Double-shell heat exchanger

A technology of heat exchanger and double shell, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve problems such as heat exchanger leakage, prevent impact and wear, reduce thermal pollution, Effect of preventing deformation of sealing parts or cracking of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

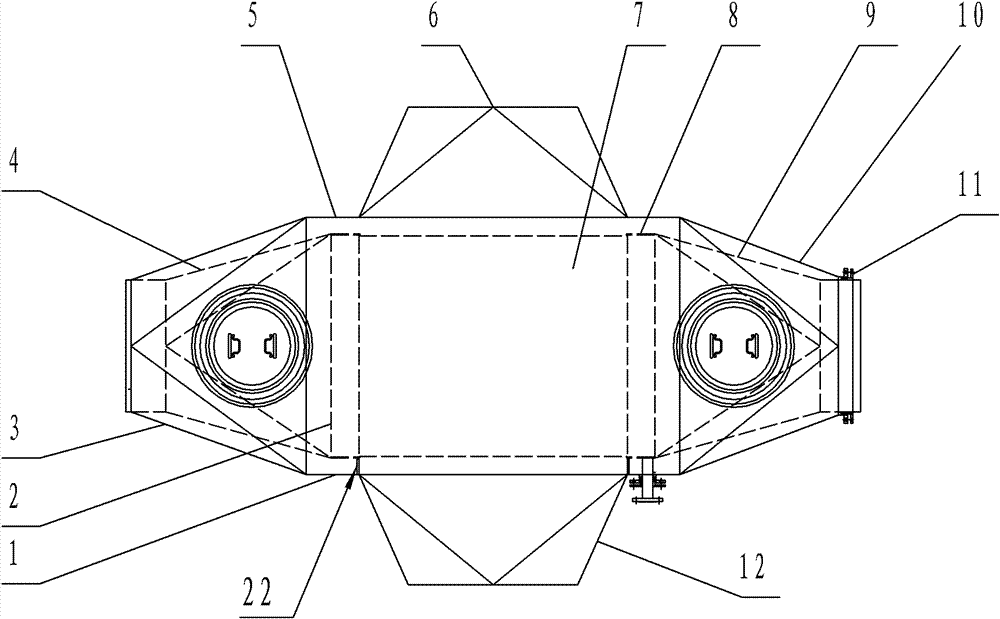

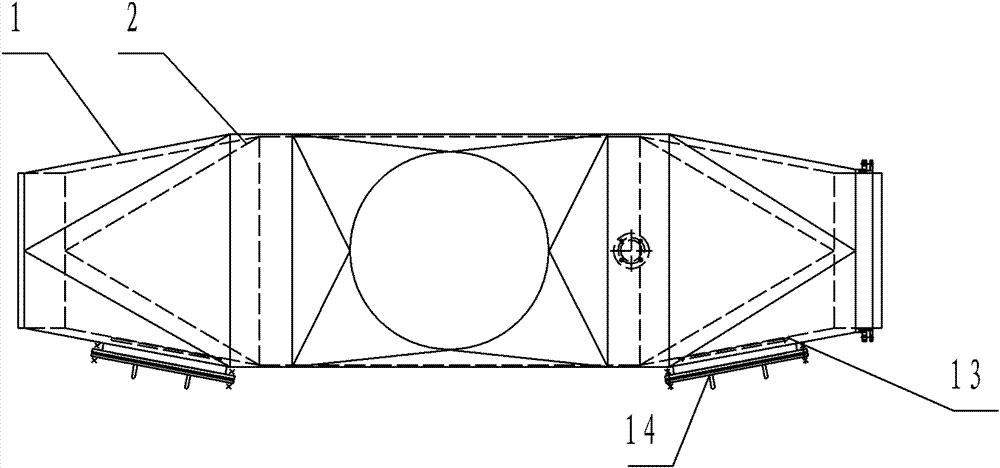

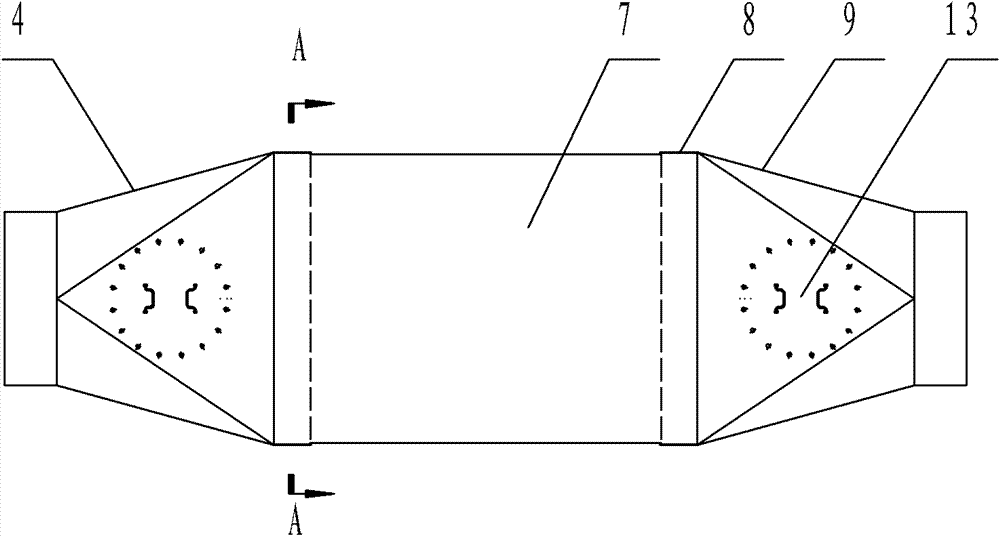

[0031] Example 1, such as figure 1 , 2 A double-shell heat exchanger is shown, which is characterized by: a refrigerant inlet outer layer reducer 3, a rectangular outer box 5, a heat medium inlet reducer 6, a heat medium outlet reducer 12, and a refrigerant outlet outer The outer casing 1 composed of layer reducing heads 10 is equipped with an inner casing 2 composed of a refrigerant inlet inner layer reducing head 4, a rectangular inner box body 8, and a refrigerant outlet inner layer reducing head 9. The outer casing and the inner casing have one end Fixed connection, the other end is connected by stuffing box sealing device 11, and the heat exchange element is installed in the rectangular inner box, and the heat exchange element is a fully welded heat exchange plate bundle or welded by multiple heat exchange tubes and tube sheets heat exchange tube bundle. The length direction of the heat exchange element is consistent with the length direction of the inner casing. The in...

Embodiment 2

[0032] Embodiment 2, a double-shell heat exchanger, is characterized in that: a refrigerant inlet outer layer reducer 3, a rectangular outer box 5, a heat medium inlet reducer 6, a heat medium outlet reducer 12, a refrigerant The outer casing 1 composed of the outlet outer layer reducing