High-temperature smelting and reducing three-phase arc furnace

A high-temperature smelting and electric arc furnace technology, which is applied in the field of high-temperature smelting and reduction three-phase electric arc furnaces, can solve problems such as difficulty in repairing the furnace and pouring out of melted materials, small tilting angle, and difficulty in keeping heat. High, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

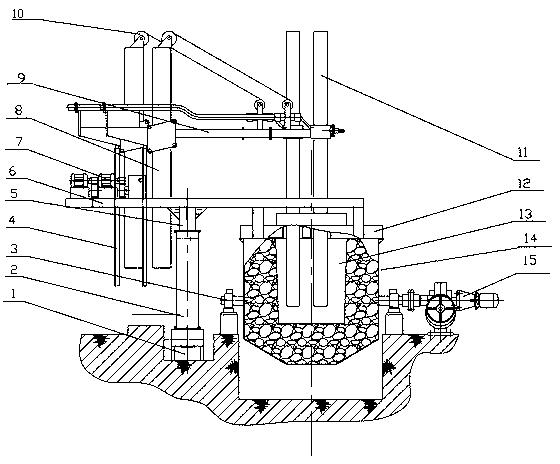

[0008] A high-temperature smelting reduction three-phase electric arc furnace, including a furnace cover lifting mechanism, an electrode 11, a furnace cover 12, a furnace 13, a furnace body 14, a furnace body rotating reducer 15, a furnace body rotating bearing seat 3, and the furnace cover lifting mechanism from the furnace Cover lifting hydraulic cylinder 1, cylindrical column 2, variable frequency speed reduction mechanism 7, conductive cross arm 9, counterweight 10, electrode lifting rack 4, furnace cover rotating shaft 5, furnace cover cradle platform 6, electrode lifting column 8 The cylindrical column 2 is fixed on the foundation, the furnace cover lifting hydraulic cylinder 1 is installed in the cylindrical column 2, and the furnace cover rotating shaft 5 is arranged in the cylindrical column 2 above the furnace cover lifting hydraulic cylinder 1. The frame platform 6 is fixedly connected to the furnace cover rotating shaft 5, three sets of electrode lifting columns 8 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com