Outdoor enclosure for electronic equipment and method for providing an outdoor enclosure for electronic equipment

A technology of electrical equipment and housing, applied in the field of protective cover of electronic equipment, can solve the problems of expensive Kevlar, damage to electrical equipment, less prevention of gunfire vibration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

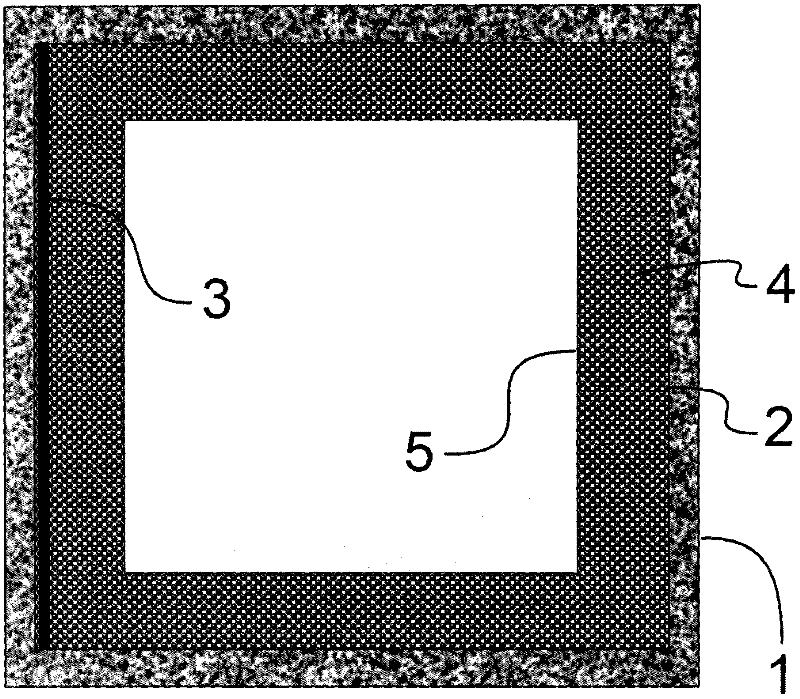

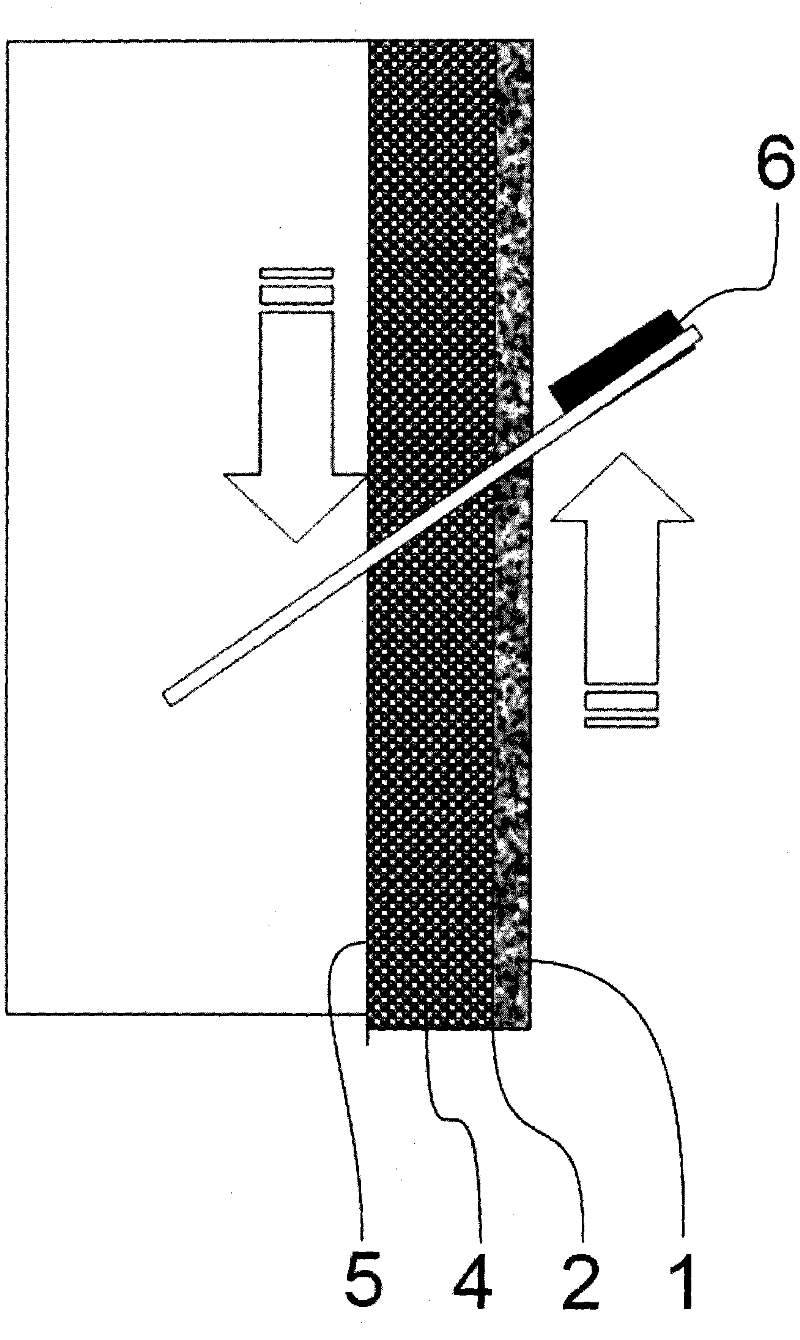

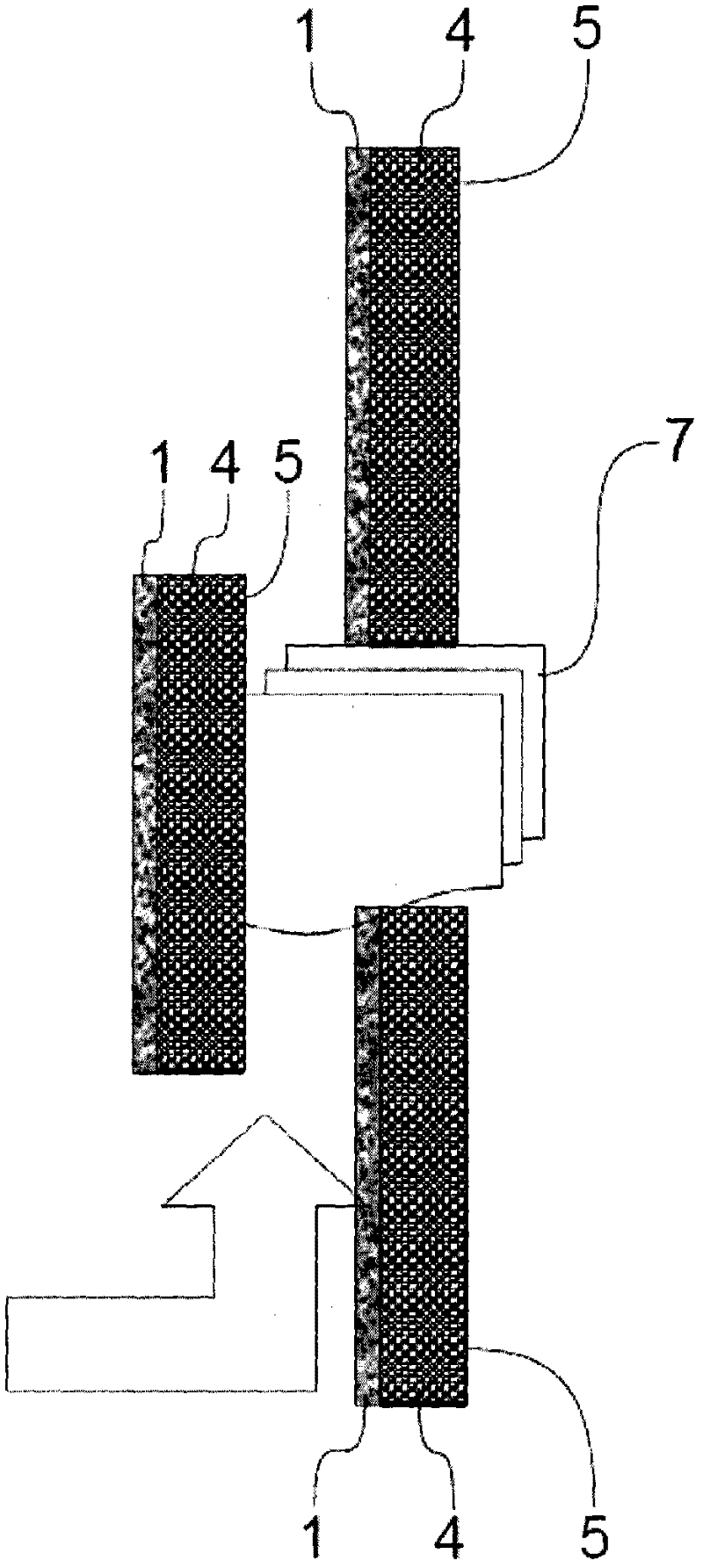

[0025] In the method according to the invention, the cover is produced in such a way that it can be equipped with protective material when the cover is installed. The cover is therefore preferably sent to the site without a protective element, ie a protective layer of absorbent material. The cover is thus made to have at least two nested shells, between which there is a cavity for receiving the protective element. Such as figure 1 As shown in , the enclosure has an inner shell 5 for receiving electrical equipment. Such shells are known per se. Electrical equipment can be any equipment that requires protection, but usually one specific type of equipment that requires enhanced protection is a frequency converter. This is because VFDs are commonly used on drilling rigs and for vulnerable operations such as this, where equipment is most likely to be exposed to sudden gunfire.

[0026] As said, the inner casing 5 surrounds the device. In the manufacturing stage, the second out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap