Colour correction method for coloured light lamp

A technology of color correction and lamps, which is applied in the field of LED lighting, can solve problems such as RGB cannot be improved synchronously, inconsistent colors of lamps, poor product consistency, etc., and achieve the effects of reducing procurement difficulty, ensuring product consistency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

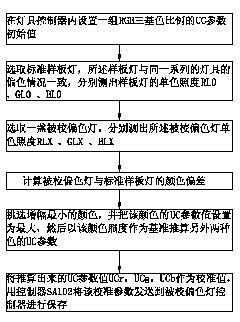

[0029] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0030] Such as figure 1 As shown, a color correction method for a color light lamp, the lamp includes a controller, and the controller controls a light source with three primary color LED chips to emit light, and the correction method includes the following steps:

[0031] (1) Set a set of UC parameter initial values of RGB three-primary color ratio in the lamp controller; UC parameter is a set of RGB three-primary color ratio parameters built into the lamp, which represents the ratio of RGB three-primary color, not brightness, before the lamp leaves the factory The initial value must be set first to work normally. The initial value of UC parameters: R: G: B = 255: 255: 255; the initial value of UC parameters is to make RGB work at full brightness. Therefore, the UC parameter value is not fixed and should be adjusted according to the color cast of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com