Improved method and system in engineering design optimization based on multi-objective evolutionary algorithm

A multi-objective evolution and engineering design technology, applied in the field of engineering design optimization, can solve the problems of Pareto optimal solution without diversification, poor diffusion and uniformity, and insufficient convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

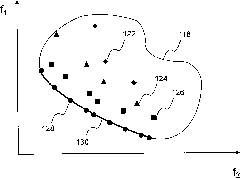

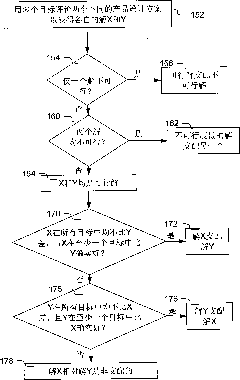

[0022] first reference Figure 1A , the tubular structural component 102 (ie, a representative engineered product) is optimized in engineering optimization where the design objective is to minimize weight under certain design load conditions to minimize the cost of a specified material (eg, common strength steel). Clearly, a thinner thickness 104 will result in a less weighty structure. However, at a certain point, the structure will become too weak to withstand the design load (such as a failed structure due to material yielding or material curvature). Therefore, engineering optimization of this tubular structure requires another design goal of maximizing strength, which leads to a safer structure. In this representative example, thickness 104 is a design variable that can have a range (eg, from 1 / 8 inch to 1 / 2 inch) as a design space. Any design proposals are selected from within this space. In a multi-objective evolutionary algorithm, each generation of populations or des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com