Device for feeding sheets to a sheet stack

A kind of technology of equipment and sheets, applied in general parts of printing machinery, printing, printing machines, etc., can solve problems such as wrinkles, sheet damage, tearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

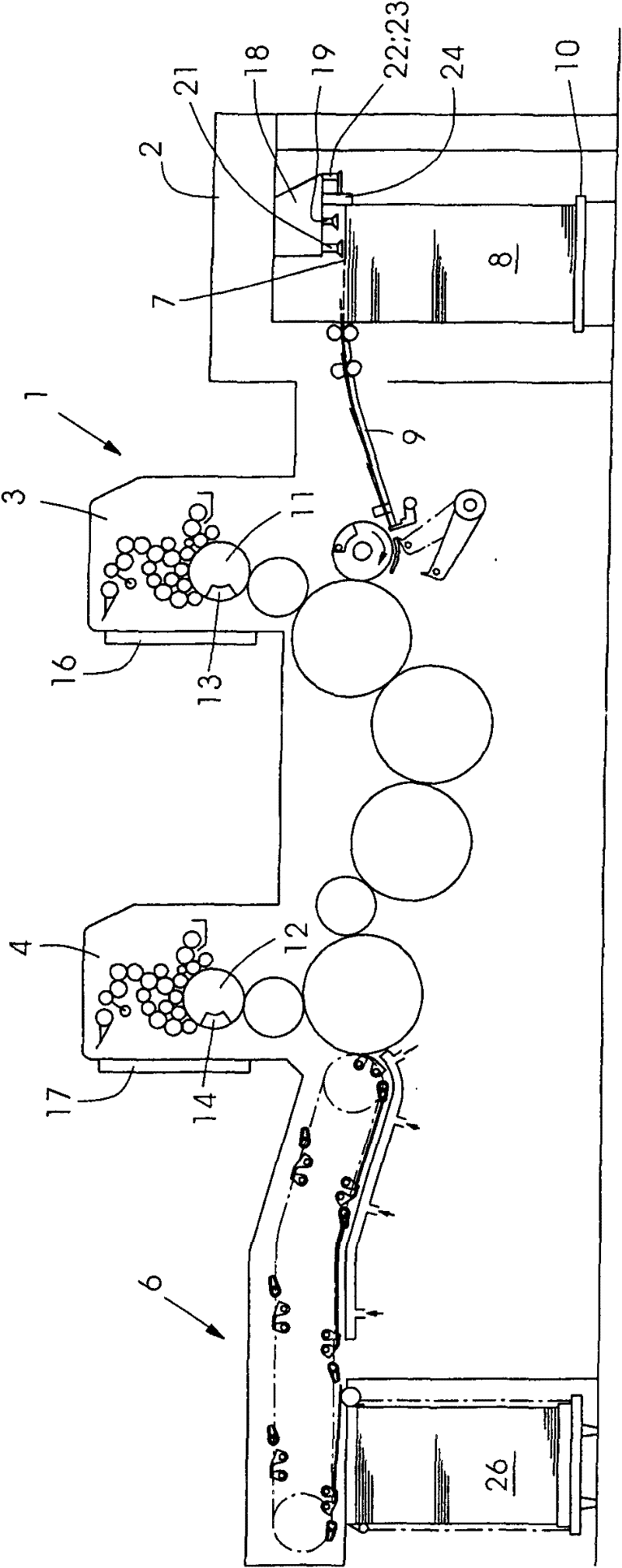

[0013] A machine for processing sheets 7 , for example a printing press 1 , has a feeder 2 , at least one printing unit 3 or 4 and a delivery 6 . The sheets 7 are removed from the sheet stack 8 and fed into the printing units 3 and 4 individually or in sheets via a supply table 9 . These printing units each comprise a printing form cylinder 11 , 12 in a known manner. The printing plate cylinders 11 and 12 each have a device 13 , 14 for fixing a flexographic printing plate. Furthermore, a device 16 , 17 for semi-automatic or fully automatic plate changing is assigned to each plate cylinder 11 , 12 .

