Liquid crystal display device

A liquid crystal display device and liquid crystal technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of complex manufacturing process and slow response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

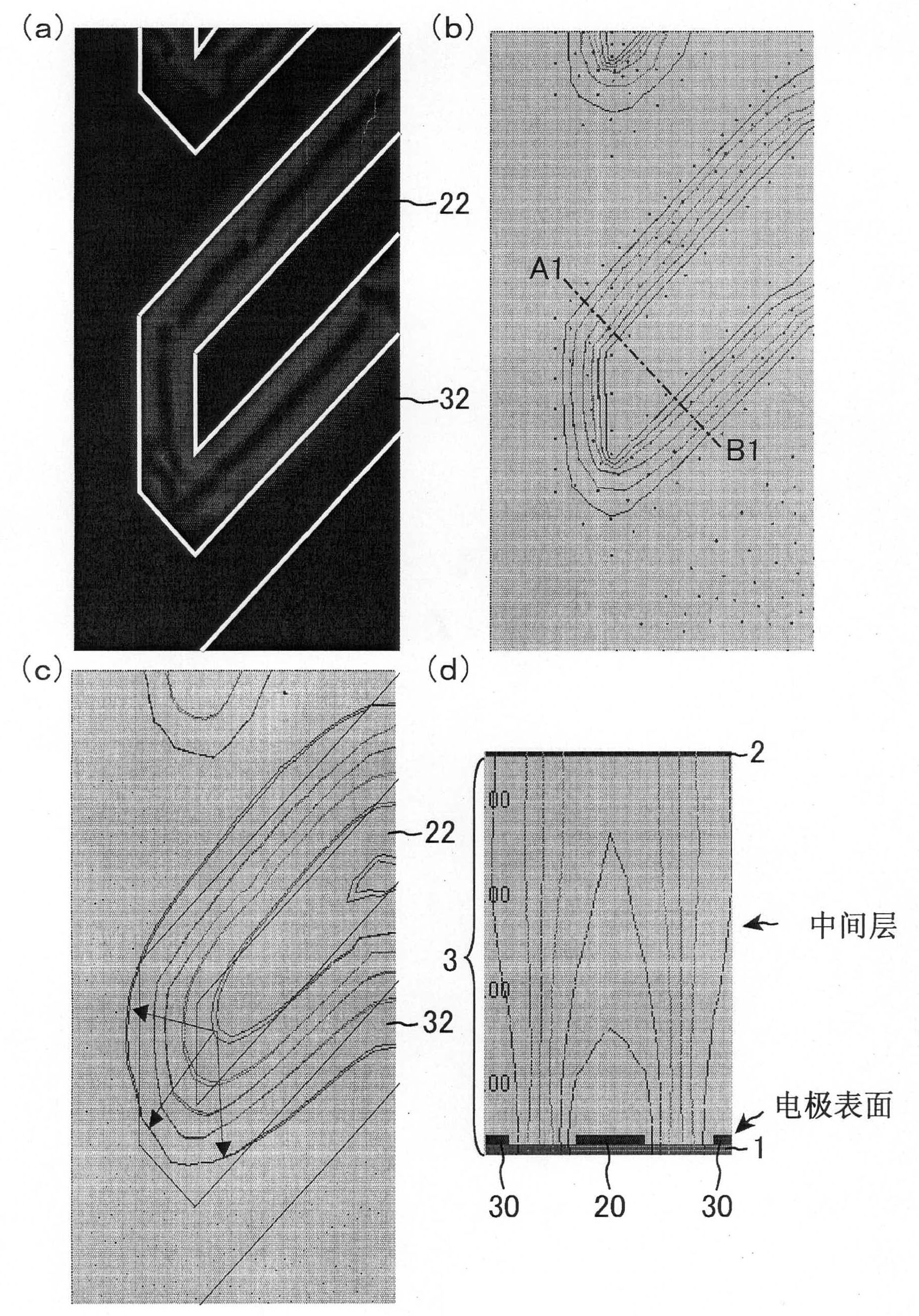

[0089] The liquid crystal display device of this embodiment is a liquid crystal display device using a transverse electric field method called a TBA method. In this transverse electric field method, an electric field (transverse electric field) in the direction of the substrate surface is applied to the liquid crystal layer to control the orientation of the liquid crystal molecules. Image display.

[0090] figure 1 It is a schematic plan view showing the configuration of the liquid crystal display device of Embodiment 1. FIG. In addition, although only one or two picture elements are shown in the following figures, a plurality of picture elements (sub-pixels) are provided in a matrix in the display area (image display area) of the liquid crystal display device of this embodiment.

[0091] The liquid crystal display device of the present embodiment includes a liquid crystal display panel having a pair of oppositely arranged substrates, namely, an active matrix substrate (TFT ...

