Magnelium base layer-shaped double-hydroxide ultraviolet barrier material used in anti-aging asphalt

A technology of double hydroxide and UV blocking, which is applied in the preparation of aging-resistant asphalt, and in the field of magnesium-aluminum-based double hydroxide UV-blocking materials for aging-resistant asphalt, which can solve the problems of poor UV aging resistance and improve the anti-aging UV aging performance, lower pass rate, good UV barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

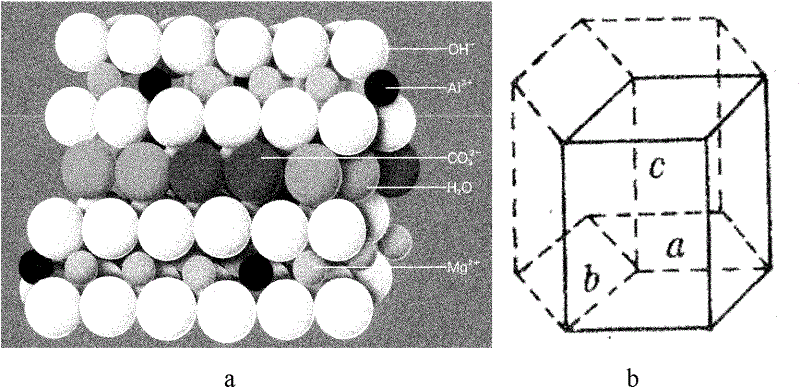

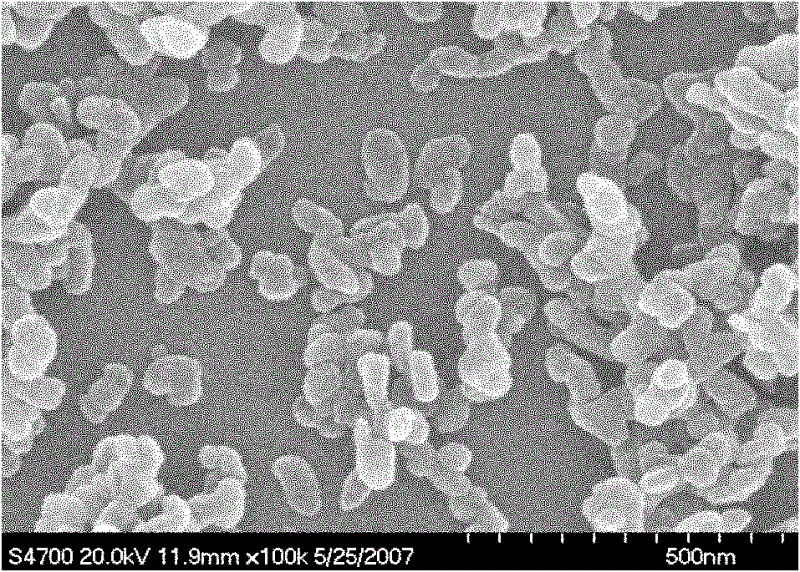

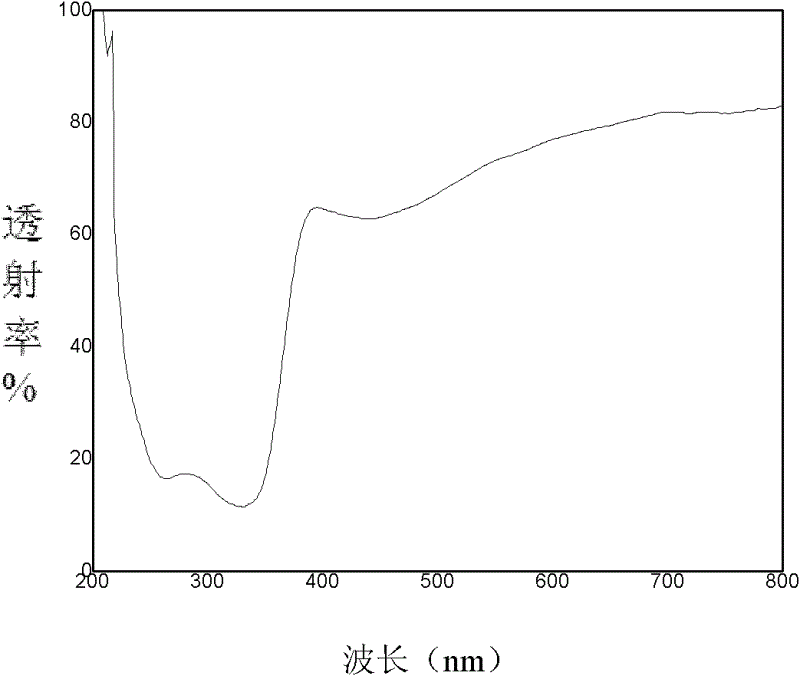

[0020] MgCl 2 and AlCl 3 Mixed salt solution is formulated according to the ratio of Mg / Al=2, so that [Mg 2+ ]=1.5mol / L, NaOH and Na 2 CO 3 Press n(Na 2 CO 3 ) / n(Al 3+ )=2, n(NaOH) / [n(Mg 2+ )+n(Al 3+ )]=2.1 ratio is made into mixed alkali solution, two kinds of solutions are added to rotating liquid film reactor simultaneously, and the slurry obtained adds templating agent n-octane-sodium dodecylsulfonate, n-octane and dodecyl The addition of sodium sulfonate is 0.5% of the solid content of the slurry, the ratio of the amount of n-octane and sodium dodecylsulfonate is 1, then stir and heat to 80°C in the flask, and react for 1h after Washing, wet modification with 2% sodium carboxymethylcellulose, and drying to obtain a magnesium-aluminum-based layered double hydroxide UV barrier material for aging-resistant asphalt, the specific composition of which is: Mg 0.67 Al 0.33 (OH) 2 (CO 3 ) 0.17 0.6H 2 O, its particle size in the a and b directions is 0.2 μm, and the p...

Embodiment 2

