Composite household garbage combustion hot-water boiler

A technology for domestic waste and hot water boilers, which is applied in combustion methods, combustion types, incinerators, etc., can solve problems such as failure to achieve energy saving and emission reduction, and achieve the effects of convenient maintenance, large treatment range and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

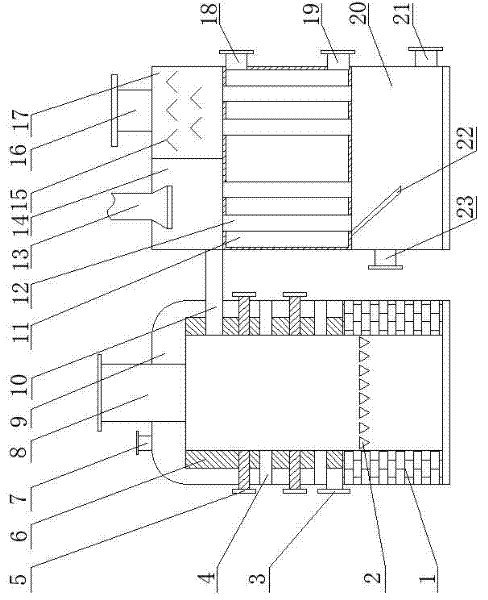

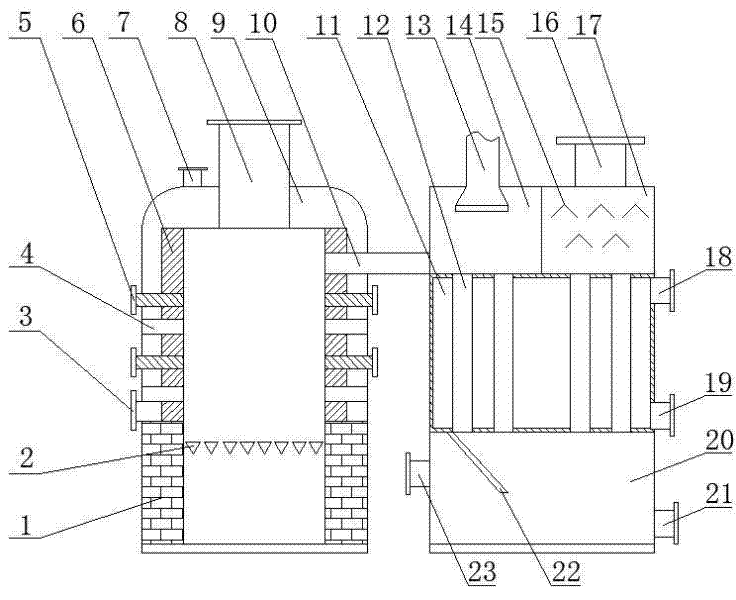

[0011] See attached figure 1 , a composite hot water boiler burning domestic garbage, comprising: a furnace body 1, an external vertical drum, the furnace body 1 is cylindrical, and the upper part of the furnace body 1 is provided with an outer water jacket 9 and a refractory material layer 6. The upper end of the outer water jacket 9 is provided with a feed inlet 8, a horizontal flue 10 and an outlet 7 of the outer water jacket, and the middle part of the outer water jacket 9 and the refractory material layer 6 is provided with a frequency conversion magnetic field generator 5 and a vent 4, The furnace cavity of the furnace body 1 is provided with a movable fire grate 2, and the horizontal smoke pipe 10 of the furnace cavity is connected with an external vertical drum, and the external vertical drum is respectively separated by a spray chamber 14 from top to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com