Lifting mechanism for a sliding roof and a vehicle roof with such mechanism

A technology for connecting mechanisms and vehicles, which can be used in transportation and packaging, roofs, vehicle parts, etc., and can solve the problem of large installation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

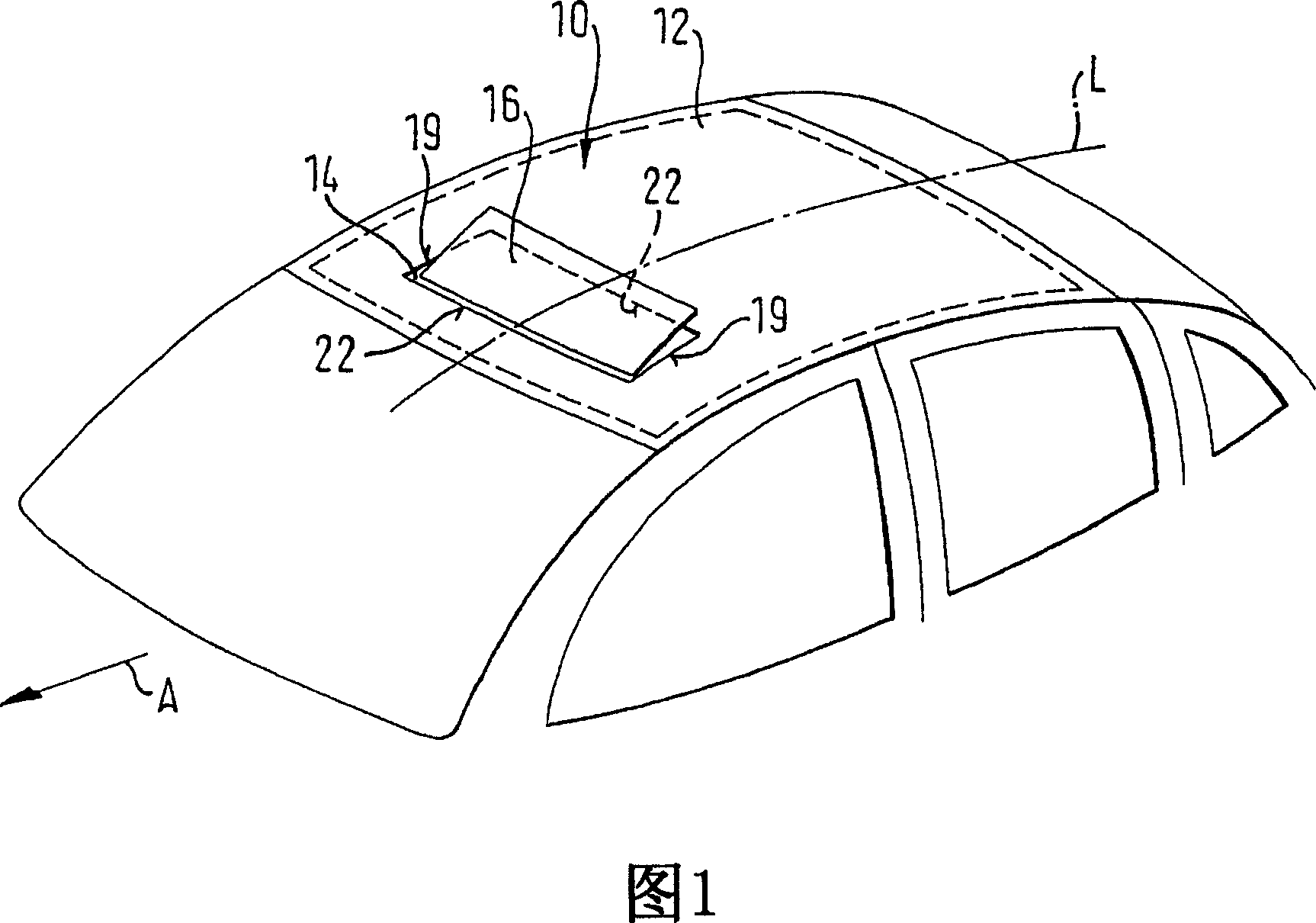

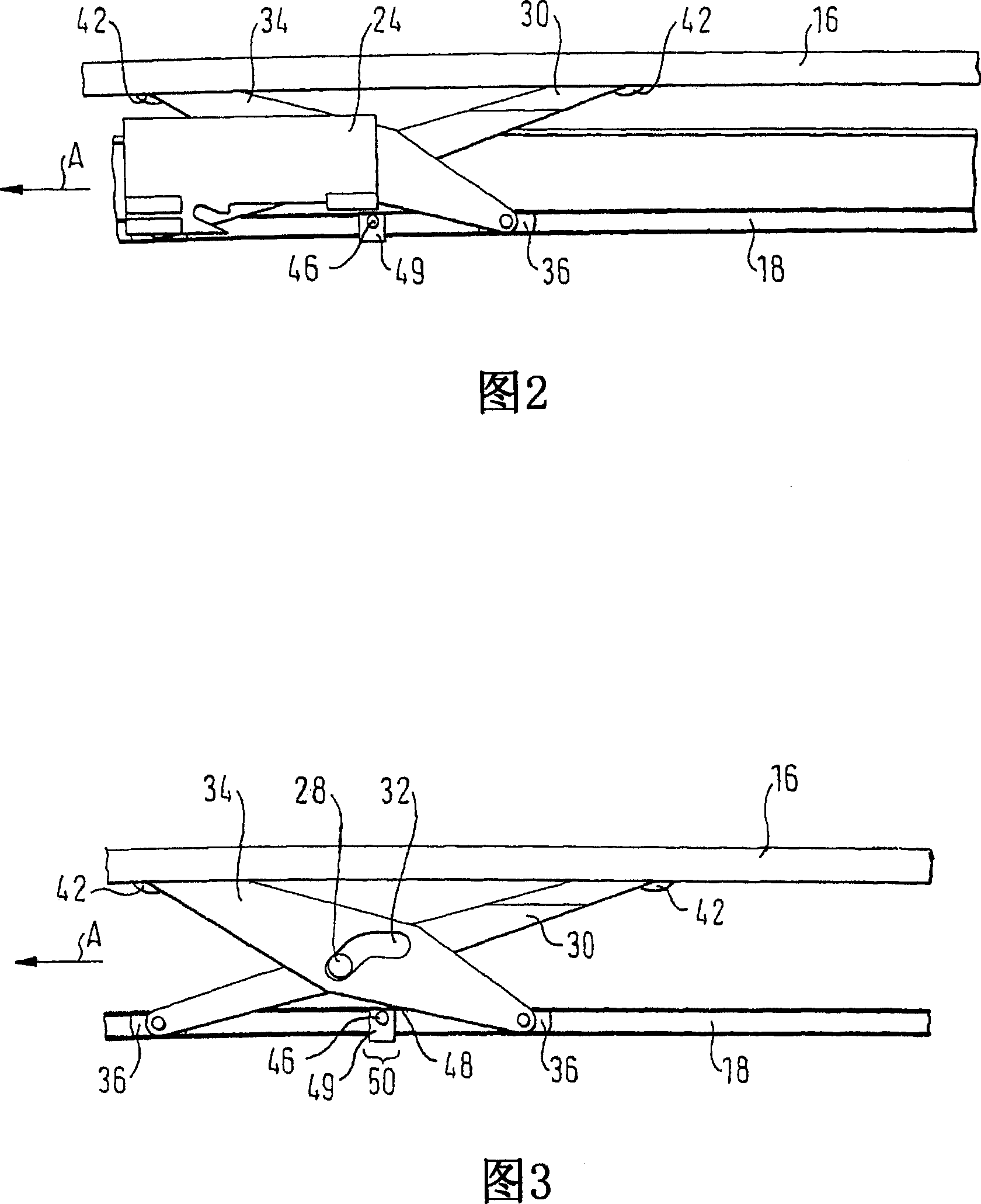

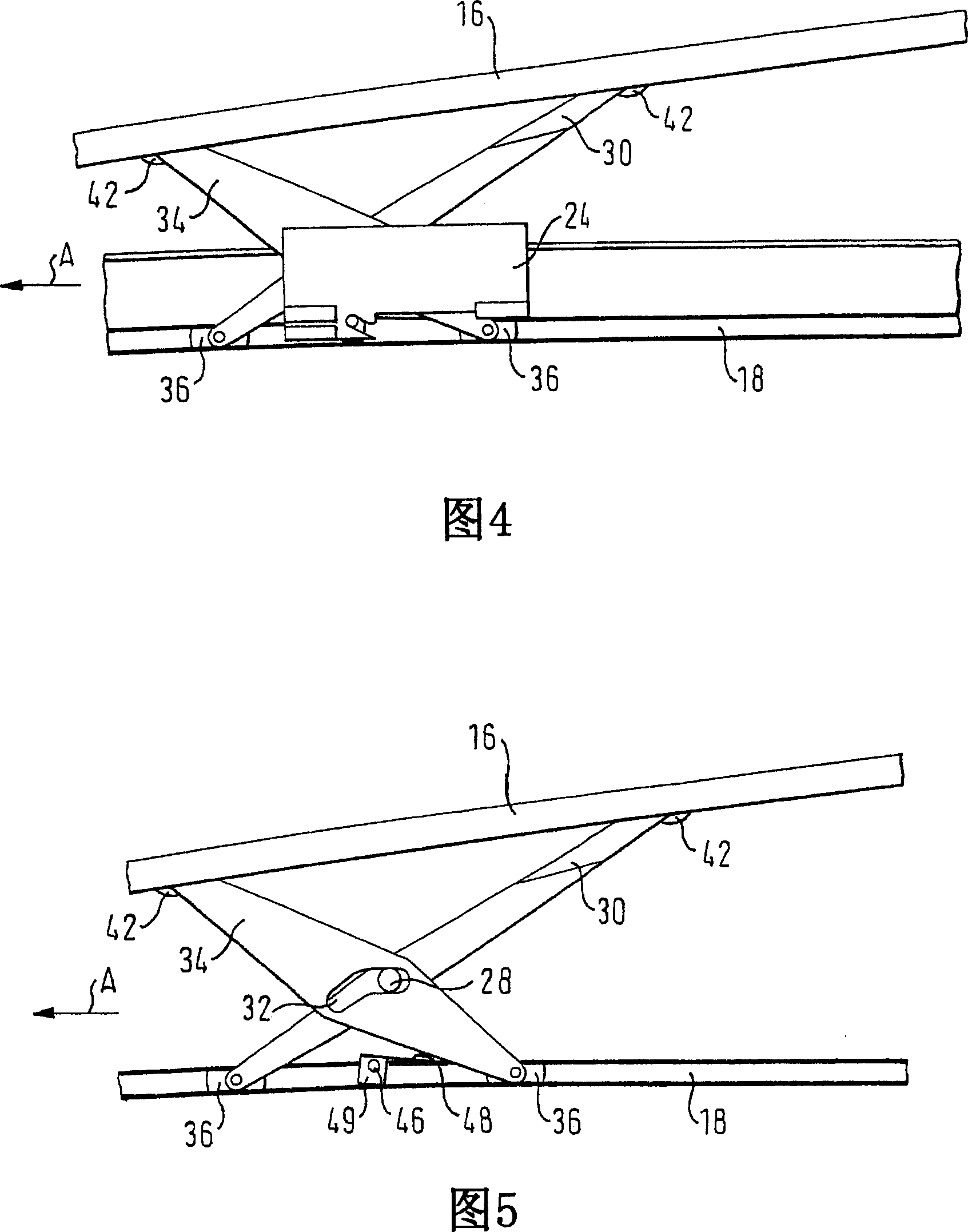

[0034] Figure 1 schematically shows a vehicle roof 10 comprising a stationary roof portion 12 in which a roof opening 14 is arranged, said roof opening 14 being closable by a cover 16 (cf Figures 2 and 3) Or exposed (see FIG. 6), the cover 16 is made of a visually transparent or opaque material. In Figures 1, 4 and 5, the cover 16 is shown in the venting position, with the cover 16 raised at its rear end.

[0035] The roof 10 shown is a sliding roof, in particular a spoiler roof, in which the cover 16 is moved over the stationary roof portion 12 . The roof 10 can also be embodied as comprising a sliding-tilt roof; in this case (not shown), the cover 16 will be moved to be positioned under the stationary roof portion 12 .

[0036] On each side of the top opening 14, the lifting mechanism for the cover 16 has a rail 18 (Figs. 1 to 6) affixed to the stationary top part 12 surrounding the top opening 14 and extending The opening 14 extends with a longitudinal side 19 which exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com