Grain status monitoring system based on fieldbus

A field bus control, field bus technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of the host computer interface is not vivid, increase farmers' income, poor anti-interference performance, etc., to achieve the monitoring interface Vivid and accurate, simple and efficient circuit, strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

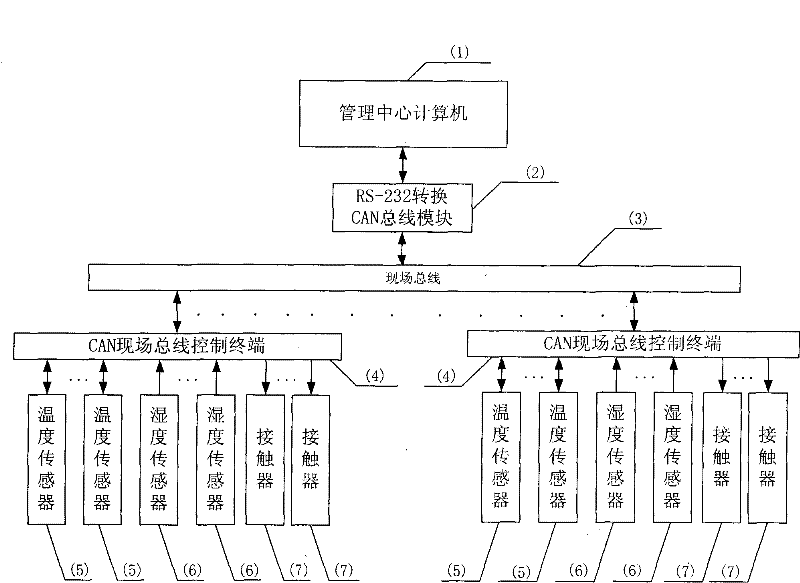

[0018] The first step: if figure 1 As shown, the industrial control configuration software is installed on the management center computer (1), and various grain situation monitoring interfaces are designed. At the same time, the management center computer (1) will also communicate with each CAN field bus control terminal (4) through the field bus (3). ) communication to set various parameters of the grain situation.

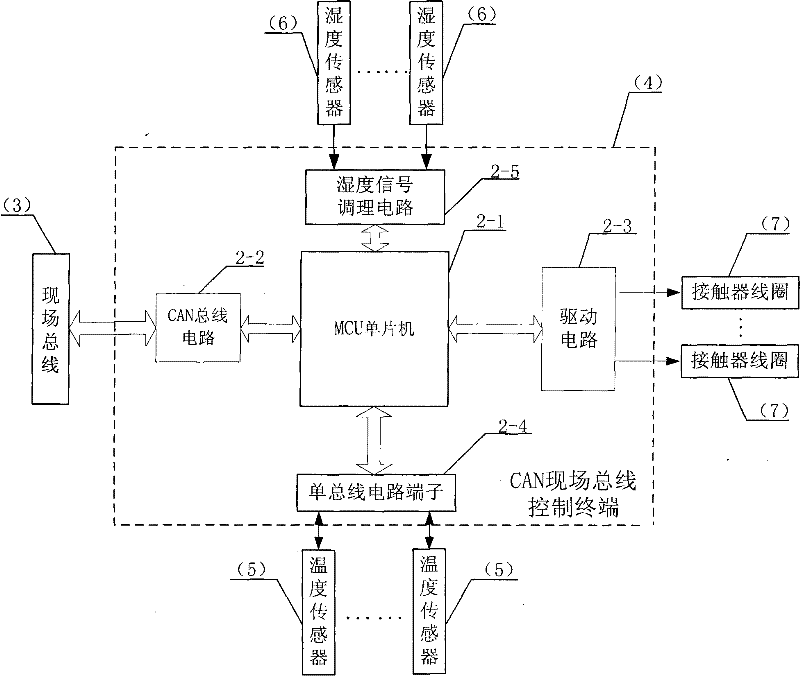

[0019] The second step: if figure 1 and as figure 2 As shown, each CAN field bus control terminal (4) collects temperature, humidity and contactor (7) signals and transmits them to the management center computer (1) through the field bus (3), and the management center computer (1) can control various food The situation monitoring interface is dynamically displayed in real time, and at the same time, the management...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com