Method for separating wafers from a wafer support and device therefor

A technology for wafers and supporting devices, which can be used in fine working devices, adhesive heating bonding methods, semiconductor/solid-state device manufacturing, etc., and can solve problems such as unfavorable wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

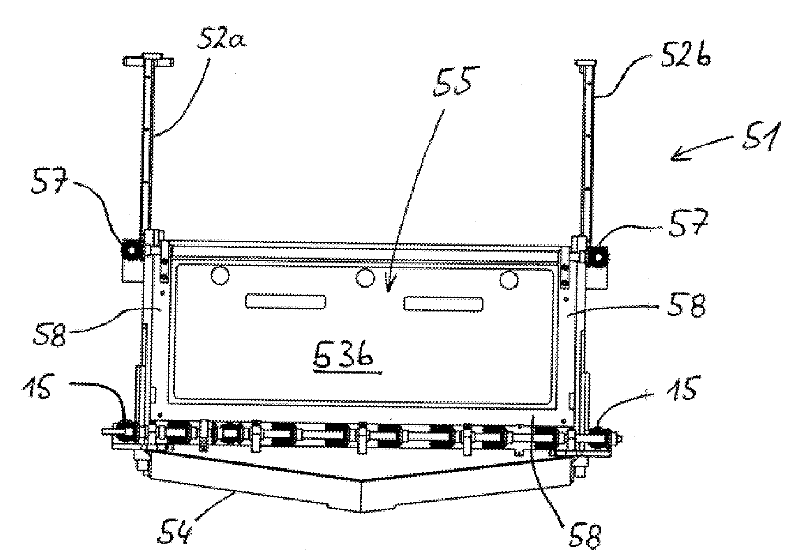

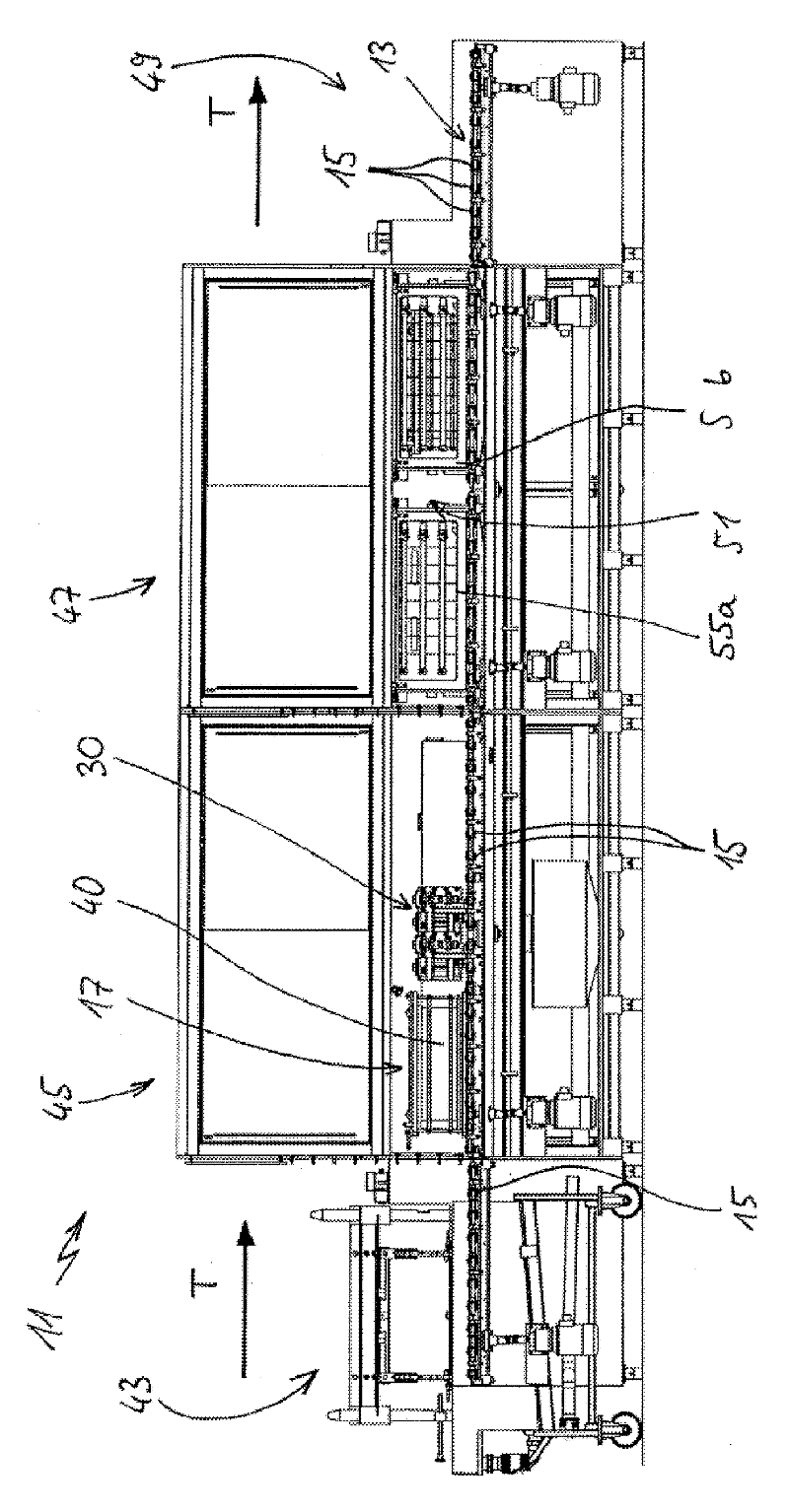

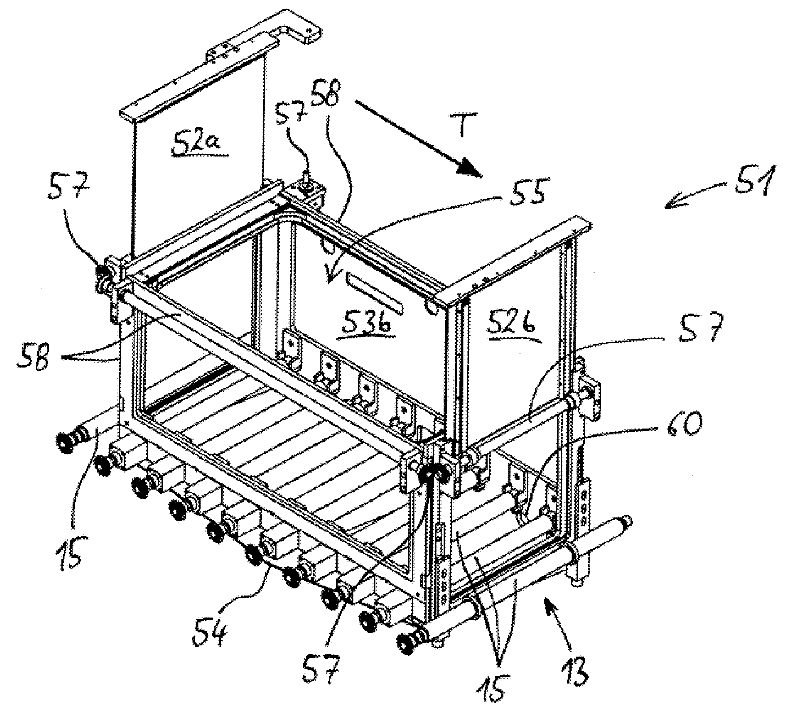

[0022] exist figure 1 The entire device 11 according to the invention is shown in side view. In this process not only the sawn wafer blocks 40 are cleaned, but mainly also debonding according to the invention, ie the individual sawn wafers are separated from the rods or stringers of the support device 17 on which the wafers are also bonded. This device 11 advantageously has a chamber surrounding it. On the far left, it has a drive-in module 43 , by means of which the cage-shaped support device 17 is brought close to the device 11 with the wafer blocks 40 located therein and then driven in. It can be seen here that the entry module 43 has rollers 15 which form roller tracks with other rollers 15 at the level of the conveyor belt 13 . The rollers are advantageously driven individually or collectively. Here too, the above-described transport of wafer pieces 40 horizontally can also be carried out.

[0023] As shown and easily imagined, the cleaning module 45 consists of a clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com