Novel paper leading tool close to vat

A large vat and a new type of technology, applied in papermaking, papermaking machines, textiles, and papermaking, etc., can solve problems such as difficult handling by operators, inconvenient re-threading, and low strength of tobacco slurry, so as to eliminate potential safety hazards and economic potential Obvious benefits and the effect of improving paper threading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

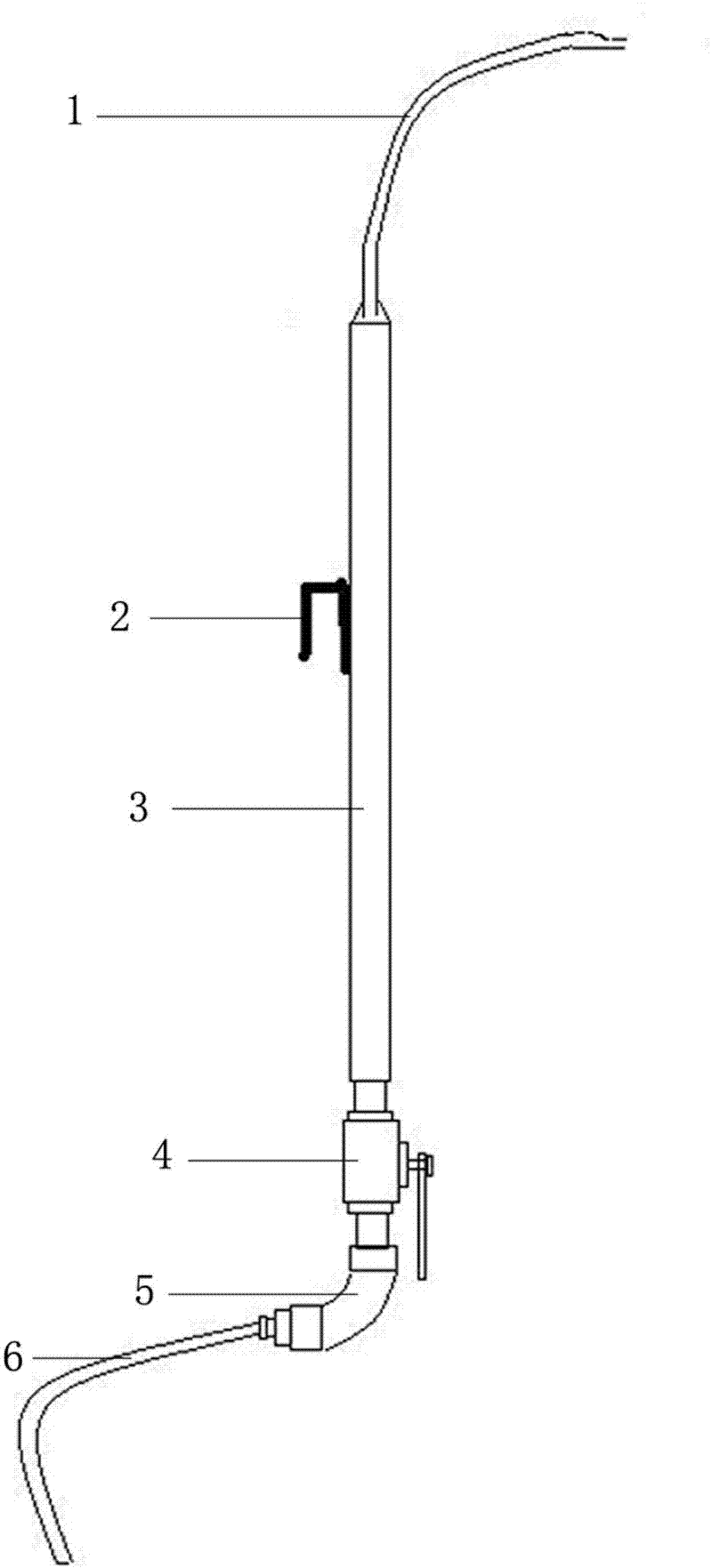

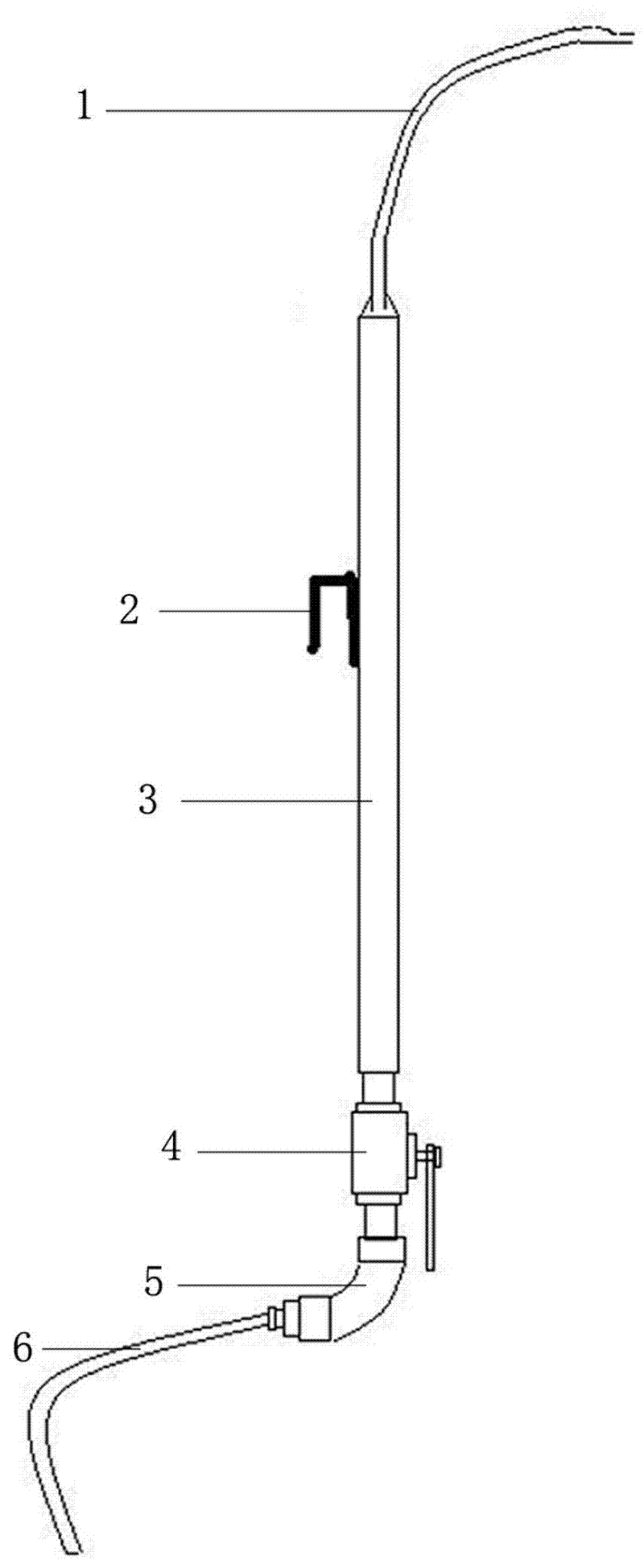

[0011] Example: such as figure 1 As shown, the new type of paper threading tool at the large cylinder includes a hollow rod body 3, the lower end of the hollow rod body 3 is provided with a manual valve 4 and a hollow handle 5, the lower end of the hollow handle 5 is connected with a compressed air source through a pipeline 6, and an arc is provided at the upper end of the hollow rod body 3. Shaped hollow nozzle body 1. The nozzle of the hollow nozzle body 1 is duckbill-shaped. A hook 2 is arranged on the outside of the hollow rod body 3 . The hollow rod body 3, the hollow nozzle body 1, the manual valve 4 and the hollow handle 5 are all made of stainless steel.

[0012] During the specific implementation, the compressed air is connected with the quick connector, and a flexible manual valve is set on the tail handle, so that the operator can easily move the tool and control the compressed air flow at any time; at the head, according to the site operation space, the tool It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com