Polymer actuator

一种致动器、聚合物的技术,应用在机器/发动机、发电机/电动机、产生机械动力的机构等方向,能够解决摩擦变大、导电性膜难以顺畅移动、绝缘性受损等问题,达到提高电绝缘性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0108] The polymer actuator and its control method according to the first embodiment of the present invention will be described.

[0109]

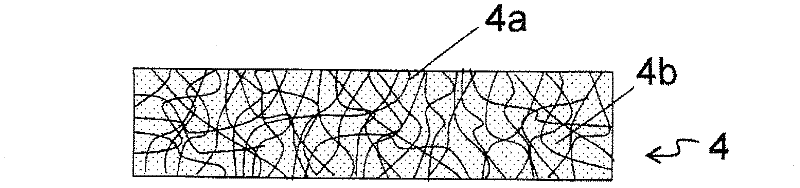

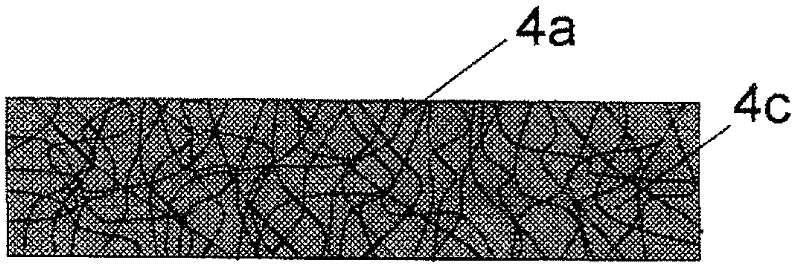

[0110] Figure 1A and Figure 1B It is a plan view and a cross-sectional view schematically showing the configuration of the polymer actuator of the first embodiment. Figure 1C is a cross-sectional view schematically showing the configuration of an actuator according to another example of the above-mentioned first embodiment, Figure 1D It is an enlarged cross-sectional view schematically showing a part of the configuration of an actuator according to still another example of the above-mentioned first embodiment.

[0111] Figure 1A and Figure 1B The shown actuator is configured to have a conductive active component layer as a first electrode layer 1, and further has a second electrode layer 2 opposite to the first electrode layer, between the first electrode layer 1 and the second electrode layer Electrolyte layer portion 11 is a...

no. 2 approach

[0164] Figure 10 is a cross-sectional view schematically showing the configuration of a polymer actuator according to a second embodiment of the present invention.

[0165] In the second embodiment, the second electrode layer 2, the second electrolyte layer 4, the first electrolyte layer 3, the active member layer 1, the first electrolyte layer 3, the second electrolyte layer 4, and the second electrode layer 2, Using the second electrode layer 2 as a common member, multiple layers are repeatedly stacked. The second electrode 2, the second electrolyte layer 4, the first electrolyte layer 3, and the active member layer 1 have the same structures as those of the first embodiment. Both ends of the plurality of active member layers 1 are connected by one force acting portion 6 .

[0166] In the configuration of the second embodiment, since the active member layers 1 are connected in parallel, a large force can be generated.

no. 3 approach

[0168] Figure 11A is a cross-sectional view schematically showing the configuration of a polymer actuator according to a third embodiment of the present invention.

[0169] In the third embodiment, the outer surface of the active member layer 1 is bonded to the supporting member 9 . The support member 9 is, for example, a film made of an organic material or metal, and can be bent in a direction (thickness direction) perpendicular to the film surface. By applying a voltage between the working electrode (active member layer 1) and the counter electrode (second electrode layer 2), the active member layer 1 expands and contracts, but one side of the active member layer 1 is bonded to the supporting member 9. , so the active member layer 1 and the supporting member 9 perform bending action as a whole.

[0170] Figure 11B is a schematic representation of the state of bending motion. At once Figure 11B In the state (a) on the left, a positive voltage is applied to the active ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com