Fast wave eliminating/energy dissipating/cushioning device for mining

A buffer device and fast technology, applied in the direction of mining equipment, earthwork drilling, pillars/brackets, etc., can solve problems such as support equipment instability damage, hydraulic buffer damage, high-speed deformation of rock mass, etc., to avoid mechanical production equipment Effect of damage, high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

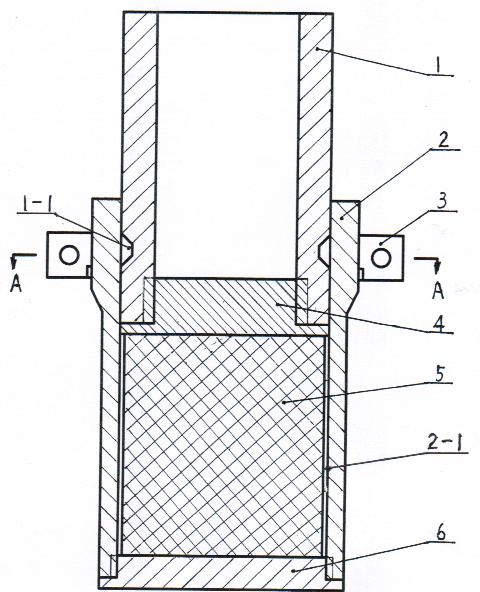

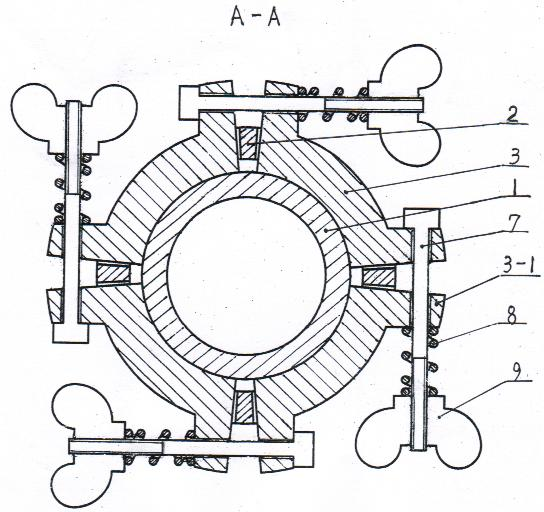

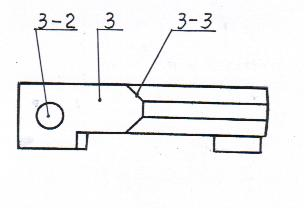

[0015] Examples, see attached Figure 1~3 , the lower rigid sleeve 2 of the mine-used rapid wave dissipation and energy consumption buffer device is a cylinder with a thickened upper wall, the lower part is screwed to fix the external bottom cover 6, and the lower rigid sleeve 2 above the external bottom cover 6 is equipped with a cylinder Shaped plastic energy-absorbing material 5, leaving a gap 2-1 between the energy-absorbing material 5 and the inner wall of the lower rigid sleeve 2. An internal rigid bottom cover 4 is provided on the energy-absorbing material 5, and the internal rigid bottom cover 4 is screwed to fix the upper rigid sleeve 1. The upper rigid sleeve 1 overlaps with the upper thickening of the lower rigid sleeve 2. 1. A trapezoidal groove 1-1 is provided at the overlap between the outer wall and the inner wall of the lower rigid sleeve 2. At the trapezoidal groove 1-1 on the outer wall of the corresponding upper rigid sleeve 1, four pin clips 3 of the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com