Horn elastic wave with different hardness and manufacturing method thereof

A technology of horns and horns, applied in electrical components, sensors and other directions, can solve the problems of hard resin, low frequency channels are not easy to appear, poor elasticity, etc., to improve the rebound ability, improve the output effect, and improve the sound quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

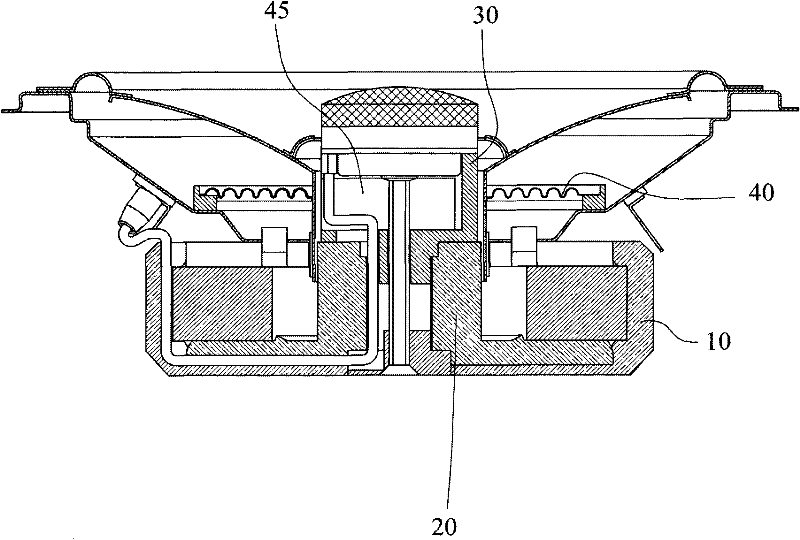

[0018] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this specification.

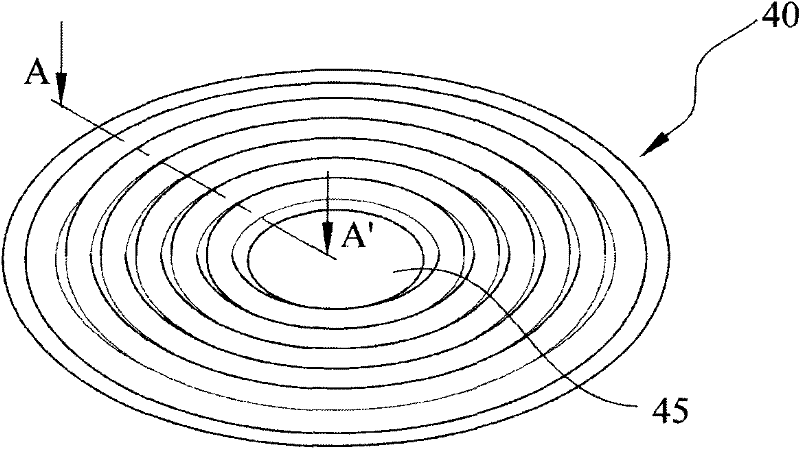

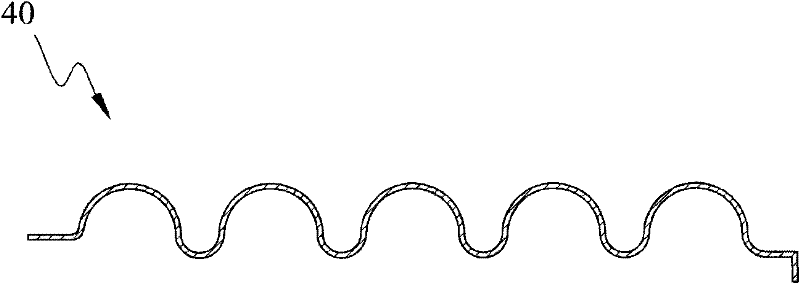

[0019] refer to Figure 4A and Figure 4B , are respectively the top view of the first embodiment of the horn elastic wave with different hardness in the present invention, and the first embodiment of the horn elastic wave with different hardness in the present invention, with Figure 4A The enlarged side view of the B-B' section in the middle, the section of the horn wave in all directions is the same as the B-B' section, and only the B-B' section is taken as an example. like Figure 4A and Figure 4B As shown, the horn spring 50 of the present invention with different hardness includes a body 60 and a rubber coating 71 . The body 60 is a kind of circular body made of fabric impregnated with resin, has a central through hole 65 for connecting the voice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com