Preparation method of silicon-doped lead zirconate titanate non-oriented film with high electrocaloric effect

An electrothermal effect and lead zirconate titanate technology, which is applied in the field of preparation of silicon-doped lead zirconate titanate non-oriented films, can solve the problems of lack of integrated circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

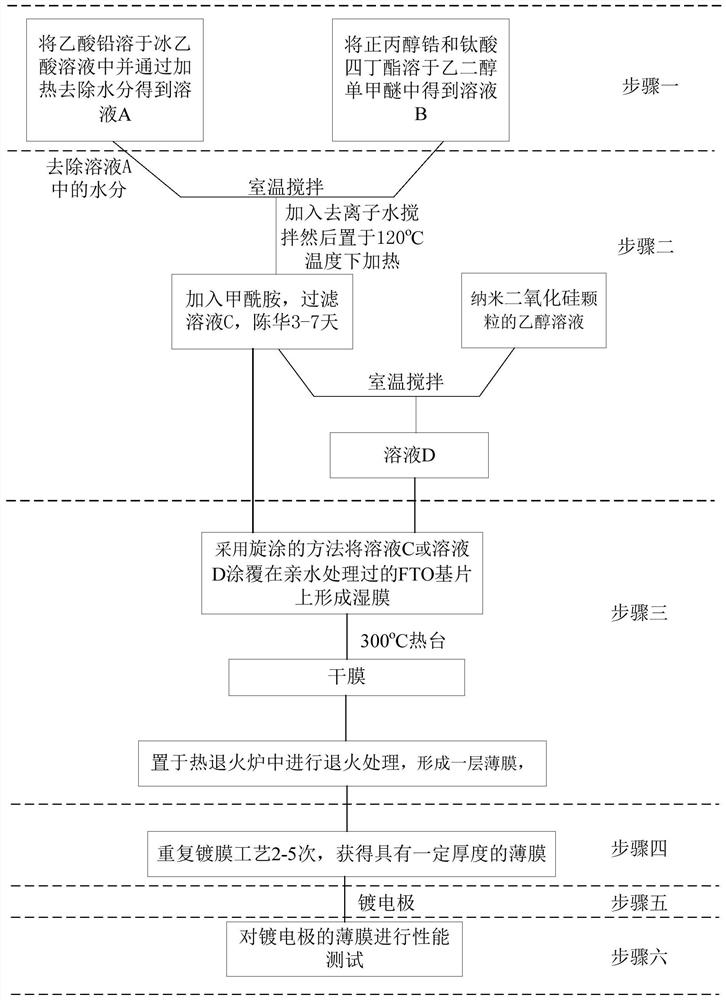

[0020] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, the method for preparing a silicon-doped lead zirconate titanate non-oriented film with high electrothermal effect described in this embodiment, the method includes the following steps:

[0021] Step 1, dissolving lead acetate in glacial acetic acid solution and removing water by heating to obtain solution A, dissolving zirconium n-propoxide and tetrabutyl titanate in ethylene glycol monomethyl ether to obtain solution B;

