Movable static contact structure for plastic-shell circuit breaker

A technology for molded case circuit breakers, dynamic and static contacts, applied in the direction of circuit breaker contacts, circuit breaker components, etc., can solve the problems of copper braided wires not being well insulated, protection is not in place, fusion welding, etc., to achieve static contacts Reliable structure, high machining accuracy and reduced parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

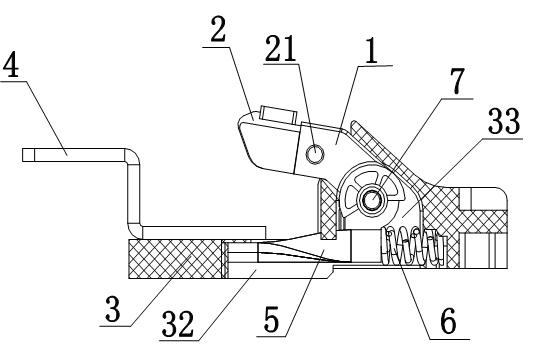

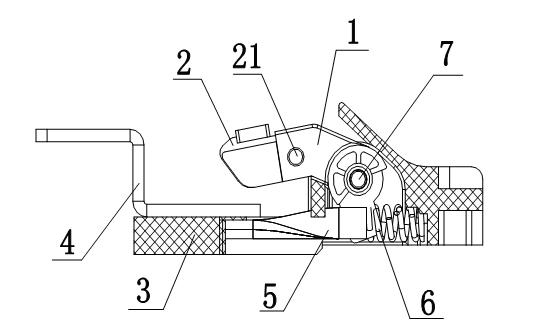

[0021] Such as figure 1 and 2 As shown, the present invention is made up of static contact plastic part 1, static contact 2, plastic support 3, connecting row 4, copper braided wire 5, spring 6 and static contact rotating shaft 7. The static contact plastic part 1 is wrapped outside the static contact 2, the rear part of the static contact plastic part 1 and the static contact 2 is connected to the plastic bracket 3 through the static contact rotation shaft 7, and the lower part of the connecting row 4 is fixed on the plastic bracket 3 , The spring 6 is located between the rear of the static contact 2 and the plastic bracket 3, and the braided copper wire 5 is located in the plastic bracket 3 and connects the connecting row 4 and the static contact 2.

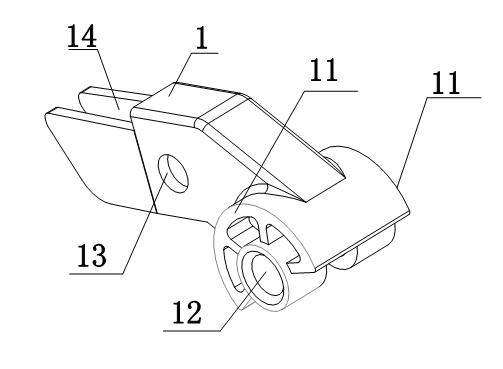

[0022] Such as image 3 As shown, the front part of the static contact plastic part 1 is provided with a groove 14, the middle part is provided with a second through hole 13, and the rear part is two fan-shaped bosses 11 symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com