Liquid electrophotographic ink with a charge director system

A technology of liquid electrophotography and charge director, which can be used in inks, developers, household appliances, etc., and can solve problems such as printing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 – Preparation of liquid electrophotographic (LEP) inks

[0048] Several LEP inks use alkaline Barium Petronate (LT); Ba[(C 13 h 27 )-O-C(O)CH 2 CH(SO 3 - )C(O)-O-(C 13 h 27 )] 2 and BaHPO 4( SCD); isopropylamine dodecylbenzenesulfonate (GT); light isoparaffinic oil (ISOPAR® L, Exxon Mobile); ethylene acrylic acid copolymer, ethylene methacrylic acid copolymer; and Cabot monarch 800 to prepare. The percentages of LT, SCD and GT for different inks are shown in Table 1.

[0049] Table 1

[0050] Charged System No.

SCD

LT

GT

1

0.04

0.1

0.06

2

0.02

0.1

0.06

3

0.01

0.1

0.06

4

0.04

0.08

0.06

5

0.04

0.06

0.04

6

0.04

0.04

0.06

7

0.04

0.1

0.04

8

0.04

0.1

0.02

9

0.04

0.1

0.01

10

0.02

0.08

0.04

11

0.04

0.14

0.06

12

0.03

0.1

0.08

13

0.05

0.08

0.0...

Embodiment 2

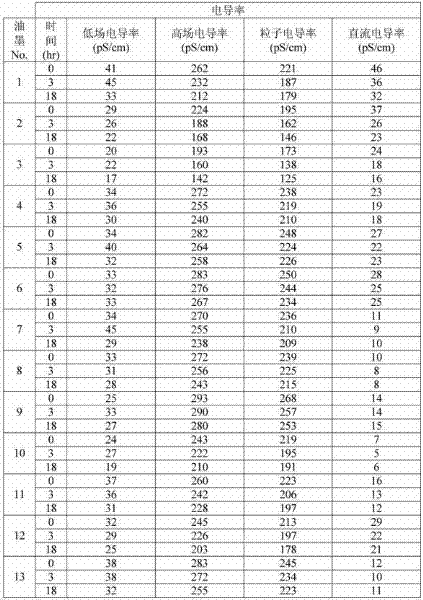

[0054] Example 2 – Conductivity of LEP ink

[0055] During preparation, the conductivity of the LEP ink of Example 1 was tested after 3 hours and 18 hours of electrophorhetic mobility. The results are shown in Table 2.

[0056]

Embodiment 3

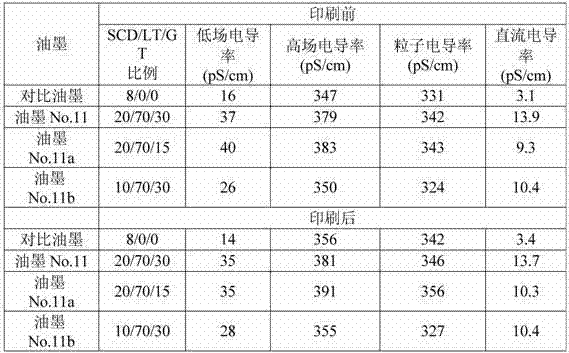

[0057] Example 3 – Evaluation of LEP Ink No.11

[0058] The LEP ink No. 11 of Example 1 was further evaluated for streak performance. The SCD / LT / GT ratio of LEP Ink No. 11 was slightly changed to provide two additional LEP inks (11a and 11b). In addition, a comparative LEP ink without the charge director system of the present invention was used as indicated by the SCD / LT / GT ratio. All inks were formulated according to the composition of LEP Ink No. 11 except for the ratio of SCD / LT / GT shown. Table 3 shows the obtained conductivity before and after printing.

[0059] table 3

[0060]

[0061] LT – Alkaline Barium Petronate;

[0062] SCD-Ba[(C 13 h 27 )-O-C(O)CH 2 CH(SO 3 - )C(O)-O-(C 13 h 27 )] 2 and BaHPO 4 ;

[0063] GT-dodecylbenzenesulfonic acid isopropylamine salt

[0064] As shown in Table 3, LEP inks No. 11, 11a and 11b achieved a low-field conductivity of at least 20 pS / cm, while the comparative ink did not. The LEP inks are stable after printing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap