Baking oven with uniform large-air-volume hot air convection barbecuing function

A large air volume, oven technology, applied in the oven field, can solve the problem of not being able to get heat, and achieve the effects of high heat utilization rate, uniform temperature distribution, and large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

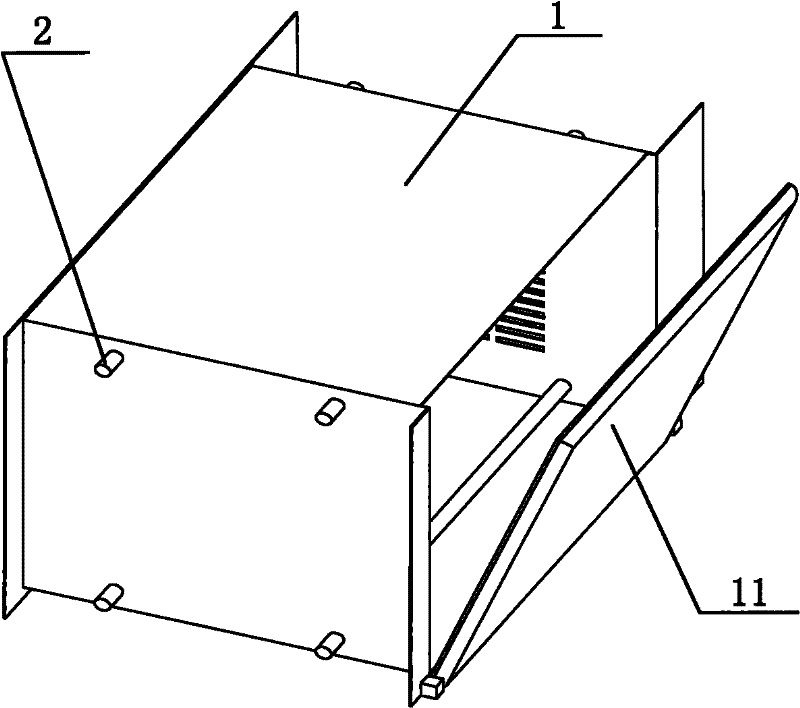

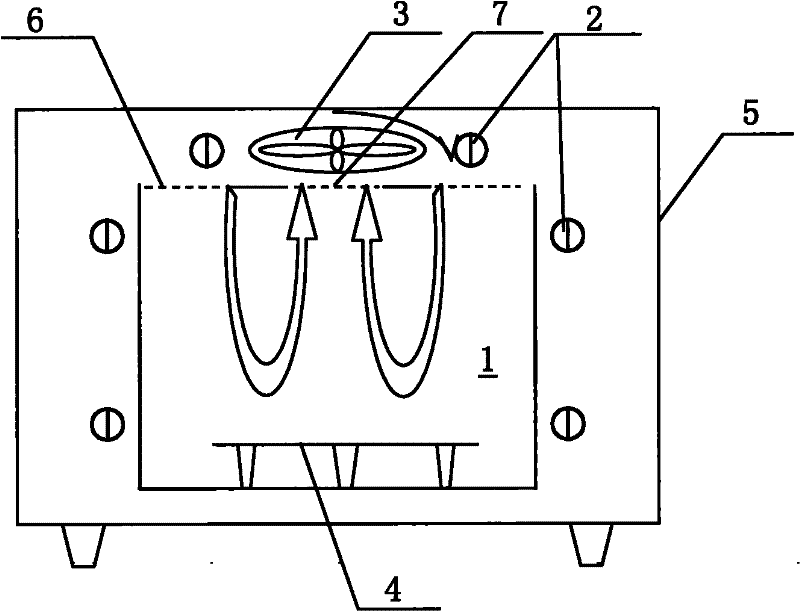

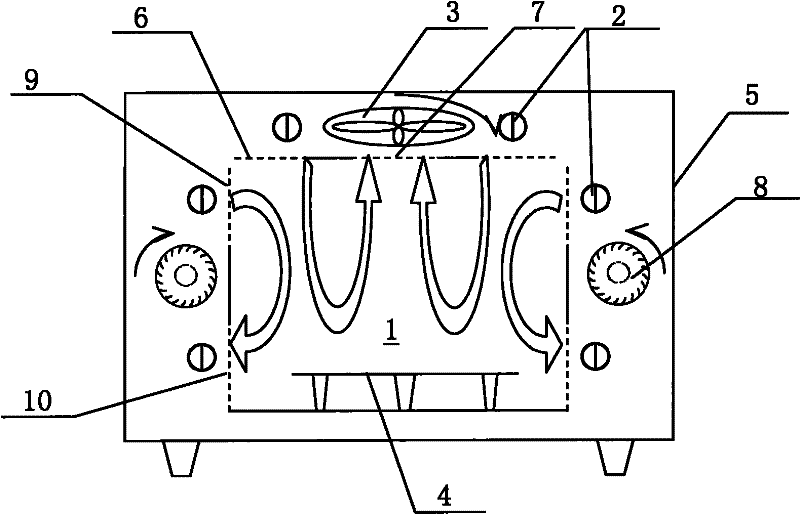

[0023] Hereinafter, the oven for hot air convection grilling with uniform large air volume and hot air convection according to the present invention will be described in detail with reference to the accompanying drawings and embodiments.

[0024] Such as figure 2 As shown, the oven of the present invention with uniform large air volume and hot air convection grilling includes an oven shell 5 and an oven cavity 1 located in the oven shell 5, which is arranged between the oven shell 5 and the oven cavity 1 and is located A centrifugal fan 3 at the top of the oven cavity 1, an air outlet 6 and a return air outlet 7 corresponding to the centrifugal fan 3 are formed on the top wall of the cavity 1, and a plurality of baking pipes 2 and A grill 4 arranged in the cavity 1 of the oven. In order to distribute the heat emitted by the plurality of baking tubes 2 around the cavity 1 evenly in the cavity 1, between the oven shell 5 and the oven cavity 1 and on the left and right sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com