Method and device for detecting and maintaining modular equipment and modular equipment

A technology for equipment testing and maintenance devices, applied in the field of communication, can solve problems such as inability to recover quickly, affect the normal operation of the whole machine, and fail to realize the detection and maintenance of modular equipment, so as to achieve the effect of increasing speed and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

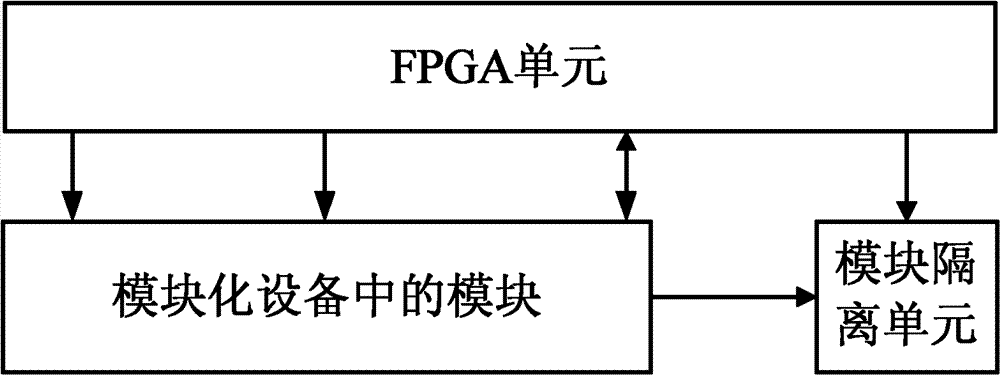

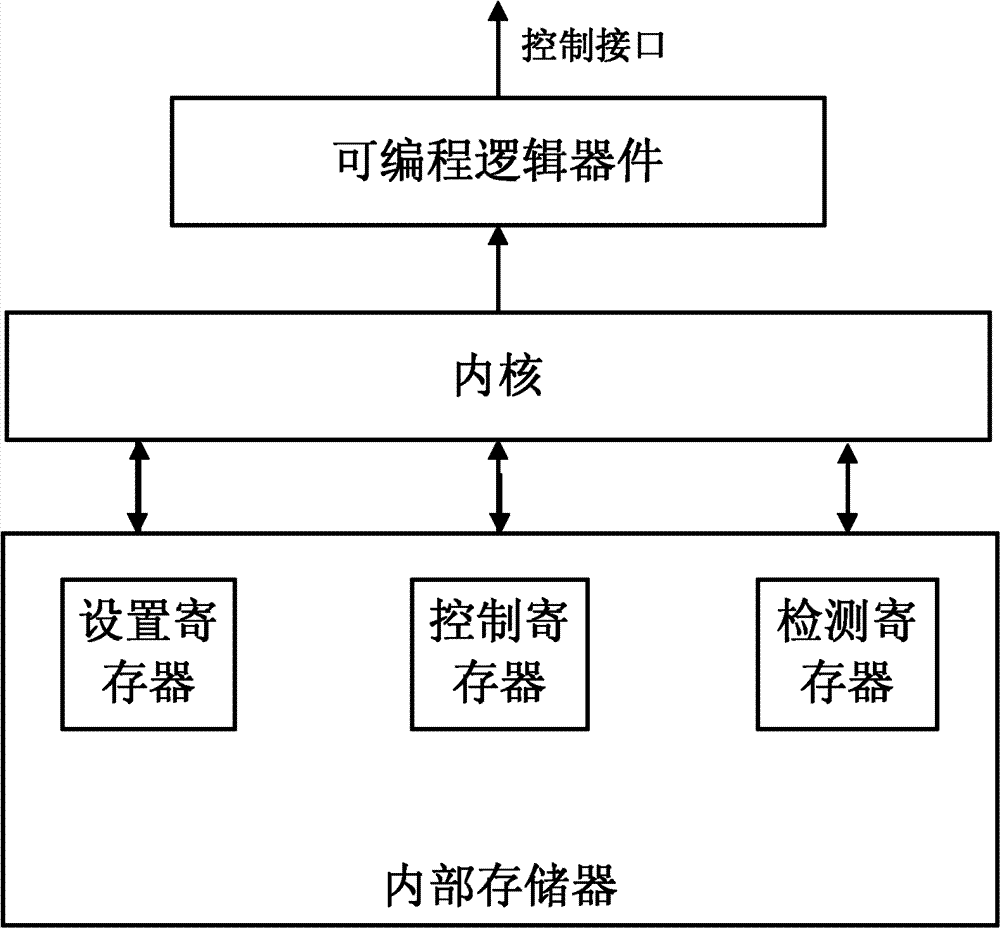

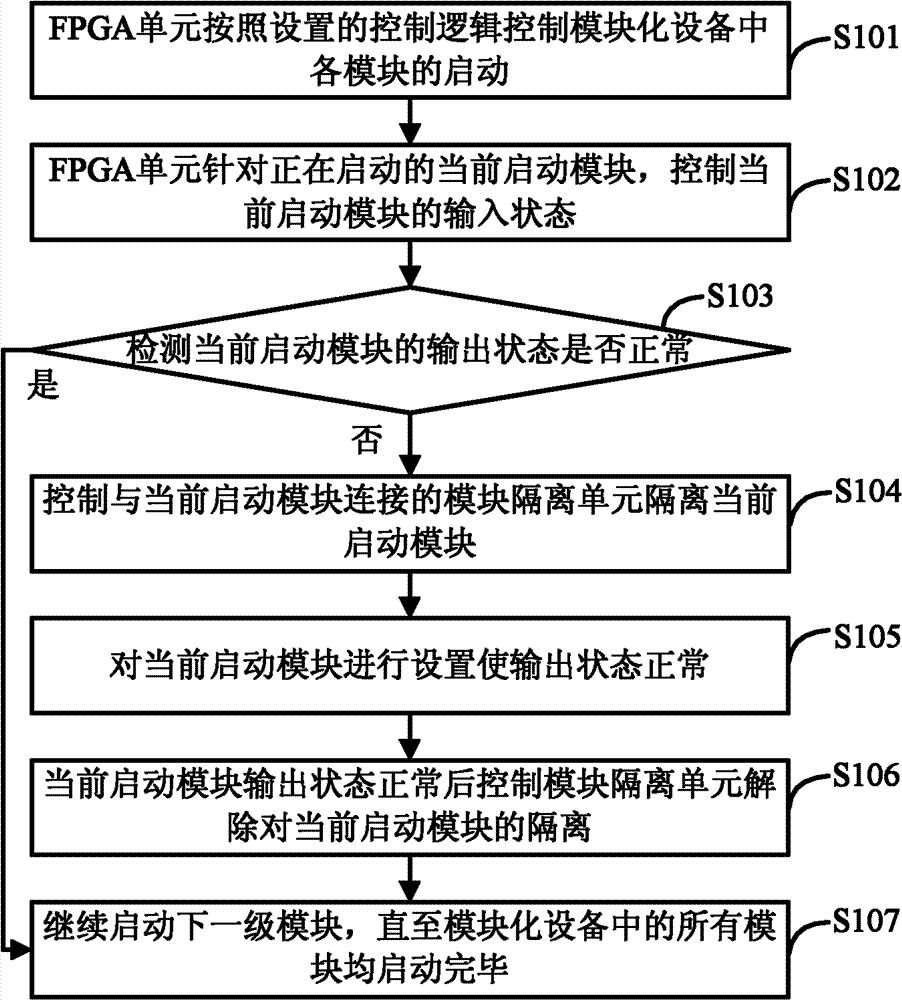

[0033] The modularized equipment inspection and maintenance device provided by Embodiment 1 of the present invention has a structure as follows: figure 1 As shown, including: FPGA unit and module isolation unit. The control, detection and fault recovery settings of the modules in the modular equipment are realized through the FPGA unit and the module isolation unit.

[0034] The FPGA unit is used to control the start-up of each module in the modular equipment according to the set control logic; for the current start-up module being started, control the input state of the current start-up module, and detect whether the output state of the current start-up module is normal; if normal, Then continue to start the next-level module; if it is not normal, control the module isolation unit connected to the current startup module to isolate the current startup module, and set the current startup module so that the output state is normal. After the control module isolation unit release...

Embodiment 2

