Special hoisting tool for replacing capacitor bank

A technology for hoisting tools and capacitor banks, which is applied to hoisting devices, portable lifting devices, cranes, etc., can solve the problems of time-consuming and labor-intensive replacement process, increase operating costs, and reduce work efficiency, so as to save time and effort in operation and low manufacturing cost , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

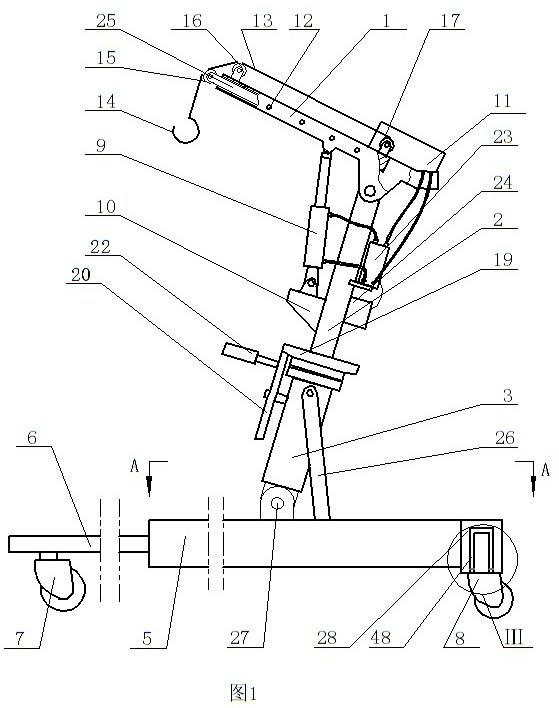

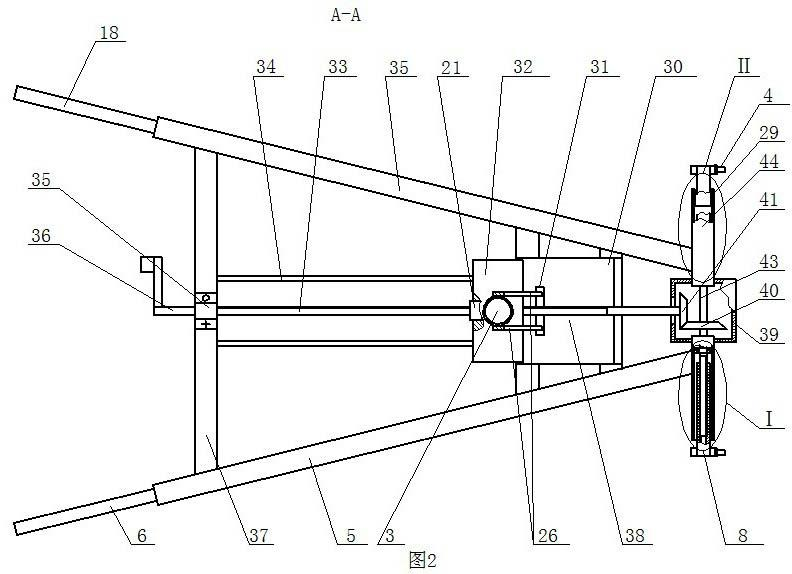

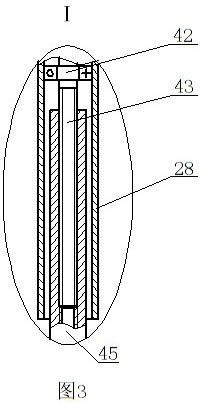

[0009] The special hoisting tool for replacing capacitor banks according to the present invention includes a first outrigger cover 5 and a second outrigger cover 35, and a connecting rod 37 and a bracket 30 are installed between the first outrigger cover 5 and the second outrigger cover 35, Connecting rod 37 is positioned at support 30 front parts, as figure 2 As shown, the first leg cover 5, the second leg cover 35, the connecting rod 37 and the bracket 30 are connected to form a triangular base with a wide front and a narrow rear; the rear end of the second leg cover 35 is equipped with a second horizontal support cover 44, The rear end of the first leg cover 5 is equipped with the first cross support sleeve 28, and the gear box 39 is fixedly installed between the second cross support sleeve 44 and the first cross support sleeve 28, the second cross support sleeve 44, the first cross support sleeve 28 and the second leading screw 43 are installed in the gear case 39, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com