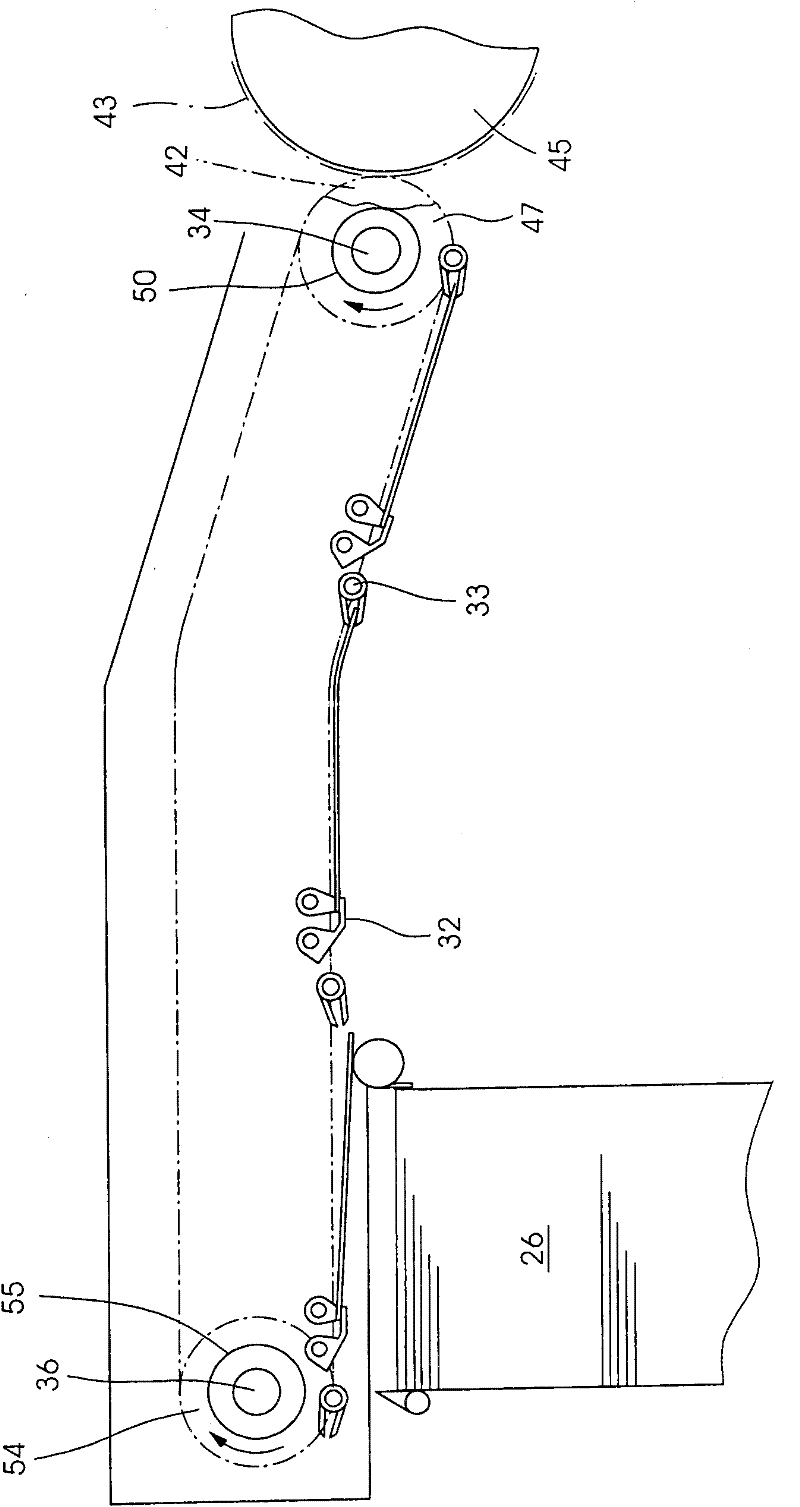

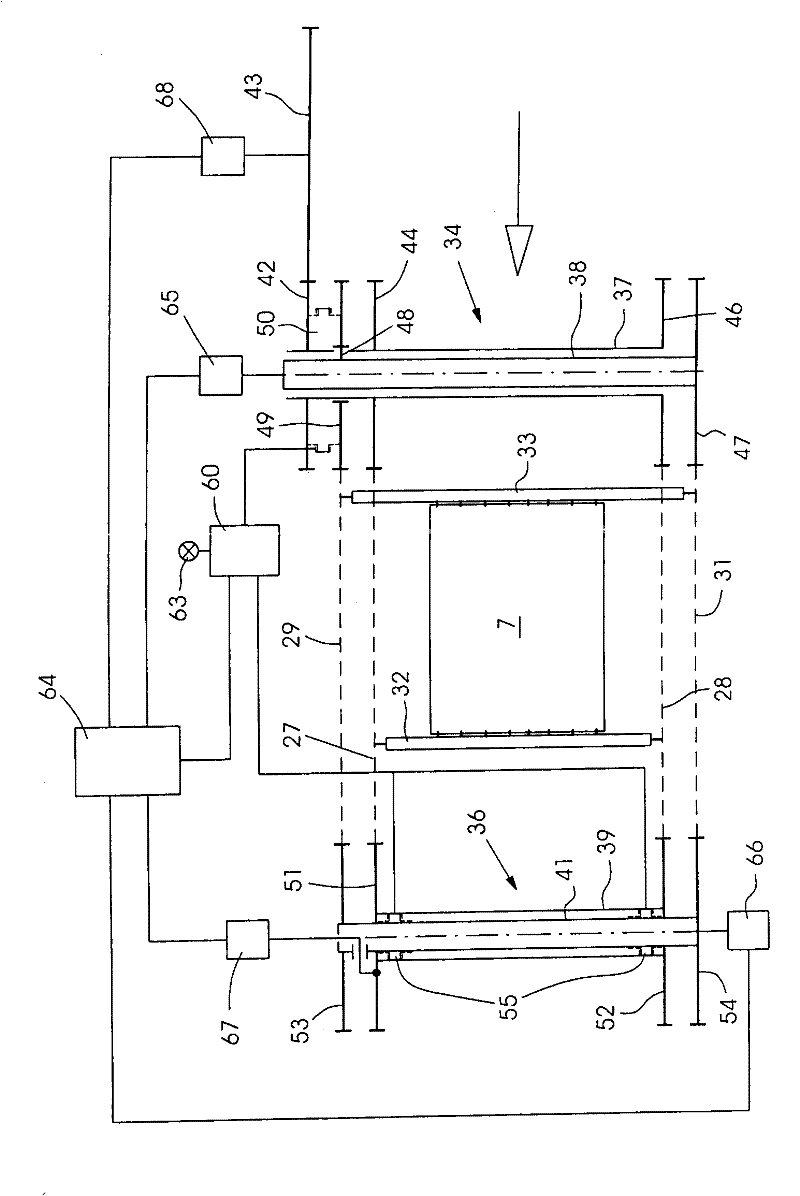

[0014] The sheet stack 8 is supported on a stack plate 10 which can be raised and lowered in a controlled manner. The extraction of the sheets 7 takes place from the upper side of the sheet stack 8 by means of a so-called suction head 18, which essentially has a plurality of lifting and pulling suction devices 19, 21 for pulling the sheets 7 Split into sheets. Furthermore, a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com