Sheet-type micro refrigerator applying lead-free ferroelectric material

A ferroelectric material and refrigerator technology, which can be applied to machines, refrigerators, refrigeration and liquefaction using electrical/magnetic effects, etc., can solve problems such as environmental pollution and human poisoning, and achieve low cost, high electrothermal effect, and simple structure. Effect

Active Publication Date: 2011-09-21

THE HONG KONG POLYTECHNIC UNIV

View PDF7 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the electrothermal effect of lead-based ferroelectric materials is better, lead-containing materials will cause serious environm

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Breakdown field strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

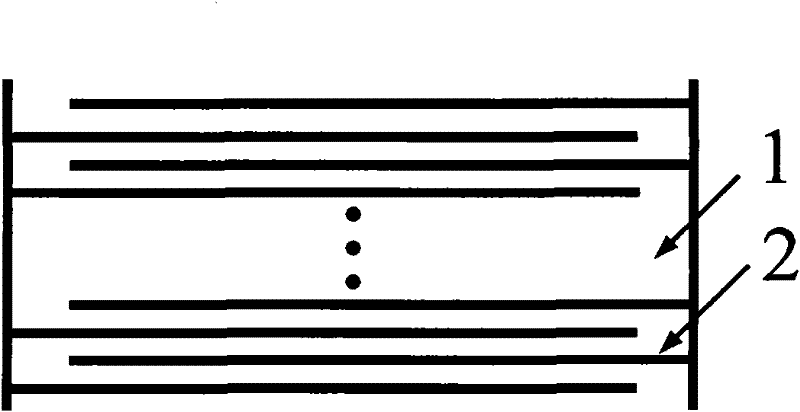

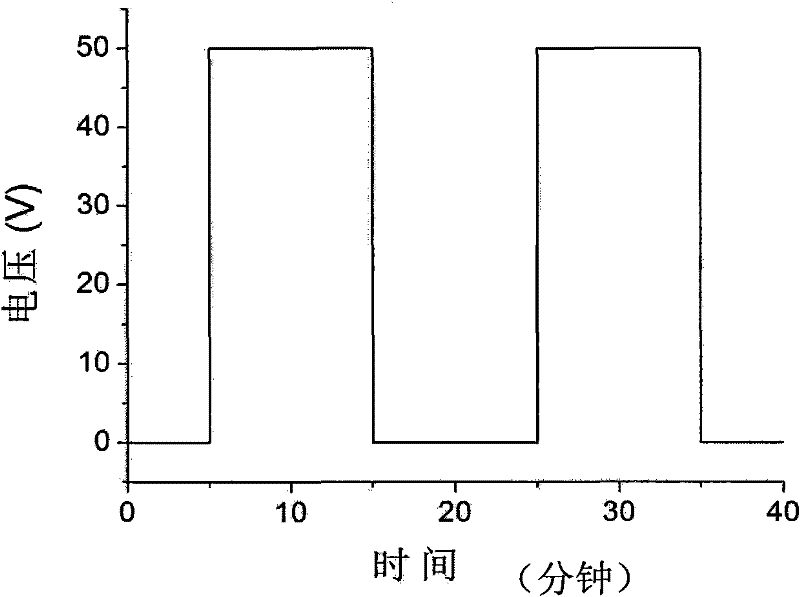

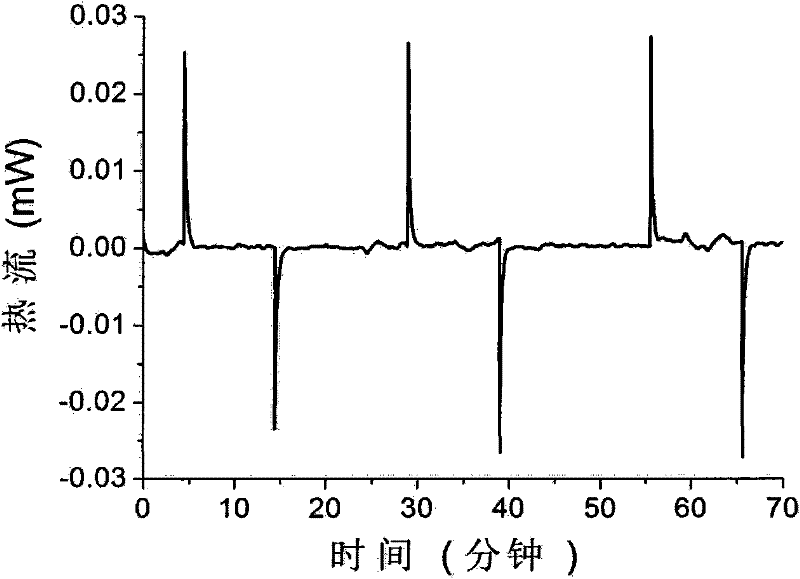

Abstract

The invention relates to a sheet-type micro refrigerator applying a lead-free ferroelectric material. The micro refrigerator comprises a multi-layer structure which is composed of a ferroelectric dialectric layer and a metal electrode layer alternatively; the ferroelectric dielectric layer is made of the lead-free ferroelectric material; periodic square wave signals with alternative changes of working electric fields for controlling the ferroelectric dialectric layer are applied on the metal electrode layer, thus the changes of the working electric fields of the ferroelectric dialectric layer are higher than 100kv/cm. A curtain coating technology is adopted to manufacture the multi-layer thick film structure for the sheet-type micro refrigerator provided by the invention, the high electrocaloric effect is realized through a superelevation electric field condition, and the sheet-type micro refrigerator has the following beneficial effects: 1) environmental protection: a lead-free ferroelectric ceramic is adopted as a working medium, which correponds to the environment protection requirement; 2) high efficiency: the actual refrigerating amount can reach more than 2J/g; and 3) the structure is simple, the production technology is mature, and the cost is low.

Description

technical field [0001] The invention relates to the field of electronic components, in particular to a chip-type microrefrigerator using lead-free ferroelectric materials. Background technique [0002] The rapid growth of high-performance portable electronic devices in the past ten years has promoted the rapid development of electronic technology in the direction of miniaturization and integration, and three-dimensional high-density packaging has become the mainstream technology in the industry. More and more components in electronic equipment are integrated into smaller and smaller closed spaces. When the equipment is working, a large number of components will release heat at the same time, which will cause local high temperature, cause various failures, and greatly reduce system reliability. Therefore, the overall heat dissipation of the system The design and application of efficient cooling devices has become the key to the reliable operation of electronic systems. [00...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F25B21/02

Inventor 白洋郑广平石三强

Owner THE HONG KONG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com