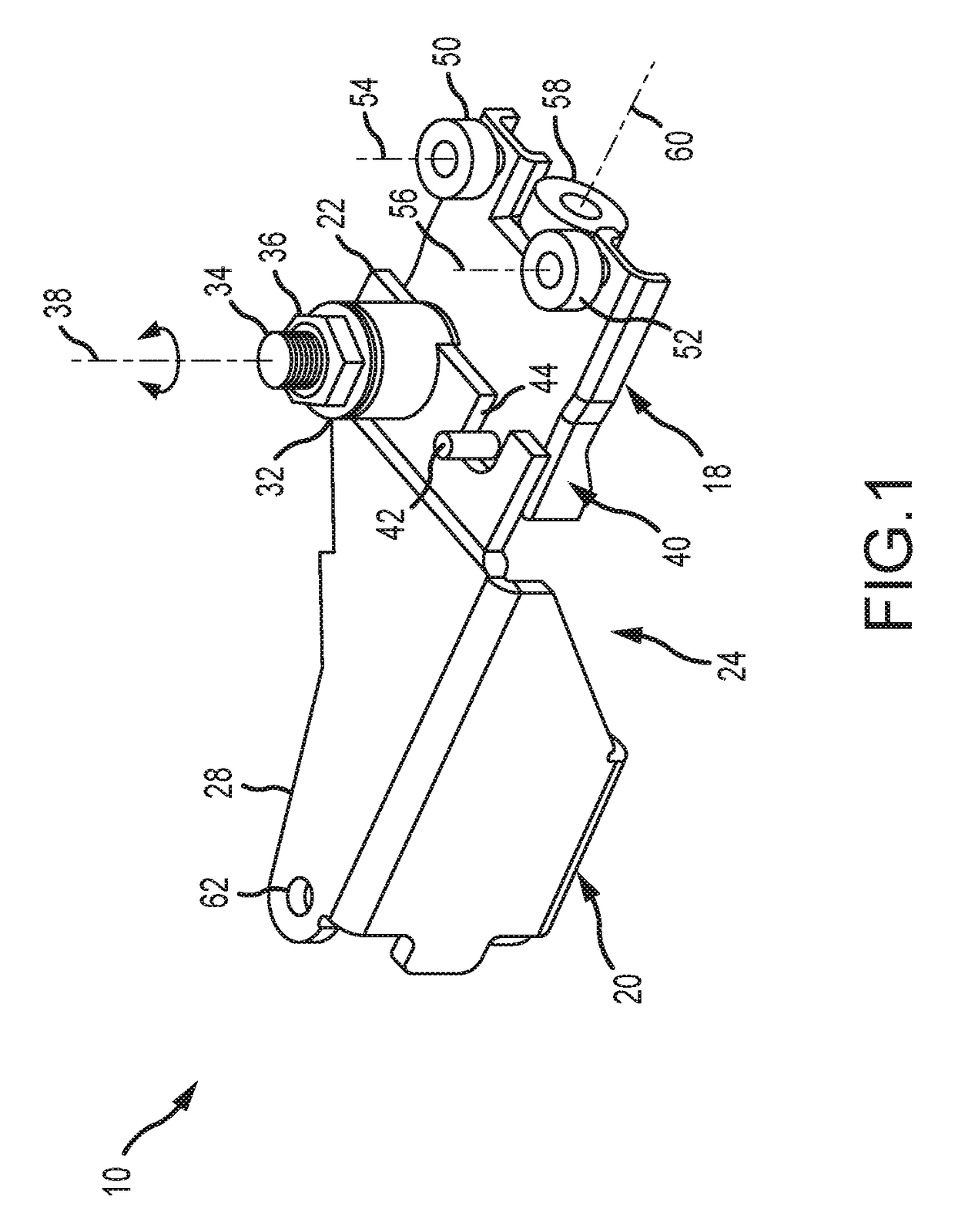

Sliding door of machine tool

ActiveUS20150252604A1Increased door opening widthIncrease opening widthWindow/door framesEngineering safety devicesMachine tool

In a sliding door disposed in an opening of a cover surrounding a machine tool,From among two adjacent door panels, at least one of sliding members of the door panel which is located closer to a door frame slides on a door frame guide track, whereas at least one of sliding members of the door panel which is located farther from the door frame slides on the door frame guide track, and at least one of the remaining sliding members slides on the door panel guide track. Thus, guide means can be prevented from projecting vertically.

Owner:FANUC LTD

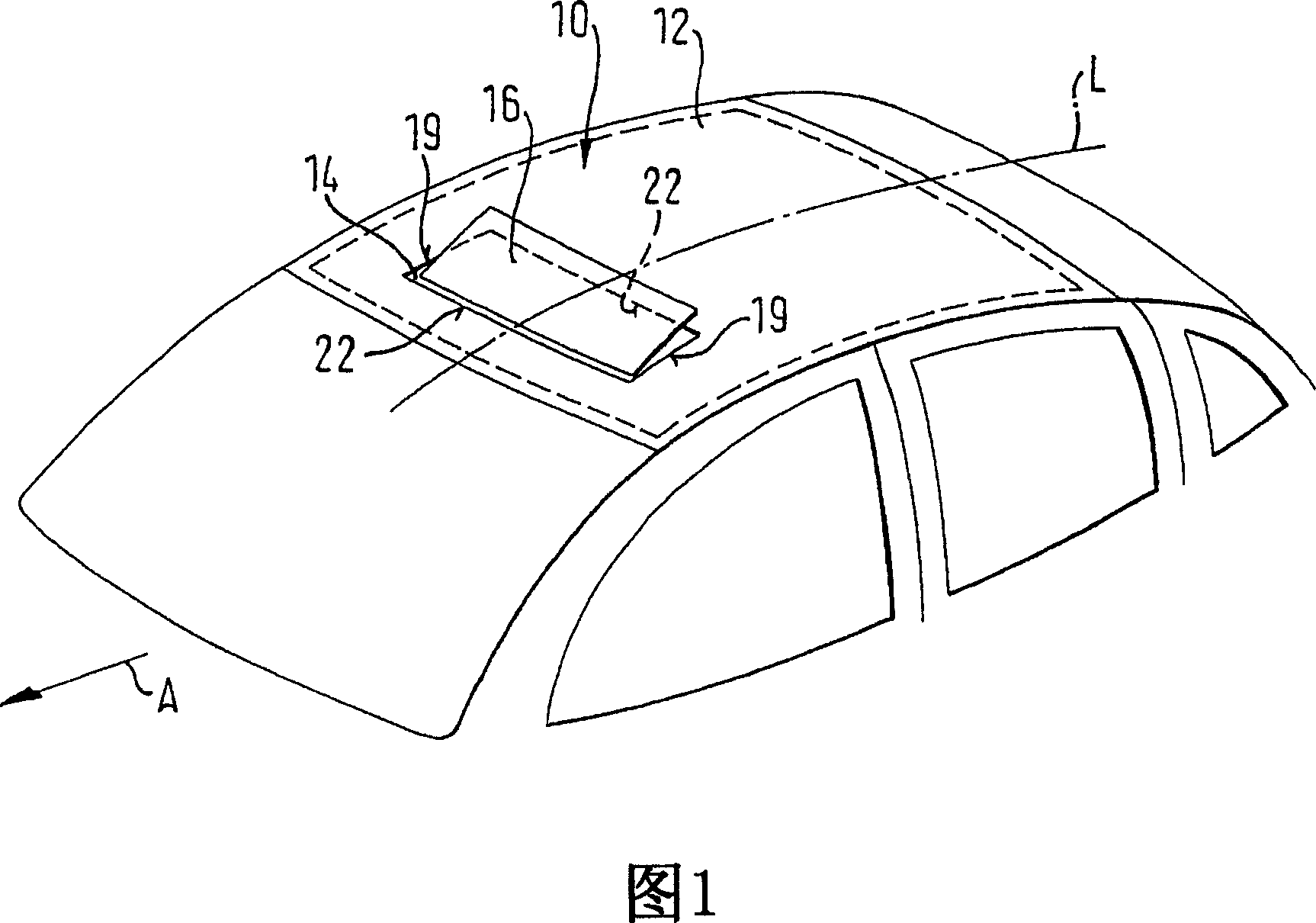

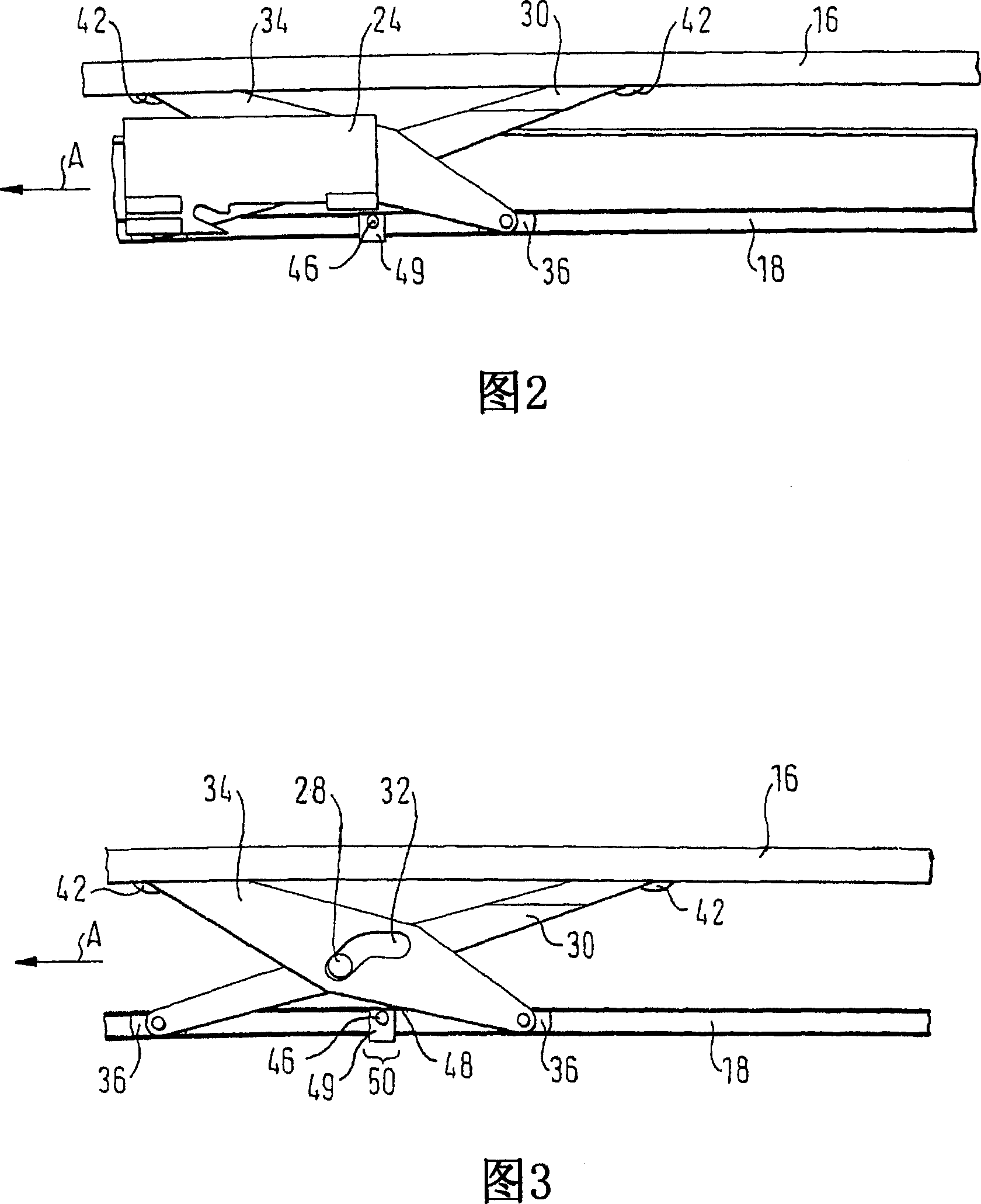

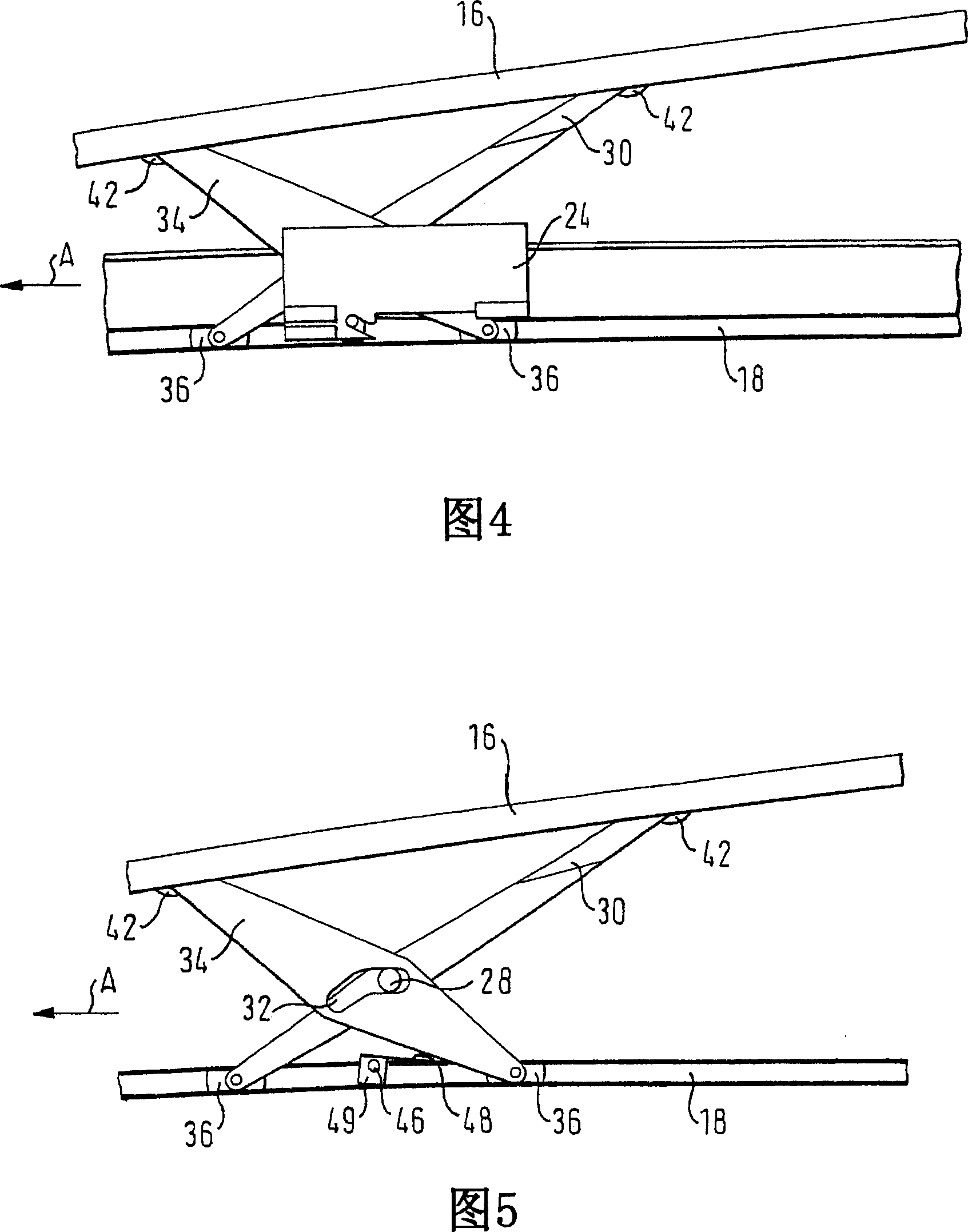

Lifting mechanism for a sliding roof and a vehicle roof with such mechanism

The invention relates to a raising mechanism for a sliding roof, comprising a guide rail, a pair of levers, and a carriage. Each lever has a guide rail side end and a cover side end, and the levers are pivotally coupled with each other through a joining axle. During traversing movement, the carriage exerts a vertical force on the joining axle and lifts the joining axle, in order to thereby move the pair of levers to a raised position. The invention further relates to a vehicle roof with such a raising mechanism.

