Numerically-controlled multi-point side-pressing frame hydraulic machine

A technology for hydraulic presses and blank holders, applied in the field of hydraulic presses, can solve problems affecting product quality, poor stability, uneven pressure, etc., and achieve the effects of high product quality, guaranteed strength, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

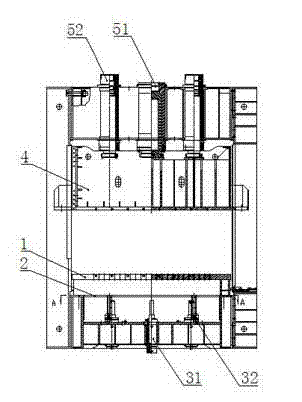

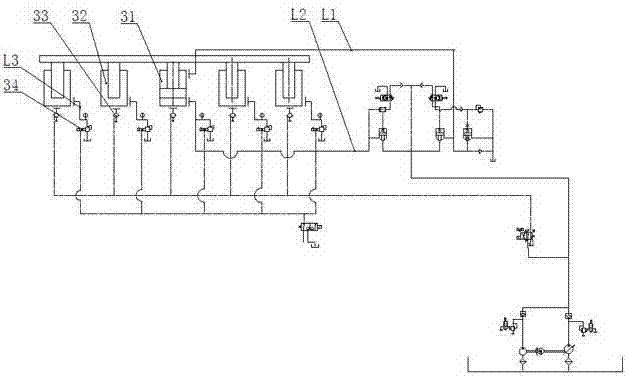

[0016] Such as figure 1 , 2 As shown, the hydraulic press workbench 1 is built with a hydraulic cushion 2, which is driven by several hydraulic cushion cylinders evenly distributed in the workbench, and each hydraulic cushion cylinder can independently control the pressure by the hydraulic oil circuit of the hydraulic cushion. A slider 4 is set directly above the workbench 2, and the slider 4 is driven by a slider oil cylinder installed in the upper beam of the hydraulic machine. A hydraulic buffer oil circuit 5 and a quick pressure relief oil circuit 6 are arranged on the hydraulic oil circuit of the slider oil cylinder. See Figure 4 .

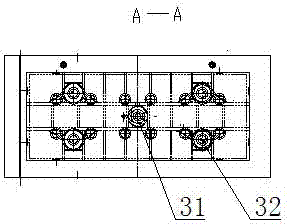

[0017] There are five hydraulic cushion oil cylinders in this embodiment, including a piston cylinder 31 located in the center and four plunger cylinders 32 evenly distributed at the four corners of the hydraulic cushion 2. The hydraulic oil circuit of the hydraulic cushion is as follows image 3 As shown, it mainly includes a filling val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com