Embodiment approach 2

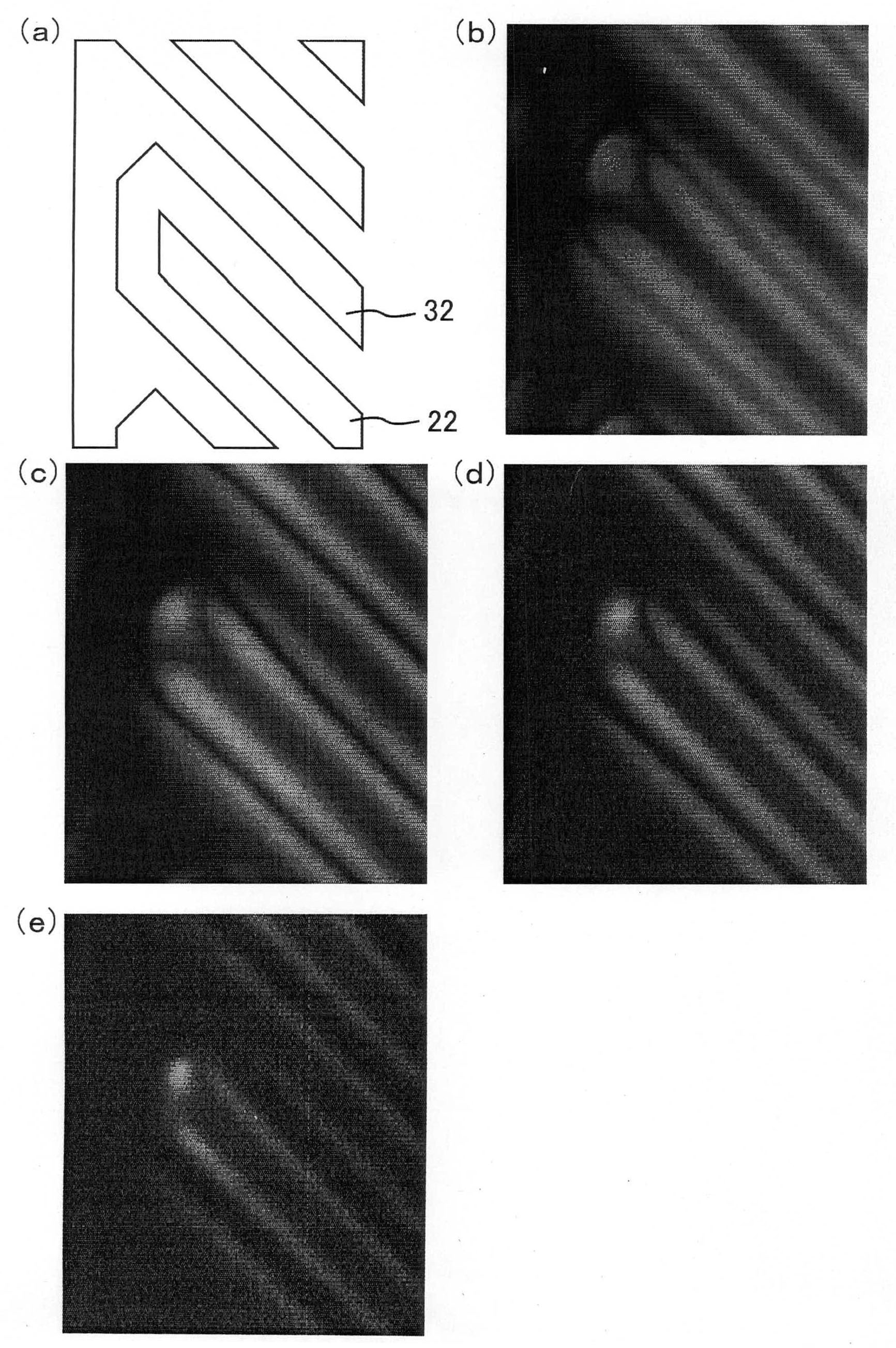

[0217] Figure 25 It is a schematic plan view showing the configuration of a liquid crystal display device according to Embodiment 2. FIG.

[0218] The liquid crystal display device of this embodiment has the same configuration as that of the first embodiment except for the layout of the pixel electrodes and the common electrodes, so only the differences from the first embodiment will be described in detail.

[0219] The liquid crystal display device of this comparative method such as Figure 25 As shown, it includes: a comb-shaped pixel electrode 220 having a trunk portion 221 and branches 222 ; and a comb-shaped common electrode 230 having a trunk portion 231 and branches 232 . In addition, the gaps between the electrodes in the area surrounding the branch portion 222 or the branch portion 232 are not chamfered, and the electrode intervals in this area are not evenly spaced.

[0220] Figure 26 It is a figure which shows the simulation result of the liquid crystal display...

