Mine monitoring method and equipment

A technology for monitoring equipment and mines, applied in the field of drilling, which can solve problems such as difficulty in judging the effectiveness of drilling and fracturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

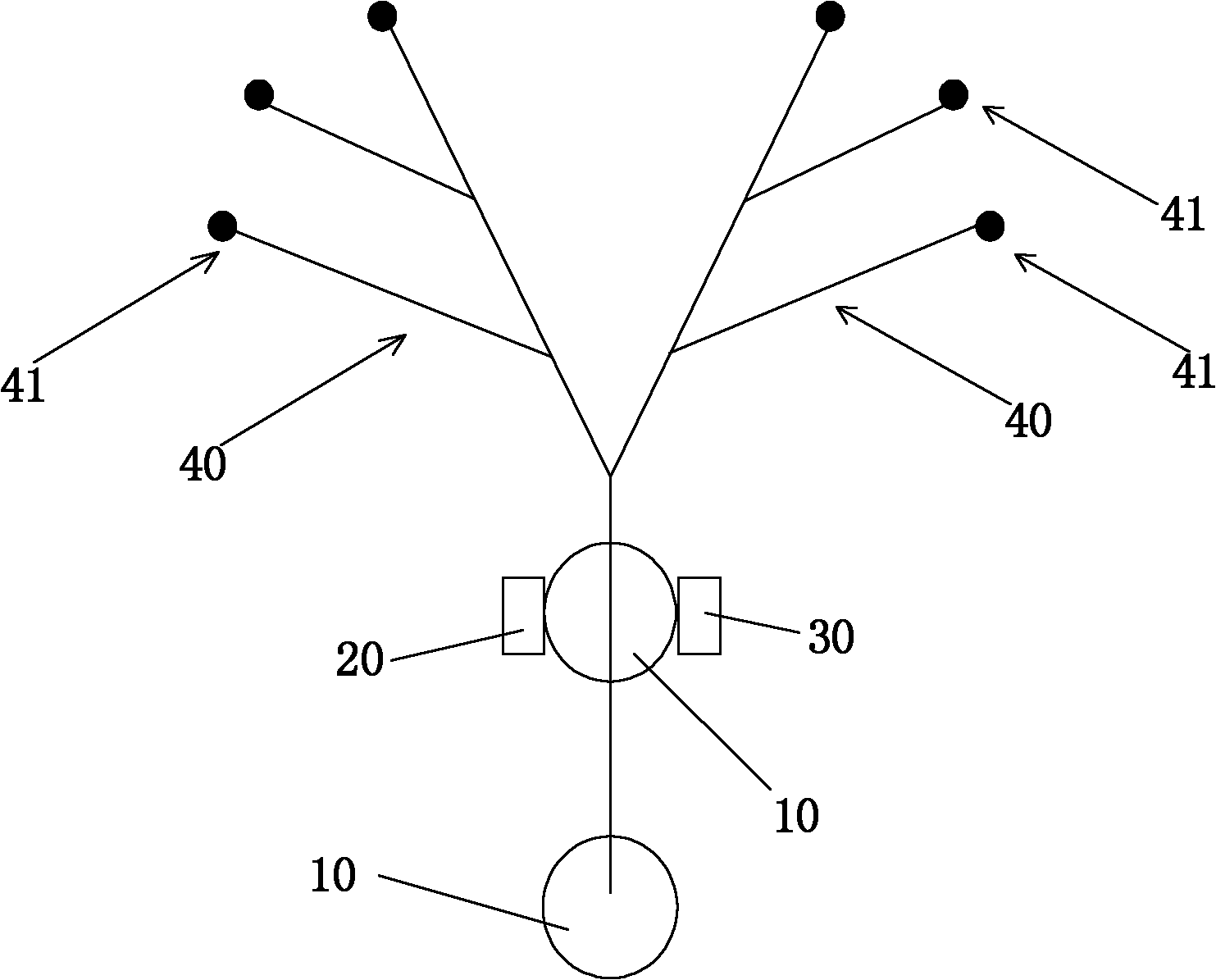

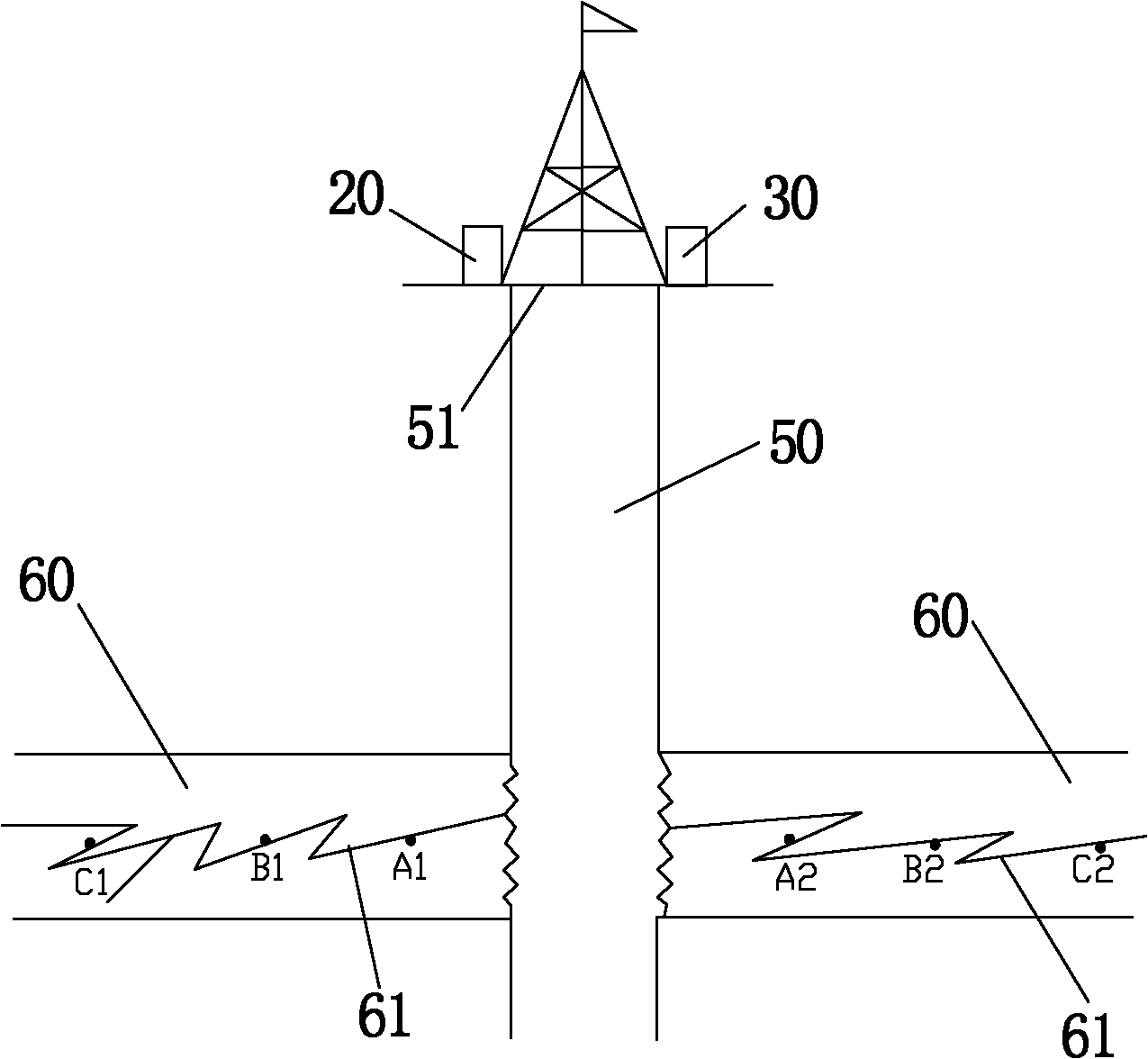

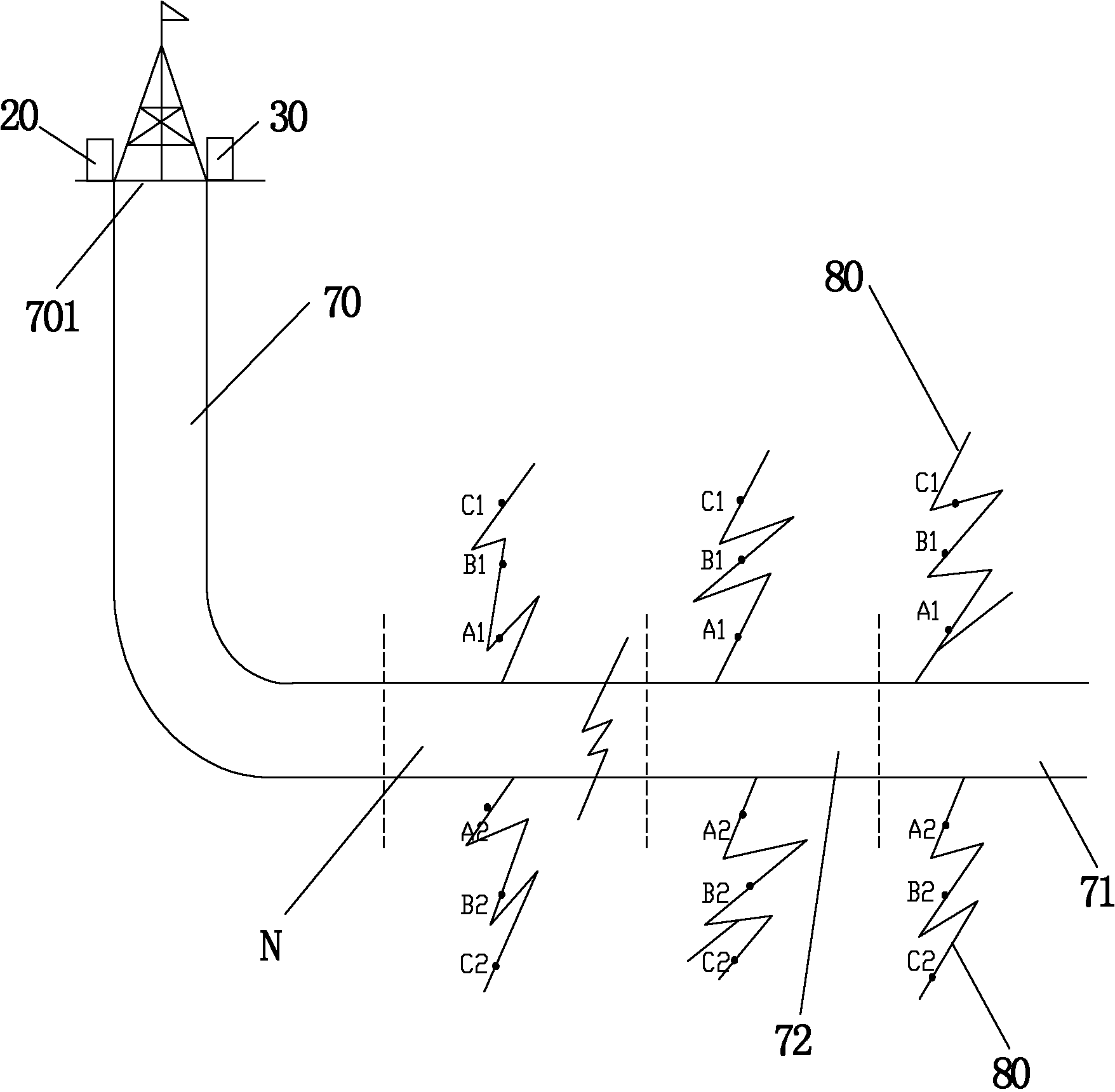

[0025] Such as figure 1 , figure 2 and image 3 As shown, the mine monitoring equipment according to the embodiment of the present invention includes: a pump 20 for driving drilling fluid or fracturing fluid containing fluorescent powder into the underground of the mine, and the pump 20 is connected to the mine, such as being set at the wellhead; detecting fluorescence Powder spectrophotometer 30, connected with the mine. The spectrophotometer 30 is set outside the mine, for example, at the head of the well, so as to detect in time. When drilling or fracturing, the fluorescent powder is driven into the underground. During production, the mine is drained and depressurized, and the water discharged from the mine to the ground i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com