Screw tap overload protection device

An overload protection and tap technology, applied in thread cutting devices, metal processing equipment, manufacturing tools, etc., can solve problems such as troublesome tap removal, scrapped cylinder block, increased cost, etc., achieves ingenious and reasonable structure design, avoids tap breakage, and reduces production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

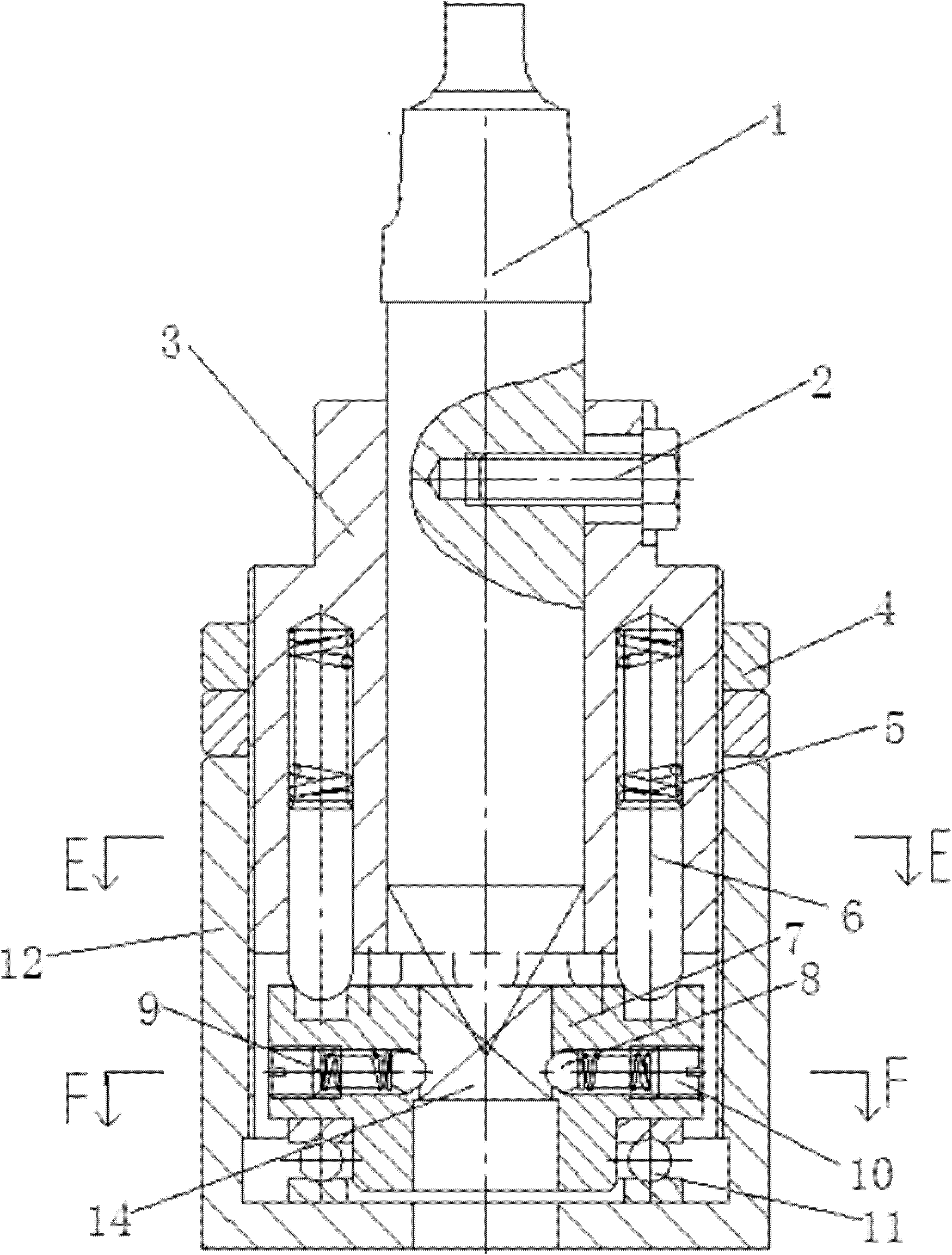

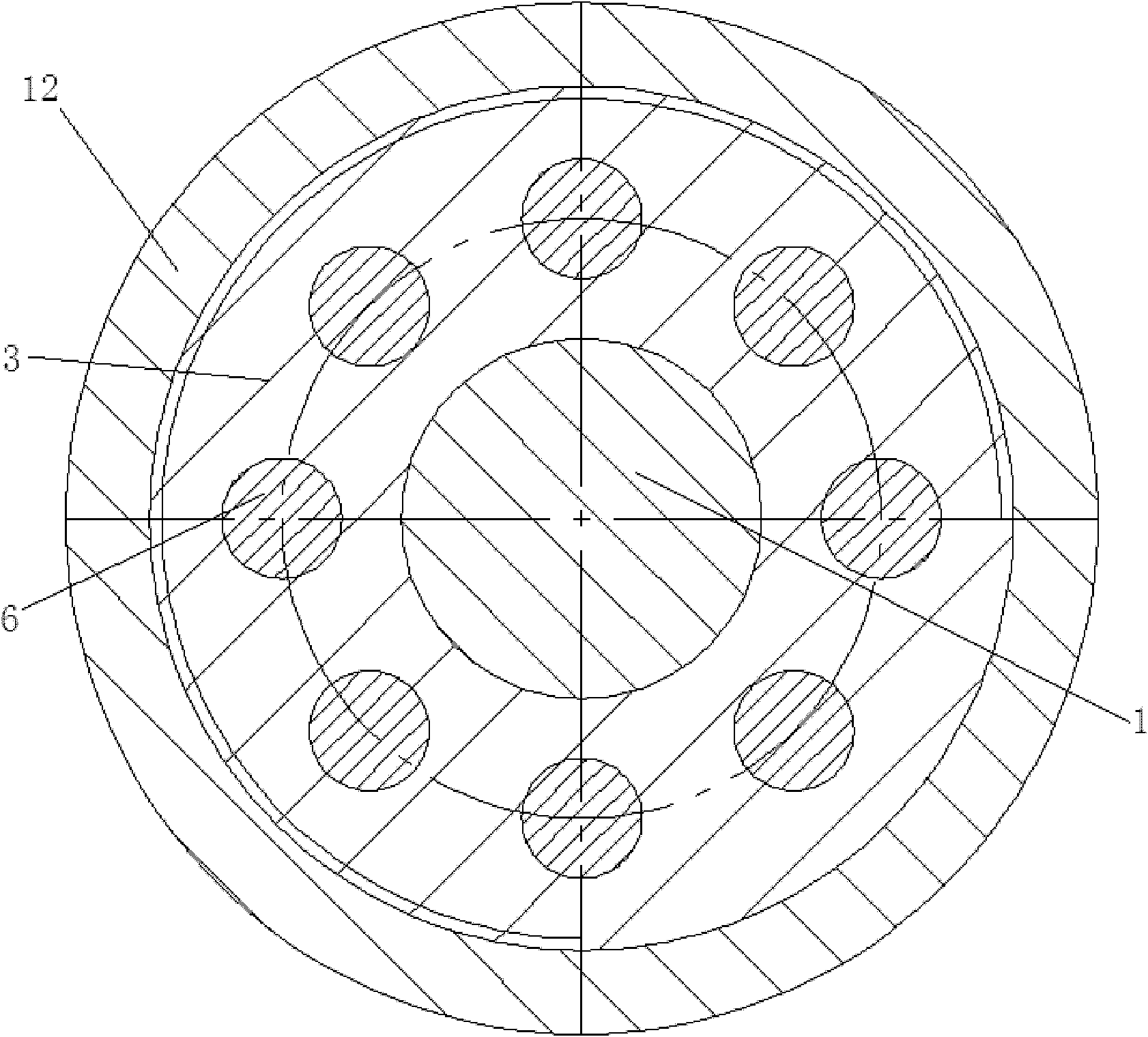

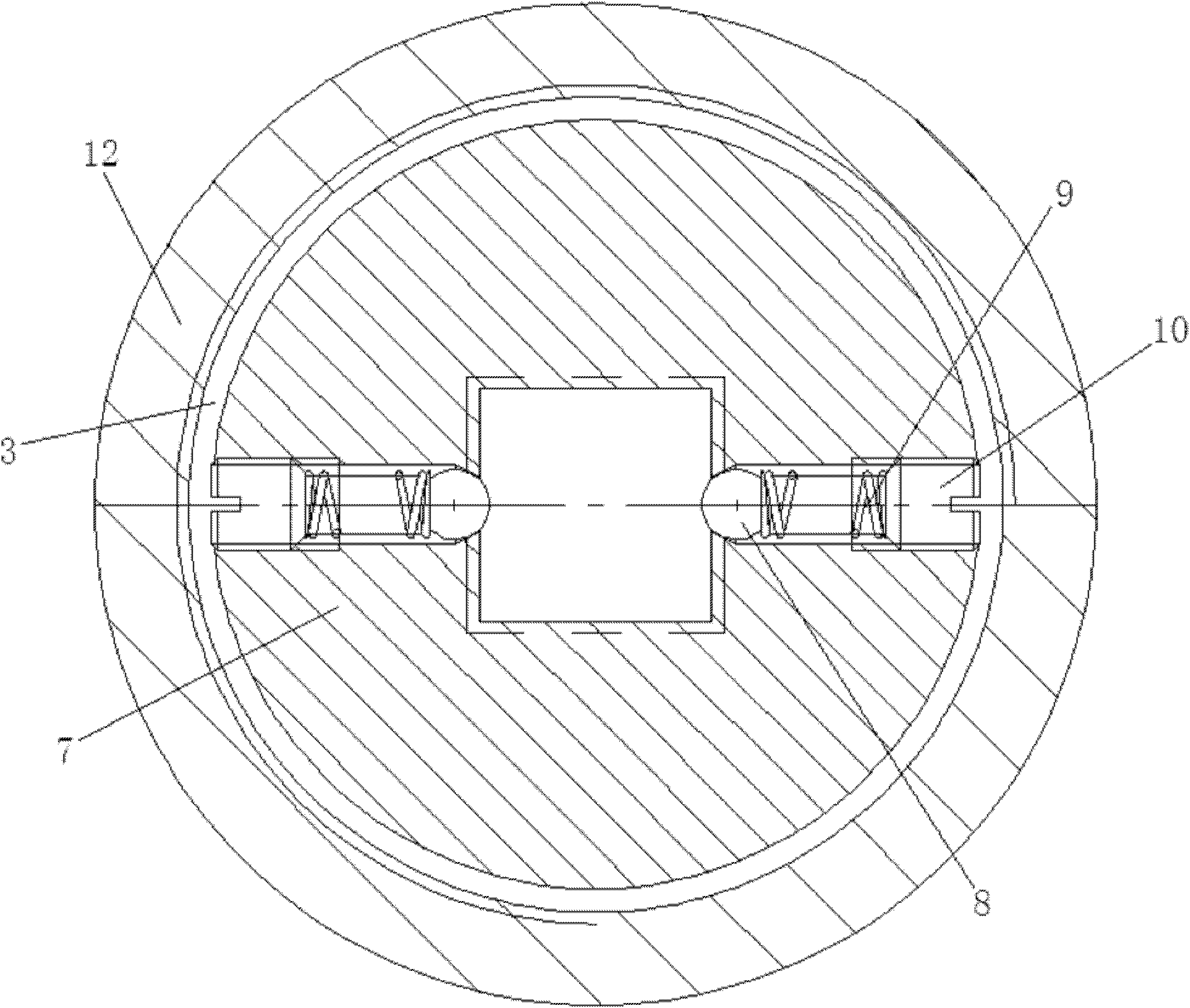

[0017] see figure 1 , 2 , 3, 4, a tap overload protection device, including a handle 1, the bottom of the handle 1 is a tapered structure, the outer sliding sleeve of the handle 1 has a transmission sleeve 3, the cone of the handle 1 Shaped bottom protrudes from the bottom surface of the transmission sleeve 3; a waist-shaped groove 13 is opened on the handle 1, and a bolt 2 passes through the transmission sleeve 3 and extends into the waist-shaped groove 13 of the handle to connect the transmission sleeve 3 with the handle 1. connection; the transmission sleeve 3 is covered with a nut sleeve 12, and the transmission sleeve 3 is tightly connected to the nut sleeve 12 through the lock nut 4; the nut sleeve 12 is located below the transmission sleeve 3 and is installed with a taper by pushing the ball bearing 11 Collet 7, a square hole 14 is arranged in the middle of the tap chuck 7, the tapered bottom of the handle 1 is facing the center of the square hole, the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com