[0066] The modular equipment detection and maintenance device provided in Embodiment 2 of the present invention is different from the modular equipment detection and maintenance device provided in Embodiment 1 in that the device controls, detects and and the different needs of the settings, in figure 1 On the basis of the modular equipment detection and maintenance device shown, one or a combination of the following modules is set between the FPGA unit and the modules in the modular equipment: a module control unit, a module detection unit and a module setting unit. Specifically, when the control of the FPGA unit to the module requires the cooperation of an external control unit, the module control unit is set; when the detection of the FPGA unit to the module requires the cooperation of an external detection unit, the module detection unit is set; When the setting requires the cooperation of an external control unit to be realized, set the module to set the unit. The struct...

Embodiment 3

[0078] The third embodiment of the present invention specifically describes the specific implementation process of detecting the power module in the modularized device and recovering the device from a fault.

[0079] Modular devices, such as router hosts, generally have strict requirements on the power-on time of power modules. Various power modules must be powered on in a set order, otherwise the modular devices will not be able to be configured normally and malfunction. For example: first, power on the power supply module at 1.2V to precharge the CPU and other components, and then power on at 5V to power the CPU.

[0080] Currently, when realizing the above-mentioned power supply sequence control, the following methods are generally adopted: Figure 7 The enable circuit shown in the figure realizes the control, through the 1.2V VDD input (VDD1V2 shown in the figure), the 5V enable output (5V_EN shown in the figure) is obtained to control the power supply module.

[0081] An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com