Automatic correcting belt conveyor

A tape machine, automatic technology, applied in the directions of sending objects, thin material handling, transportation and packaging, etc., can solve the problems of poor product surface finish, cavity thickness deviation, uneven product edge thickness, etc., to eliminate product thickness unevenness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

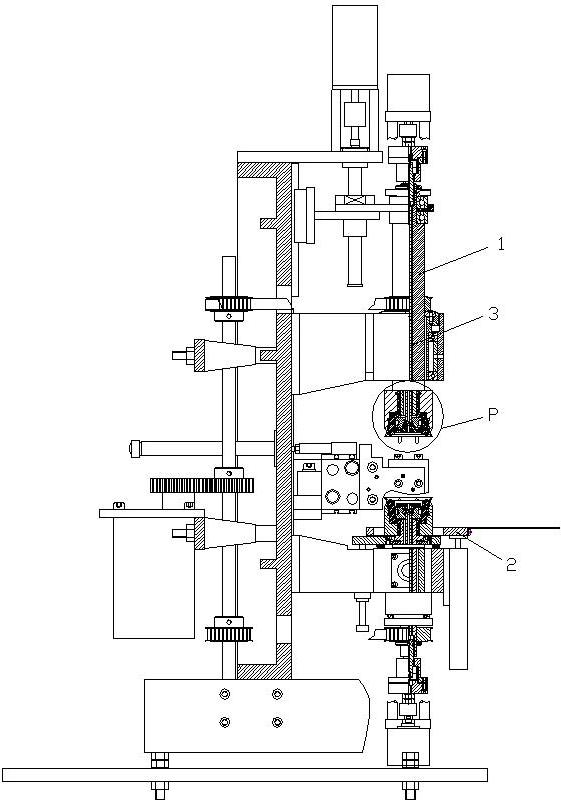

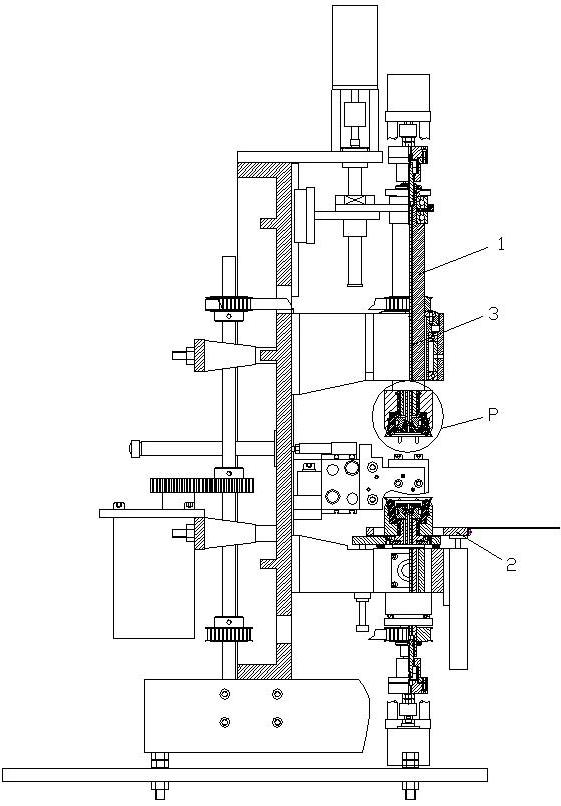

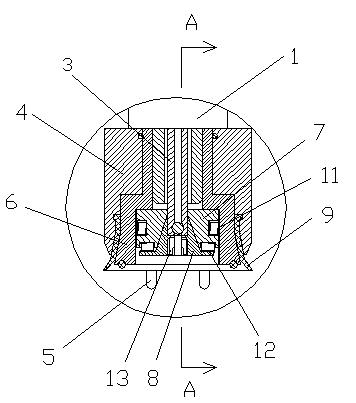

[0021] figure 1 It is a cross-sectional view of the overall structure of the automatic straightening tape machine of the present invention; figure 2 for figure 1 Enlarged view of part P (enlarged view of suction head); image 3 for figure 2 Sectional view along A-A.

[0022] As shown in the figure, the automatic straightening tape machine of the present invention includes a main shaft 1, a workbench 2, and a vacuum pull rod 3 coaxially arranged in the main shaft 1. The lower end of the main shaft 1 and the workbench 2 are respectively provided with a mold for absorbing the lens. The suction head of the upper and lower dies, the suction head includes a suction head jacket 4, a die correction positioning rod 5, a positioning rod limit sleeve 6, a positioning rod locking block 7, a locking block extrusion head 8 and an elastic suction cup 9;

[0023] The locking block extrusion head 8 is fixedly arranged on the lower end of the vacuum pull rod 3, the positioning rod locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com