Method for adding oxidizable alloy in molten steel

An easy-to-oxidize, strong deoxidation alloy technology, which is applied in the field of metallurgy, can solve the problems of unguaranteed mechanical properties of steel, unstable microalloy content, and increased smelting costs, achieving mechanical performance assurance, stable microalloy content, and reduced smelting costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

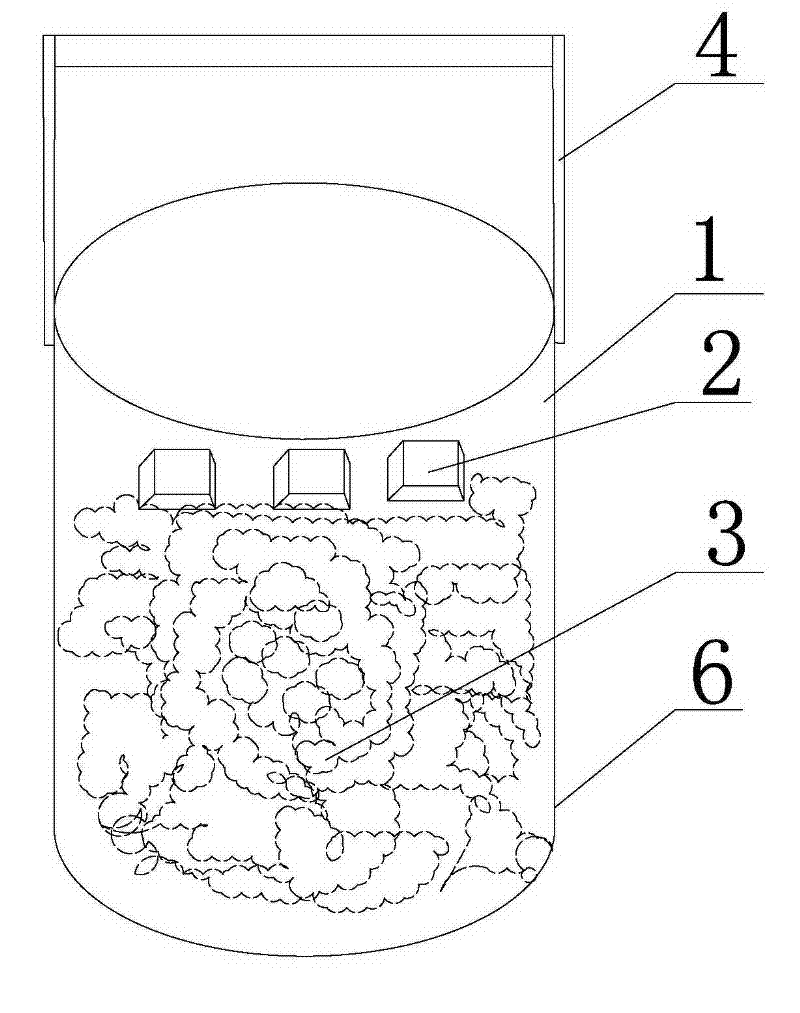

[0014] like figure 1 As shown, the alloy tank 1 used in the present invention is composed of a barrel body 6 and a high temperature resistant mop 4 at the upper end thereof. The barrel 6 is made of 5mm steel pipe, and its height is adjusted according to actual needs.

[0015] Certainly. The barrel 6 is equipped with an easily oxidizable alloy 3 and a strong deoxidized alloy layer 2 covering it.