Owner:ARVINMERITOR GMBH

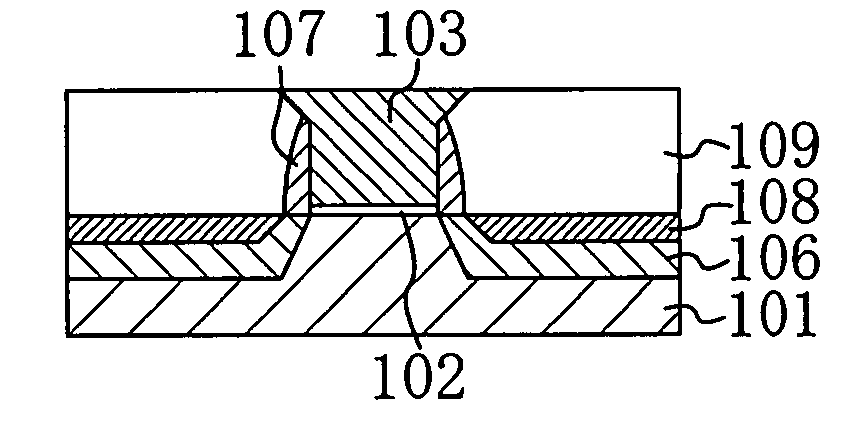

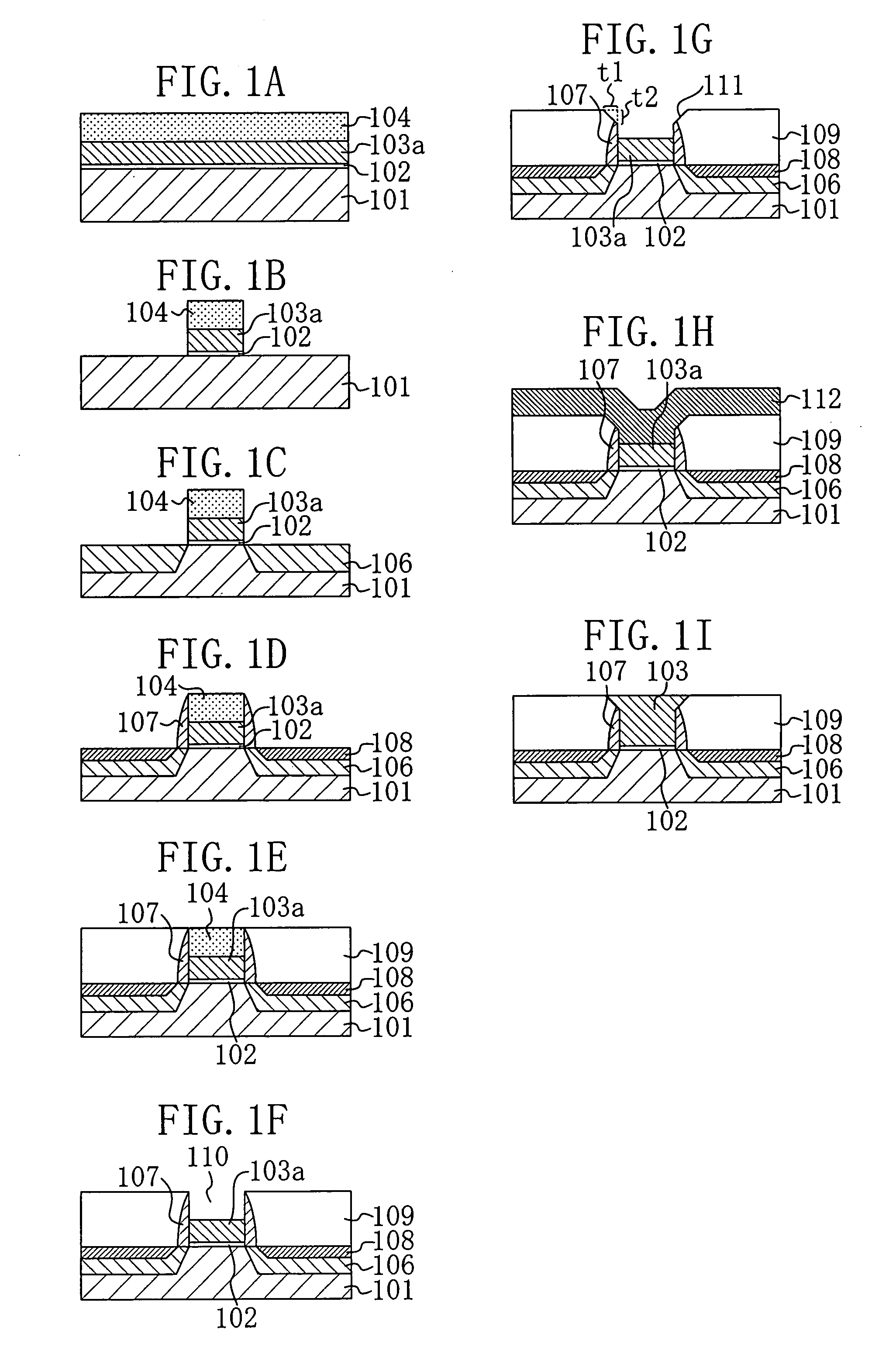

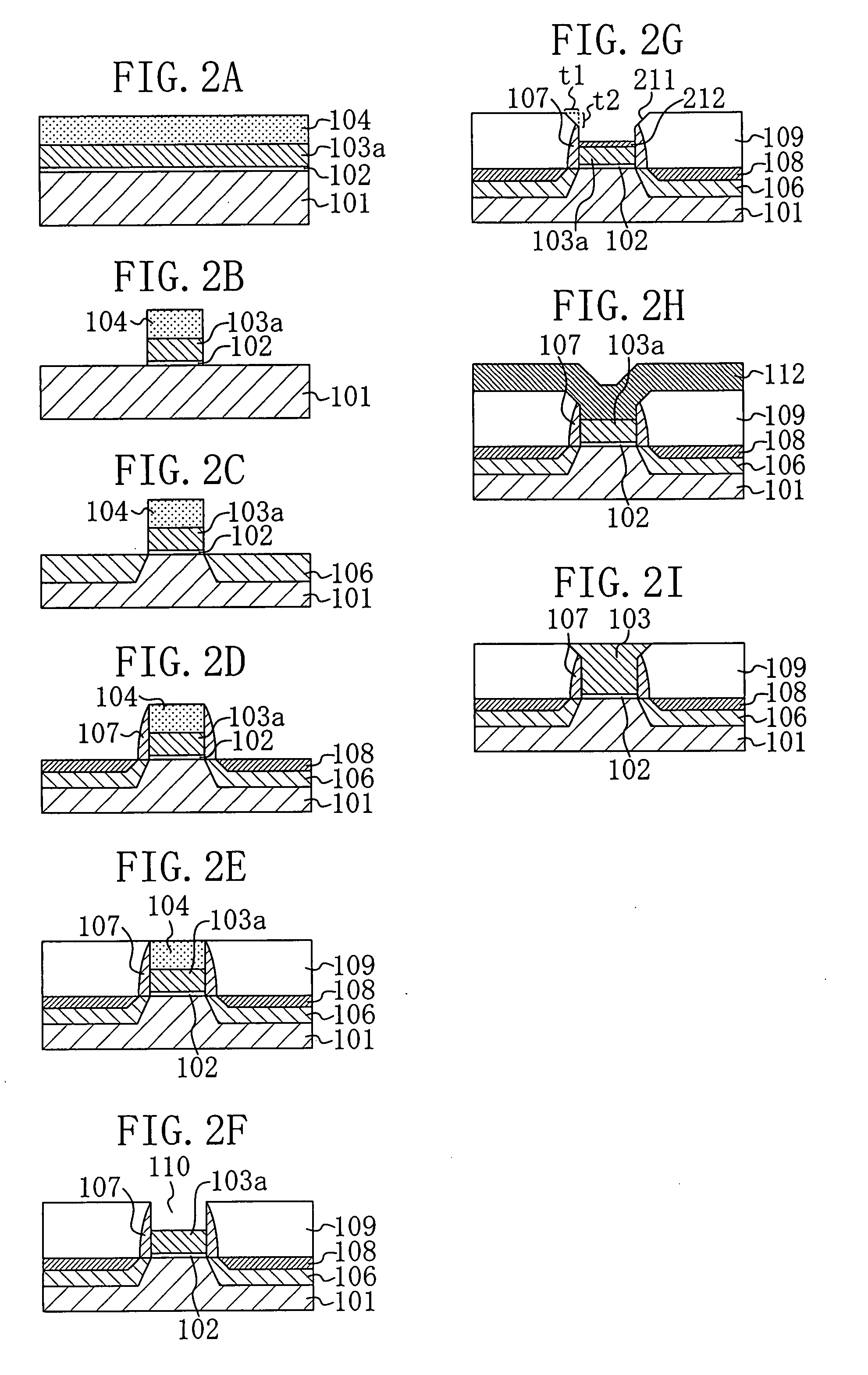

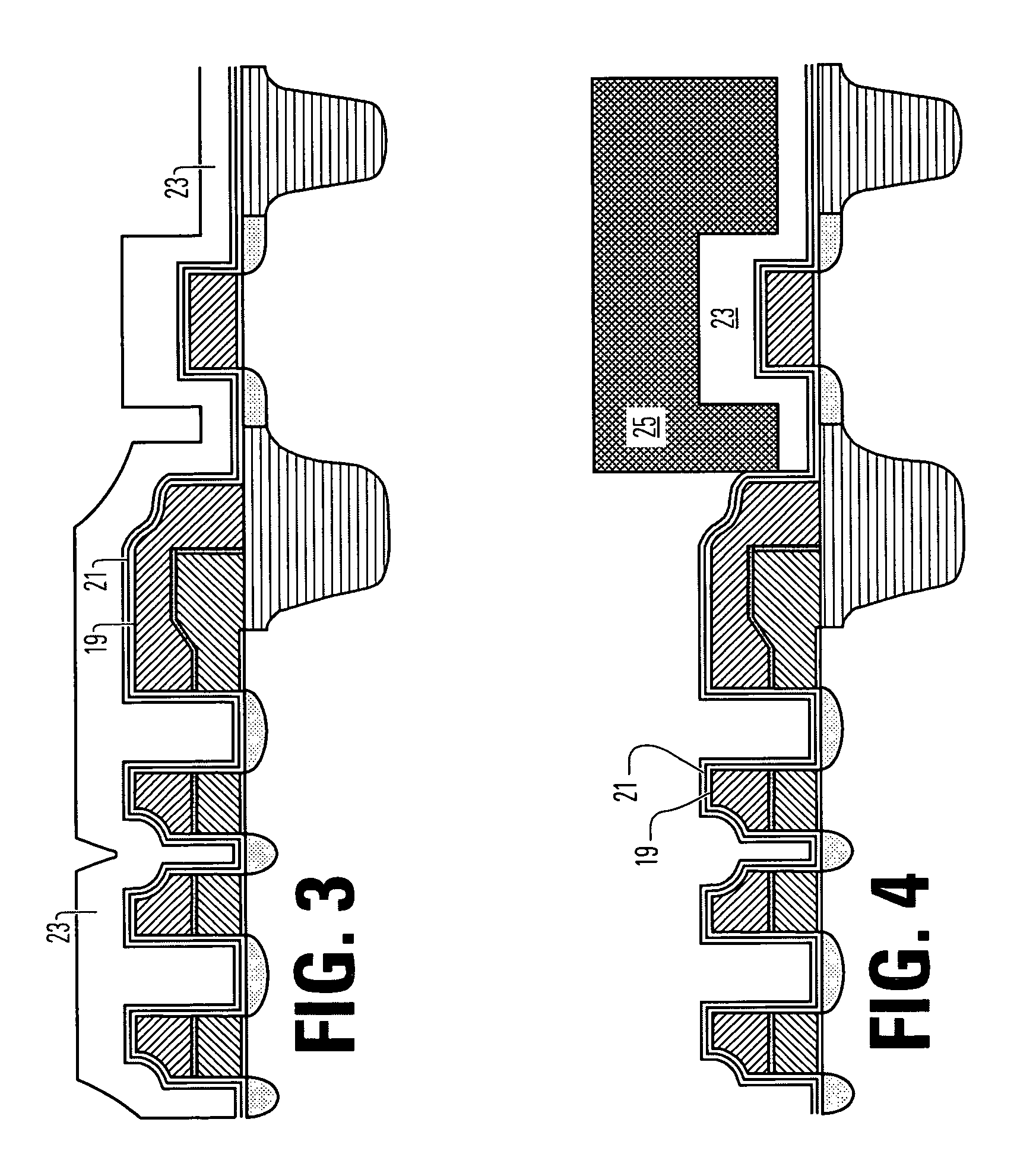

Semiconductor device and method for fabricating the same

InactiveUS20080135955A1Increase opening widthReduce resistanceTransistorSemiconductor/solid-state device manufacturingSalicideHigh concentration

A semiconductor device includes low concentration source / drain regions and high concentration source / drain regions each being formed in a semiconductor substrate, a gate insulation film formed on part of the semiconductor substrate located between the low concentration source / drain regions when viewed from the top and a gate electrode formed of metal silicide on the gate insulation film. A gate length of upper part of the gate electrode is larger than a gate length of other part of the gate electrode.

Owner:PANASONIC CORP

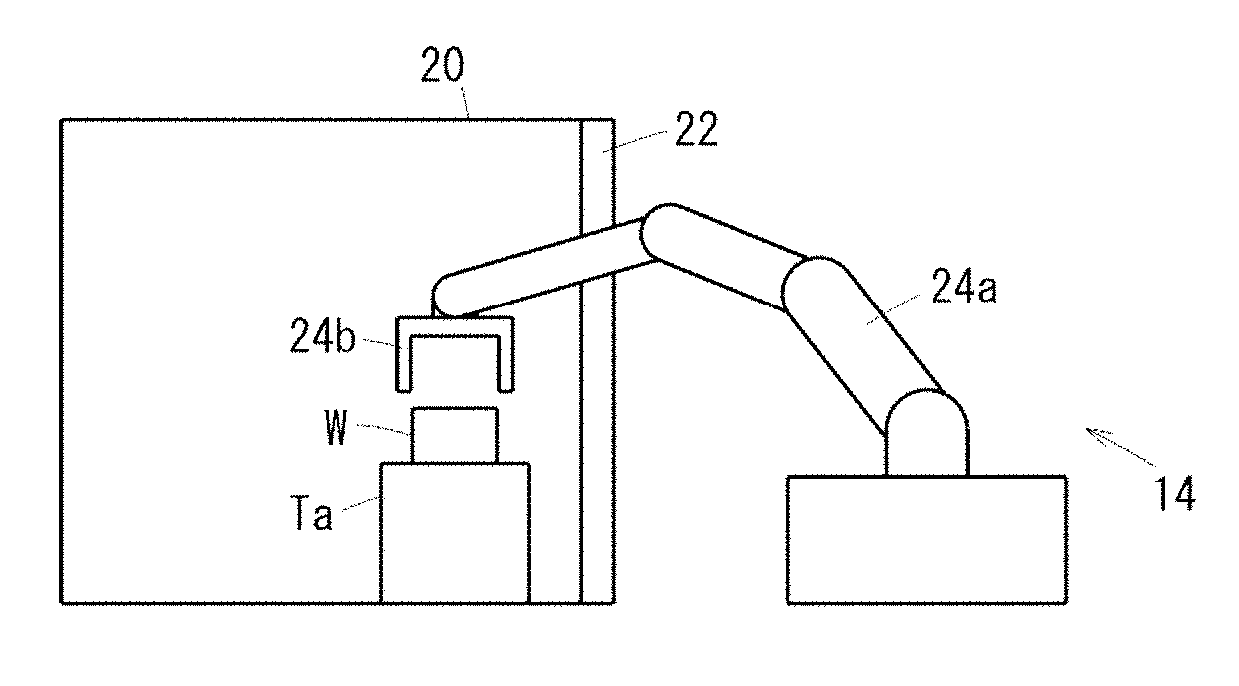

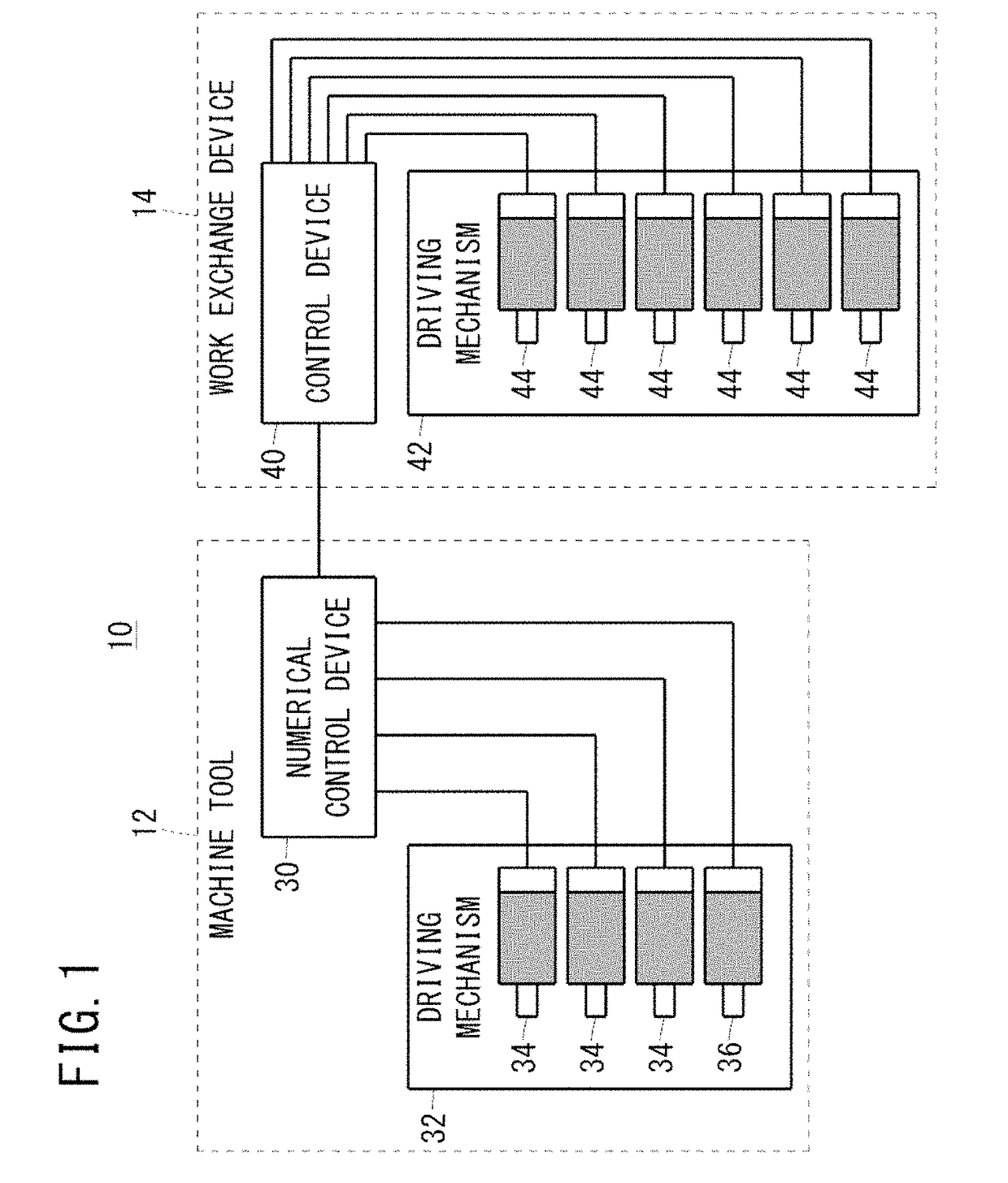

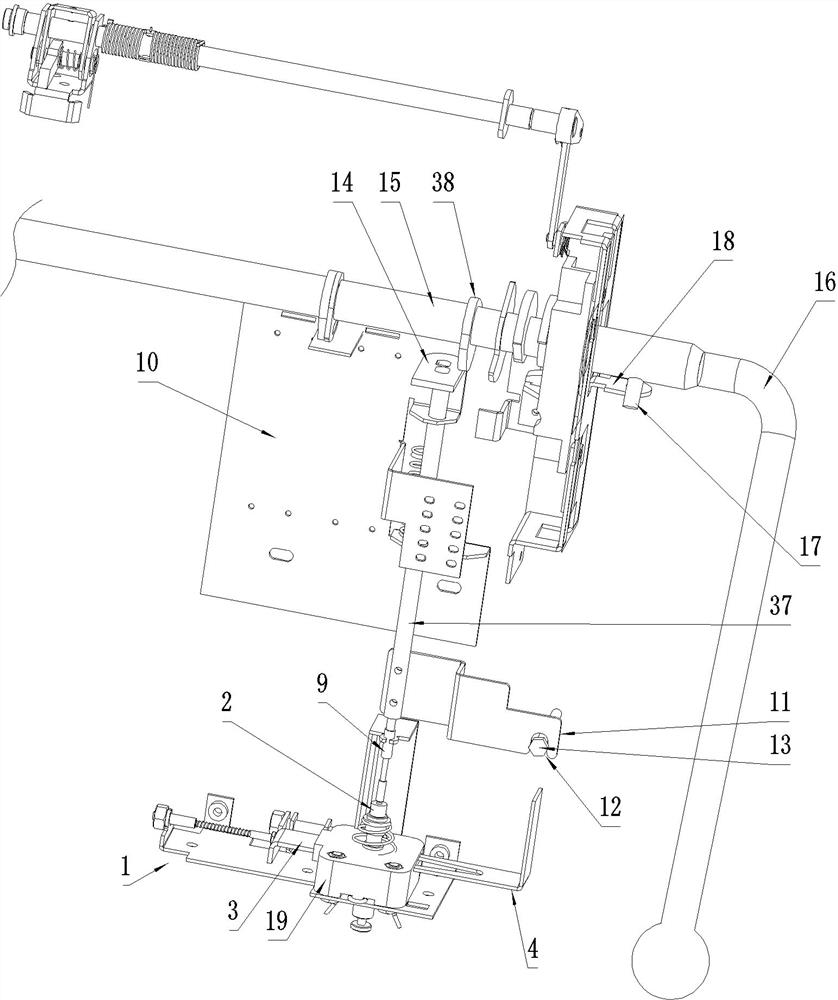

Machine tool system

ActiveUS20170284146A1Reduce door movement speedIncreasing door opening widthAutomatic workpiece supply/removalEngineering safety devicesMachine toolControl unit

A machine tool system includes: a machine tool that includes an openable door configured to block an opening of a cover surrounding the machine tool, and a door driving unit configured to open and close the door; and a work exchange device configured to exchange a work disposed in the cover. Further, the machine tool system includes: a first opening width setting unit configured to set a door opening width of the door; a second opening width setting unit configured to set a turnback opening width; and a door control unit configured to control the door driving unit to move the door in an opening direction from a completely closed position of the door to a position of the turnback opening width of the door, then move the door in a closing direction and stop the door at a position of the door opening width.

Owner:FANUC LTD

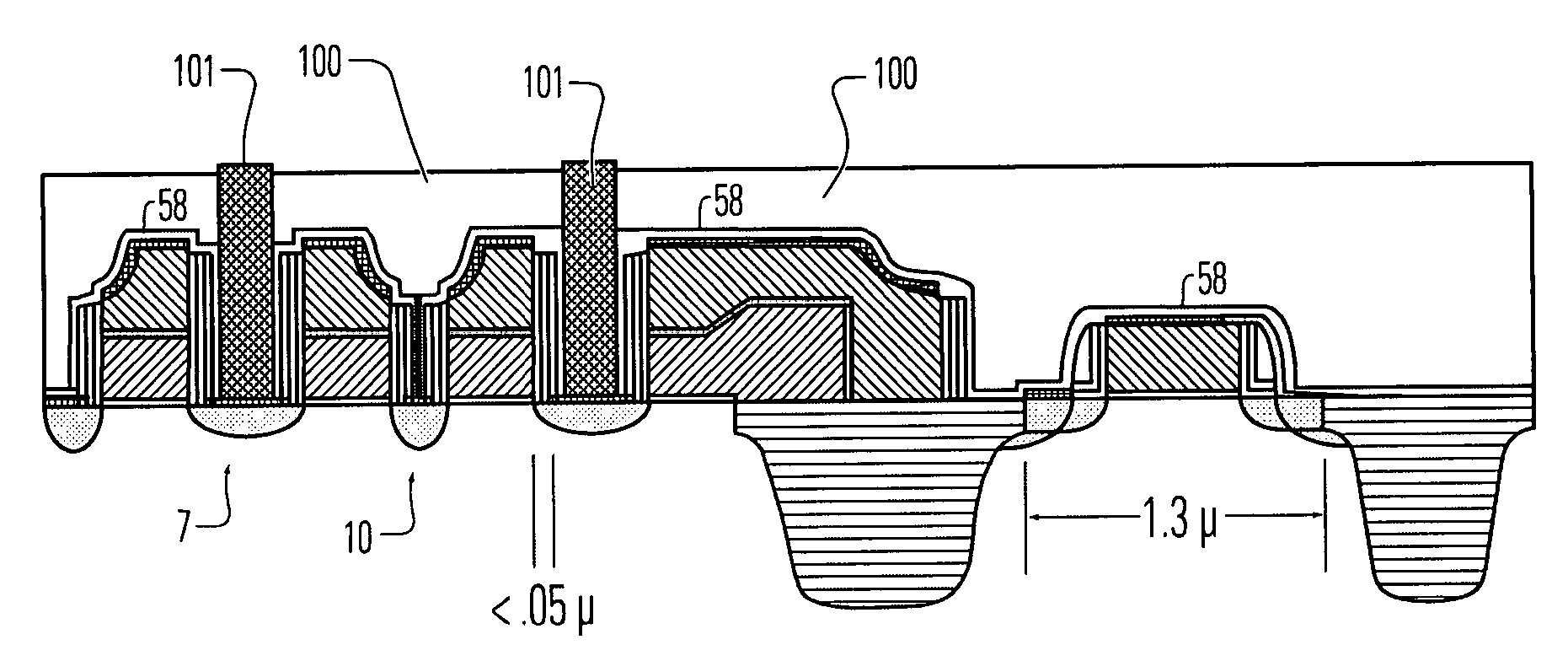

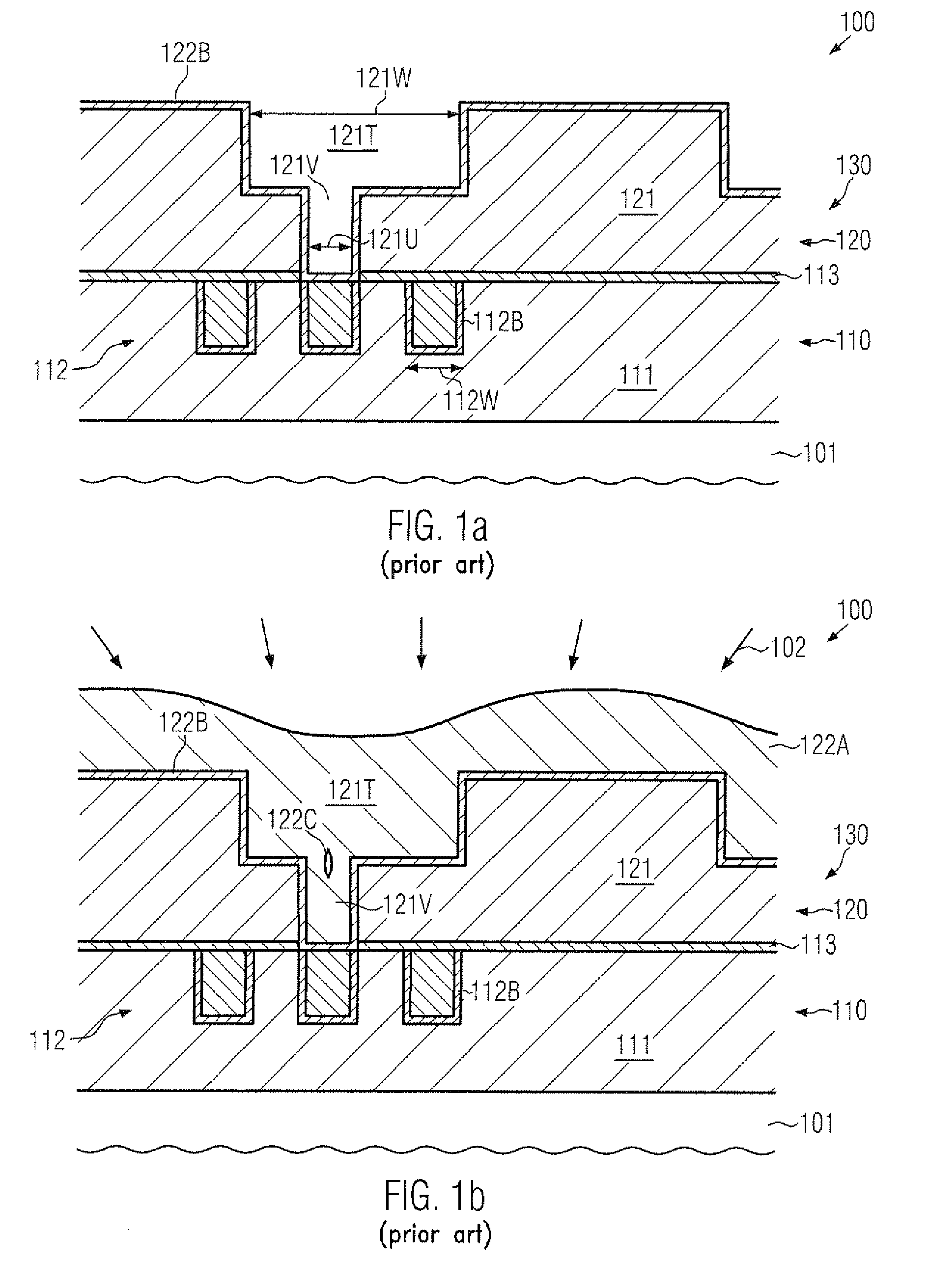

Manufacturing methods and structures of memory device

ActiveUS7067374B2Improve pressure performanceIncrease opening widthSolid-state devicesSemiconductor/solid-state device manufacturingCell regionEngineering

