Method for preparing magnetic nano ferroferric oxide particle thin film on surface of chinlon fabric

A technology of ferroferric oxide and magnetic nanometers, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of poor hand feeling and air permeability, unsustainable washing performance, and non-magnetism of ordinary nylon fabrics, so as to save raw materials and operate The effect of simplicity and excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

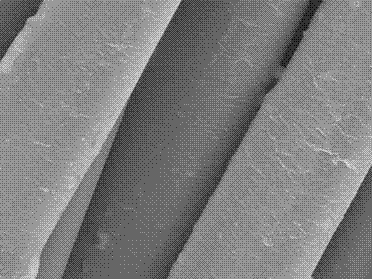

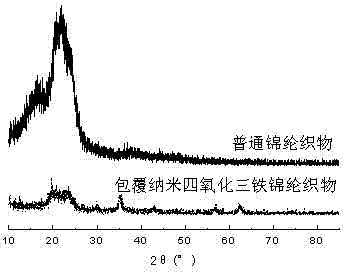

Embodiment 1

[0031] Prepare a 300ml / L dilute solution with hydrochloric acid with a mass concentration of 36%, roughen the nylon fabric at 40°C for 1 hour, then wash it with deionized water and dry it. Weigh a certain amount of ferrous chloride and ferric chloride, dissolve them in deionized water, control the total iron concentration to 0.01mol / L, and the mass ratio of ferrous chloride to ferric chloride is 1:4, and the crude The melted nylon fabric was immersed in the mixed solution at 10°C for 1min, and slowly added dropwise ammonia water with a concentration of 28% while stirring, so that the pH value of the solution was 5, and stirred at a constant temperature of 100r / min for 1h, and the nylon fabric was taken out after the reaction was completed. The fabric was dried in a vacuum oven at 60°C for 15 min, and washed in deionized water at 80°C for 30 min. Wash with 2g / L soap flakes and 2g / L soda ash at a bath ratio of 1:50, wash at 90°C for 60 minutes, then wash with 80°C hot water and ...

Embodiment 2

[0034] Prepare a 100ml / L dilute solution with hydrochloric acid with a mass concentration of 36%, roughen the nylon fabric at 60°C for 5 hours, then wash it with deionized water and dry it. Weigh a certain amount of ferrous chloride and ferric chloride, dissolve them in deionized water, control the total iron concentration to be 0.1mol / L, and the mass ratio of ferrous chloride to ferric chloride is 4:1. The melted nylon fabric was immersed in the mixed solution at 50°C for 10 minutes, and slowly added dropwise ammonia water with a concentration of 28% while stirring, so that the pH value of the solution was 11, and treated at a constant temperature of 900r / min for 3 hours, and the nylon fabric was taken out after the reaction was completed. , dried in a vacuum oven at 60°C for 15 min, and washed with deionized water at 80°C for 30 min. Wash with 2g / L soap flakes and 2g / L soda ash at a bath ratio of 1:30, wash at 70°C for 10 minutes, then wash with 80°C hot water and cold water...

Embodiment 3

[0037] Prepare a 200ml / L dilute solution with hydrochloric acid with a mass concentration of 36%, roughen the nylon fabric for 3 hours at 40°C, then wash it with deionized water and dry it. Weigh a certain amount of ferrous chloride and ferric chloride, dissolve them in deionized water, control the total iron concentration to 0.05mol / L, and the mass ratio of ferrous chloride to ferric chloride is 2:1, and the crude The melted nylon fabric was immersed in the mixed solution at 30°C for 5 minutes, and slowly added dropwise ammonia water with a concentration of 28% while stirring, so that the pH value of the solution was 9, and treated at a constant temperature of 500r / min for 2 hours, and the nylon fabric was taken out after the reaction was completed. , dried in a vacuum oven at 60°C for 15 min, and washed with deionized water at 80°C for 30 min. Use the washing solution prepared with 2g / L soap flakes and 2g / L soda ash at a bath ratio of 1:40, wash at 80°C for 30 minutes, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com