Polyhydroxy-structure emulsifier and oil-base drilling fluid containing same

An emulsifier and polyhydric technology, which is applied in the field of oil-based drilling fluid and polyhydric structural emulsifiers, can solve the problems of limited high temperature resistance of emulsifiers, no technical advantages, high addition amount, etc., and achieve good fluidity and good electrical stability and system stability, good chemical stability and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

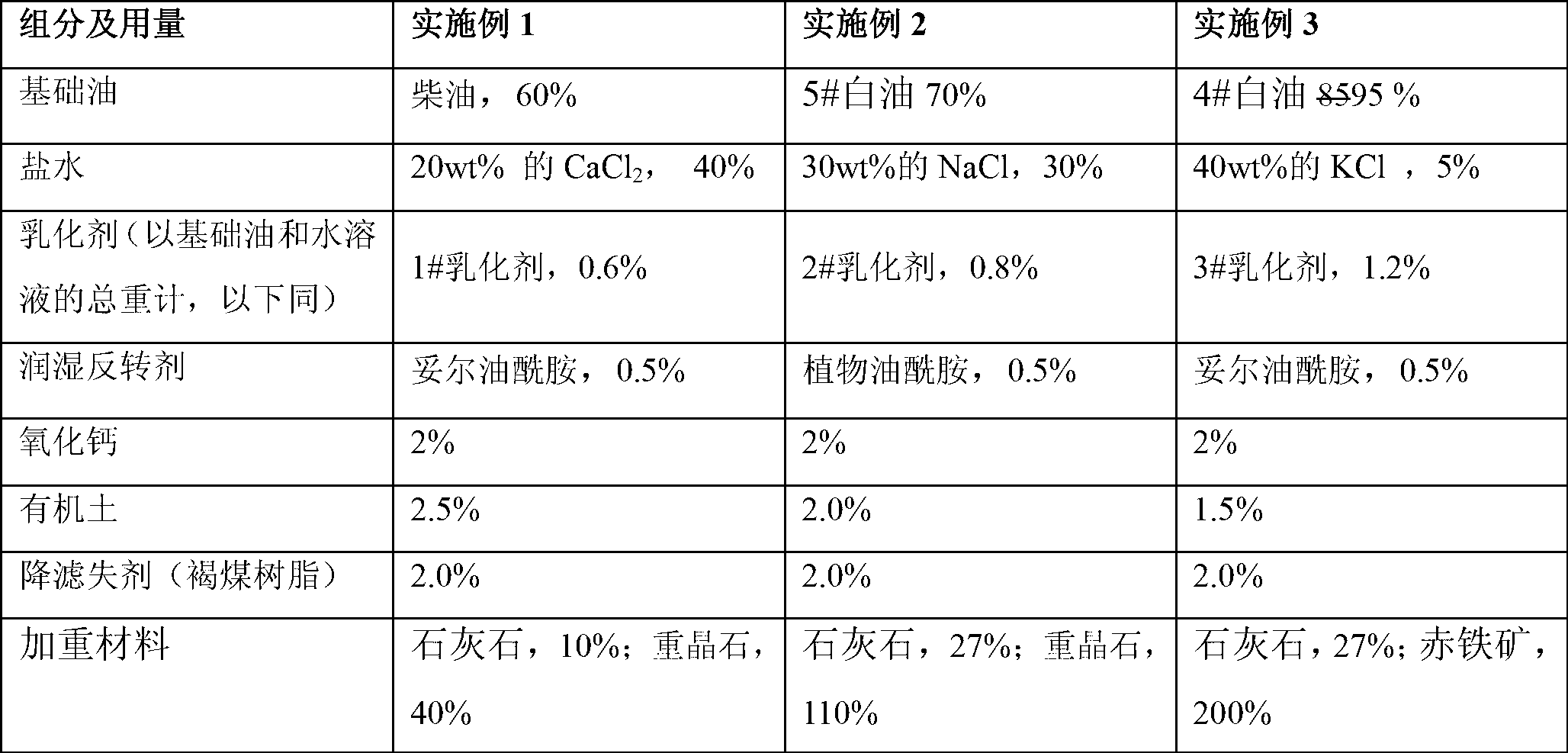

[0022] The emulsifier of the present invention and the drilling fluid containing the emulsifier will be described in detail below in conjunction with the examples.

[0023] Emulsifier of the present invention has following chemical structural formula:

[0024] R 1 -(CH 2 -CH 2 ) n -C(OH)-(CH 2 ) m -C(O)-OCH 2 -CH(O-C(O)-R 2 )-CH 2 O-C(O)-(CH 2 ) m -CH(OH)R 3

[0025] where R 1 , R 3 for C 15 ~C 21 alkanes or monoalkenes, R 2 for hydrogen or C 12 ~C 22 Alkanes, mono-olefins or di-olefins, n value is 1-3, m value is 1-4.

[0026] The above-mentioned emulsifier is an oxidatively polymerized fatty acid ester, which is liquid at room temperature and does not need to add a solvent. Its hydroxyl value is 50-87, and its acid value is 5-50. The fatty acid used is derived from one of coconut oil, cottonseed oil, castor oil, rapeseed oil, soybean oil, palm oil, peanut oil or tall oil, or any two or more of them in any ratio mixture.

[0027] Use vegetable oil and ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap