Method for determining parameter of polycrystalline diamond compact bit

A composite drill bit and polycrystalline diamond technology, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as nozzle size, position, and angle that have not been optimized and determined, and cannot be optimized and determined.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

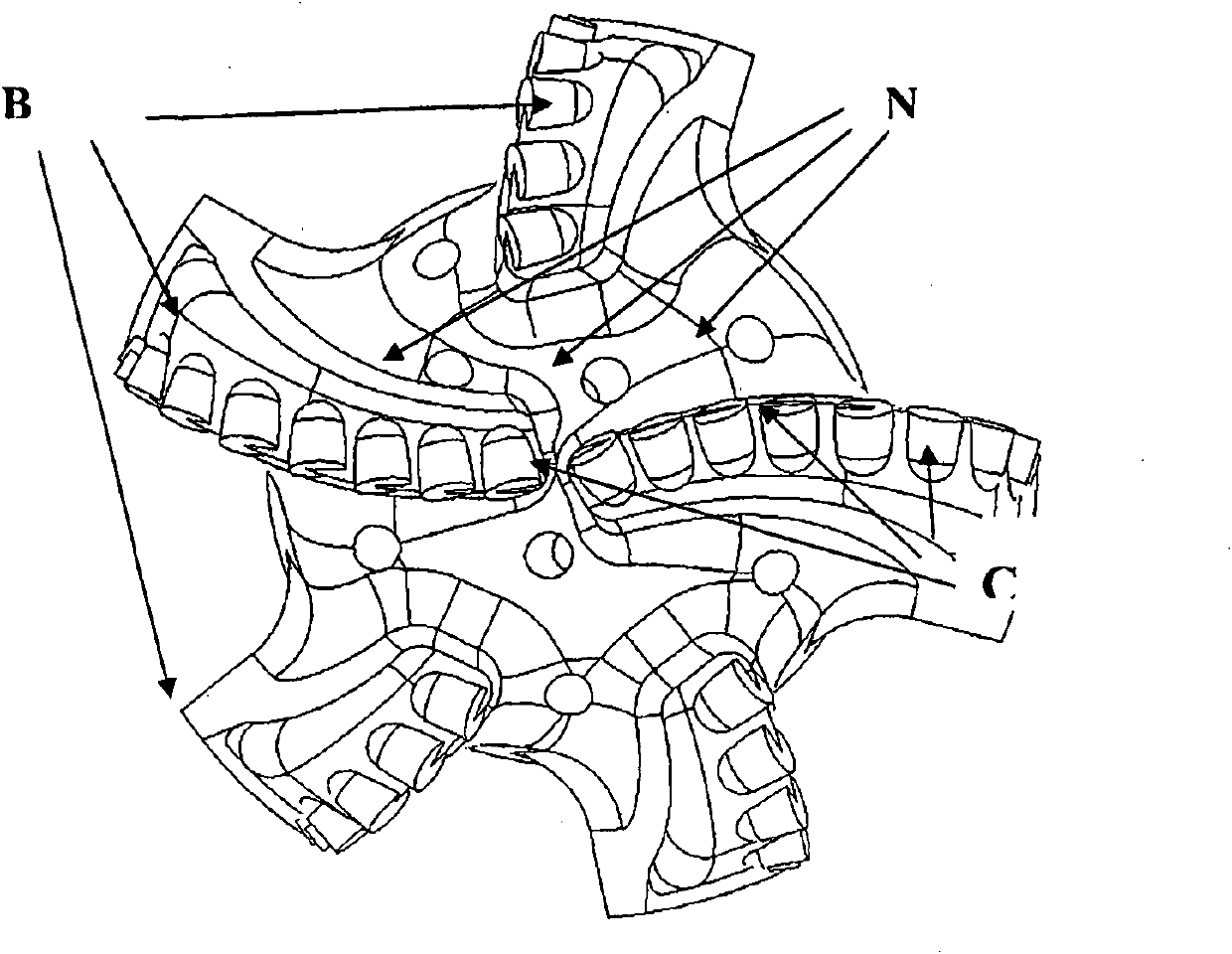

[0011] attached figure 1 It shows the bottom view of the PDC drill bit viewed from the bottom of the drill bit, which shows the structure of the main part of the drill bit, where the letter B indicates the blade, and the number of blades is multiple. B1, B2, and B3 are used in this application. ..Bn way to sort them, n represents the number of blades. The letter N indicates the nozzle, and there are multiple nozzles, which are sorted in the manner of N1, N2, N3...Nn in this application; the letter C indicates the cutting teeth, and the number is multiple.

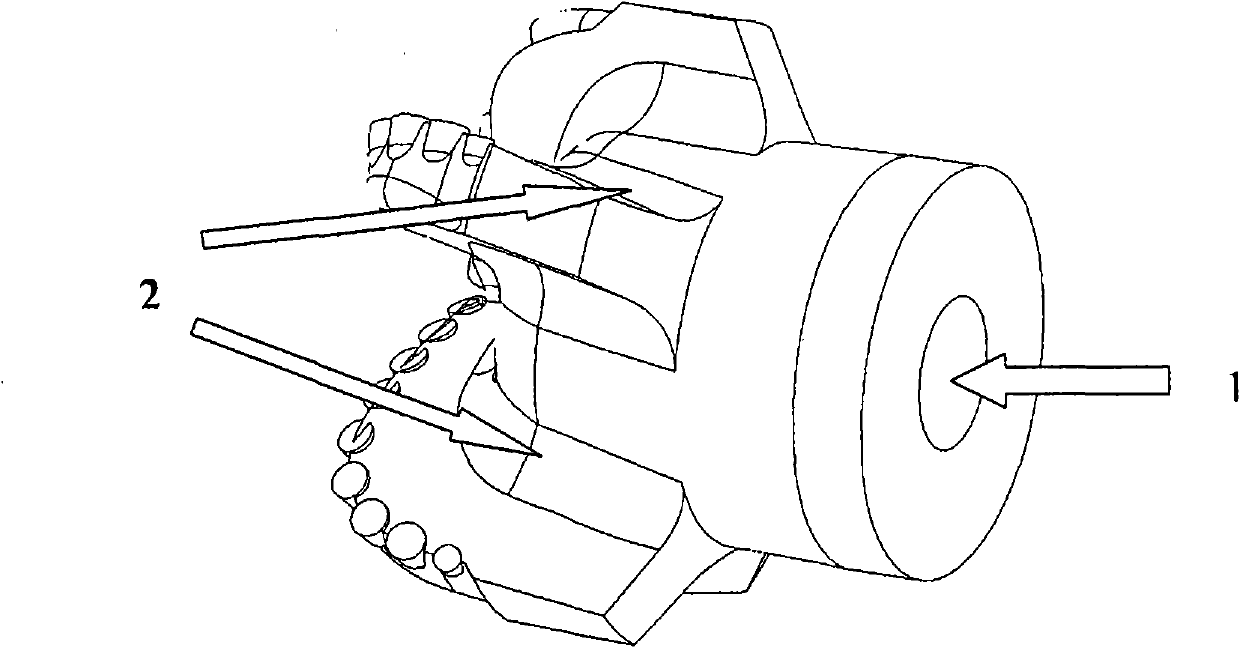

[0012] attached figure 2 A side view of the PDC bit is shown, where the right arrow indicates the drilling fluid inlet 1, while the left arrow indicates the drilling fluid outlet 2, the drilling fluid inlet flow rate of inlet 1 is represented by the letter P, and the drilling fluid outlet The outlet pressure of 2 is represented by the letter P.

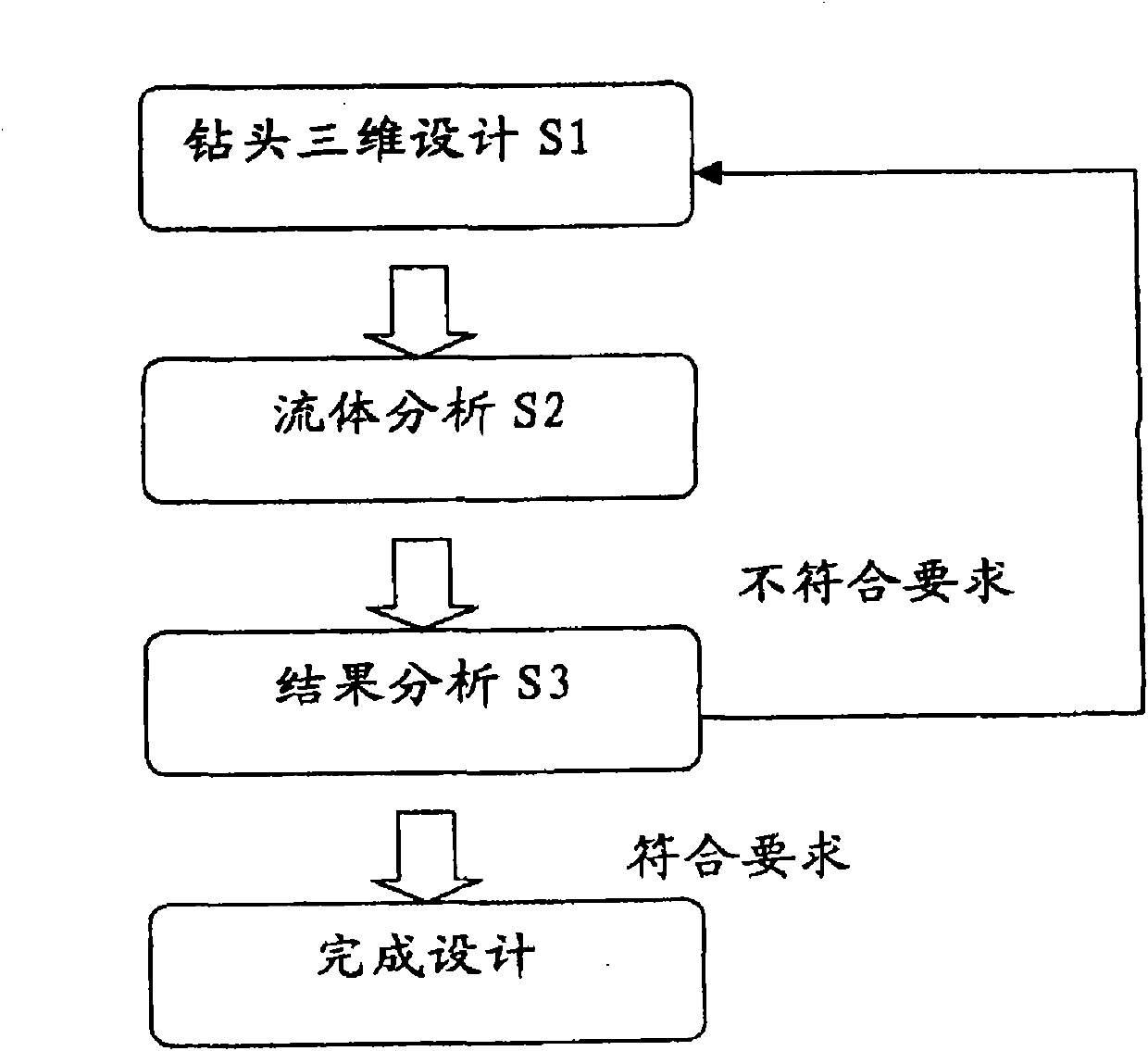

[0013] attached image 3 The steps to determine the parameters of the PDC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com