Gravure roll for application of pressure-sensitive adhesive and process for producing pressure-sensitive adhesive tape

A technology for adhesives and manufacturing methods, applied to adhesives, devices for coating liquid on surfaces, film/sheet adhesives, etc., can solve the problems of slowing down, poor productivity, etc., and achieve uniform adhesive layer and transfer rate Improvement, effect of improvement per unit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The best way to practice the invention

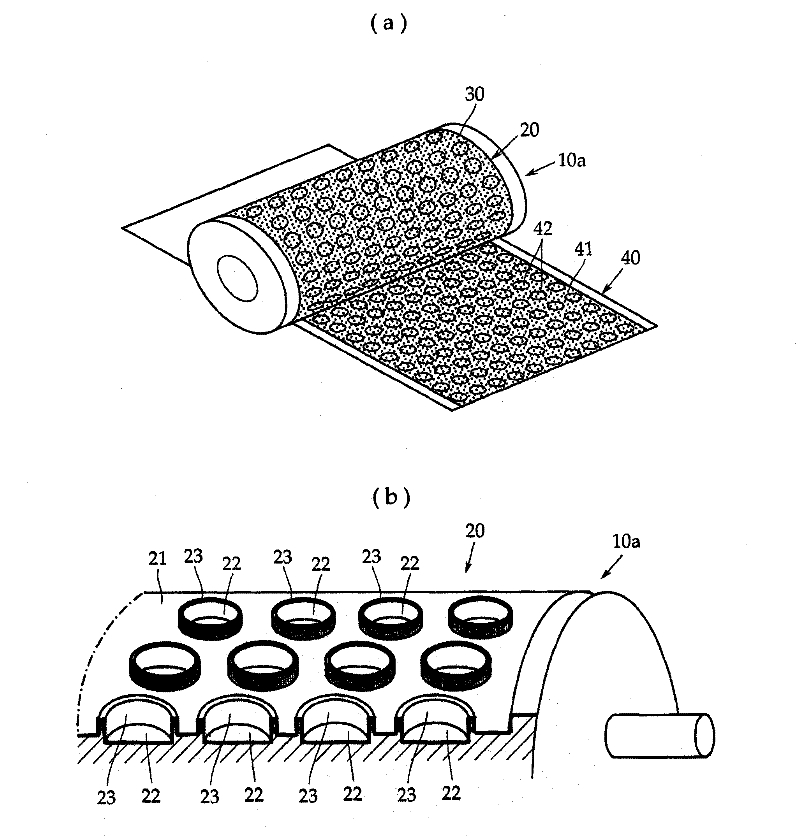

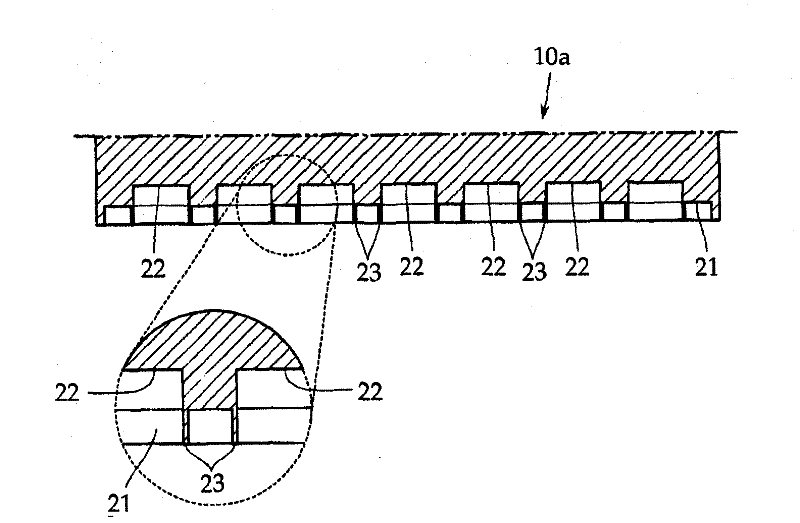

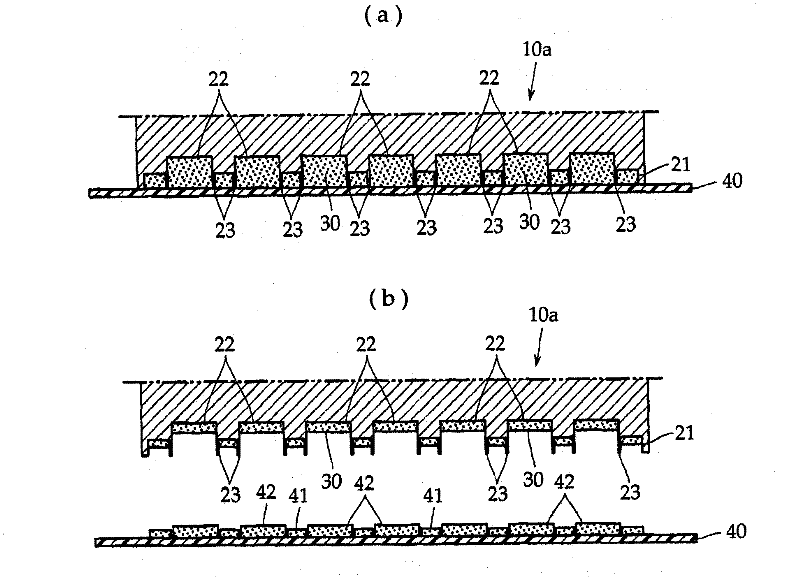

[0044] Such as figure 1 and figure 2 As shown, the adhesive coating grooved roll 10 a (hereinafter simply referred to as a grooved roll) of the first embodiment is a metal roll, and the pool 20 filled with the adhesive 30 is formed on the surface thereof. The material of the grooved roll 10a, the roll diameter, etc. can be arbitrary according to a specification.

[0045] In this example, the tank 20 has: a first tank 21 for forming a full-surface adhesive layer 41 along the substrate 40; and a second tank 22 for further forming a dispensing adhesive layer on the full-surface adhesive layer 41 42. The number or shape of pools 20 can be designed arbitrarily according to specifications.

[0046] The first pool 21 is formed by a concave surface further lowered along the surface of the grooved roll 10a, and is continuously formed in a belt shape along the outer peripheral surface of the grooved roll 10a for full-surface coating....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com