Aluminum alloy material for mobile phone structural part and preparation method of aluminum alloy material

A technology of aluminum alloy material and mobile phone structure, applied in the field of aluminum alloy processing, can solve the problems of poor specular effect, low strength, poor surface decoration material effect, etc., and achieve good surface treatment adaptability, improved alloy strength, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

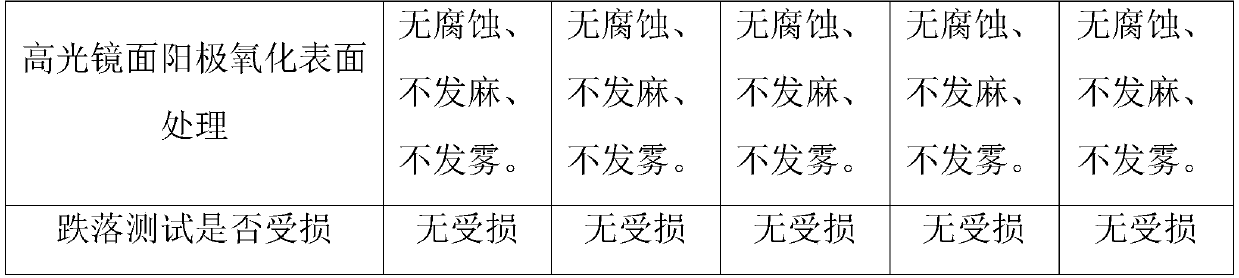

Examples

Embodiment 1

[0037] An aluminum alloy material used for mobile phone structural parts, the composition and mass percentage of the aluminum alloy material are: Mg 0.80%, Si 0.52%, Cu 0.52%, Mn 0.12%, Zr 0.05%, Fe≤0.1%, others The sum of impurities is ≤0.10%, and the balance is Al.

[0038] A method for preparing an aluminum alloy material for mobile phone structural parts as described above, comprising the following steps:

[0039] A. Smelting and refining: Melting is carried out according to the composition and mass percentage requirements of the aluminum alloy material, and refined in argon gas with a purity of 99.99%;

[0040] B. On-line refinement: adding a refiner to the refined aluminum alloy material in step A for on-line refinement;

[0041] C. On-line degassing and impurity removal: degas the aluminum alloy material after online refinement in step B, and remove impurities through a composite filter device;

[0042] D. Casting: semi-continuous water-cooled casting is carried out o...

Embodiment 2

[0054] An aluminum alloy material used for mobile phone structural parts, the composition and mass percentage of the aluminum alloy material are: Mg 0.84%, Si 0.56%, Cu 0.56%, Mn 0.16%, Zr 0.08%, Fe≤0.1%, others The sum of impurities is ≤0.10%, and the balance is Al.

[0055] A method for preparing an aluminum alloy material for mobile phone structural parts as described above, comprising the following steps:

[0056] A. Smelting and refining: Melting is carried out according to the composition and mass percentage requirements of the aluminum alloy material, and refined in argon gas with a purity of 99.99%;

[0057] B. On-line refinement: adding a refiner to the refined aluminum alloy material in step A for on-line refinement;

[0058] C. On-line degassing and impurity removal: degas the aluminum alloy material after online refinement in step B, and remove impurities through a composite filter device;

[0059] D. Casting: semi-continuous water-cooled casting is carried out o...

Embodiment 3

[0071] An aluminum alloy material used for mobile phone structural parts, the composition and mass percentage of the aluminum alloy material are: Mg 0.87%, Si 0.59%, Cu 0.59%, Mn 0.20%, Zr 0.11%, Fe≤0.1%, others The sum of impurities is ≤0.10%, and the balance is Al.

[0072] A method for preparing an aluminum alloy material for mobile phone structural parts as described above, comprising the following steps:

[0073] A. Smelting and refining: Melting is carried out according to the composition and mass percentage requirements of the aluminum alloy material, and refined in argon gas with a purity of 99.99%;

[0074] B. On-line refinement: adding a refiner to the refined aluminum alloy material in step A for on-line refinement;

[0075] C. On-line degassing and impurity removal: degas the aluminum alloy material after online refinement in step B, and remove impurities through a composite filter device;

[0076] D. Casting: semi-continuous water-cooled casting is carried out o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com