head 10 is equipped with the inner casing 2 composed of the refrigerant inlet inner layer reducing head 4, the rectangular inner box body 8, and the refrigerant outlet inner layer reducing head 9. The outer casing and the inner casing One end of the body is fixedly connected, and the other end is connected by a stuffing box sealing device 11. A heat exchange element is installed in the rectangular inner box, and the heat exchange element is a fully welded heat exchange plate welded by a plurality of heat exchange plates 15. The length direction of the heat exchange element is consistent with the length direction of the inner casing, and the surface of the inner casing facing the inlet and outle...

Embodiment 3

[0033] Example 3, such as Figure 9 A double-shell heat exchanger is shown, which is characterized by: a refrigerant inlet outer layer reducer 3, a rectangular outer box 5, a heat medium inlet reducer 6, a heat medium outlet reducer 12, and a refrigerant outlet outer The outer casing 1 composed of layer reducing heads 10 is equipped with an inner casing 2 composed of a refrigerant inlet inner layer reducing head 4, a rectangular inner box body 8, and a refrigerant outlet inner layer reducing head 9. The outer casing and the inner casing have one end Fixed connection, the other end is connected by a stuffing box sealing device 11, and a shell flange 19 is arranged on the outer shell. A heat exchange element is installed in the inner box, and the heat exchange element is a heat exchange tube bundle welded by a plurality of heat exchange tubes 16 and a tube sheet 17, and the length direction of the heat exchange element is consistent with the length direction of the inner shell. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com