Semiconductor device

A semiconductor and device technology, applied in the field of semiconductor devices, can solve the problems of uneven current, the reduction of the maximum cut-off current of semiconductor chips, and the inability to cut off the current of MOS gate, so as to eliminate fluctuations and unevenness, increase the maximum cut-off current, and reduce the number of screws. fixed number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

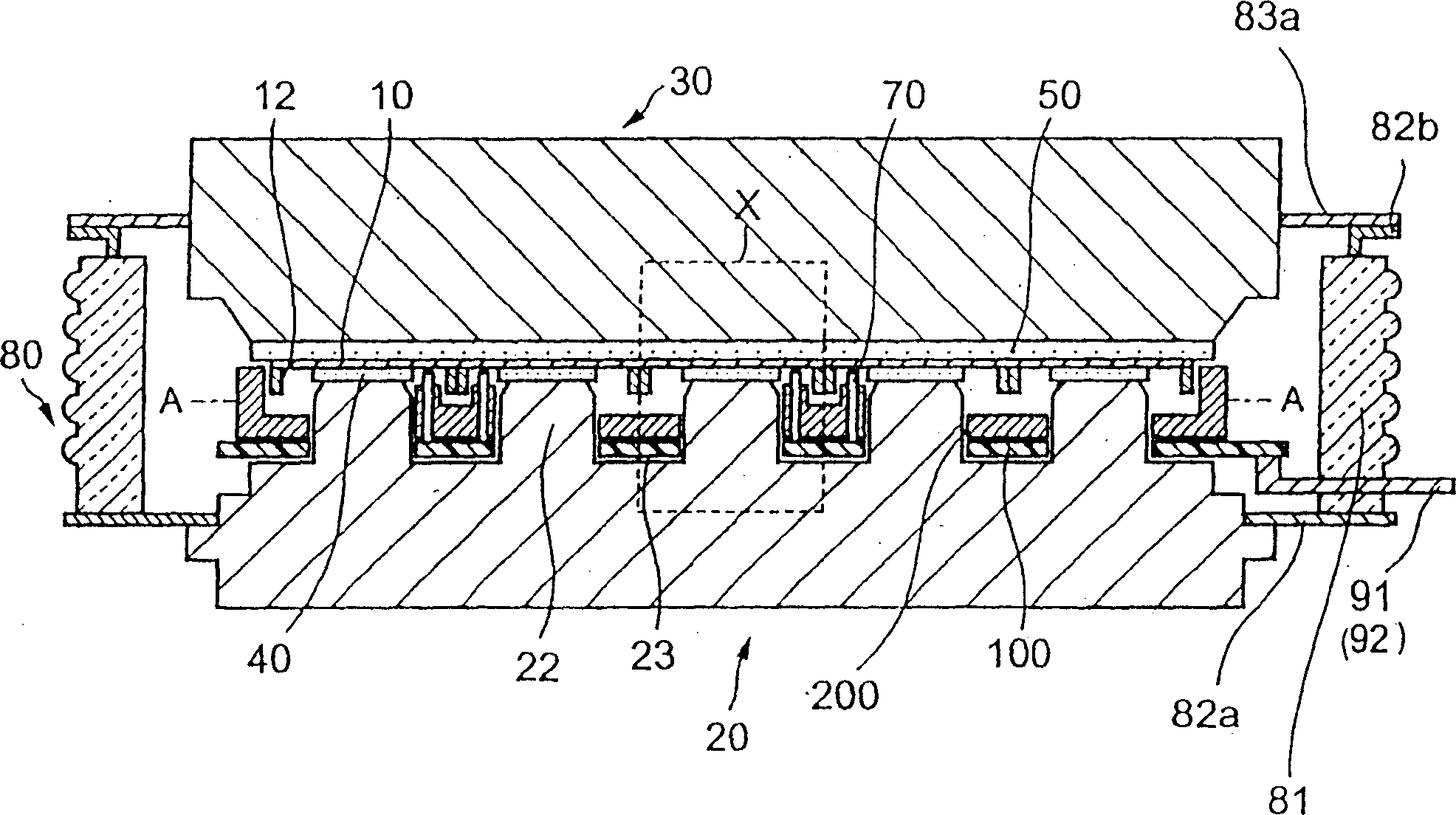

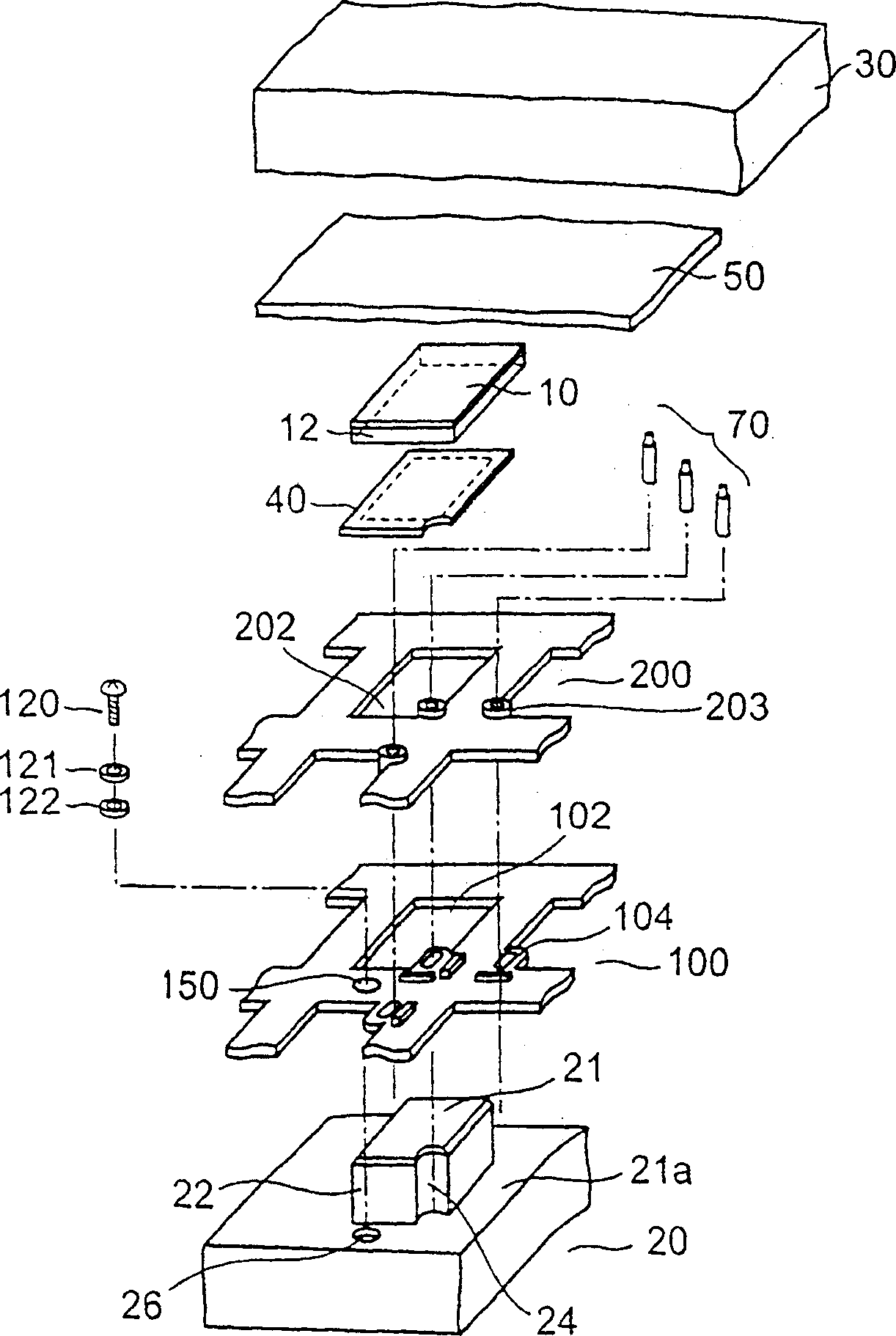

[0085] First, refer to figure 1 , the outline of the configuration of the power control semiconductor device will be described. figure 1 It is a sectional view of the power control semiconductor device according to the embodiment of the present invention.

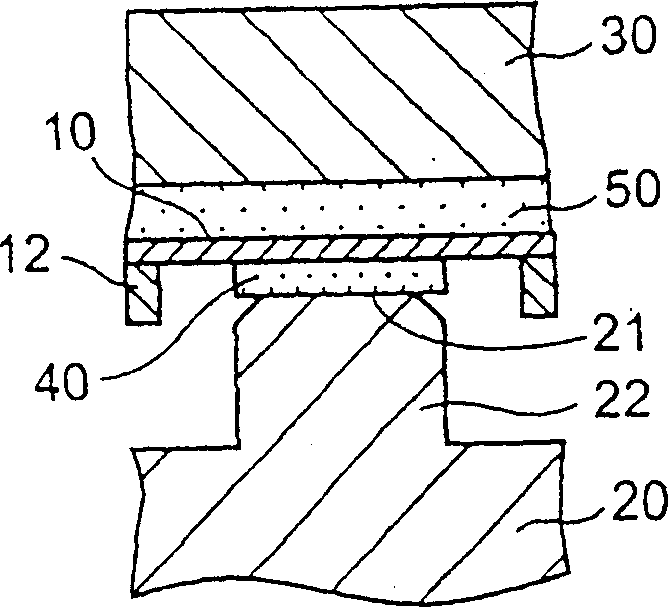

[0086] That is to say, the semiconductor device for power control, for example, the second main electrode member (hereinafter referred to as the emitter copper post) 20 and the first main electrode member (hereinafter referred to as the collector copper post) having a planar square-shaped column 22 and a concave portion 23 Columns) 30 are arranged in an opposed state. Semiconductor chips 10 such as IGBT and IEGT are arranged between each column 22 of the emitter copper column 20 and the above-mentioned collector copper column 30 through molybdenum (Mo) buffer plates (hereinafter referred to as Mo buffer plates) 40, 50, The semiconductor chip 10 is electrically and thermally connected to the emitter copper pillar 20 and ...

no. 2 Embodiment approach

[0161] refer to Figure 19 , and the power control semiconductor device according to the second embodiment of the present invention will be described in detail.

[0162] Figure 19 It is a schematic sectional view showing the main part of the power control semiconductor device according to the second embodiment. In the figure, the same reference numerals are assigned to the same parts as those of the first embodiment, and repeated description of these parts will be omitted, and only different parts will be described.

[0163] In this embodiment and the above-mentioned first embodiment, the contact between the emitter copper post 20 and the emitter wiring pattern 110 of the circuit wiring board 100 is connected by the circuit board mounting screw (second connection conductor) 120 in the above-mentioned first embodiment. , but this embodiment is different in that the emitter pin (second connection conductor) 300 is used for connection.

[0164] That is, in the emitter wiring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com