Loose stacking boiling-off box for medium weight fabric

A thick fabric, scouring technology, applied in the processing of textile materials, the configuration of equipment for processing textile materials, textiles and papermaking, etc., can solve the problems of water waste, difficulty in complete immersion and swelling, and increased difficulty in the next oscillating washing process. To achieve the effect of novel design, better effect, and improved washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

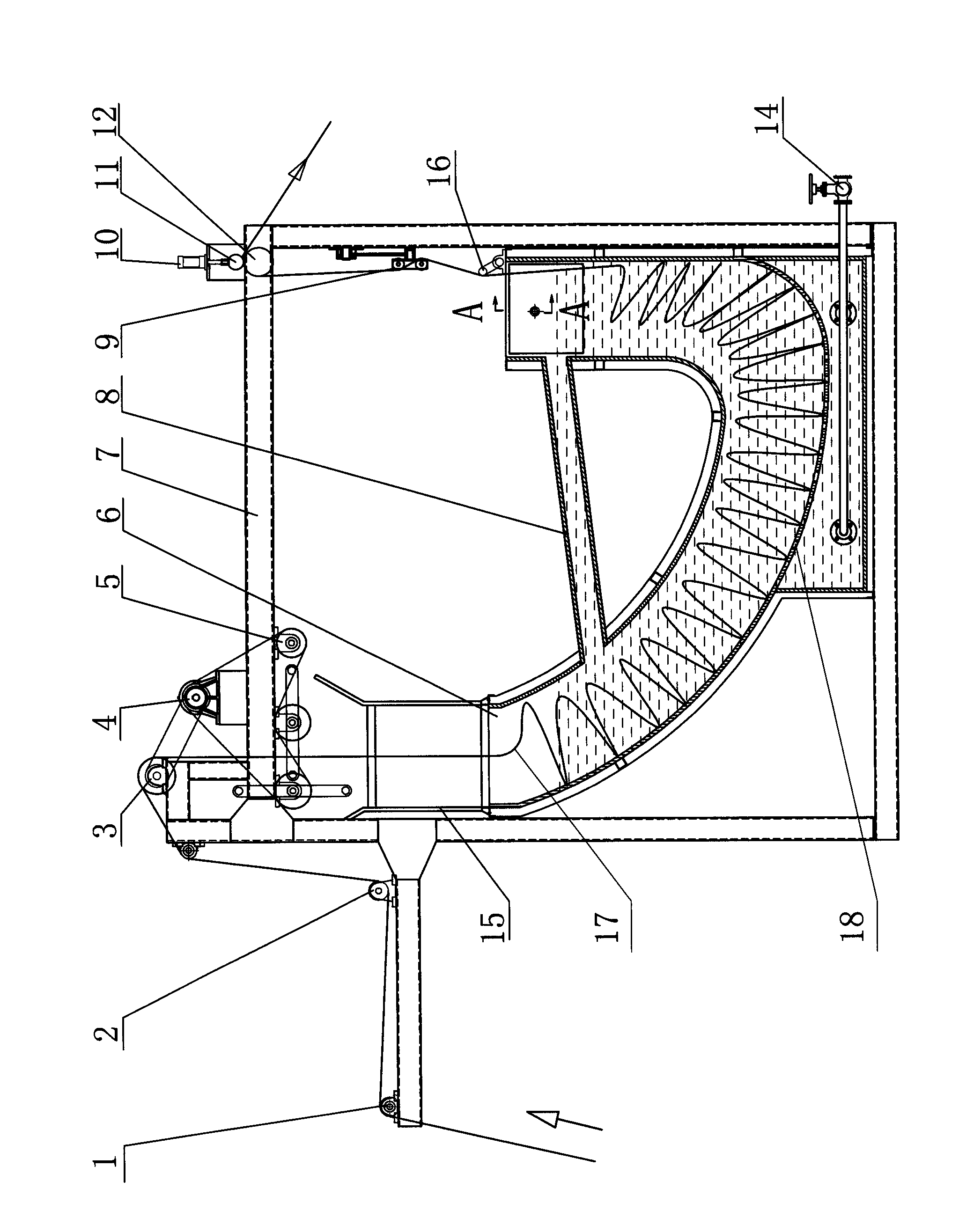

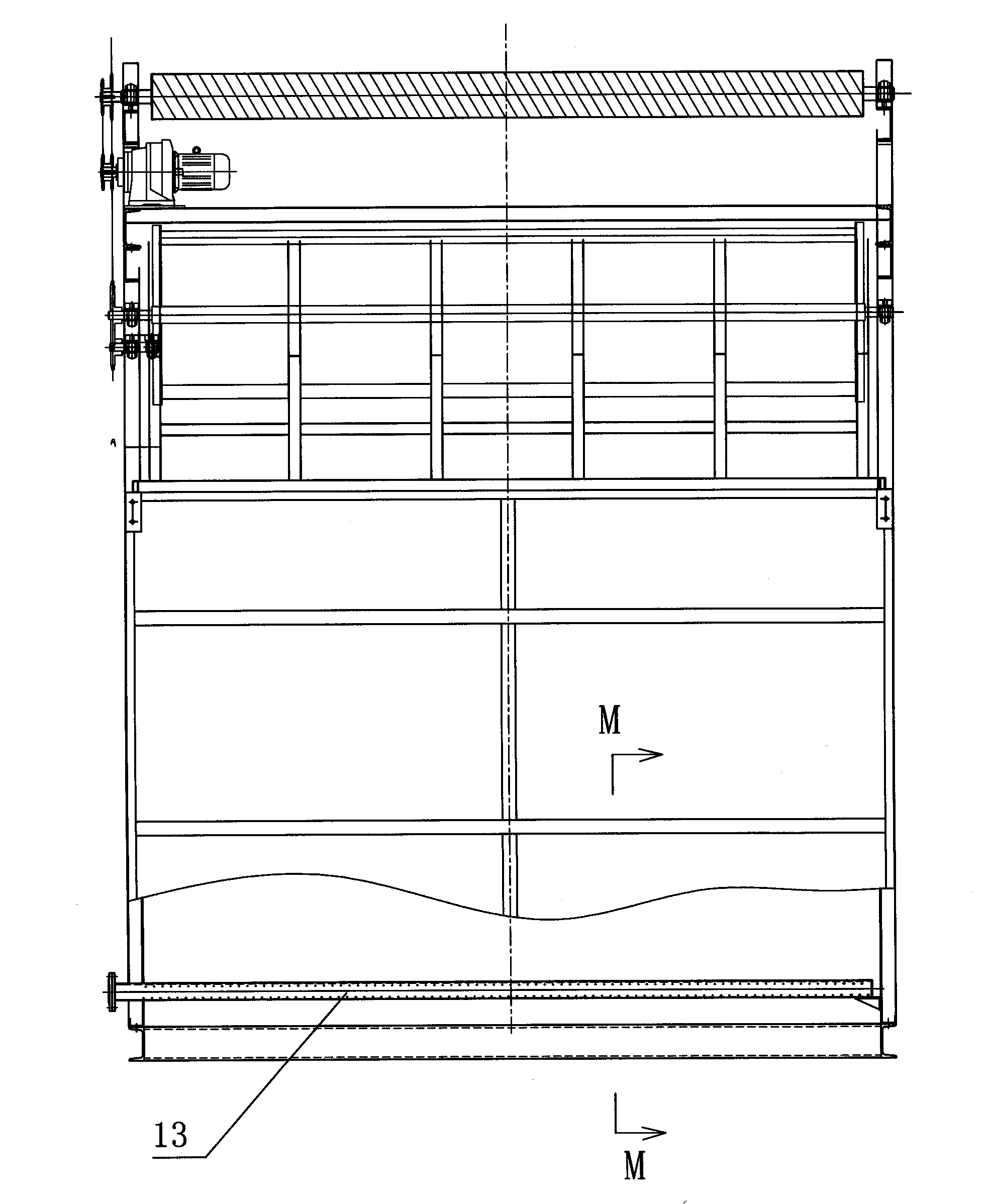

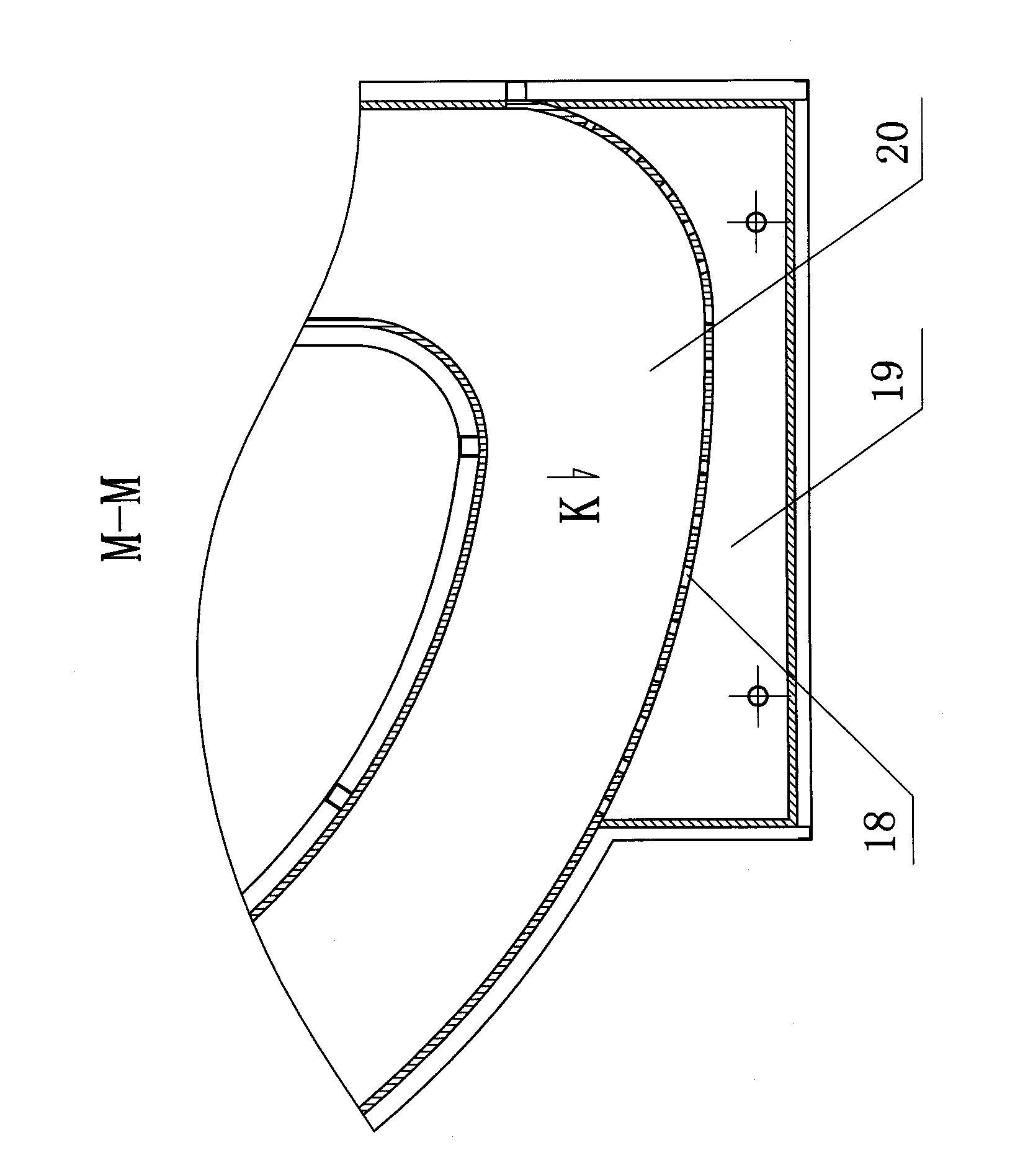

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0017] The loose stacking scouring box of the medium-thick fabric of the present invention is as figure 1 , figure 2 , image 3 As shown, it includes: a fixed bracket 7, a stacking scouring box 6 is installed in the fixed bracket 7, and the cloth feeding end on the fixed bracket 7 is equipped with a cloth introduction roller 1, a cloth introduction roller 2, an active cloth feeding roller 3 and a motor deceleration Machine 4; the fixed bracket 7 above the cloth inlet of the stacking scouring box 6 is equipped with a cross frame 5; the cloth outlet end on the fixed bracket 7 is equipped with a cloth deviation correction device 9, a cloth pressing roller 11 and a cloth pulling roller 12. It is characterized in that: the cross-section of the liquid tank of the stacked scouring box 6 is a J-shaped structure; the lower part of the stacked scouring box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com