Process for weaving knitted lace cloth and knitted lace cloth

A lace and craftsmanship technology, applied in knitting, warp knitting, textiles and papermaking, etc., can solve the problems of complicated weaving technology, difficult promotion, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

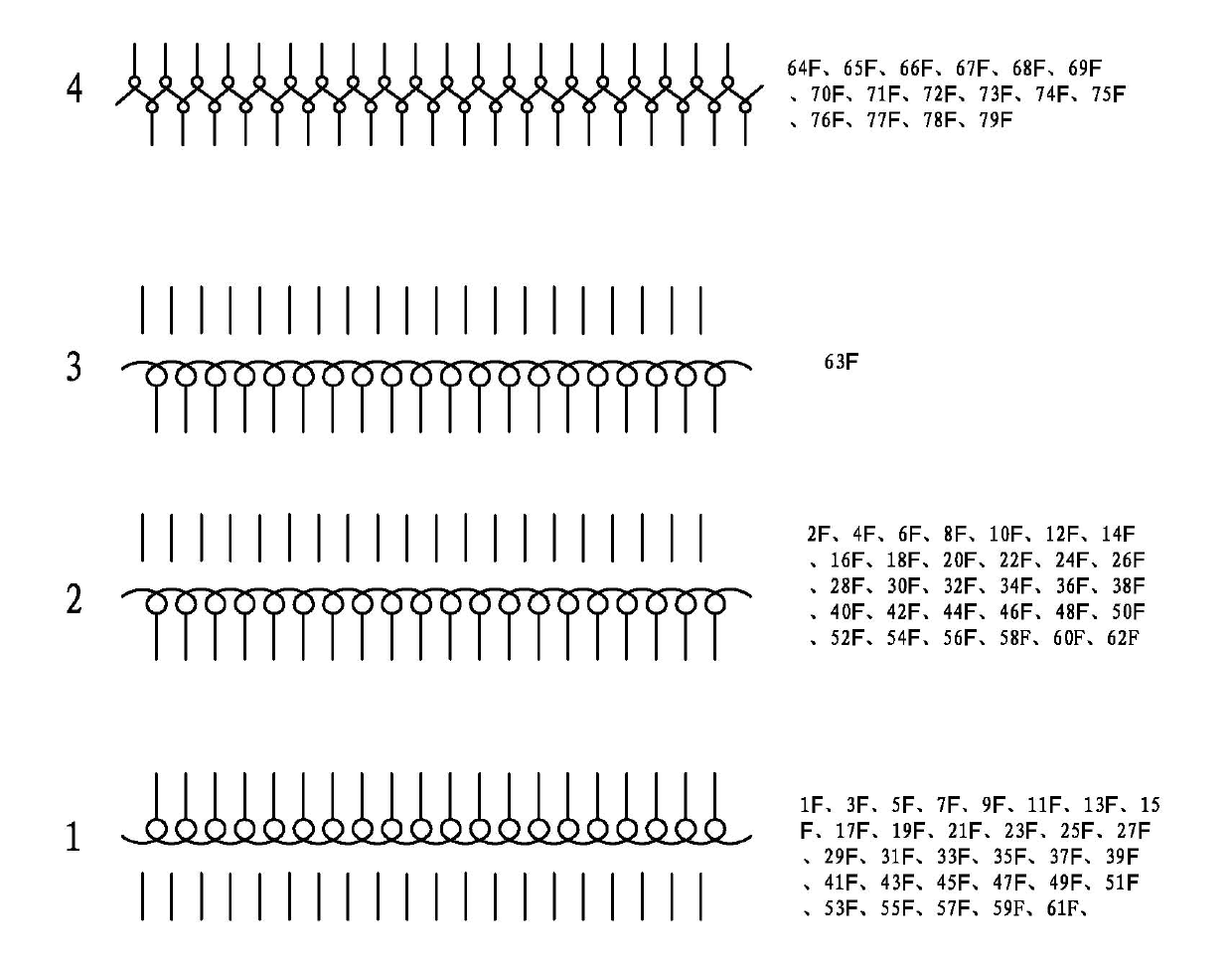

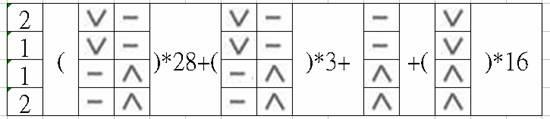

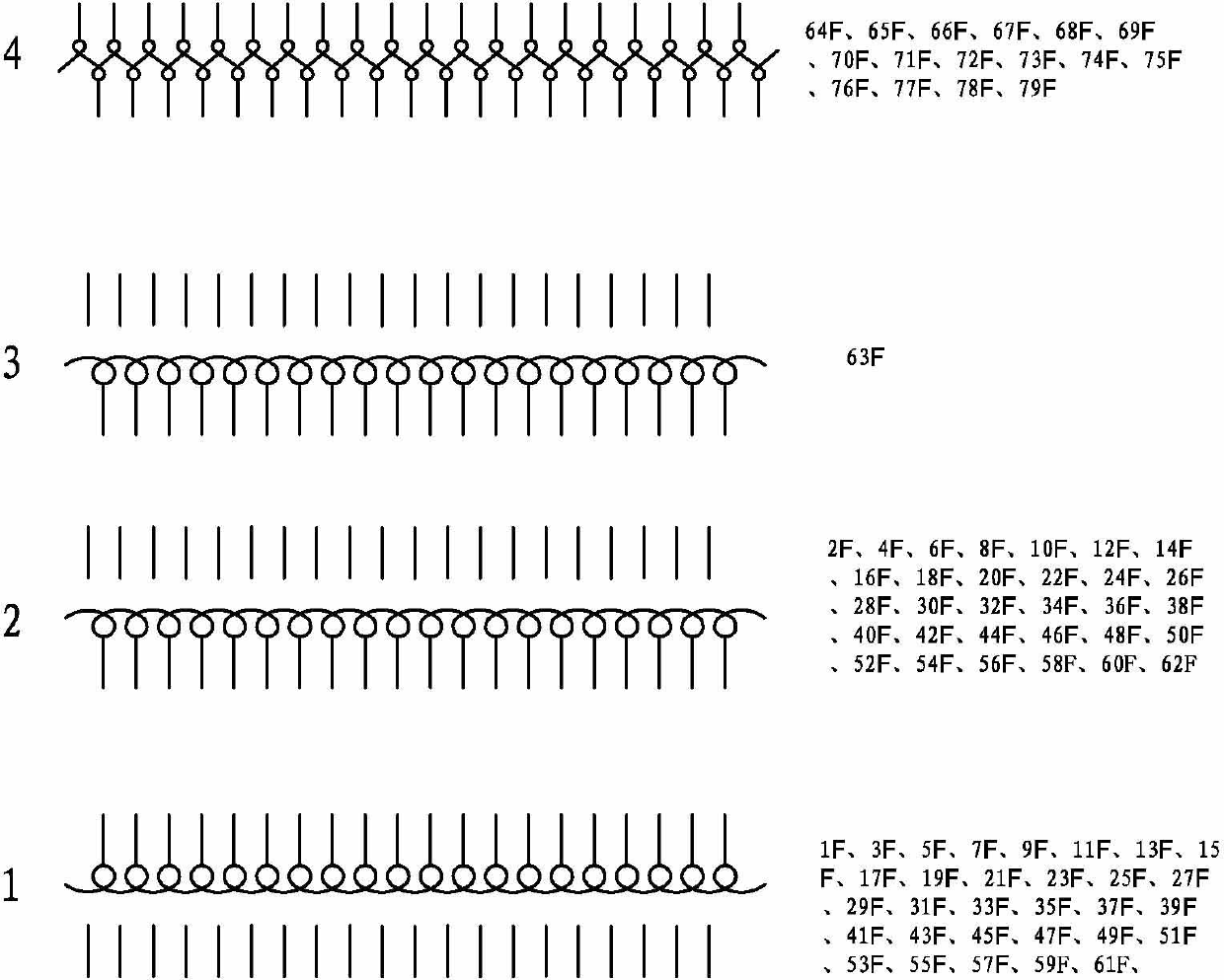

[0033] One of the specific implementations of the weaving process of a kind of knitted lace cloth of the present invention comprises the following steps:

[0034] Step 1. Weaving: The elastic root-wrapped yarn and vinylon water-soluble fiber are mixed and woven into the fabric basic raw material fibers to weave the primary fabric, and the vinylon water-soluble fiber is woven into the smallest flower of the corresponding primary fabric in the form of a loop structure. The course in the type cycle; the elastic root-wrapped yarn is woven in the adjacent course of the course where the vinylon water-soluble fiber is located;

[0035] Step 2. Finishing: Soak the primary fabric woven in step 1 in water to dissolve the vinylon water-soluble fiber, so that the corresponding wales of the vinylon water-soluble fiber in the form of a loop structure lose connection, and the elastic root-wrapped yarn shrinks , form a lace structure, and obtain a finished fabric with a lace structure.

[00...

Embodiment 2

[0053] One of the specific implementations of the weaving process of a kind of knitted lace cloth of the present invention comprises the following steps:

[0054] Step 1. Weaving: The elastic root-wrapped yarn and vinylon water-soluble fiber are mixed and woven into the fabric basic raw material fiber to weave the primary fabric, and the vinylon water-soluble fiber is woven in the corresponding said fabric in a loop structure and tuck form A course in the minimum pattern cycle of the primary fabric; the elastic root wrapping yarn is woven in the adjacent course of the course where the vinylon water-soluble fiber is located;

[0055] Step 2, after-finishing: soak the primary fabric woven in the step 1, dissolve the vinylon water-soluble fiber, and make the corresponding wales of the vinylon water-soluble fiber in the form of a loop structure lose connection, and the elastic bag The root yarn shrinks to form a lace structure to obtain a finished fabric with a lace structure.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com