Embodiment approach 3

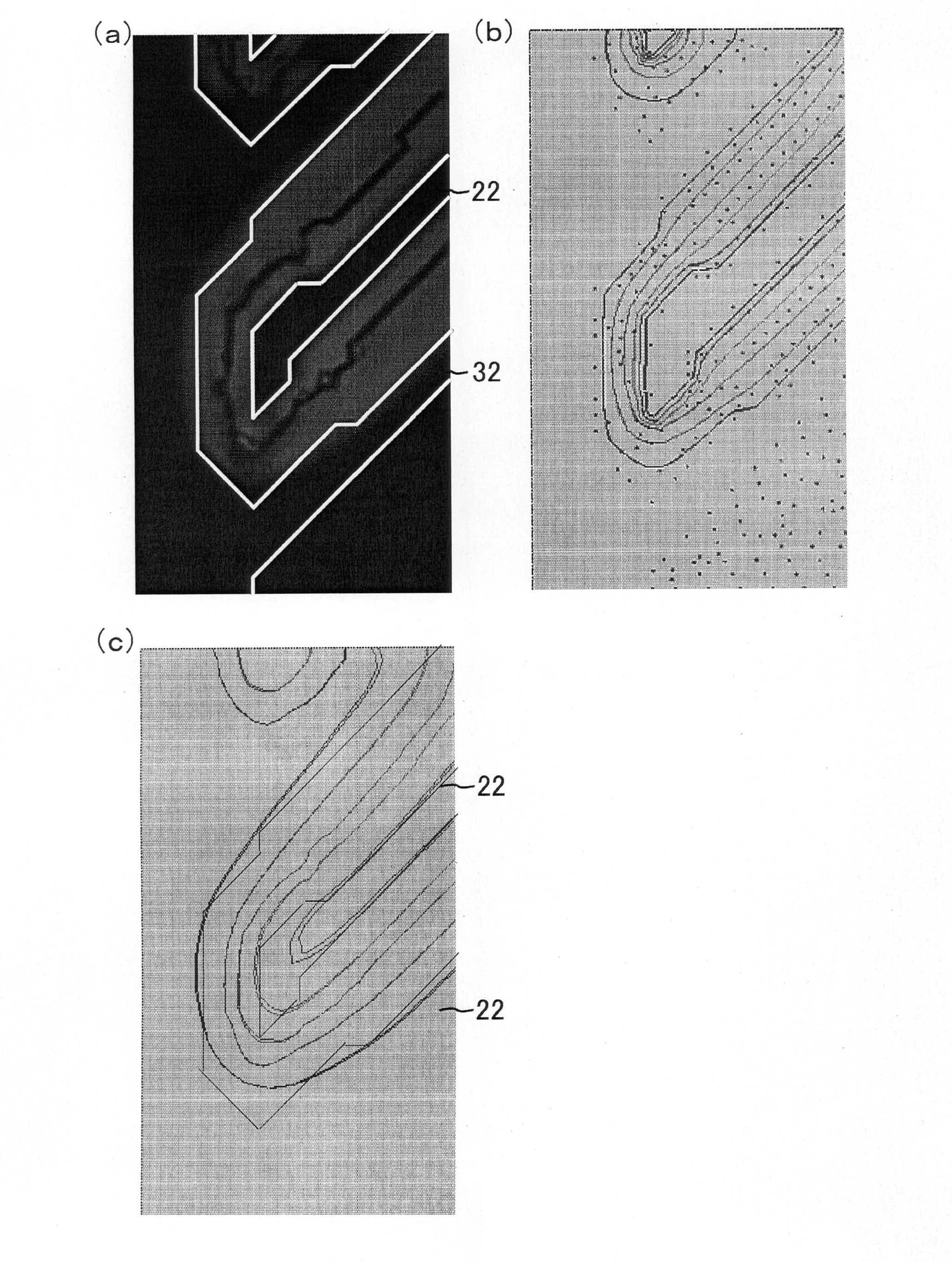

[0224] The liquid crystal display device of Embodiment 3 has the same configuration as that of the liquid crystal display device of Embodiment 2 except that L / S=4.0 μm / 12.0 μm is set.

[0225] (comparison method 2)

[0226] The liquid crystal display device of Comparative Embodiment 2 has the same configuration as the liquid crystal display device of Embodiment 2 except that L / S=2.5 μm / 7.5 μm is set.

[0227] (comparison method 3)

[0228] The liquid crystal display device of Comparative Embodiment 3 has the same configuration as the liquid crystal display device of Embodiment 2 except that L / S=2.5 μm / 5.0 μm is set.

[0229] (comparison method 4)

[0230] The liquid crystal display device of Comparative Embodiment 4 has the same configuration as the liquid crystal display device of Embodiment 2 except that L / S=2.5 μm / 4.0 μm is set.

[0231] (comparison mode 5)

[0232] The liquid crystal display device of Comparative Embodiment 5 has the same configuration as the liquid cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com