Dual spacer structures are fabricated such that sidewall spacers in a cell region are thinner than sidewall spacers in a periphery region. The fabricating method of memory includes forming a stop layer over the first semiconductor feature and the second semiconductor feature in cell region and periphery region. A spacer layer is formed over the stop layer in the periphery region. The spacer layer is patterned to form a spacer on a sidewall of the second semiconductor feature. An etching process is performed to form a resultant spacer on an interior sidewall of the opening between first semiconductor features. The stop layer on top surfaces of the first and second semiconductor features is removed.

Owner:MACRONIX INT CO LTD

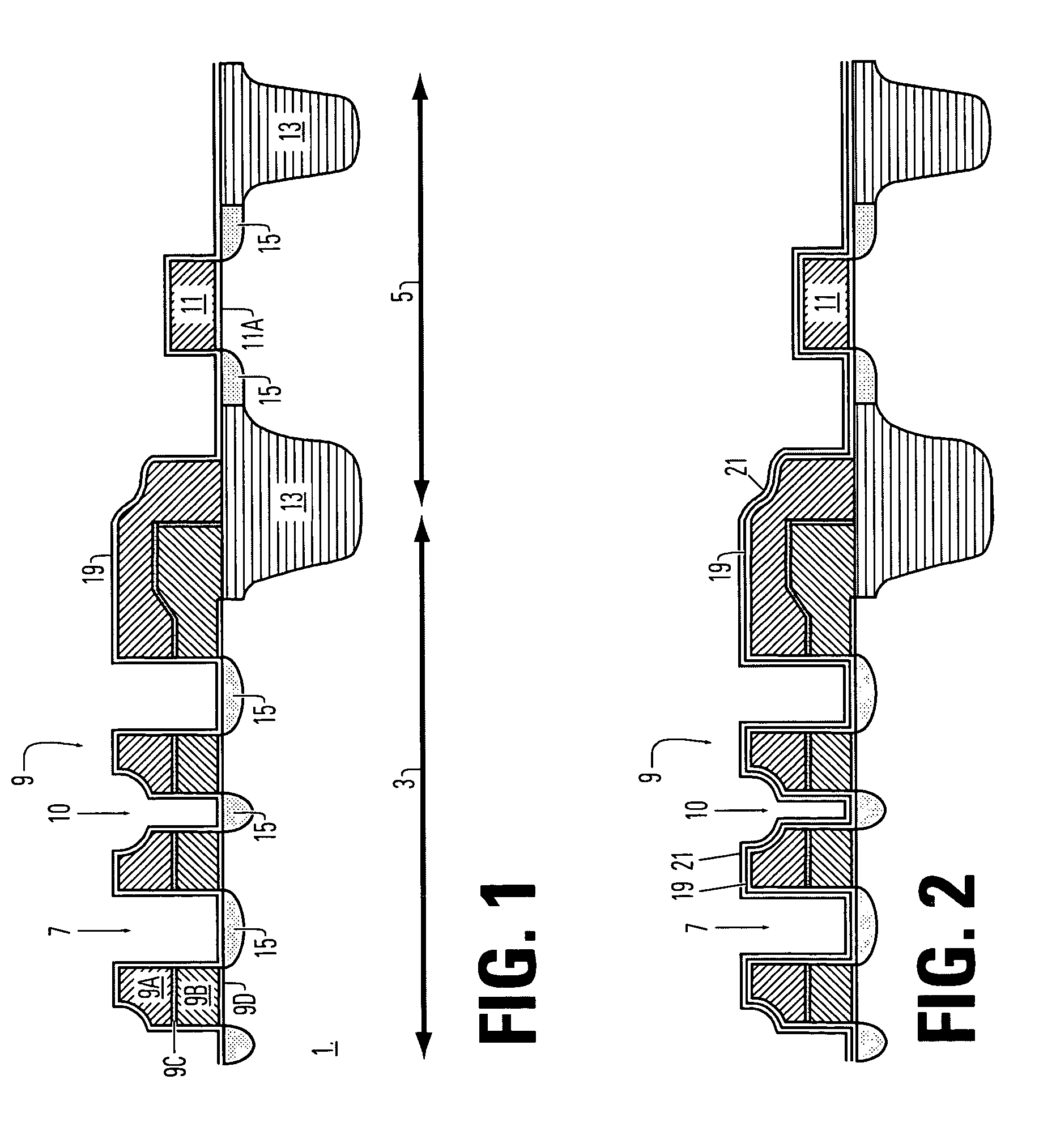

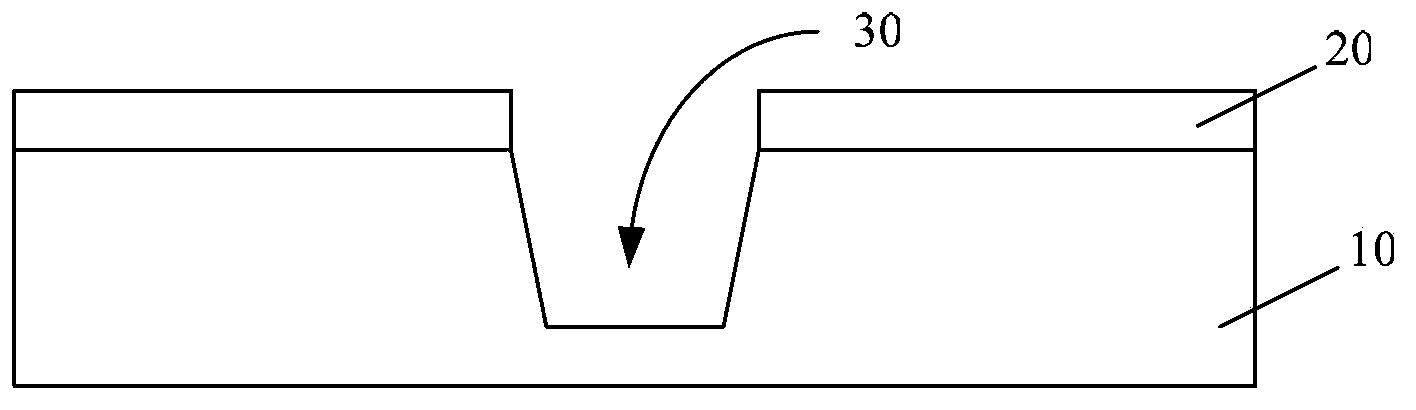

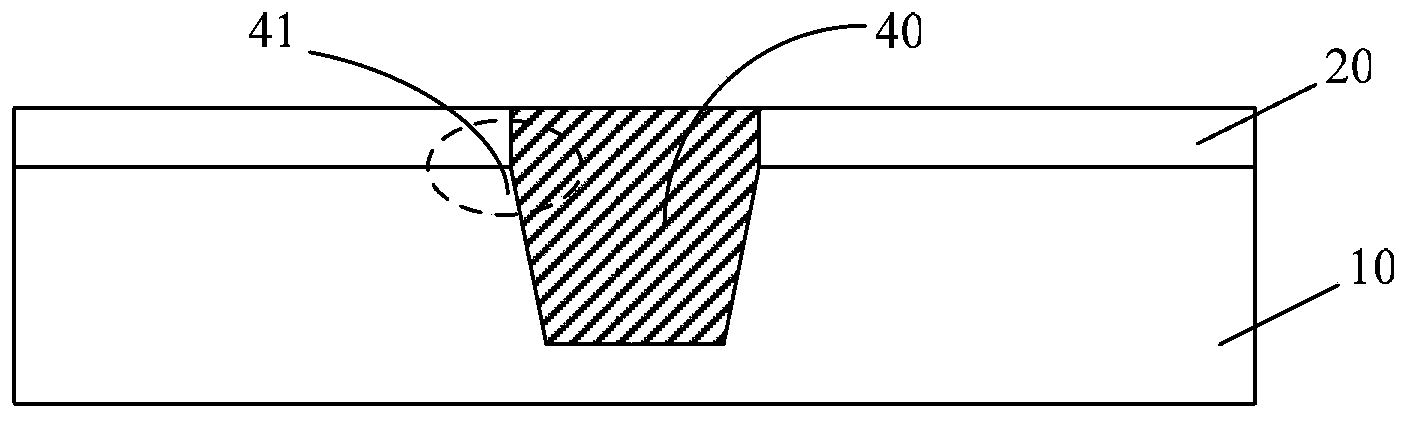

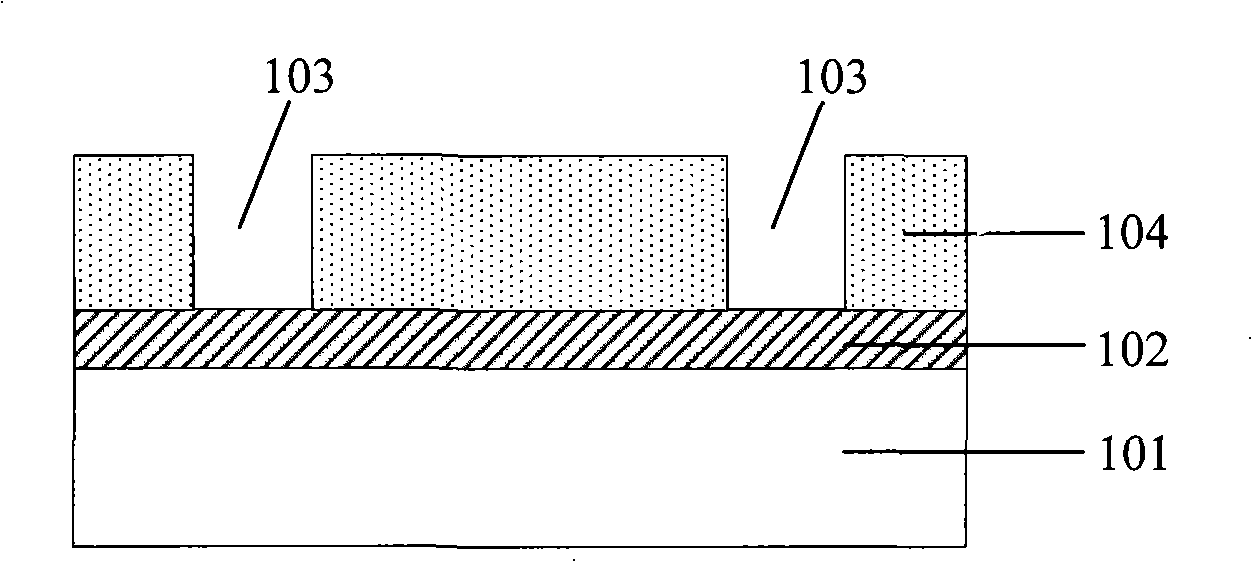

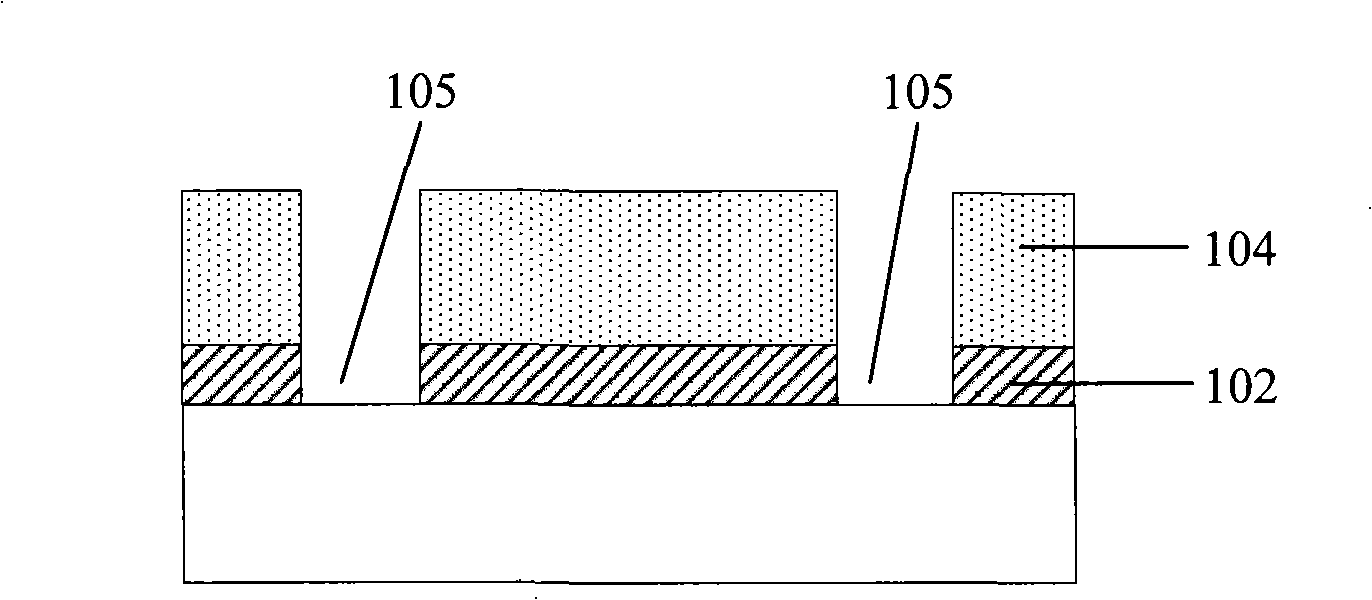

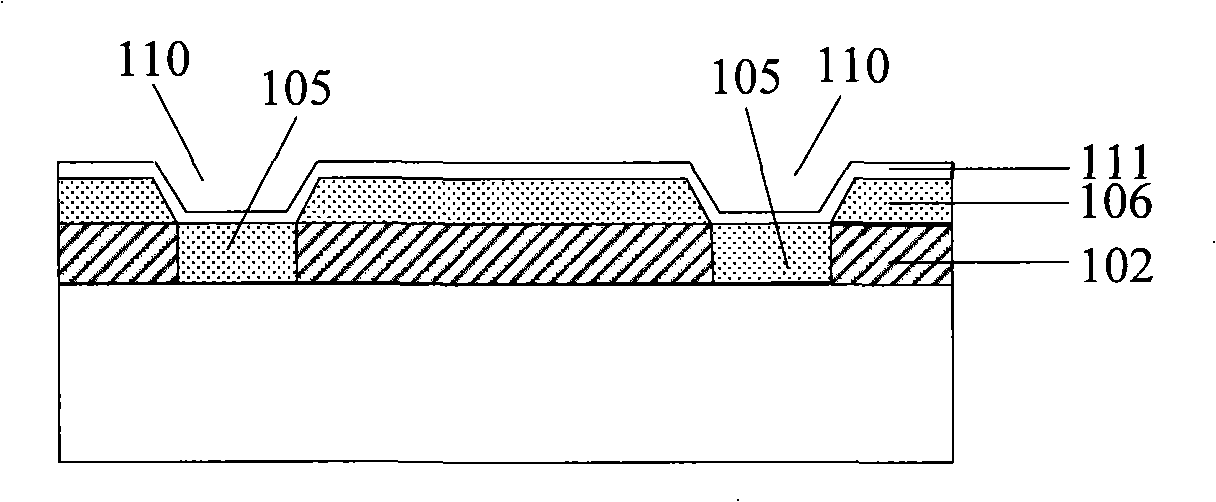

Shallow-trench isolation structure and forming method thereof

InactiveCN104347473AIncrease opening widthLow densitySolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerEngineering

Semiconductor devices and fabrication methods are disclosed. A mask layer having an opening is formed on a semiconductor substrate. The semiconductor substrate is etched along the opening of the mask layer to form a trench therein. The mask layer is laterally etched from the opening of the mask layer along a top surface of the semiconductor substrate to expose a surface portion of the semiconductor substrate on each side of the opening. A liner oxide layer is formed by a thermal oxidation process on interior surface of the trench and on the exposed surface portion of the semiconductor substrate. The thermal oxidation process is controlled such that an upper corner between the top surface of the semiconductor substrate and the trench is rounded after the liner oxide layer is formed. An insulation layer is formed on the liner oxide layer and fills the trench.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

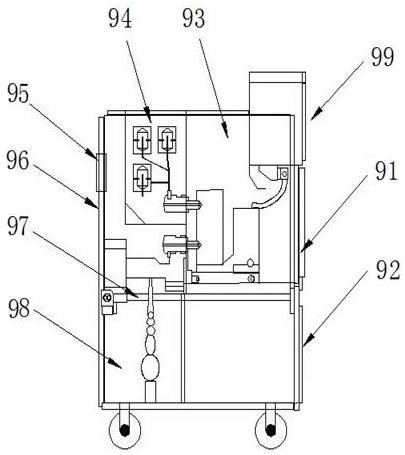

Box jogged method and apparatus and manufacturing system of packaging box

InactiveCN102179958ALow costHigh operational reliabilityBoxes/cartons making machineryMechanical engineeringFitting methods

To certainly automate the fitting of an inner box and an outer box by inserting the inner box in the outer box by one side. In a box fitting method, the outer box is held by an outer box holding mechanism and the side surface thereof is pressed by a side surface pressing mechanism to expand the opening part of the outer box. The inner box is grasped by an inner box fitting robot to insert the first side of the inner box in the opening part. Subsequently, the inner box is moved in the outer box to be put aside so that the first side is allowed to approach the first side surface of the outer box. The shift quantity of the second side of the inner box and the opening part of the outer box is measured by a shift quantity measuring part using imaging and image processing. The inner box is moved on the basis of the measuring result of the shift quantity and the second side thereof is inserted in the opening part. Thereafter, the inner box is pressed to be fitted in the outer box.

Owner:FUJIFILM CORP

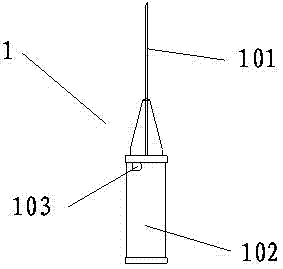

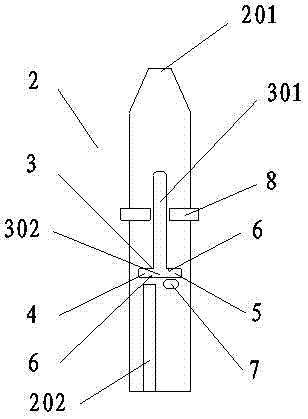

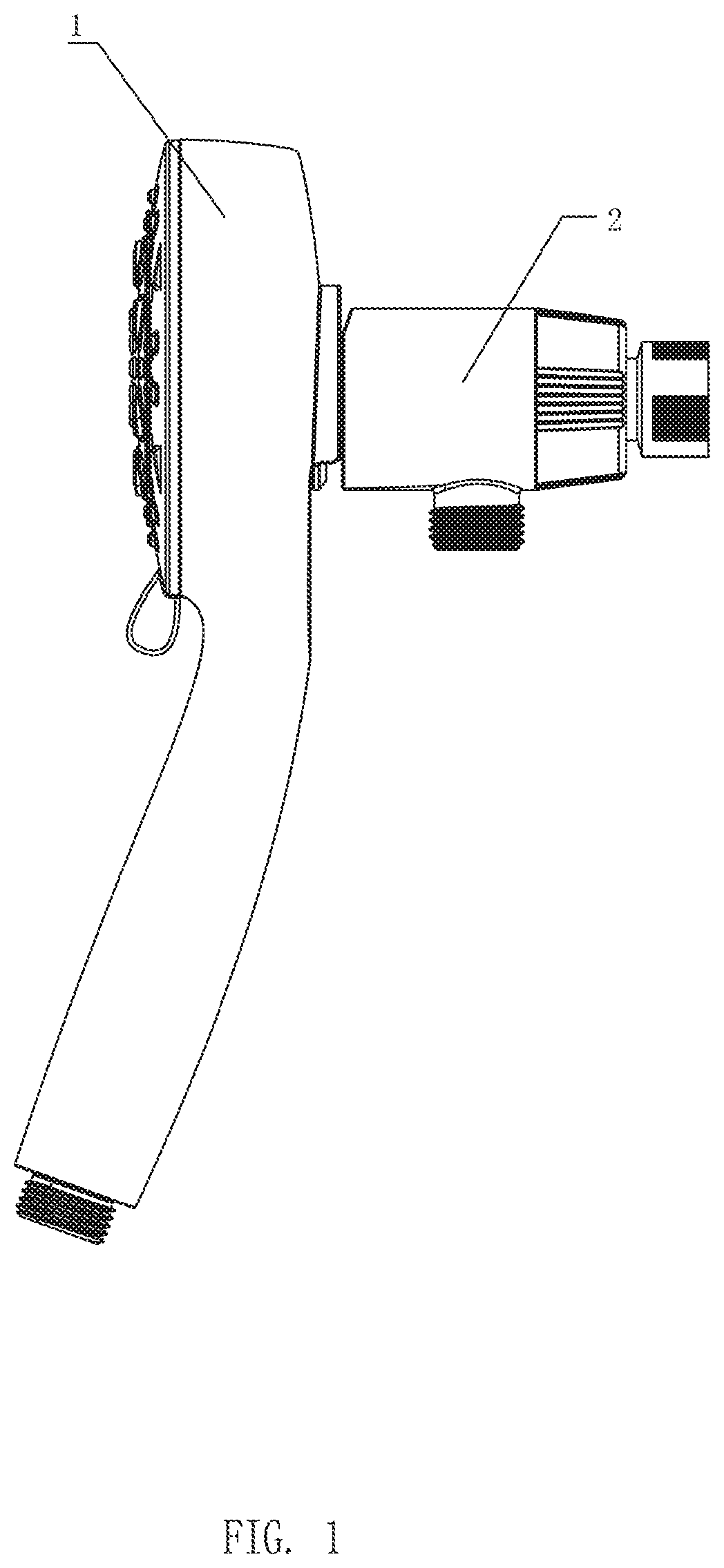

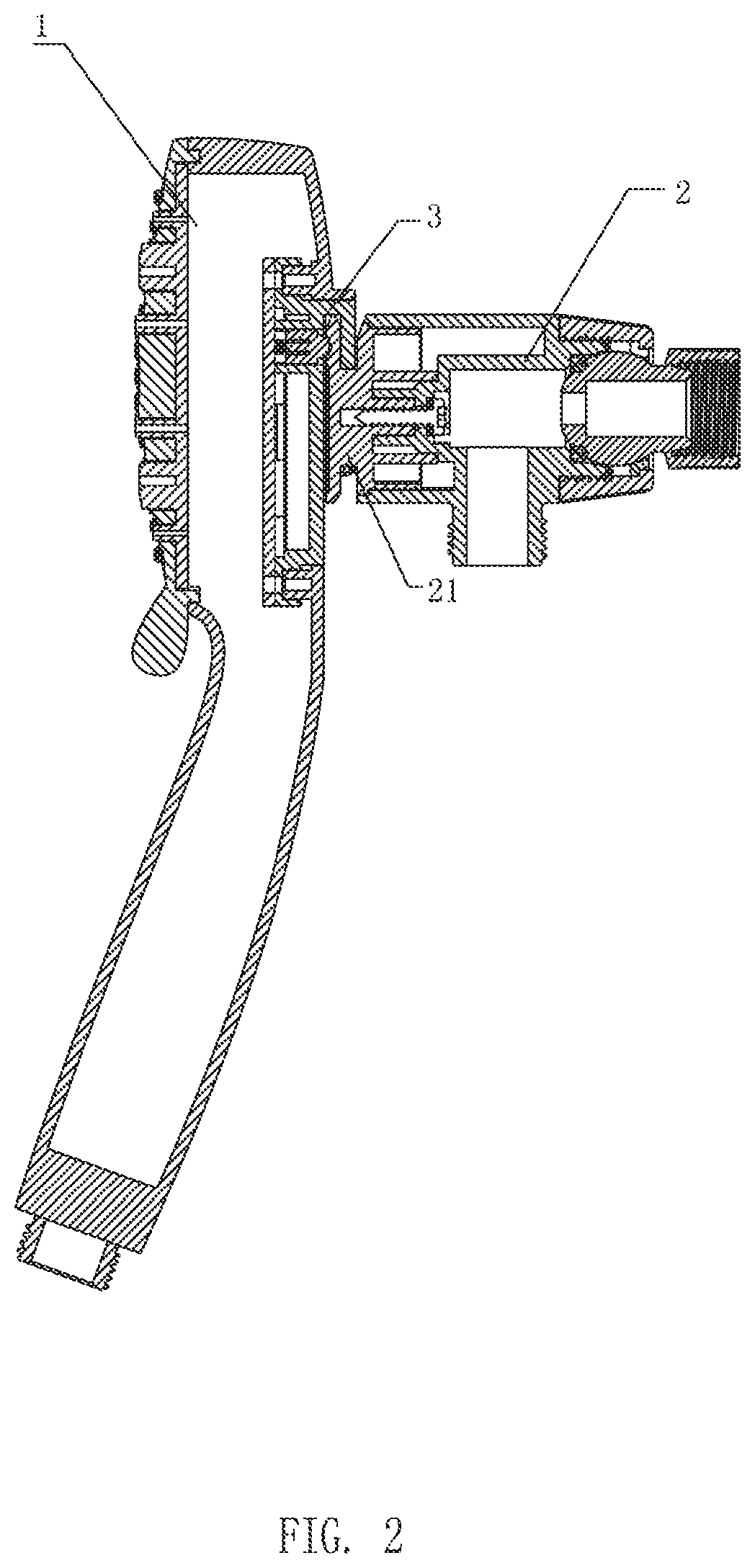

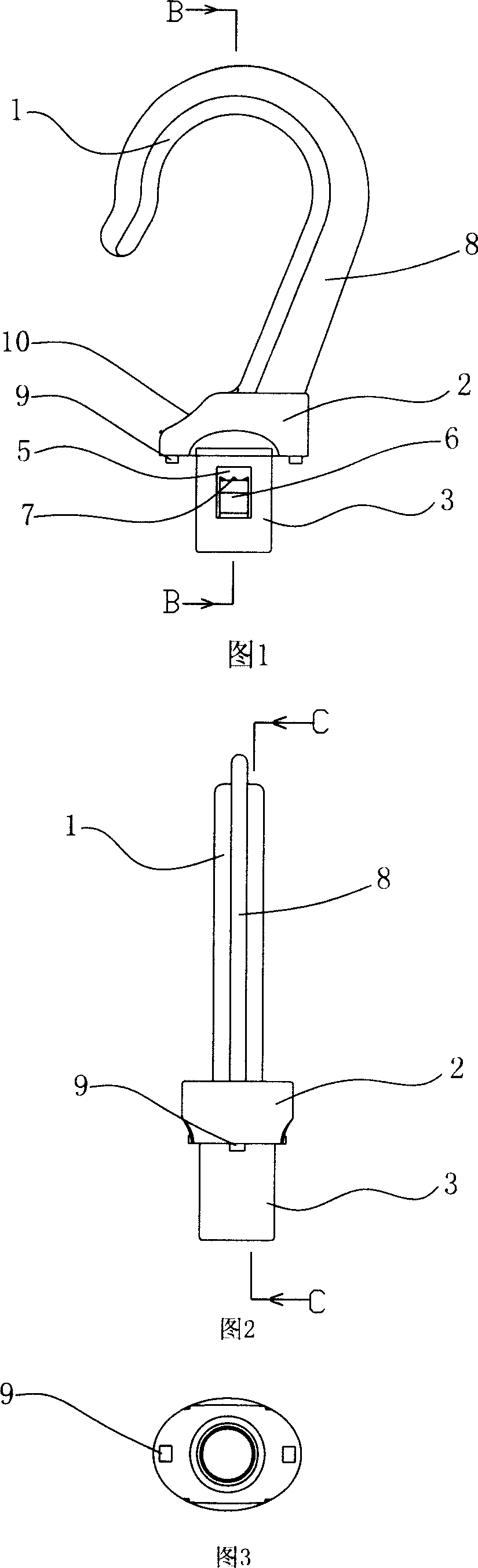

Safety pin

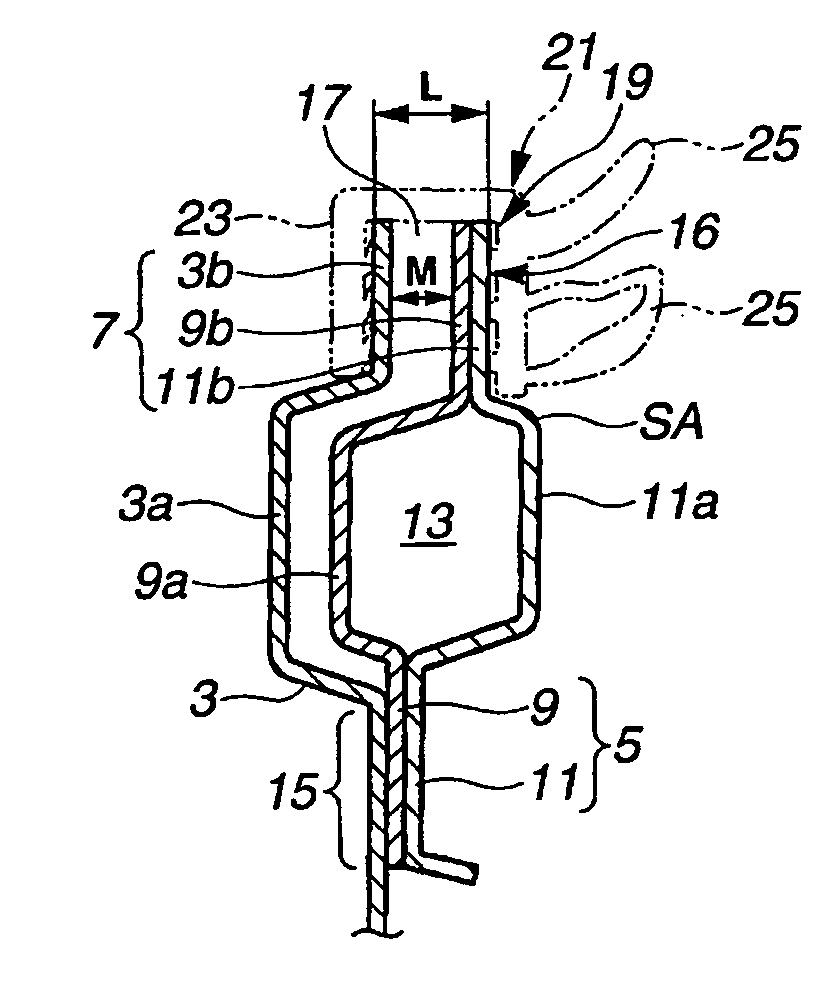

ActiveCN102371015AEasy accessPrevent secondary useInfusion syringesIntravenous devicesSyringeEngineering

Owner:GUANGDONG HAIOU MEDICAL APP STOCK

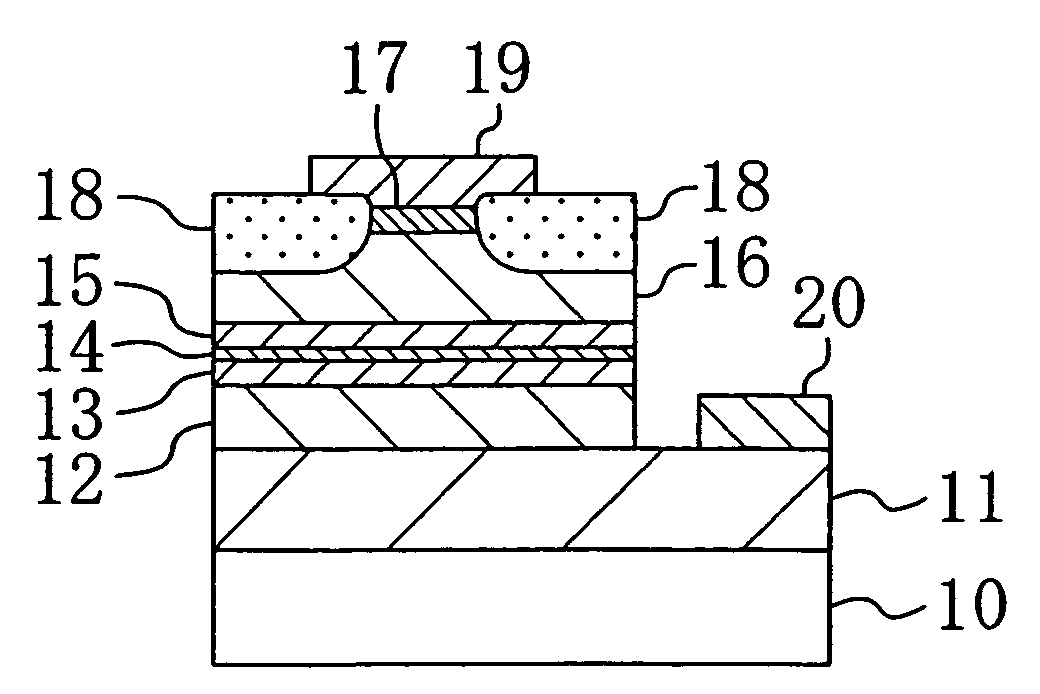

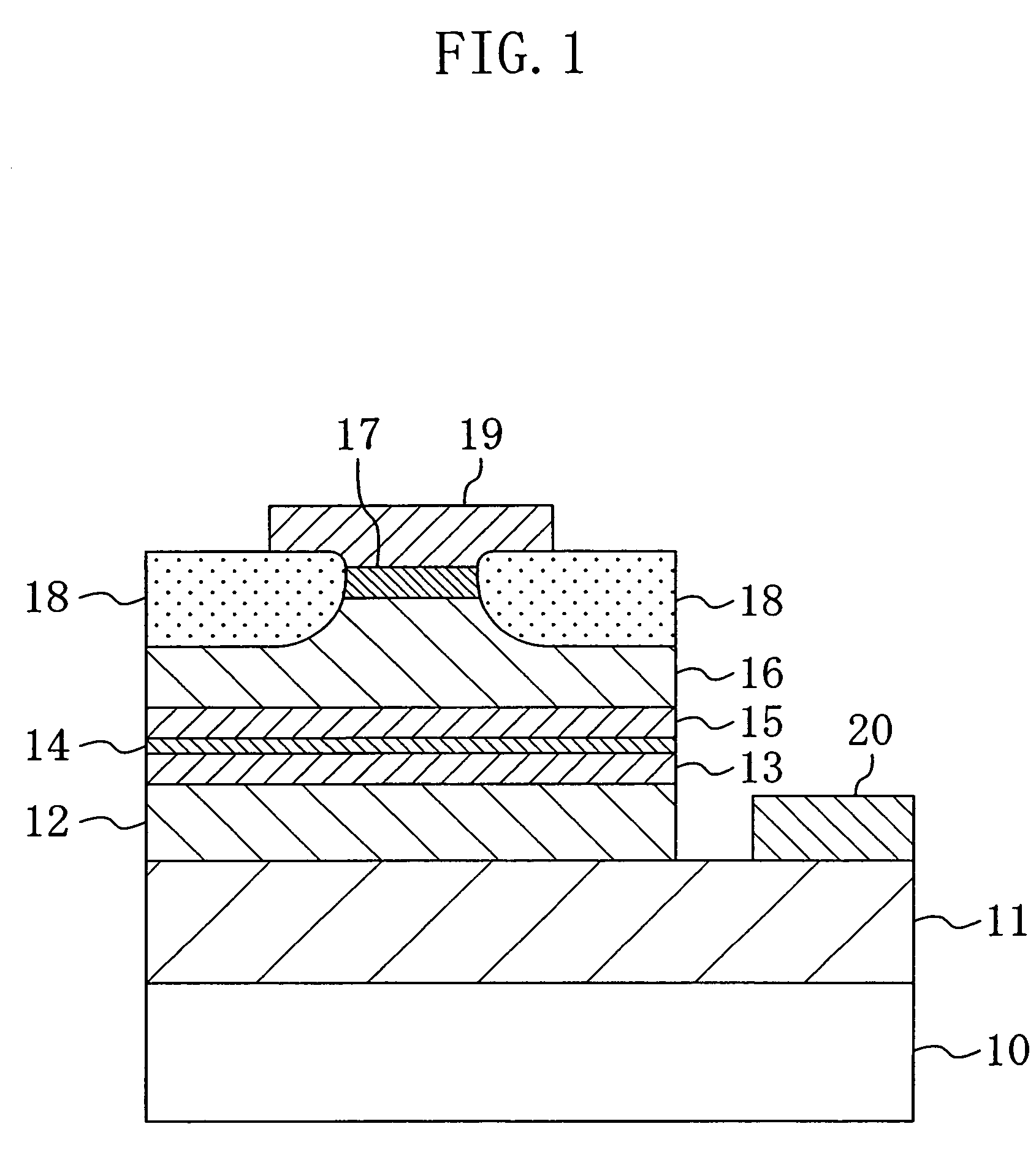

Semiconductor light-emitting device and method for fabricating the same

InactiveUS7170108B2Improve adhesionReduce densityOptical wave guidanceLaser detailsBlock layerOxygen atom

An n-type buffer layer composed of n-type GaN, an n-type cladding layer composed of n-type AlGaN, an n-type optical confinement layer composed of n-type GaN, a single quantum well active layer composed of undoped GaInN, a p-type optical confinement layer composed of p-type GaN, a p-type cladding layer composed of p-type AlGaN, and a p-type contact layer composed of p-type GaN are formed on a substrate composed of sapphire. A current blocking layer formed in an upper portion of the p-type cladding layer and on both sides of the p-type contact layer to define a ridge portion is composed of a dielectric material obtained by replacing some of nitrogen atoms composing a Group III–V nitride semiconductor with oxygen atoms.

Owner:PANASONIC CORP

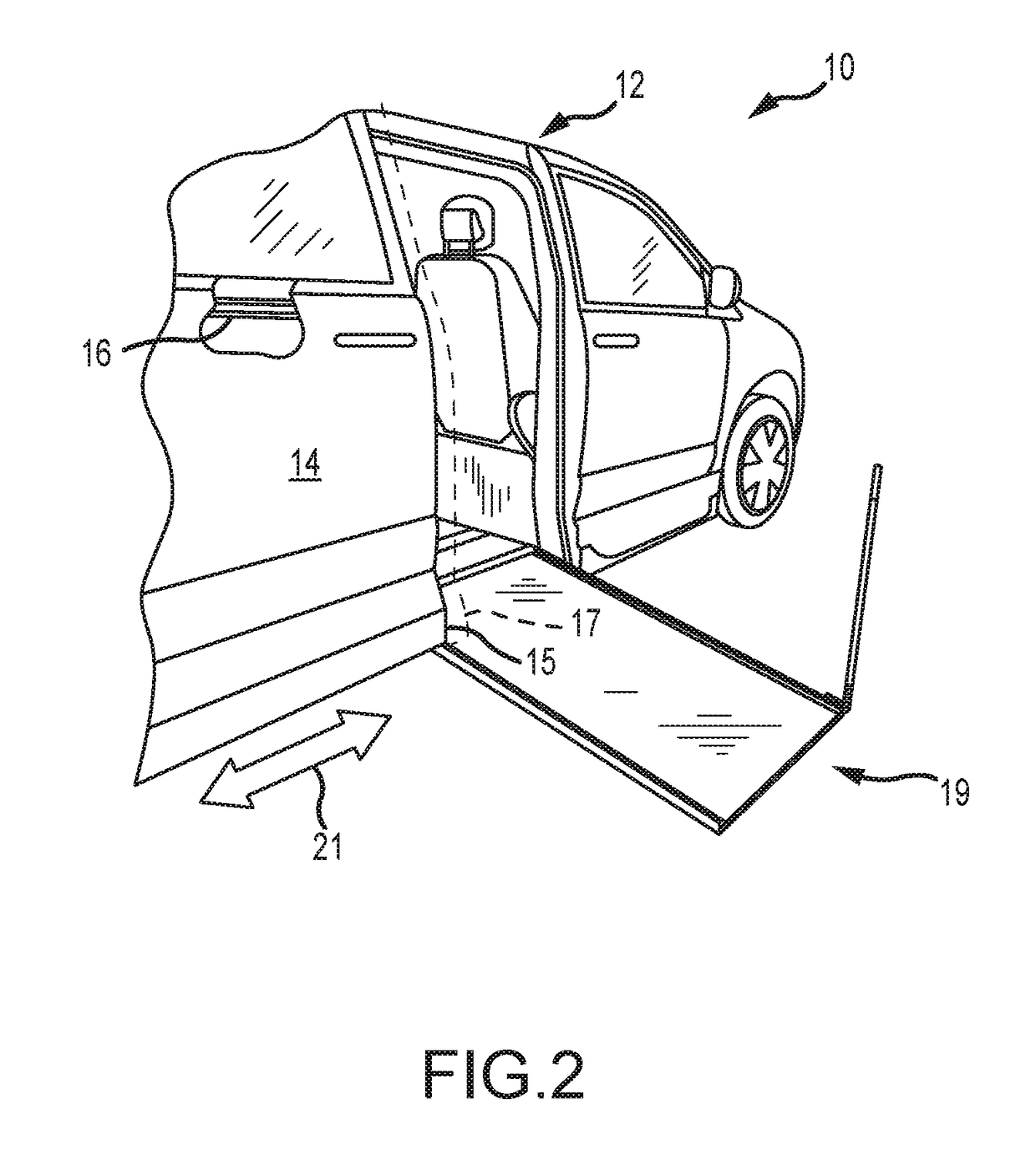

Method of extending opening ranges of vehicle sliding doors

ActiveUS9896871B2Increase opening widthPin hingesWing suspension devicesEngineeringStandard position

An extended range sliding door hinge may include a track bracket assembly and an intermediate bracket. The track bracket assembly is sized to be operatively received by a vehicle door track assembly. A first end of the intermediate bracket is movably mounted to the track bracket assembly so that the intermediate bracket may be moved with respect to the track bracket assembly between a retracted position and an extended position. A second end of the intermediate bracket is sized to operatively engage a vehicle sliding door. The extended range sliding door hinge allows the vehicle sliding door to be moved between a standard position when the intermediate bracket is in the retracted position and an extended position when the intermediate bracket is in the extended position.

Owner:VANTAGE MOBILITY INT

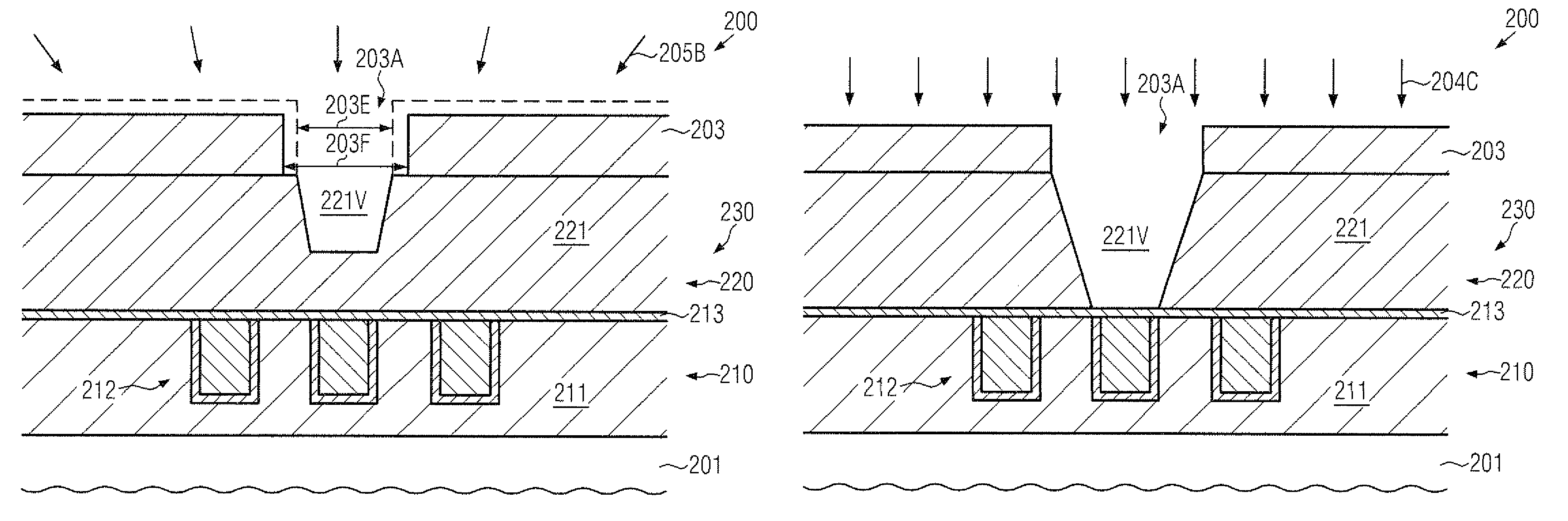

Metallization system of a semiconductor device comprising extra-tapered transition vias

ActiveUS8835303B2Increase horizontal widthTaper can be gradualSemiconductor/solid-state device detailsSolid-state devicesResistEngineering

In a metallization system of a semiconductor device, a transition via may be provided with an increased degree of tapering by modifying a corresponding etch sequence. For example, the resist mask for forming the via opening may be eroded once or several times in order to increase the lateral size of the corresponding mask opening. Due to the pronounced degree of tapering, enhanced deposition conditions may be accomplished during the subsequent electrochemical deposition process for commonly filling the via opening and a wide trench connected thereto.

Owner:ADVANCED MICRO DEVICES INC

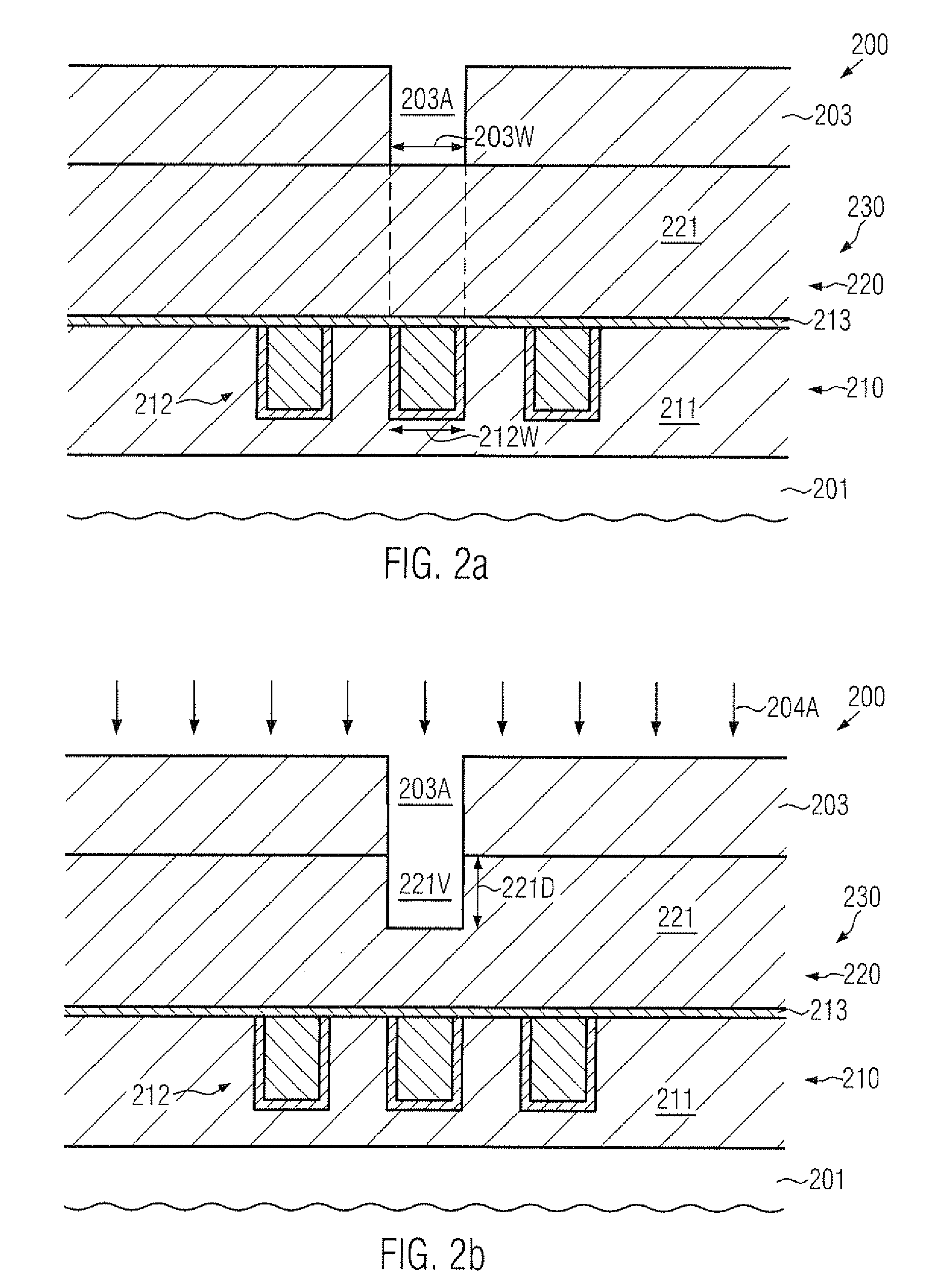

Polar-axis type solar automatic-tracking system for heating vacuum heat collector

InactiveCN102062480AImplement trackingOvercoming tracking issues under fixed targets that cannot be achievedSolar heating energySolar heat devicesPrice ratioEngineering

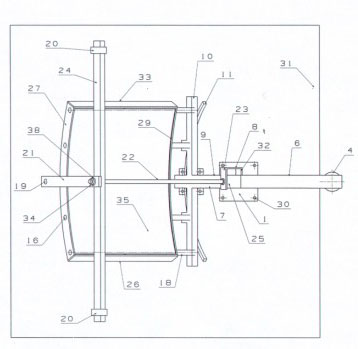

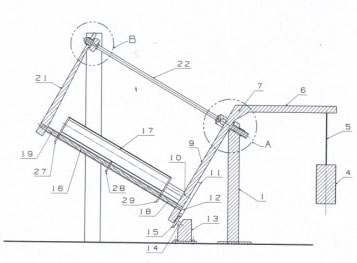

The invention discloses a polar-axis type solar automatic-tracking system for heating a vacuum heat collector, which comprises a supporting post, two upright posts, a reflector, a transmission device and a driving device and is characterized in that: a movable bracket of the reflector comprises a rail, an inclined rod and a right metal supporting-foot frame which are connected into a whole, a reflector frame and the movable bracket are connected together through a plurality of metal supporting rods, a slot-type cylindrical-surface reflector is installed in the reflector frame, a cylindrical rotating shaft is assembled on the movable bracket, and the rotating shaft is inserted into a self-lubricating bearing sleeve on the supporting post; and the vacuum heat collector which is coaxial with the rotating shaft is installed between an upper fixed ring and a lower fixed ring. The polar-axis type solar automatic-tracking system has the advantages of operation stability, lightened weight, enhanced wind-resisting performance, ultrahigh performance-price ratio and easiness of realization of commercialization; and by adopting a novel polar-axis type one-dimensional tracking mode, the polar-axis type solar automatic-tracking system can realize tracking of a fixed target, improves the light concentrating ratio of the system and reduces the manufacturing cost of a mirror surface.

Owner:吴艳频 +1

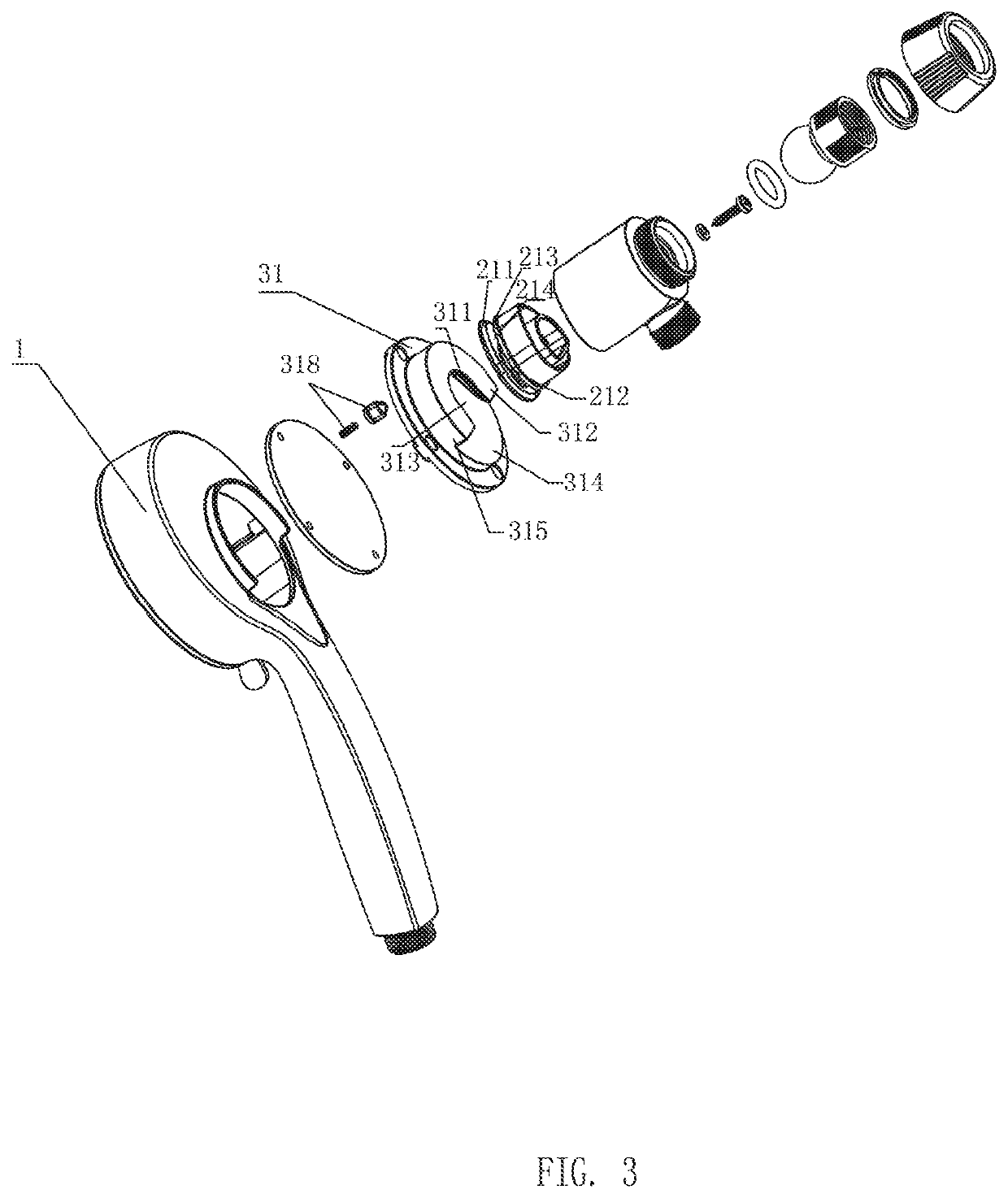

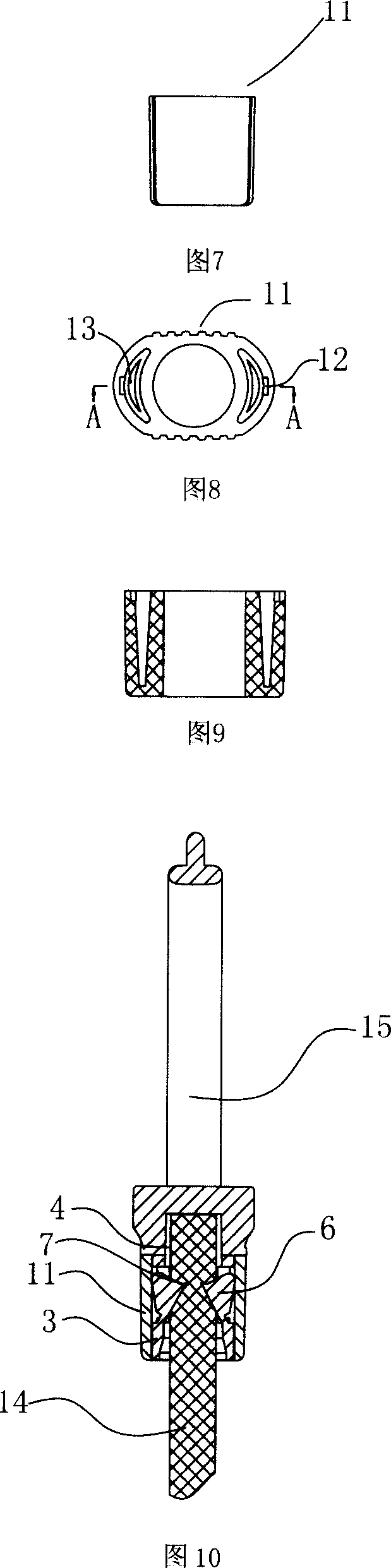

Hanging structure and handheld shower

ActiveUS20210053083A1Quick assemblySimple structureDomestic plumbingSpray nozzlesClassical mechanicsStructural engineering

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Method for improving medium layer defect between micro-reflection mirrors and producing silicon based LCD

InactiveCN101315501AReduce diffuseImprove reflectivityPhotomechanical apparatusNon-linear opticsAcid etchingDiffuse reflection

A method for improving defects of medium layer between micro-reflectors comprises the following steps: providing a silicon substrate with a metal layer having a groove penetrating through the metal layer; depositing a medium layer on the metal layer to fill the groove; acid-etching the medium layer; forming a photoresist layer on the medium layer; and etching the photoresist layer and the medium layer until the metal is exposed to form a micro-reflector array. The invention further provides a method for fabricating LCD on silicon. The medium layer is subjected to acid-etching to increase the opening aspect ratio and the opening width of the medium layer at the groove, so that no sidewalls of the medium layer is produced on the metal layer connected with the groove in subsequent etching process, thus reducing diffuse reflection and improving reflectivity of the micro-reflector.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Bundling belt hook and banding

The invention relates to a bond hook and relative bond band. Wherein, said hook comprises main body and hook base; the base has extending tube with holes; the wall of tube has several through holes with clampers; the lower end of clamper is connected to the lower side of through hole; the extending tube is sheathed by positioning sheath. The invention has reliable connection.

