Heat preserving shell for special-shaped pipeline elbow

A technology of pipe elbow and thermal insulation shell, which is applied in pipeline protection, thermal insulation, and pipeline protection through thermal insulation, etc., can solve the problems of short service life, complicated production, and cannot be reused, and achieves reduction of construction and maintenance costs and economic benefits. Significant, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

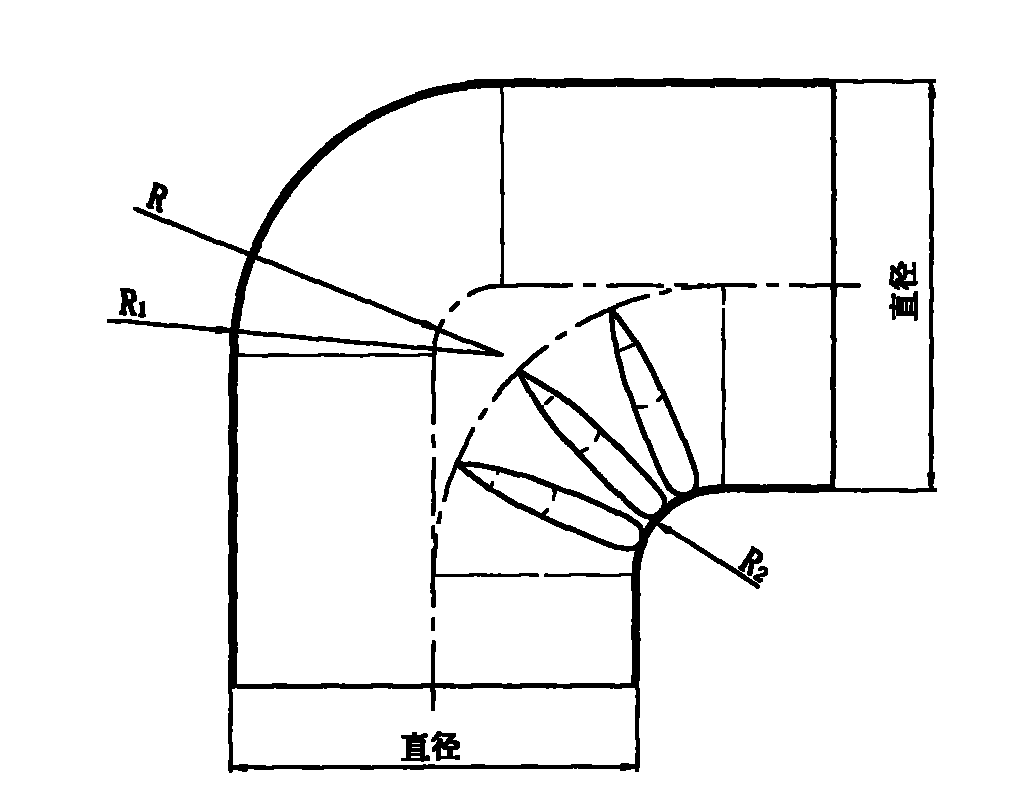

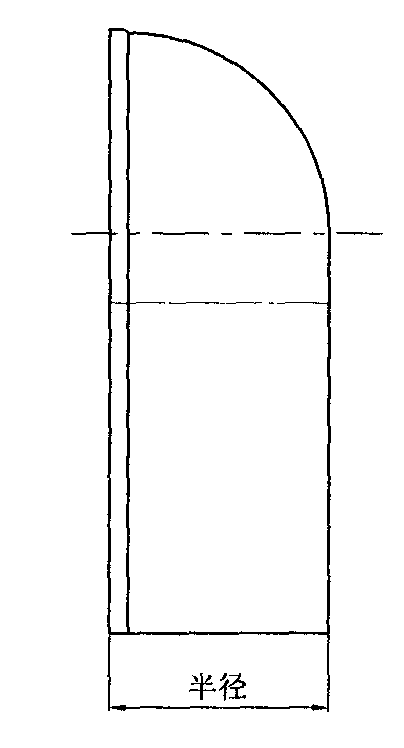

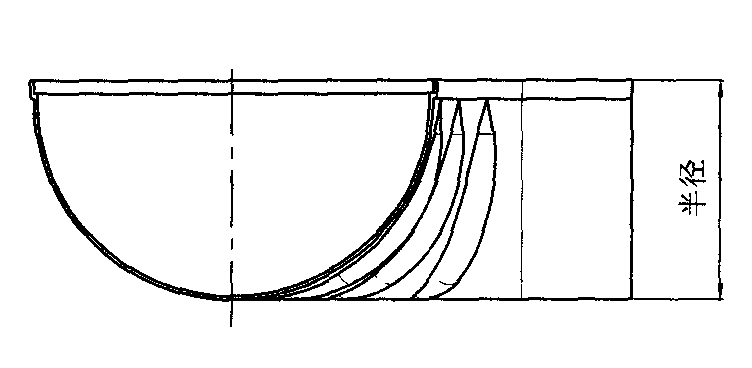

[0018] see Figure 1 to Figure 6 , The special-shaped pipe elbow insulation shell is divided into two symmetrical elbow shells 1 and 2 by the central plane 4, and the shell 3 is suitable for 90 ° special-shaped pipe elbow heat preservation shell. see Figure 5 with Image 6 The fasteners are self-tapping screws 7, and a plurality of self-tapping screws 7 fixedly connect the two symmetrical elbow shells 1 and 2 to form a complete special-shaped pipe elbow insulation shell. When in use, wrap the insulation layer 6 made of insulation material outside the high-temperature pipeline 5 , and the special-shaped pipe elbow insulation shells 1 and 2 are buckled outside the insulation layer 6 and fixedly connected with a plurality of self-tapping screws 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com