Catalyst composition with mixed selectivity control agent and polymerisation method using it

A composition and catalyst technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve problems such as reactor shutdown and production disruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0158] (1) Pre-catalyst

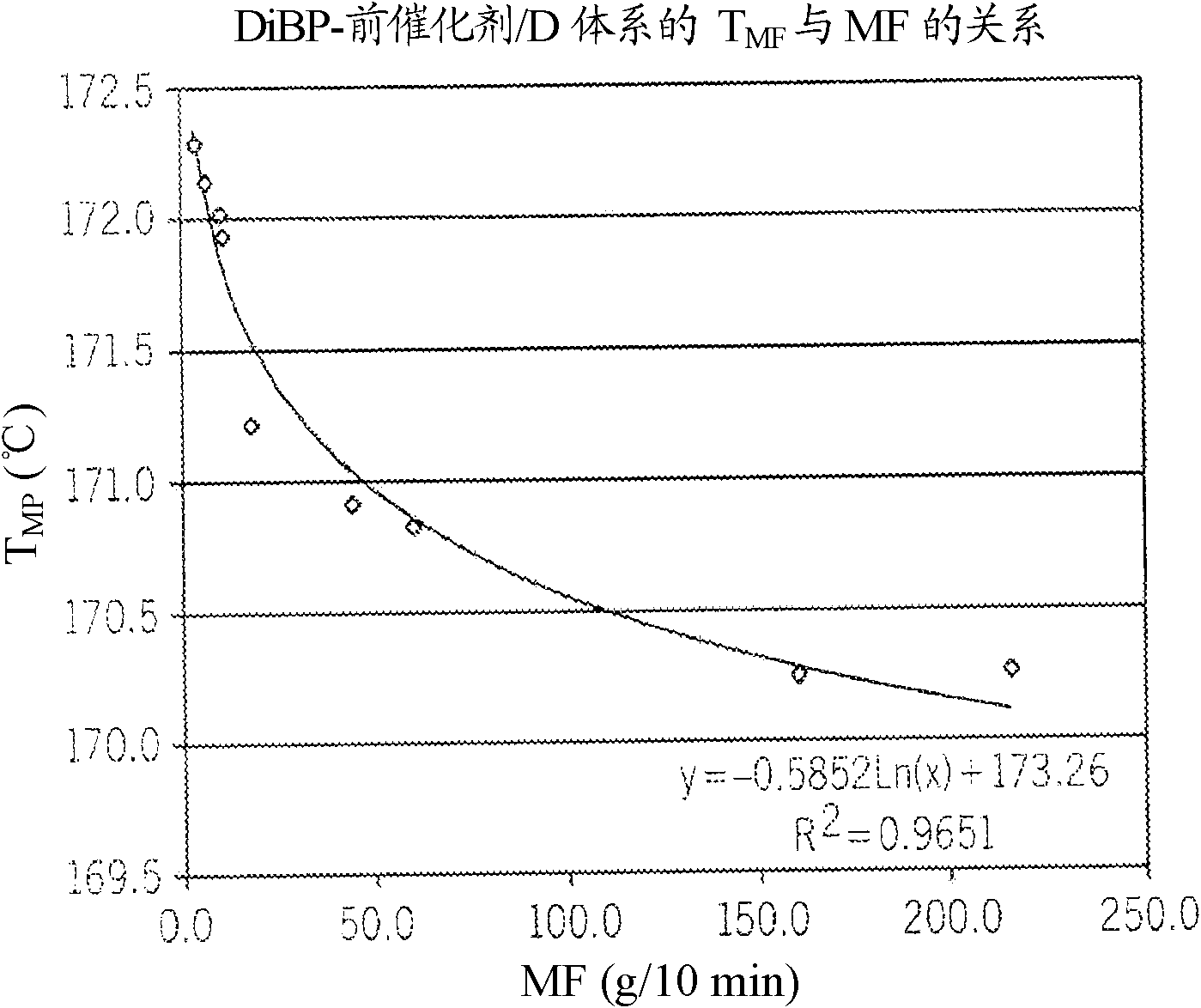

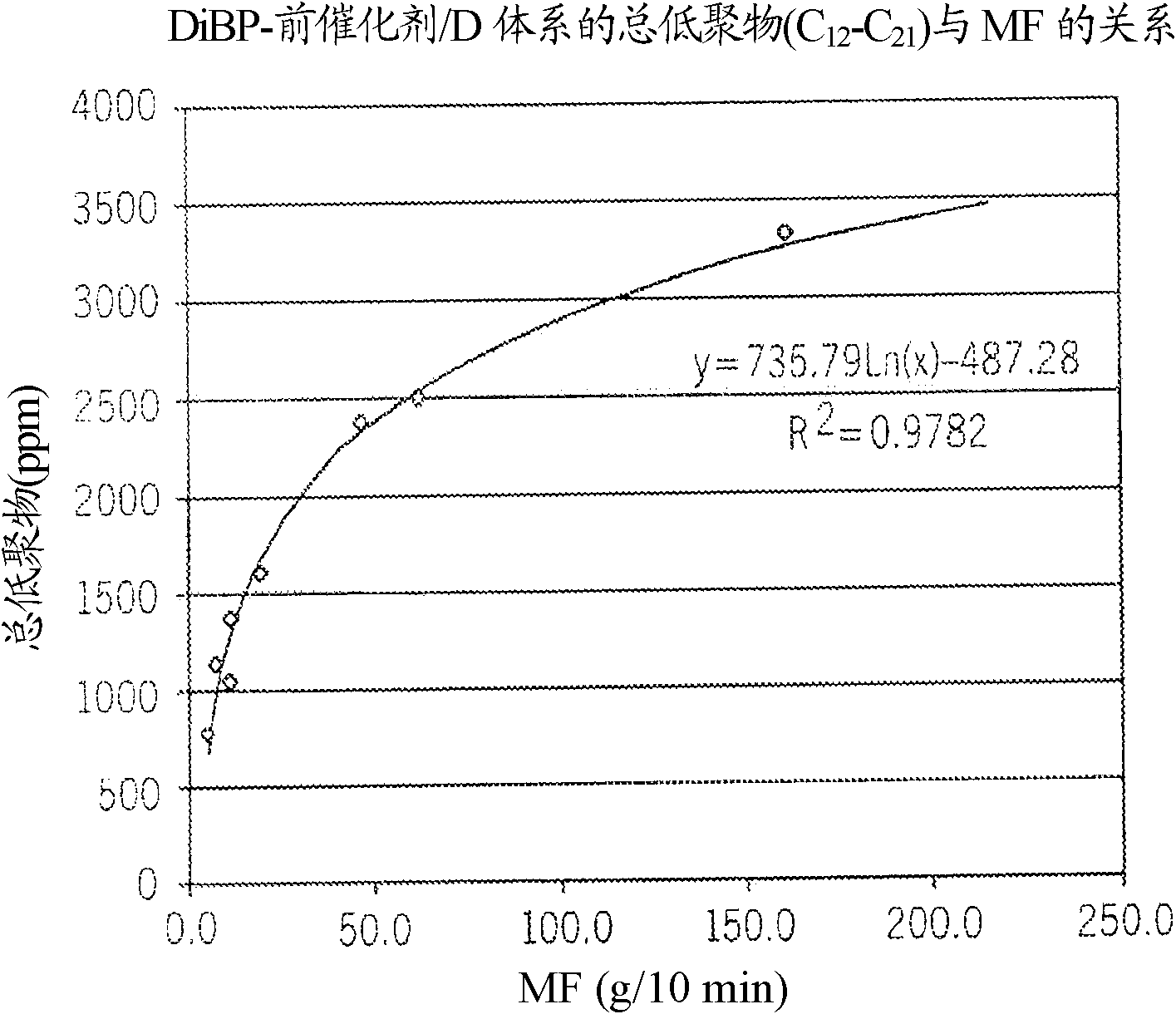

[0159] A. Procatalyst V10B is a commercial SHAC TM 320 catalyst containing 2.52 wt% Ti and 10.34 wt% di-isobutylphthalate (DiBP).

[0160] B. Procatalyst 1910-29-2 was prepared according to the procedure for catalyst 4949-25-1 in US Provisional Patent Application No. 61 / 141,902, filed December 31, 2008, the entire contents of which are hereby incorporated by reference. Procatalyst 1910-29-2 contained 3.61 wt% Ti and 14.85 wt% 3-methyl-5-tert-butyl-1,2-phenylene dibenzoate.

[0161] (2) External electron donor components:

[0162] 592420:(Triethoxysilyl)cyclohexane

[0163] BPIQ-bis(perhydroisoquinolyl)dimethoxysilane

[0164] Catepe:1-Ethoxy-2-n-pentyloxybenzene

[0165] D (or D donor): dicyclopentyldimethoxysilane

[0166] DAB-5: 1-ethoxy-2-(6-(2-ethoxyphenoxy)hexyloxy)benzene

[0167] DiBDES: Diisobutyldiethoxysilane