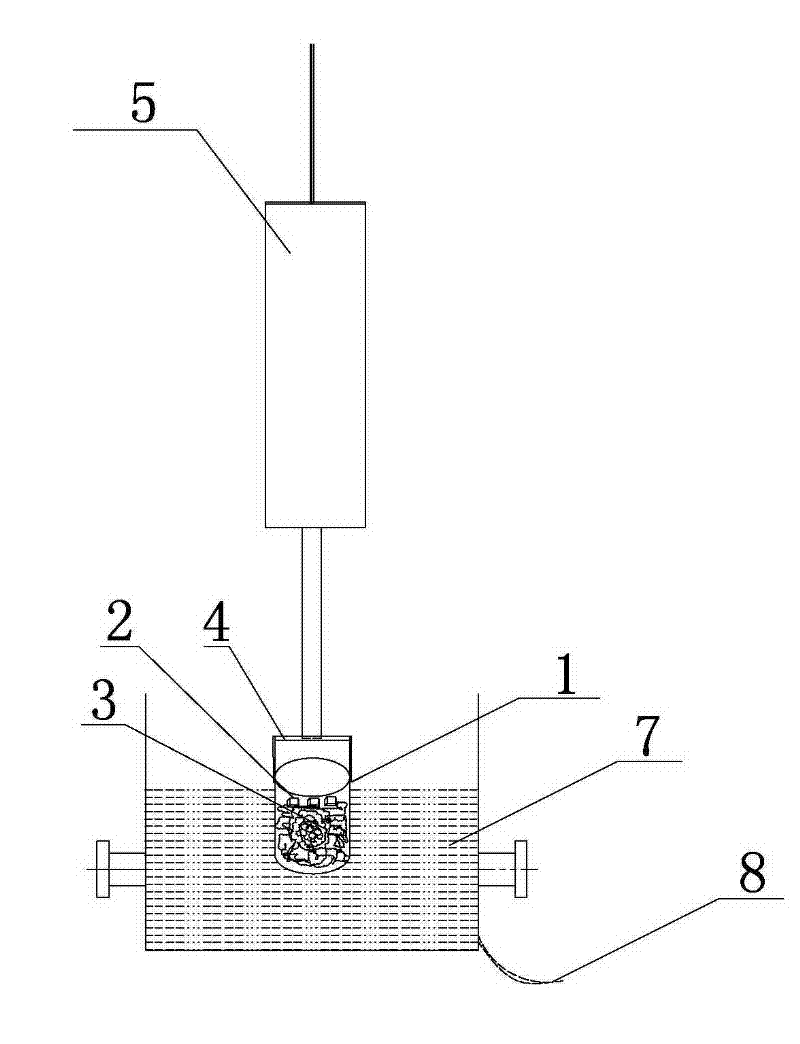

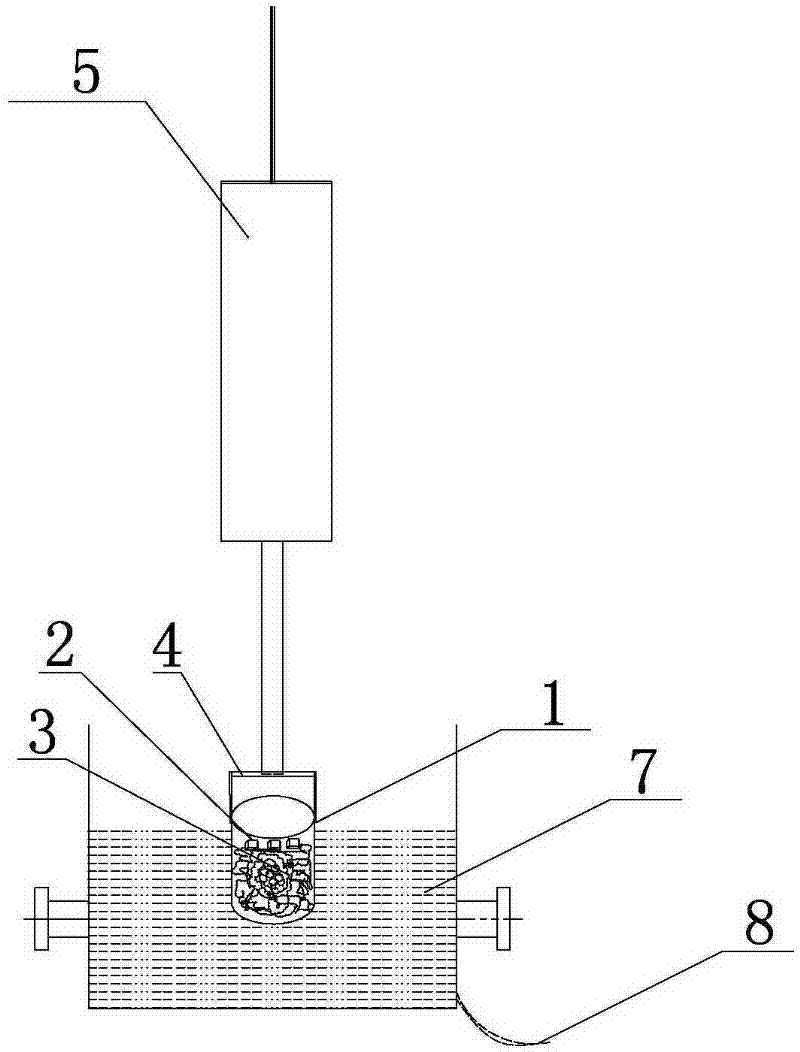

[0016] like figure 2 Shown, technological process of the present invention is as follows:

[0017] ①Take the alloy tank 1 with a high-temperature mop on the upper end, add the easily oxidizable alloy 3 into the tank according to the requirements of the molten steel alloy elements, and cover the easily oxidizable alloy with a strong deoxidized alloy layer 2. The height of the strong deoxidized alloy layer 2 is 30-50mm;

[0018] ② After the normal alloying of molten steel 7 is completed, and the bottom blowing pipe 8 starts to blow argon gas to molten steel 7, the lifting device 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com