Improved brush carrier structure

A brush holder and positioning structure technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of unfavorable wire contact, disordered wiring space, etc., to achieve easy wire contact problems, beautiful wiring, The effect of facilitating wire positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

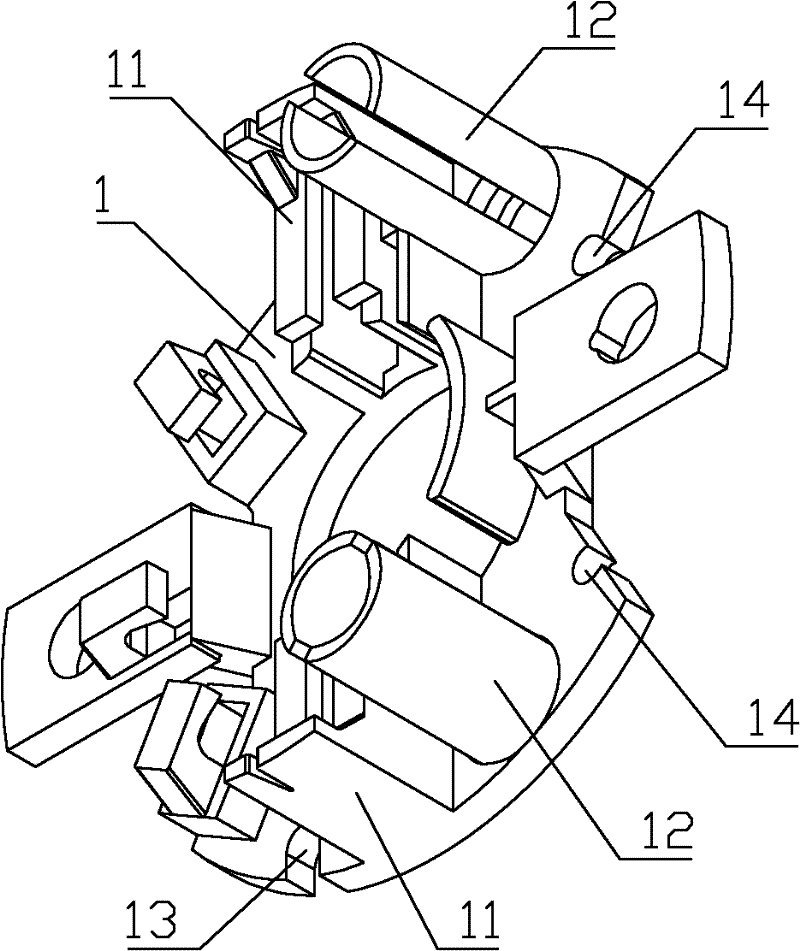

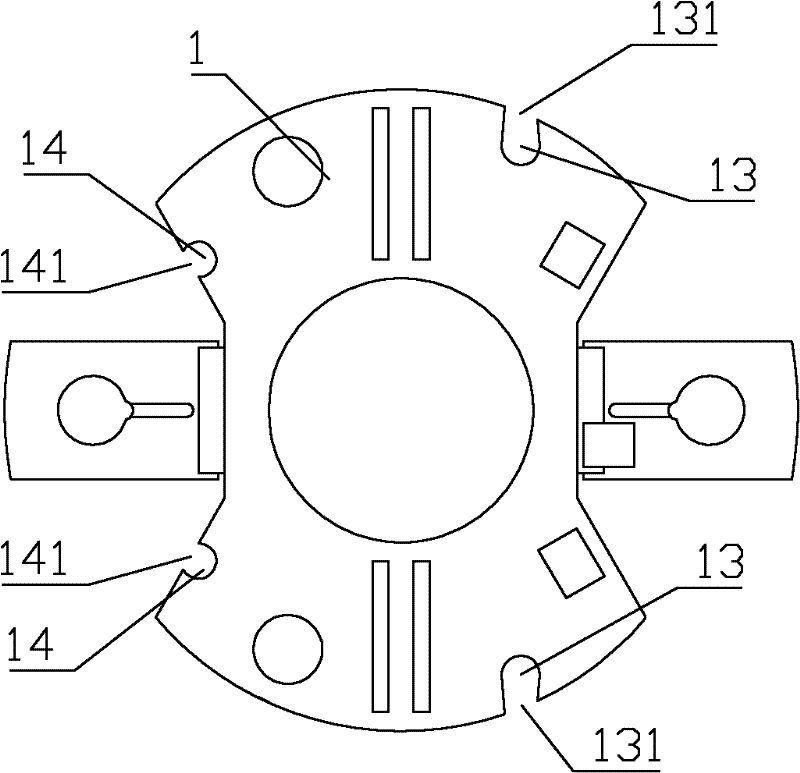

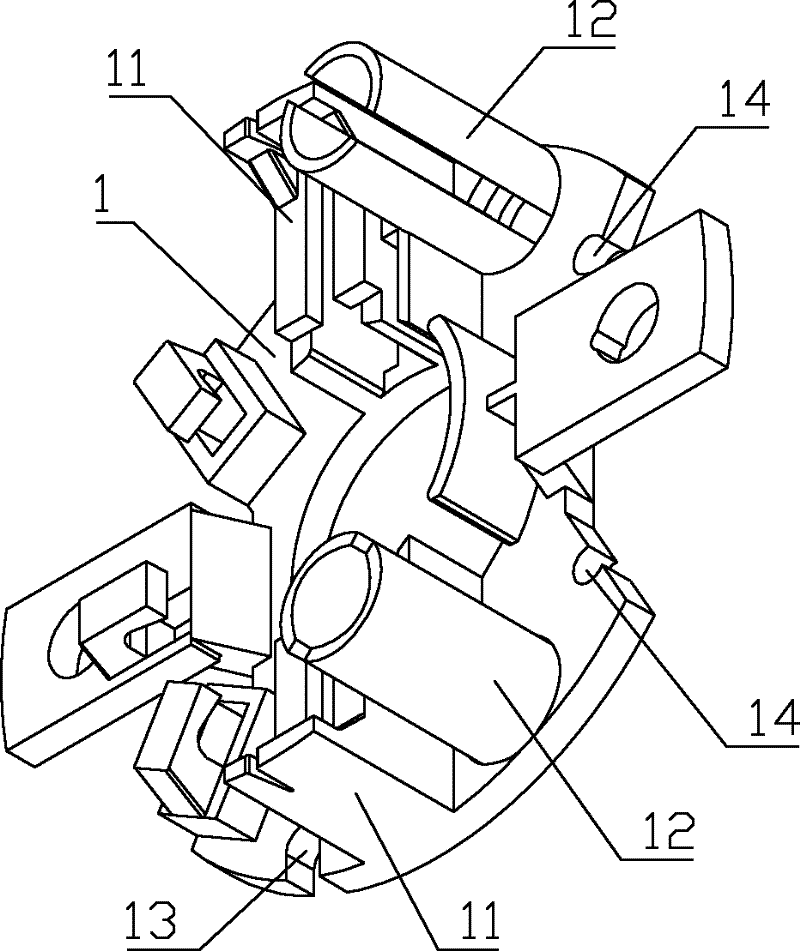

[0013] Such as figure 1 and 2 Shown is a structural schematic diagram of an embodiment of the present invention, an improved structure of a brush holder, including a brush holder plate 1, on which a positioning seat 11 for installing a carbon brush and a positioning sleeve 12 for installing an inductor are arranged, and on the positioning seat The edge of the brush holder plate next to the positioning sleeve is provided with a positioning structure for positioning wires. The positioning structure includes a bayonet I13 on the side of the positioning seat and a bayonet II14 on the side of the positioning sleeve. The bayonet I and the bayonet II are respectively transition-fit or interference-fit with the wires, and the bayonet I and the bayonet are generally preferred. II has an interference fit with the wire, which can make the wire have a certain tension.

[0014] In the above embodiment, the mouth width of bayonet I is smaller than the diameter of the wire, the mouth width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com