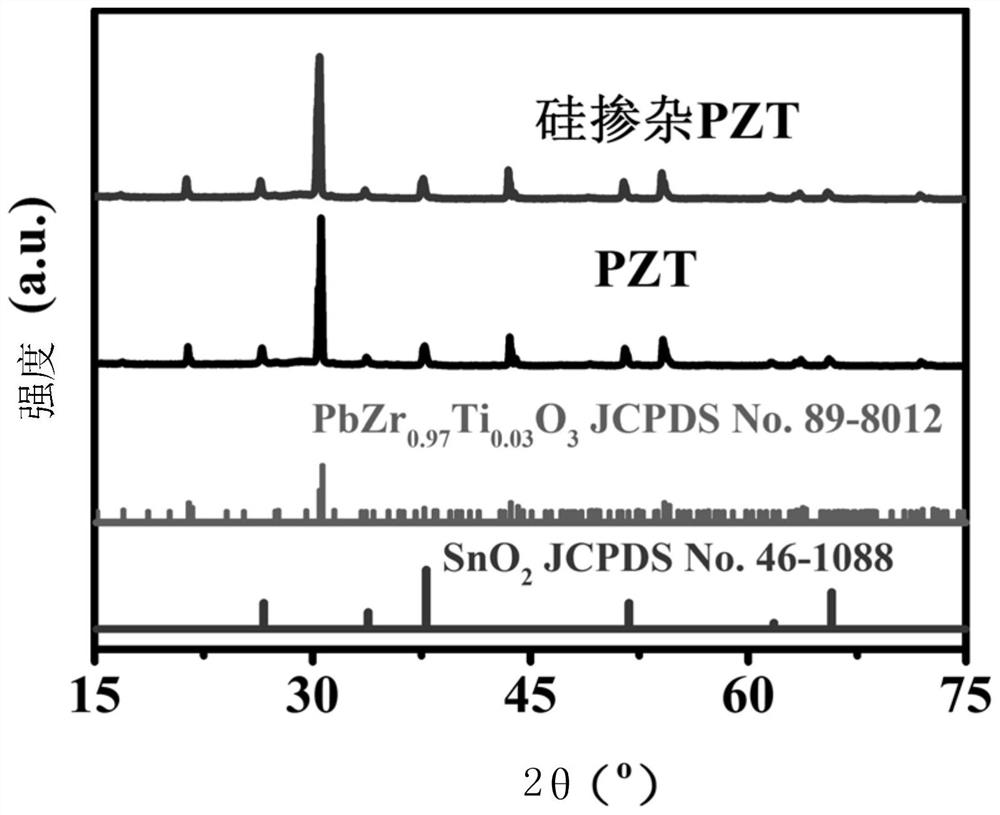

[0022] Step 2. Mix solution A and solution B under stirring to form flocculent insolubles, add ionized water to the flocculent insolubles to dissolve the insolubles, and then heat to accelerate the reaction to form PbZr 1-x Ti x o 3 sol solution, the PbZr 1-x Ti x o 3 The sol solution is used as solution C; the ethanol solution of nano silicon dioxide particles is mixed with solution C to obtain solution D;

[0023] Step 3. Coating: Coat solution C or solu...

specific Embodiment approach 2

[0031] Specific embodiment 2: This embodiment is to further illustrate the preparation method of the silicon-doped lead zirconate titanate non-oriented film with high electrothermal effect described in specific embodiment 1. In this embodiment, the method also includes the performance Test steps:

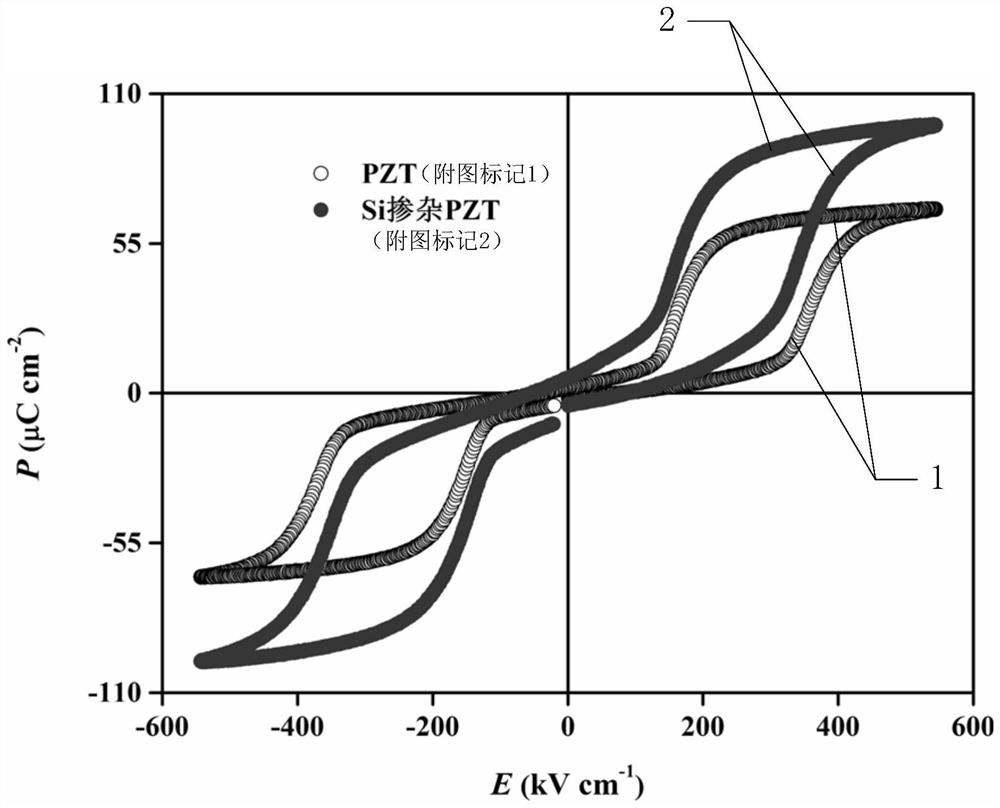

[0032]Step 6. Measure the hysteresis loops of the thin film with platinum electrodes at different temperatures during the cooling process, obtain the polarization intensity under different electric fields according to the hysteresis loop curves and draw the curves with temperature, and obtain them through Maxwell's equations The curve of electrothermal performance changing with temperature.

specific Embodiment approach 3

[0033] Specific embodiment three: This embodiment is to further illustrate the preparation method of the silicon-doped lead zirconate titanate non-oriented film with high electrocaloric effect described in specific embodiment one. In this embodiment, in step two, in the Add deionized water to the flocculent insolubles to dissolve the insolubles, and then heat to accelerate the reaction to form PbZr 1-x Ti x o 3 The concrete process of sol solution is:

[0034] Add a total volume of 25%-30% deionized water to the flocculent insoluble matter, place the transparent solution after dissolving the insoluble matter in a drying oven at 110-120°C and continue heating for 0.5-2 hours or evaporate to reflux, Fully react the transparent solution and volatilize the intermediate by-products in the transparent solution, and finally form PbZr 1-x Ti x o 3 Sol solution.

[0035] In this embodiment, the function of fully reacting the transparent solution is to obtain a sol solution that d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com