[0168] DiPDMS-Diisopropyldimethoxysilane

[0169] DMDMS-Dimethyldimethoxysilane

[0170] DnBDMS: Di-n-butyl-dimethoxysila...

Embodiment 2

[0202] (1) Procatalyst: using commercial SHAC TM 320 catalyst (2.59% Ti) and DiBP. A catalyst slurry was prepared in toluene at 0.247 mg / ml in toluene. All SCAS and ALA at Isopar E TM Diluted to 0.005M in PPR, except that S-191 was dissolved in toluene before injection into the PPR. In IsoparE TM TEA1 was prepared in and used as a 0.02 or 0.1 M solution.

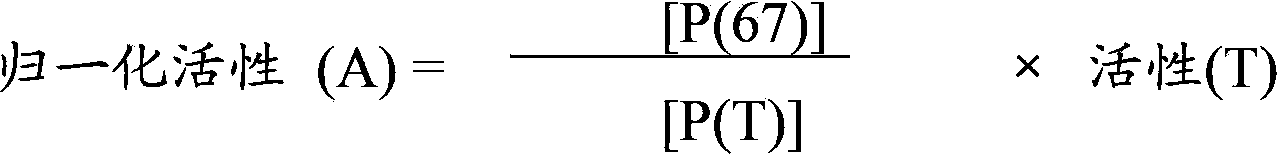

[0203] (2) Polymerization: The purged parallel polymerization reactor (PPR) was heated to 50°C, and TEA1 and Isopar E TM Make-up solvent was added to each reactor, followed by the addition of hydrogen to a steady pressure of 5 psig. The reactor was heated to the indicated temperature (67, 100 or 115°C). Propylene was added to 100 psig and allowed to stabilize for 10 minutes. Add SCA or a mixture of SCA1, SCA2 and ALA and 500 μl of Isopar E to each reactor TM Diluent (chaser), followed by immediate addition of catalyst (275 μl) and 500 μl Isopar E TM Diluent. After 60 minutes or when a maximum relative conversion o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com