[0023] MgSO 4 and Al 2 (SO 4 ) 3 Mixed salt solution is formulated according to the ratio of Mg / Al=3, so that [Mg 2+ ]=1.9mol / L, NaOH and Na 2 CO 3 Press n(Na 2 CO 3 ) / n(Al 3+ )=3, n(NaOH) / [n(Mg 2+ )+n(Al 3+ )]=2.4 ratio is made into mixed alkali solution, two kinds of solutions are added to rotating liquid membrane reactor simultaneously, and the slurry obtained adds templating agent n-octane-sodium dodecylsulfonate, n-octane and dodecyl The amount of sodium sulfonate added is 3% of the solid content of the slurry, and the ratio of the amount of n-octane to sodium dodecylsulfonate is 1.5, then stirred and heated to 100°C in a flask, and reacted for 10 hours. Washing, wet modification with 5% sodium lignosulfonate, and drying to obtain a magnesium-aluminum-based layered double hydroxide ultraviolet barrier material for aging-resistant asphalt, the specific composition of which is: Mg 0.75 al 0.25 (OH) 2 (CO 3 ) 0.12 1.2H 2 O, its particle size in the a and b di...

Embodiment 3

[0026] MgNO 3 and Al(NO 3 ) 3 Mixed salt solution is formulated according to the ratio of Mg / Al=4, so that [Mg 2+ ]=1.0mol / L, NaOH and Na 2 CO 3 Press n(Na 2 CO 3 ) / n(Al 3+ )=1.5, n(NaOH) / [n(Mg 2+ )+n(Al 3+ )]=0.9 ratio is made into mixed alkali solution, two kinds of solutions are added to rotating liquid membrane reactor simultaneously, and the slurry obtained adds templating agent n-octane and sodium dodecylsulfonate, n-octane and dodecyl The amount of sodium sulfonate added is 4.5% of the solid content of the slurry, the ratio of n-octane to sodium dodecylsulfonate is 1, and then stirred and heated to 130°C in an autoclave, after 40 hours of reaction , after washing, wet modification with 5% petroleum sulfonate, and drying, the magnesium-aluminum-based layered double hydroxide UV barrier material for aging-resistant asphalt is obtained, and its chemical composition is: Mg 0.8 al 0.2 (OH) 2 (CO 3 ) 0.1 1.8H 2 O, its particle size in the a and b directions is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com