Owner:陈法明

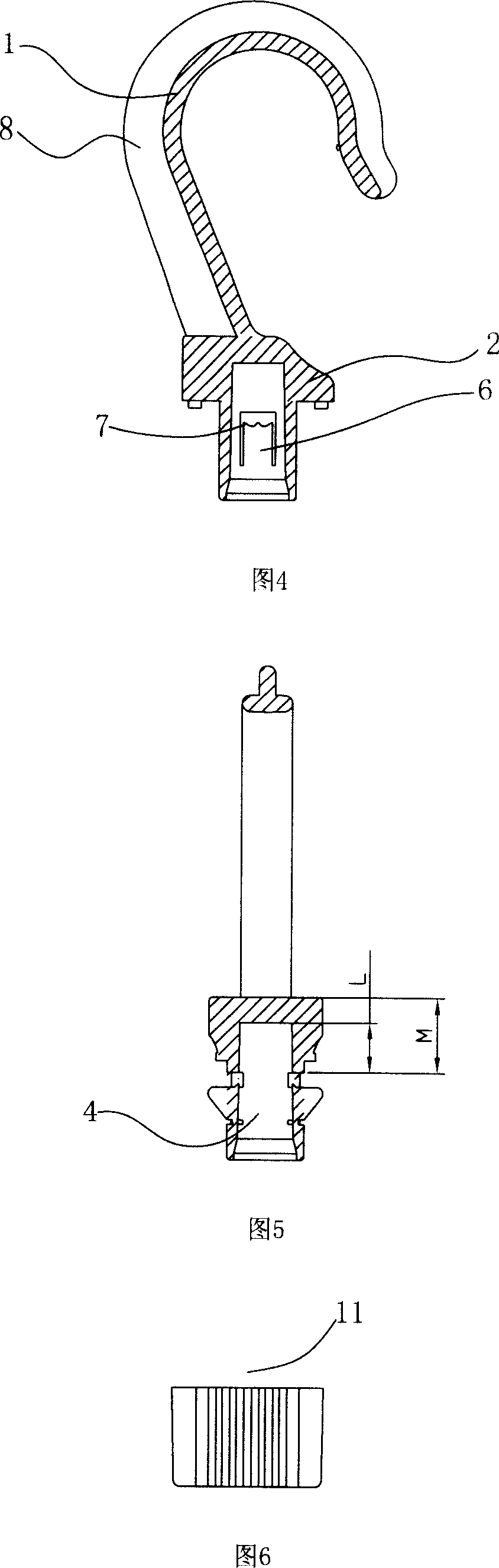

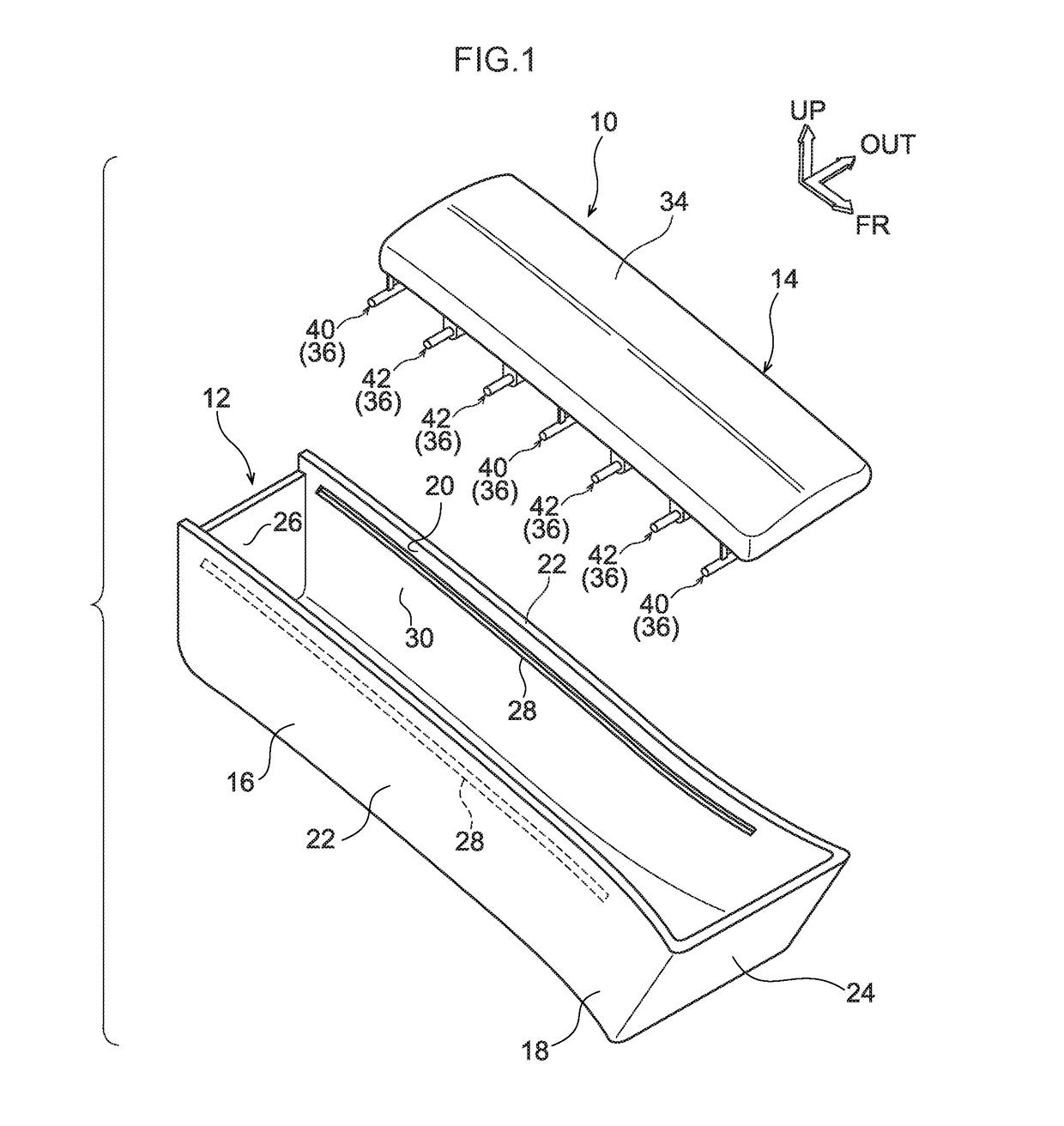

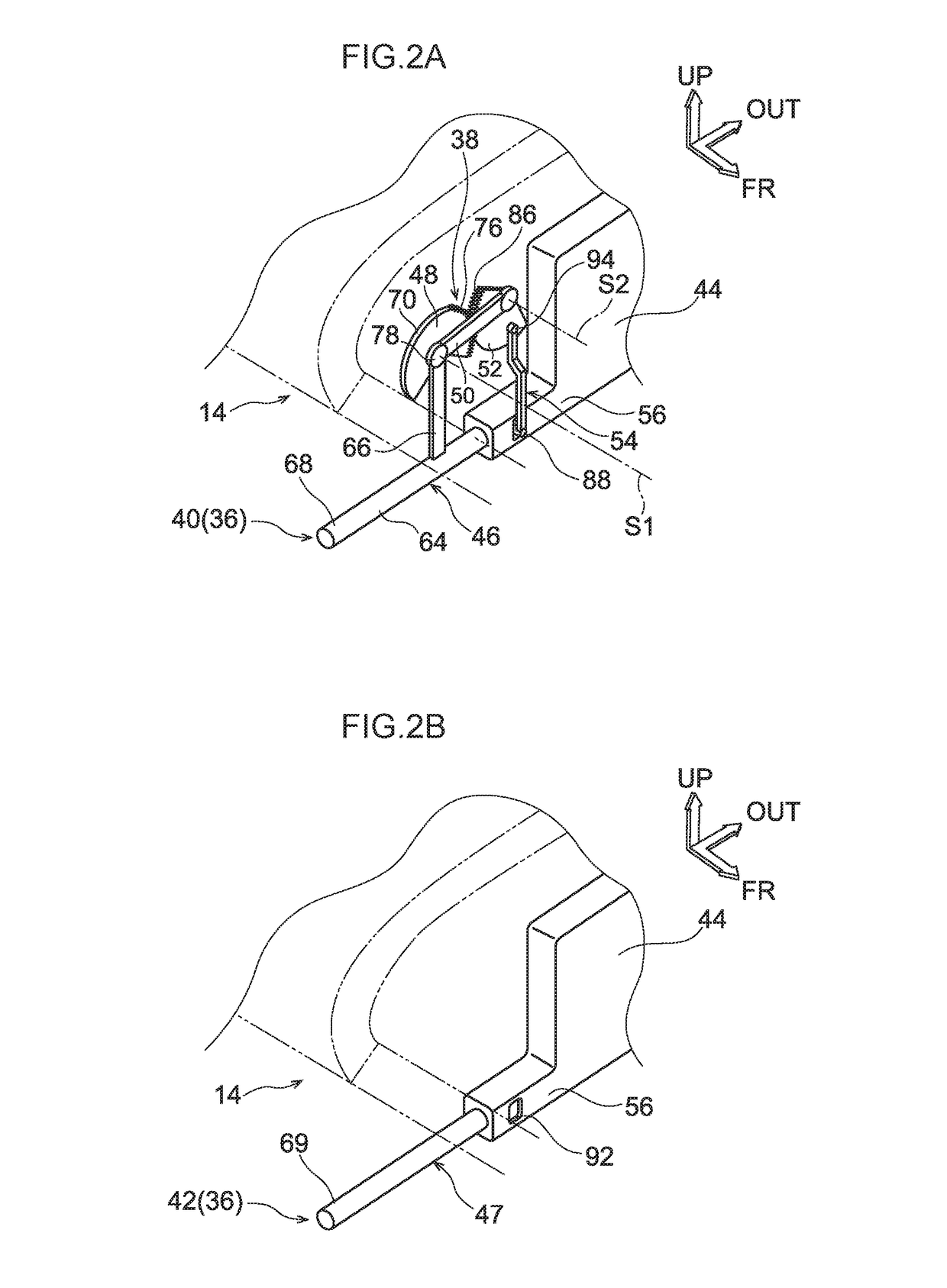

Vehicular storage unit

Owner:TOYOTA JIDOSHA KK

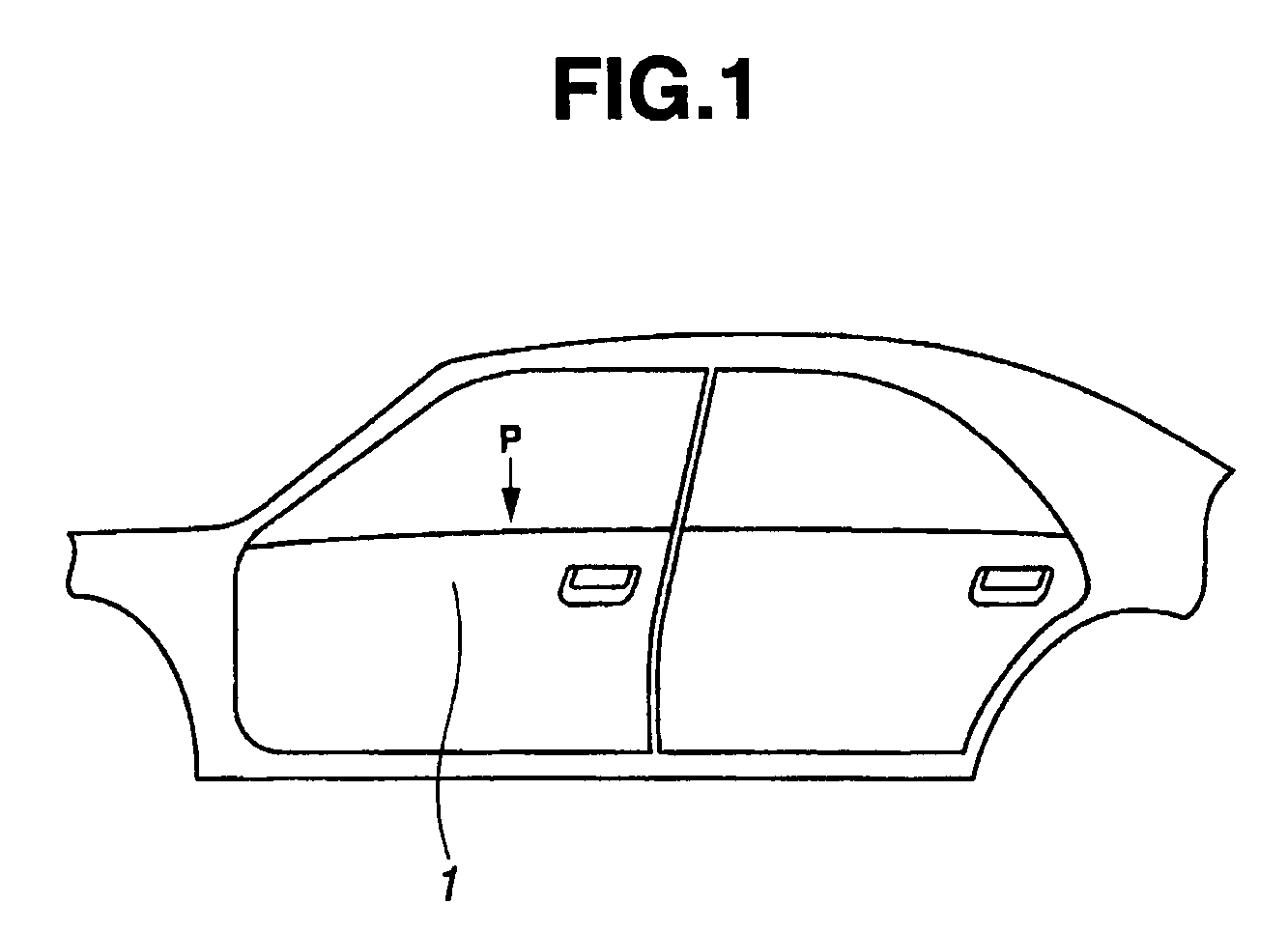

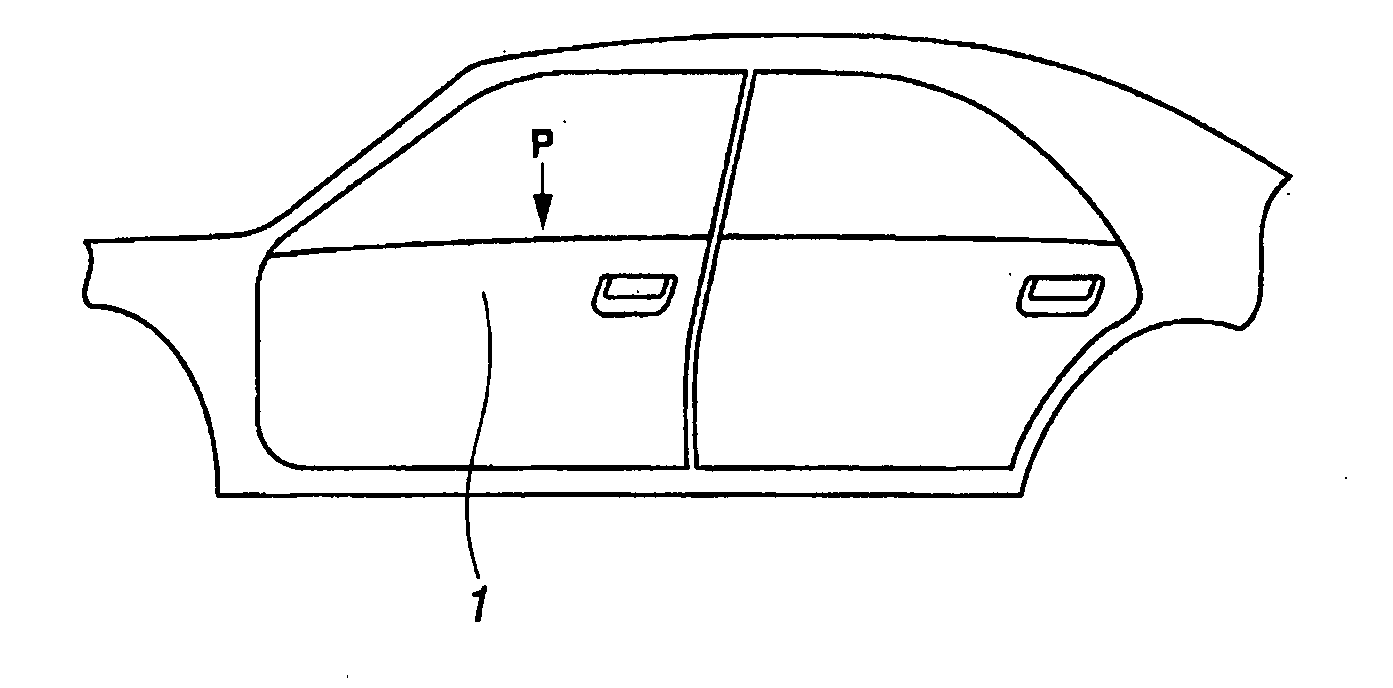

Door panel structure and method of producing the same

ActiveUS20080073932A1Reducing opening width can be eliminatedLow production costVehicle sealing arrangementsMonocoque constructionsFace sheetFlange

A door panel structure including a door panel and a door waist reinforcement connected to the door panel. The door waist reinforcement includes an inner reinforcement and an outer reinforcement. The door panel and the door waist reinforcement have respective upper end portions which form a waist flange to which a weather strip is fitted. The waist flange includes a plurality of connecting portions at which the upper end portion of the door panel and the upper end portion of the door waist reinforcement are connected to each other, and at least one spaced portion at which the upper end portion of the door panel and the upper end portion of the door waist reinforcement are spaced from each other.

Owner:NISSAN MOTOR CO LTD

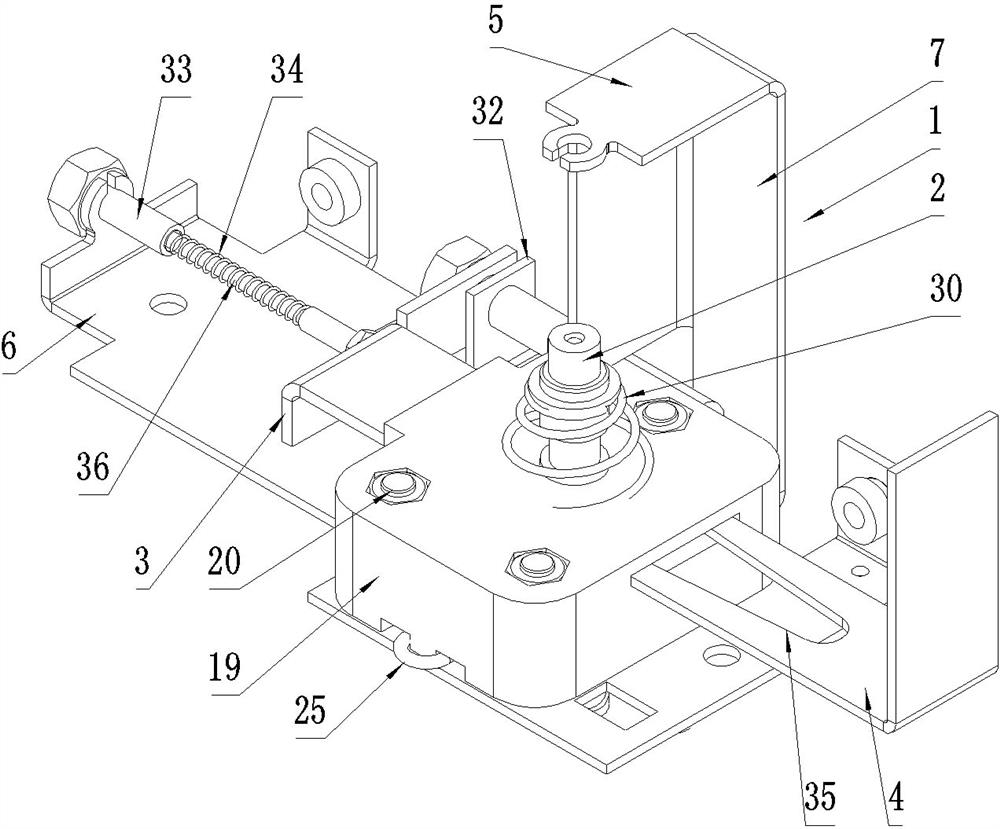

Interlocking device of grounding switch and front lower door in switch cabinet and switch cabinet

ActiveCN112509835ASolve the problem of openingEasy to pushEarthing arrangementsSubstation/switching arrangement casingsControl theoryMechanical engineering

The invention relates to an interlocking device of a grounding switch and a front lower door in a switch cabinet and the switch cabinet. The interlocking device comprises a limiting rod ejector rod and a clamping plate pushing piece; the limiting rod ejector rod has an upward movement trend under the action of a corresponding elastic structure; the limiting rod ejector rod is provided with a blocking position and a receding position in the moving stroke, and the blocking position corresponds to the upper end of the moving stroke of the limiting rod ejector rod and is used for blocking the vertical limiting rod on the switch cabinet from moving downwards; a limiting groove is formed in the outer circumferential face of the limiting rod ejector rod, an ejector rod bayonet is formed in the side, close to the limiting rod ejector rod, of an ejector rod clamping plate, and the ejector rod bayonet is used for being clamped into the limiting groove to limit downward movement of the limiting rod ejector rod when the limiting rod ejector rod is located at the blocking position; and the clamping plate pushing piece is used for pushing the ejector rod clamping plate under the driving of the front lower door when the front lower door is closed, so that the limitation of the ejector rod bayonet in the ejector rod clamping plate on the limiting rod ejector rod is relieved. According to the scheme, the problem that in the prior art, when the front lower door of the switch cabinet is not closed, the grounding switch can still be switched off is solved.

Owner:HENAN PINGGAO GENERAL ELECTRIC CO LTD +2

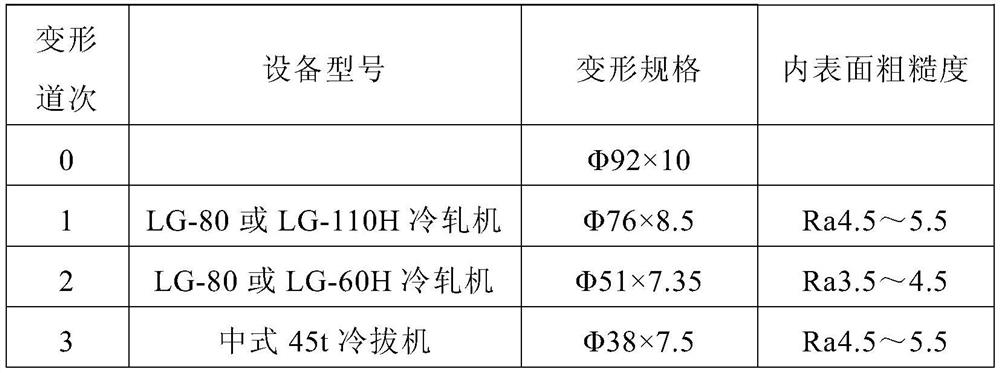

Cold rolling pipe manufacturing method for improving roughness quality of inner wall of stainless steel seamless pipe for power station boiler

ActiveCN111940518AQuality improvementImprove performanceRoll mill control devicesMetal rolling arrangementsPower stationPunching

A cold rolling pipe manufacturing method for improving the roughness quality of the inner wall of a stainless steel seamless pipe for a power station boiler adopts a two-pass cold rolling deformationprocess to roll to obtain finished pipes for delivery, that is, an LG-80 or LG-110H cold rolling mill is adopted for cogging rolling and an SKW-75 high-speed cold rolling mill is adopted for rolling to obtain the finished products. Meanwhile, by optimizing parameters such as a roller device, a hole pattern and a core rod related to cold rolling deformation and taking measures such as increasing the diameter of the core rod, widening a hole pattern opening and reducing a movement gap, the cold rolling pipe making quality and efficiency of the stainless steel seamless pipe for the power stationboiler are improved. On the basis of meeting the technical requirements for cold rolling of the boiler pipe of the power station, the quality loss of the roughness of the inner wall caused by abnormalworking conditions such as "top punching" and "insufficient rotation" of a pipe blank is reduced, the yield is increased, and the production cost is reduced.

Owner:宝武特种冶金有限公司

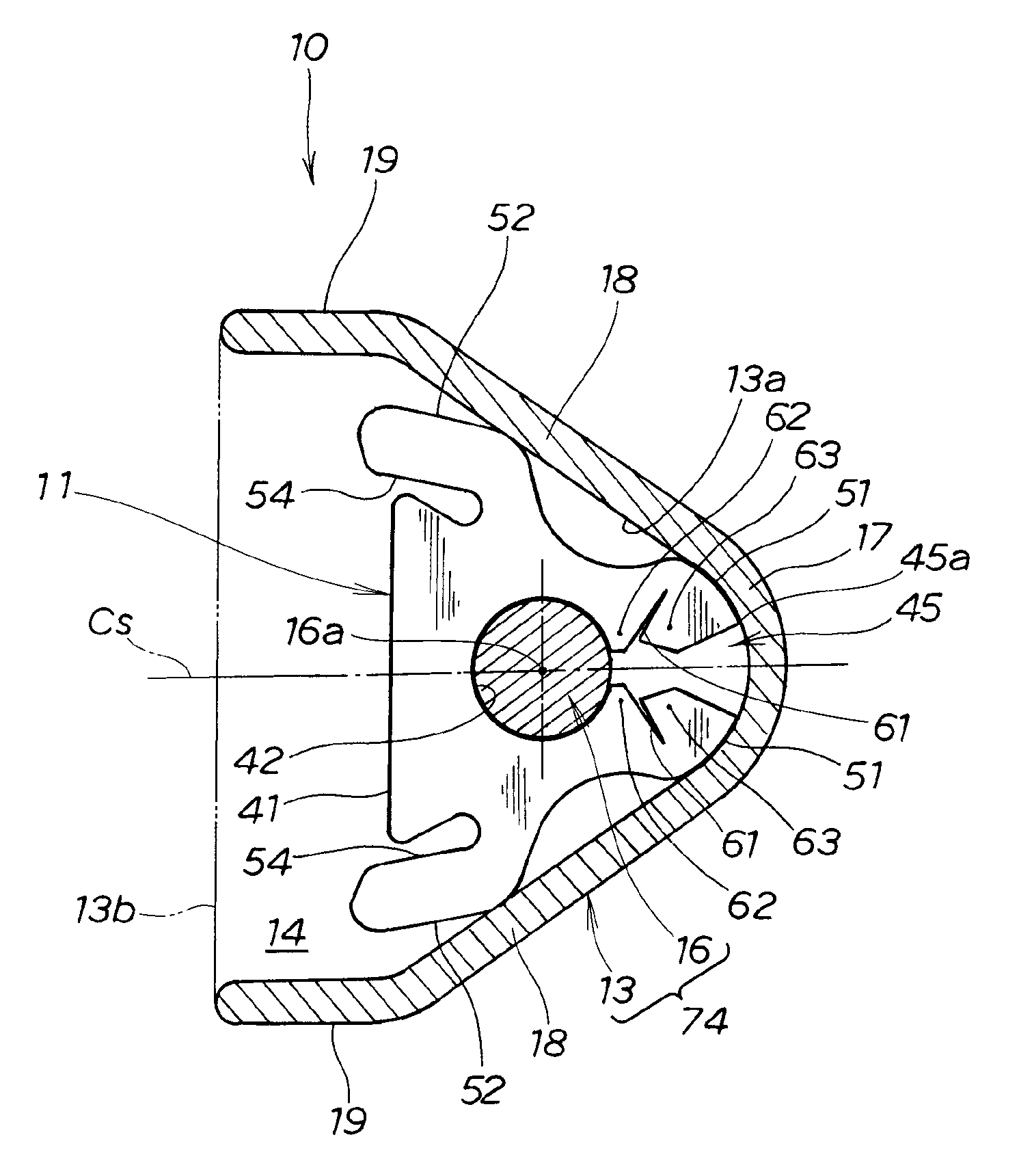

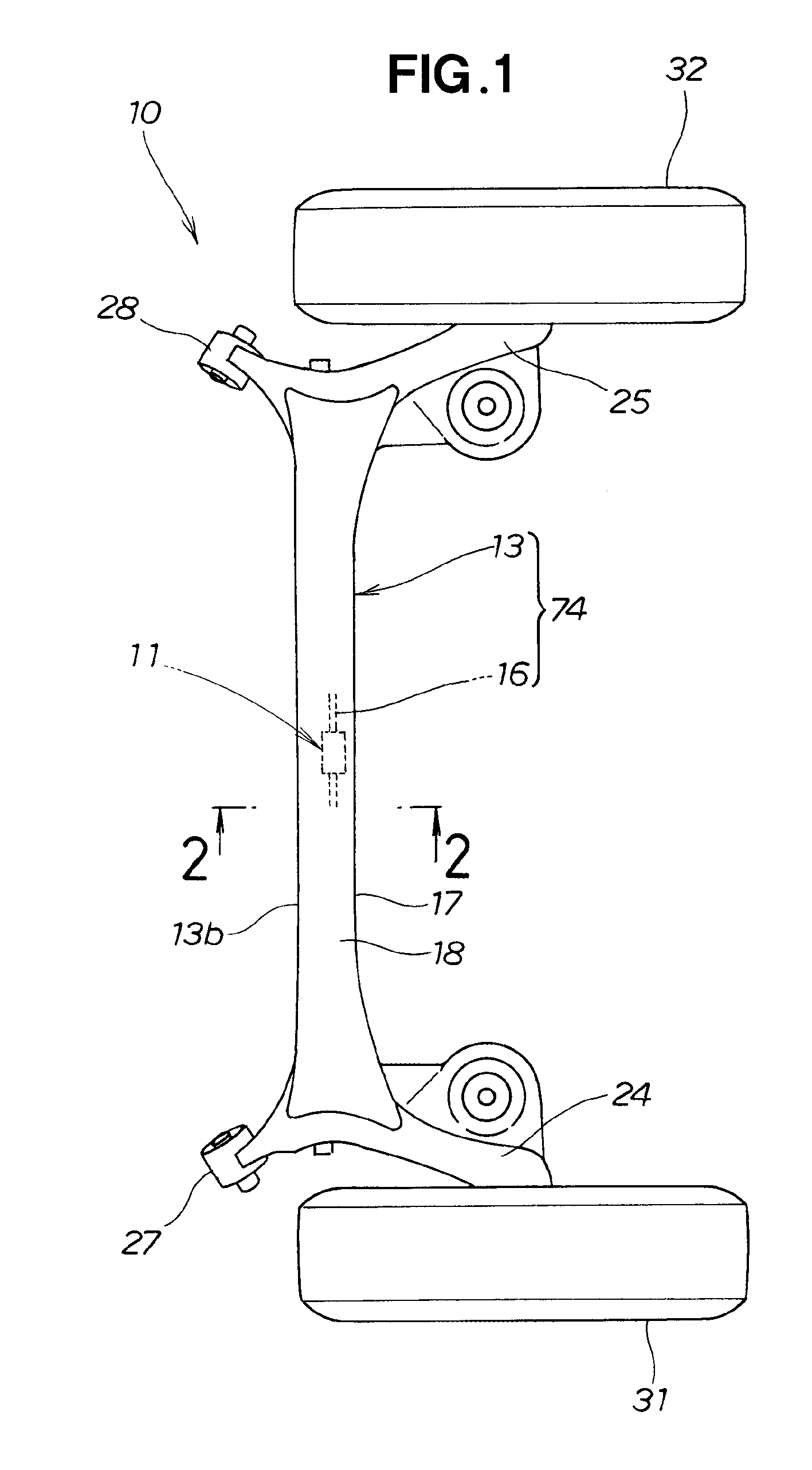

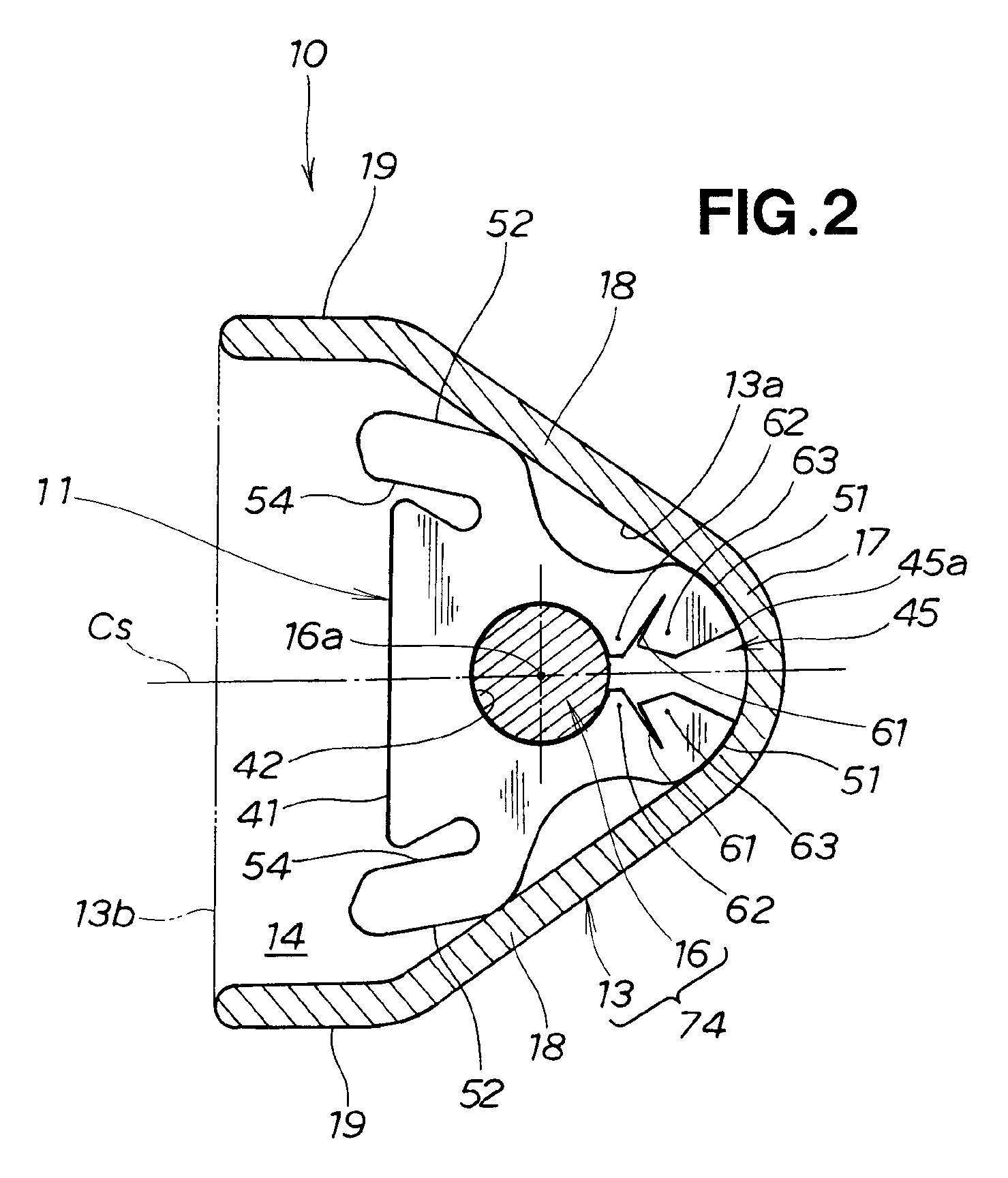

Bush for isolating stabilizer from vibration

ActiveUS8672303B2Suppression of deformationSuppresses the bush for isolating the stabilizerStands/trestlesSpecial foundation layoutEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

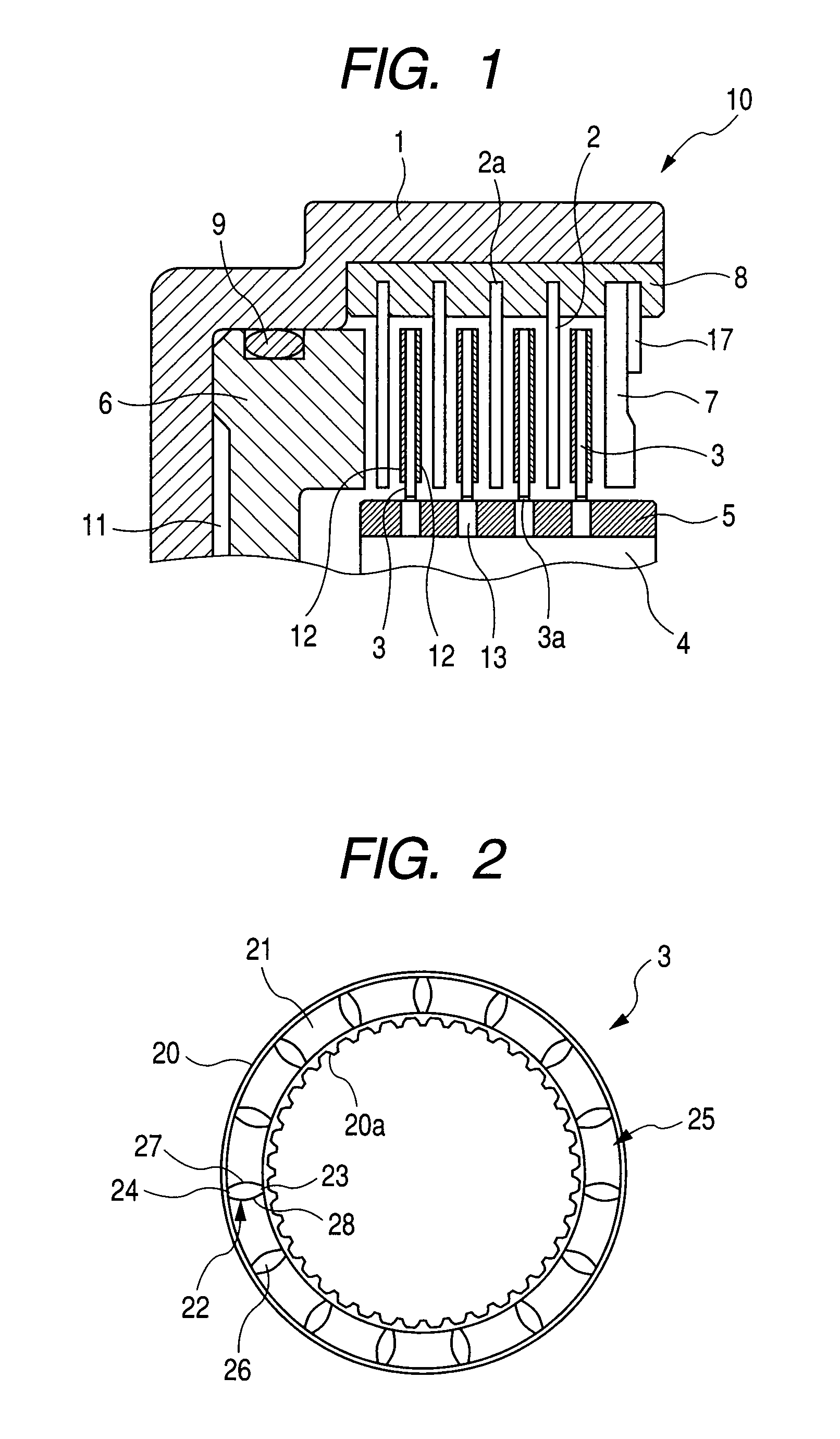

Backlight assembly and liquid crystal display apparatus having the same

InactiveUS8123390B2Avoid breakingEasy to assembleElectric discharge tubesElectric discharge lampsLiquid-crystal displayEngineering

A backlight assembly includes a plurality of lamps, a receiving container, a diffuser plate and a plurality of holding members. The lamps generate a light. The receiving container receives the lamps. The receiving container includes a bottom portion and a side portion protruded from a side of the bottom portion. The diffuser plate is over the lamps to diffuse the light generated from the lamps. The holding members are engaged with the bottom portion. Each of the holding members has a lamp holding portion that holds one of the lamps. 10 The lamp holding portion has an opening for receiving the lamp. The opening is inclined by a first angle with respect to a normal line of the bottom portion. Therefore, the lamps are securely combined with the lamp holding portion, and the lamps are easily assembled to protect the lamps from an externally provided impact.

Owner:SAMSUNG DISPLAY CO LTD

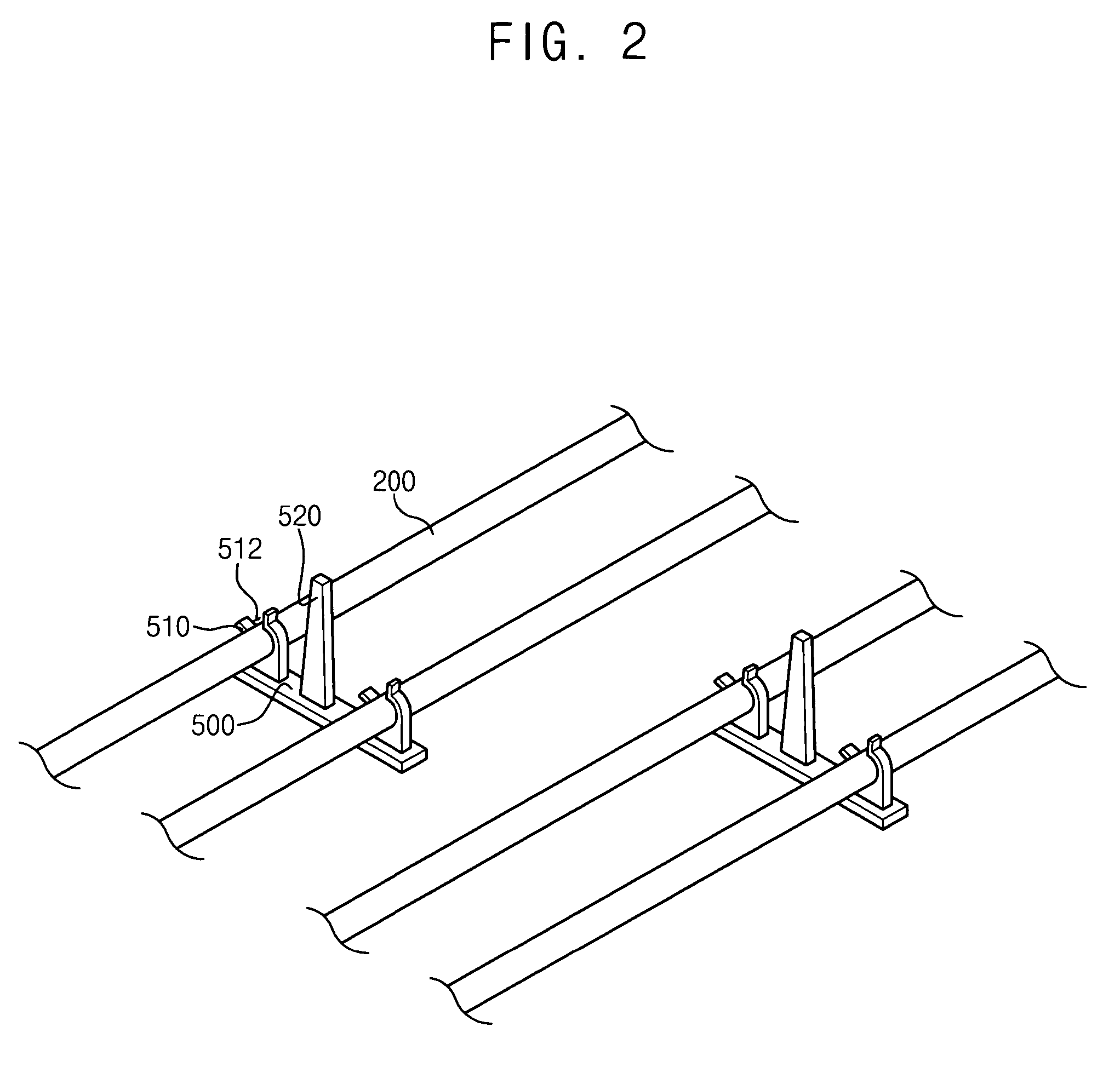

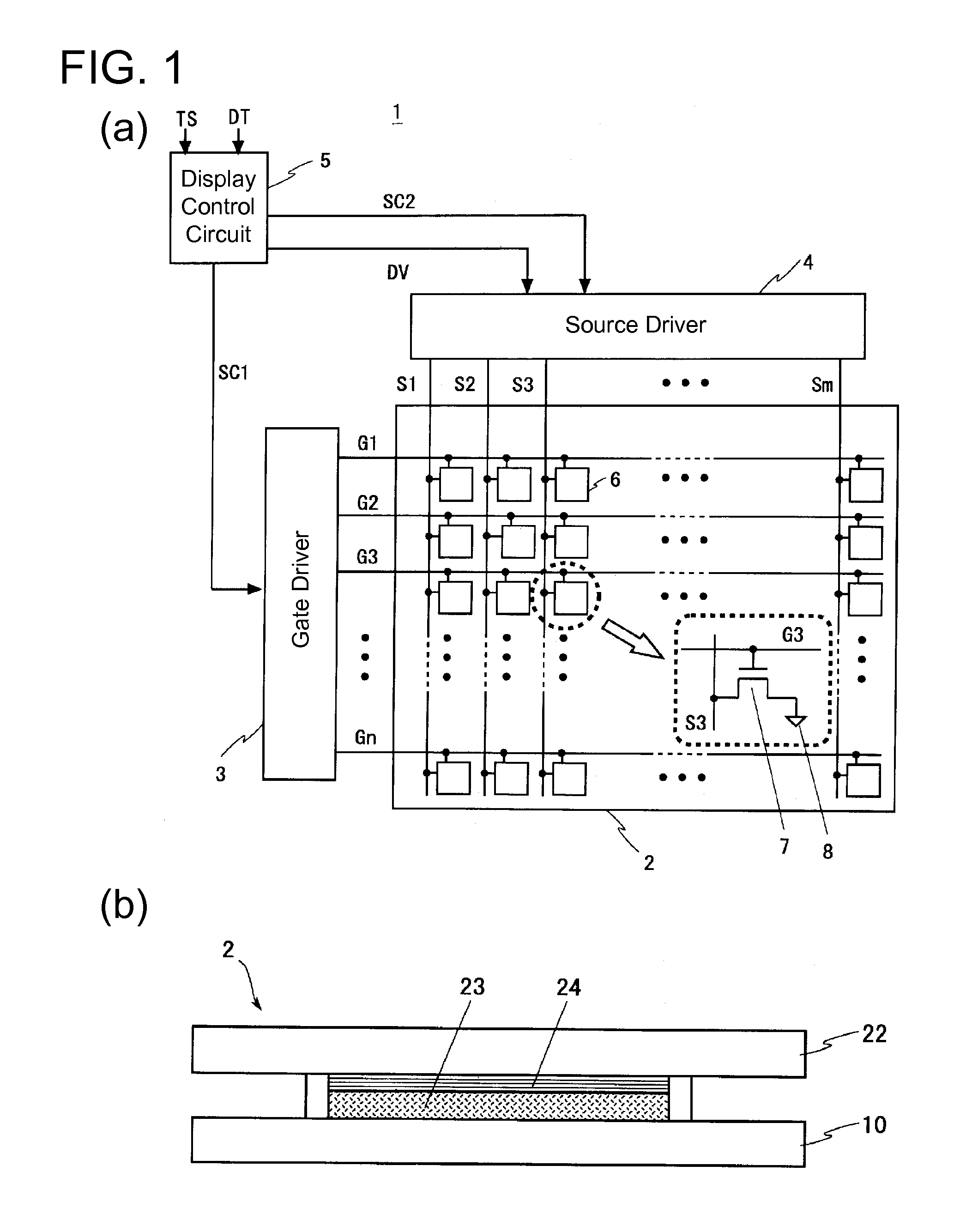

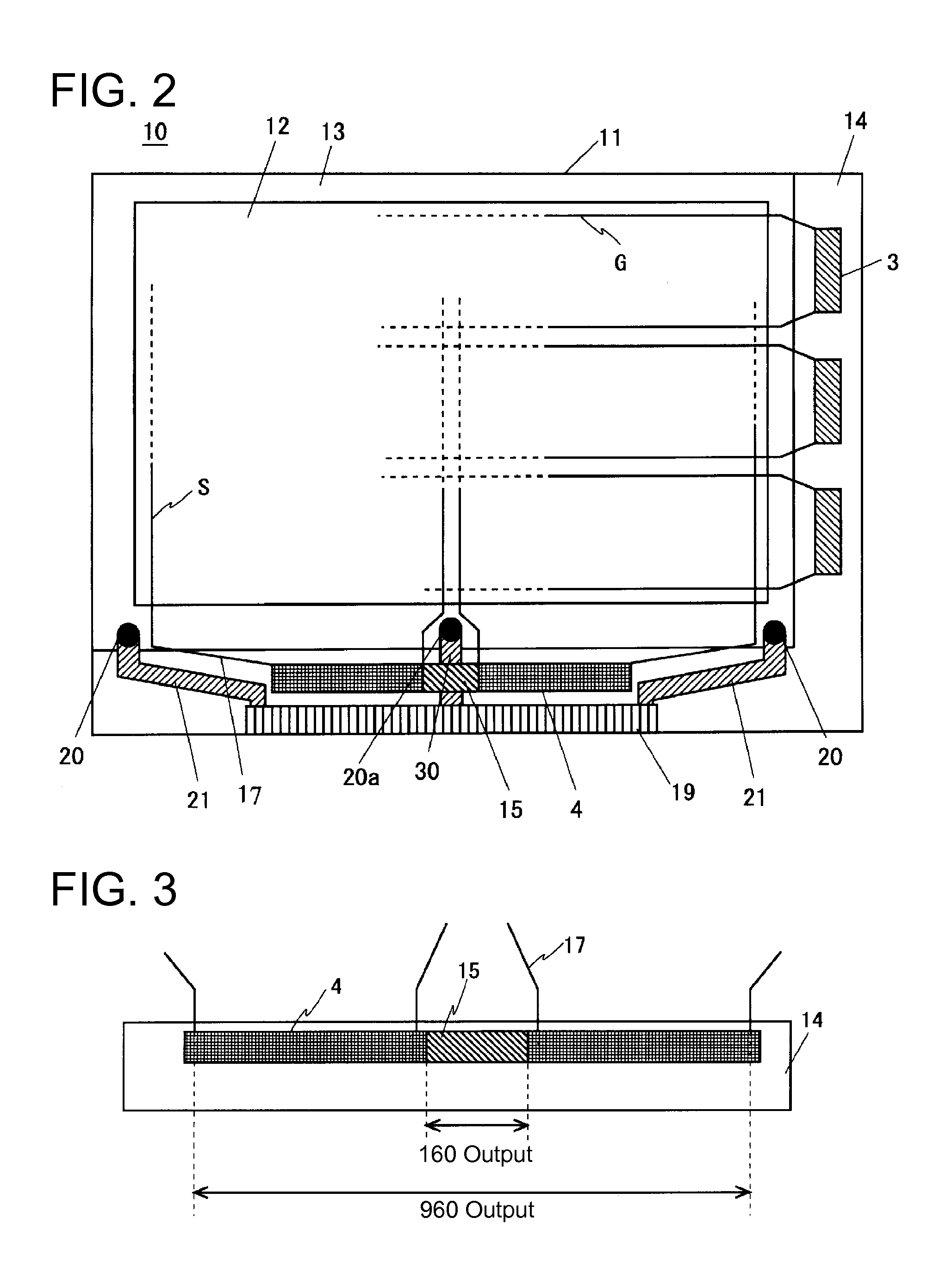

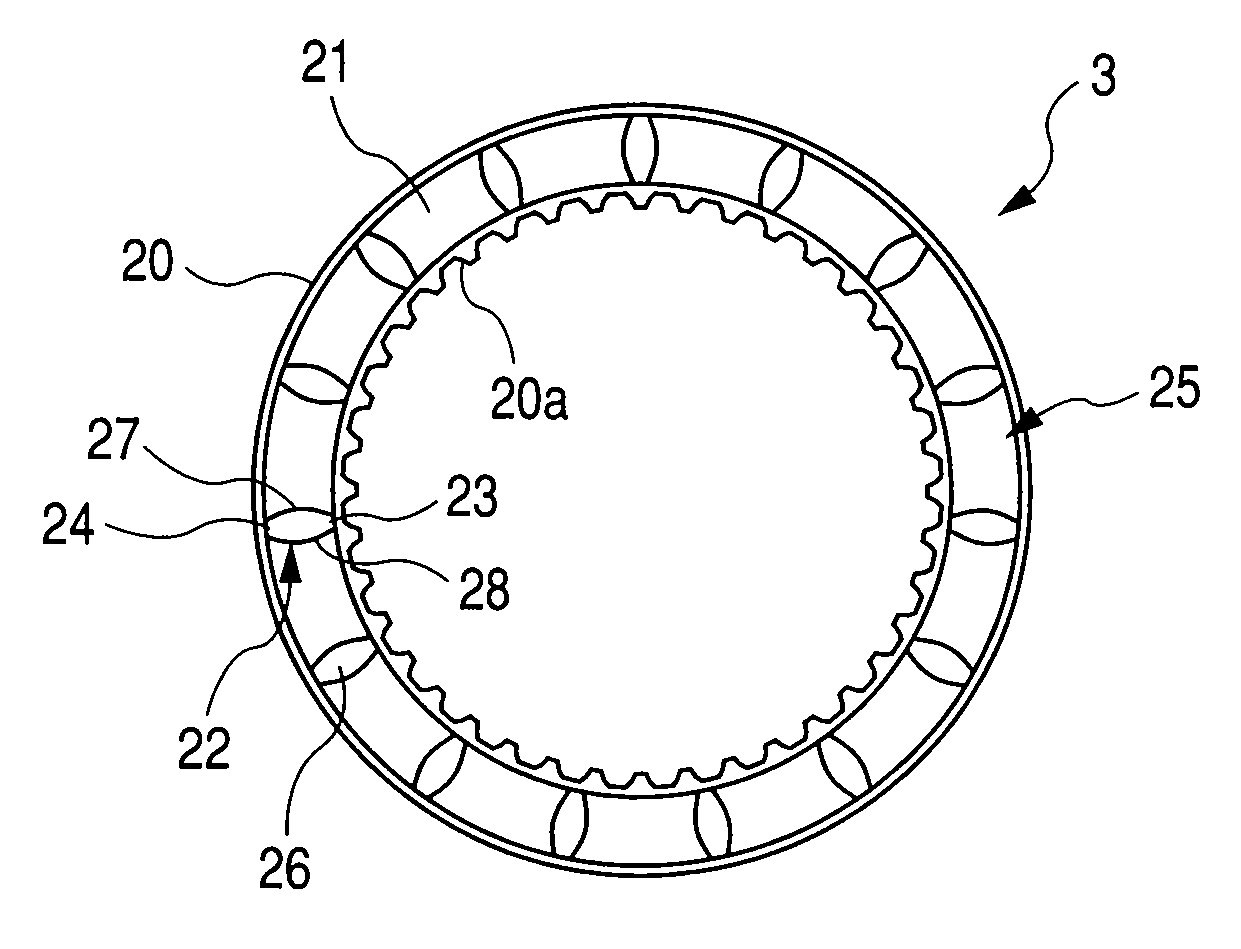

Display device and method of manufacturing same

ActiveUS20130265513A1Prevent decrease in display quality in displayIncrease valueStatic indicating devicesSemiconductor/solid-state device manufacturingShadowingsDisplay device

Provided are a display device and a method of manufacturing same, whereby deterioration in image display quality due to display unevenness or shadowing is avoided. An open region is disposed in a source driver mounting region in a position thereof that corresponds to a remaining output region 15 of a source driver 4. Next, a common signal line 30, which connects an FPC connecting region 19 to a common transfer electrode 20a, is formed passing through the open region. It is thus possible to shorten the length of the common signal line 30, and to position the common transfer electrode 20a in a desired location. Consequently, variation in the common signal rounding for each position on a common electrode is mitigated, making it possible to minimize image display unevenness. The width of the open region is also increased, allowing the width of the common signal line 30 to also be increased. Consequently, the load on the common signal line 30 can be reduced.

Owner:SHARP KK

Wet type friction plate

InactiveUS20080223686A1Improve heat resistanceEffective lubricationFluid actuated clutchesFriction clutchesEngineeringMechanical engineering

The present invention provides a wet type friction plate having a friction surface formed by fixing a friction material to a substantially annular core plate in an annular arrangement, in which a plurality of grooves extending through from an inner diameter portion to an outer diameter portion is formed in the friction surface and at least one of both side portions of the friction material defining the groove is formed as an arc configuration and the groove has a radial intermediate portion having a width greater than those of the inner diameter portion and the outer diameter portion.

Owner:NSK WARNER

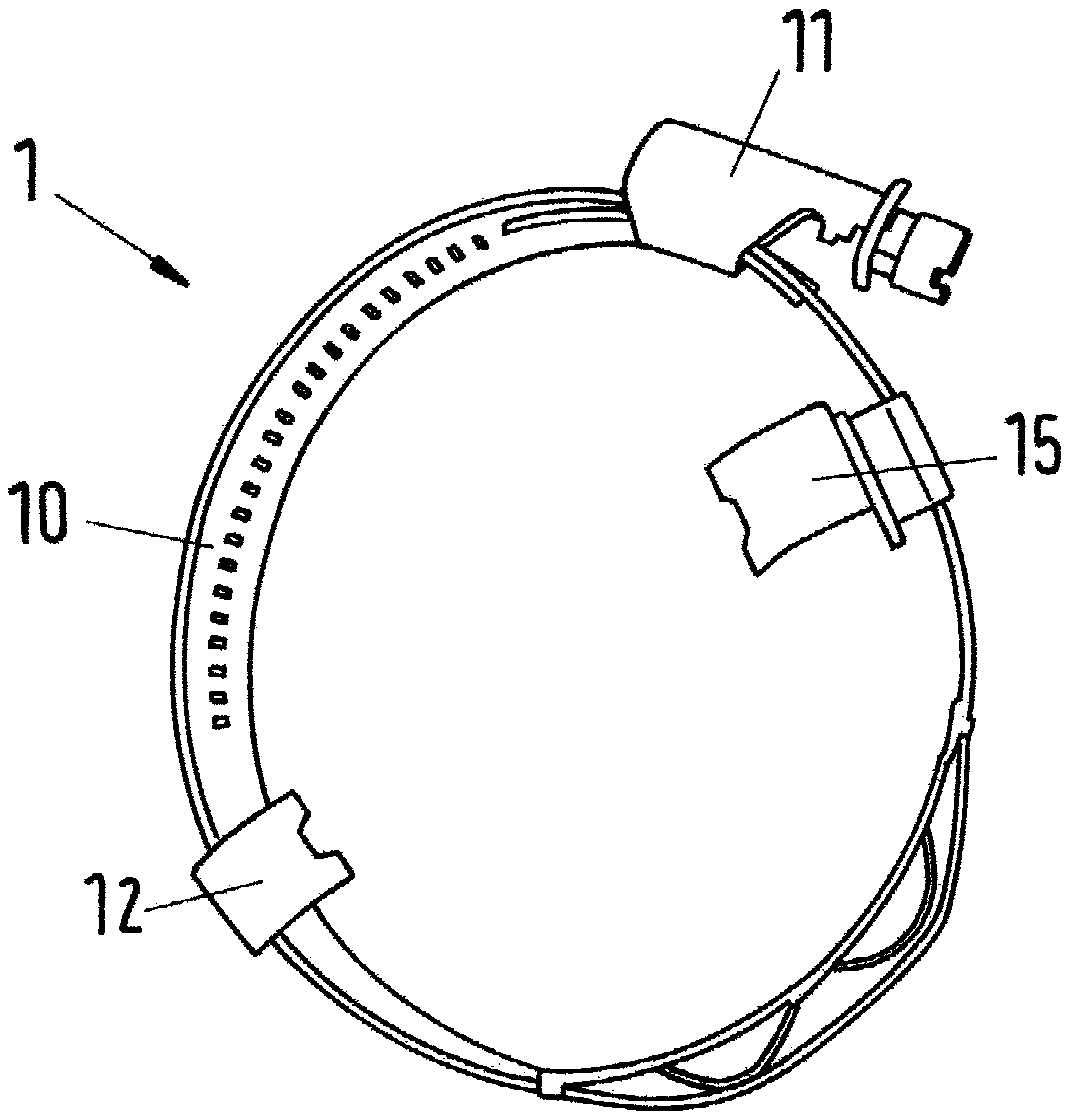

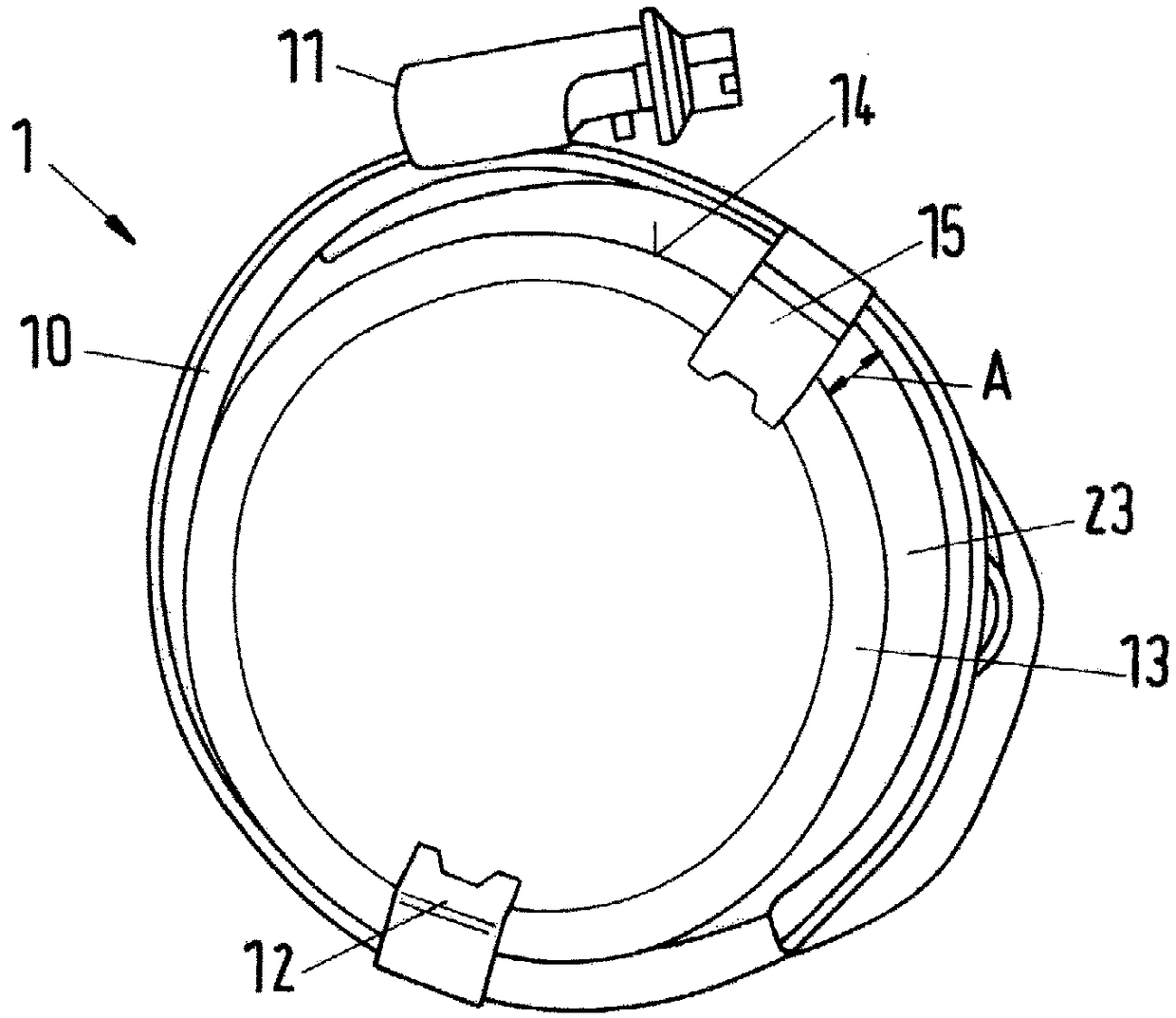

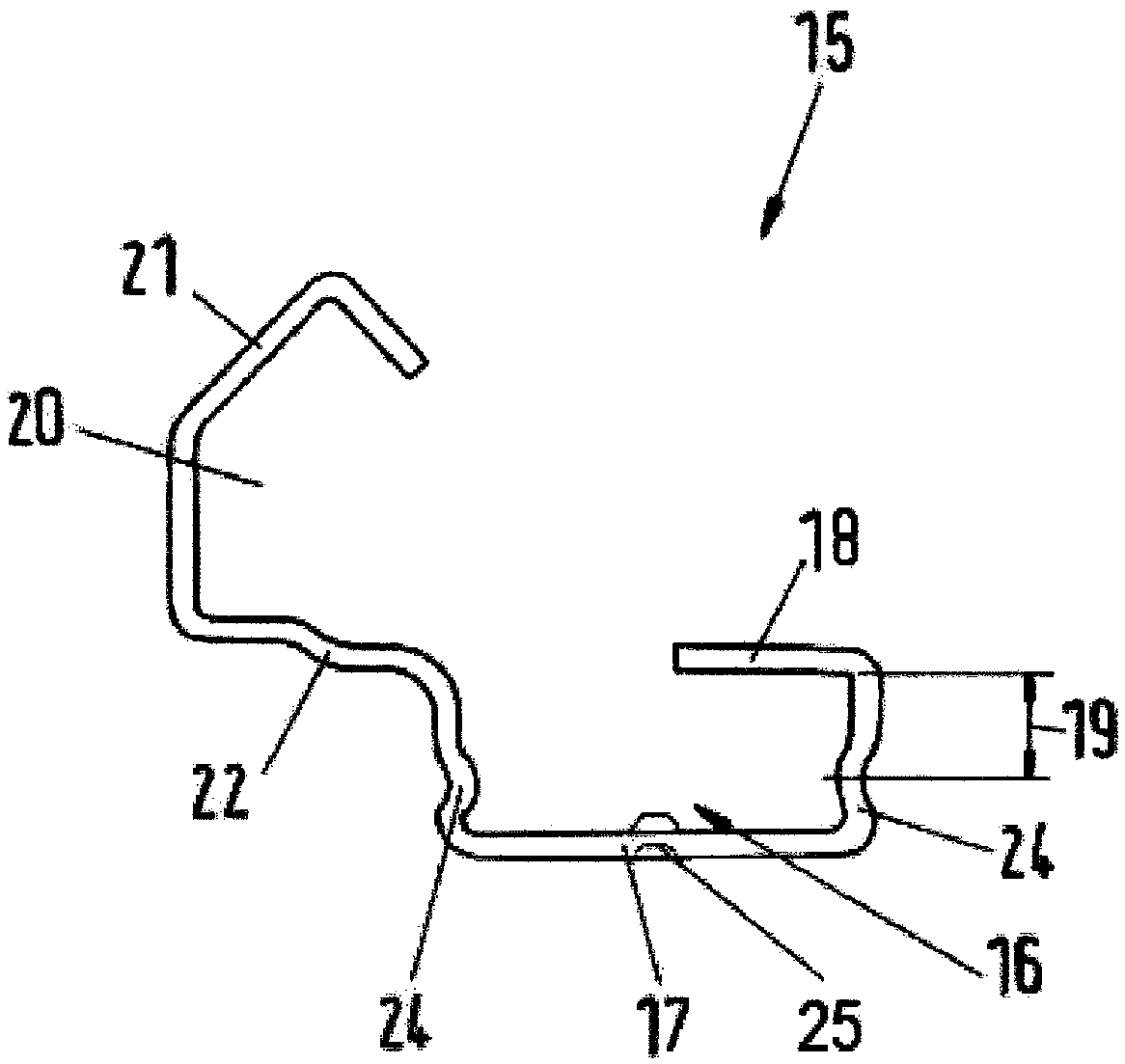

Hose clamp

ActiveCN109154412AAvoid leaningEvenly distributedFriction grip releasable fasteningsHose connectionsEngineeringMechanical engineering

Owner:NORMA GERMANY GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com