Hollow fireproof heat preservation board

A technology of fire-proof insulation board and insulation board, which is applied in the directions of heat preservation, fire prevention, building components, etc., can solve the problems such as the inability of fire-proof insulation materials to be realized, and achieve the effect of good insulation effect, good fire resistance performance, and enhanced gripping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

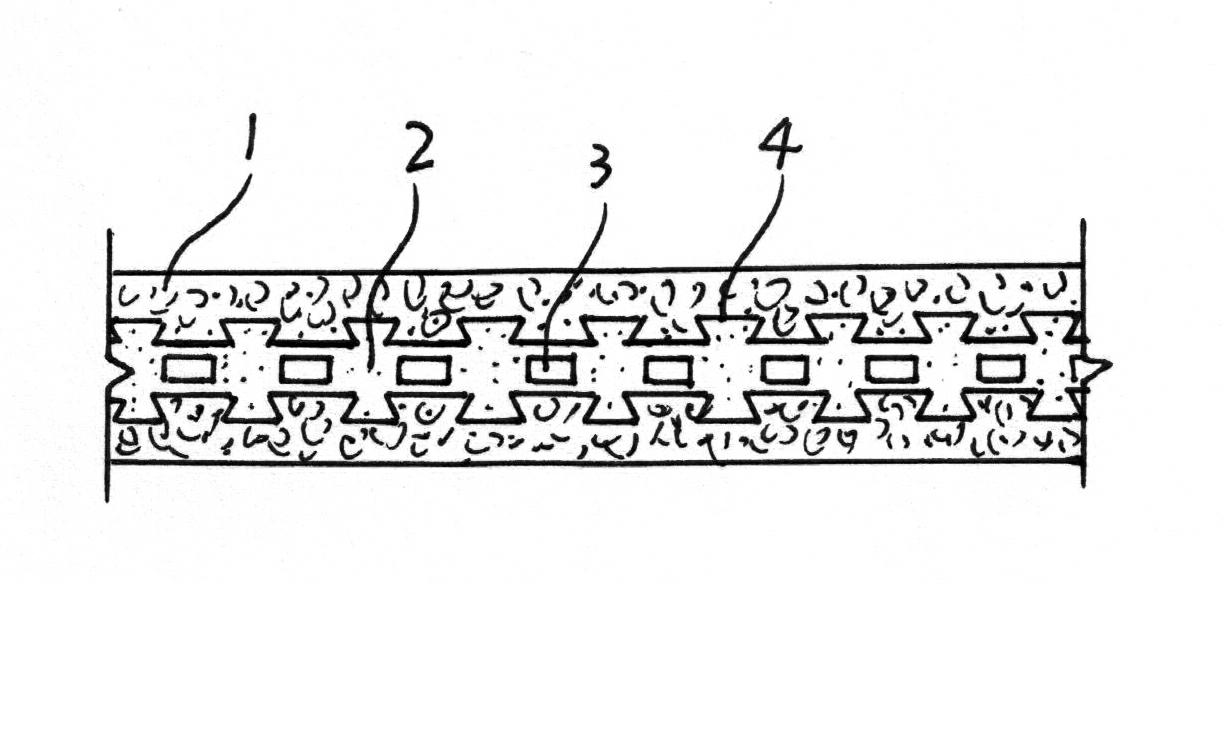

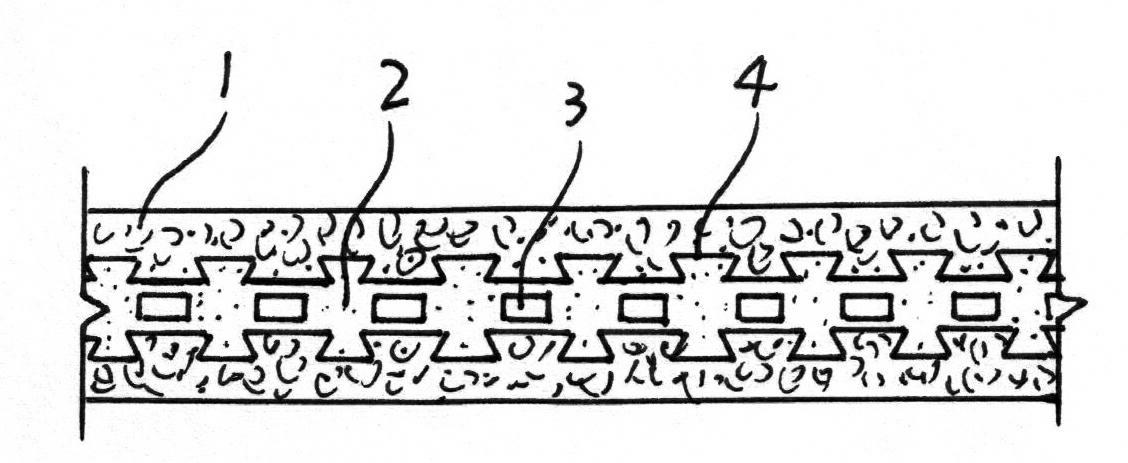

[0012] See figure 1 The hollow fireproof insulation board shown is composed of an inner core insulation board 2 and a fireproof outer body 1 board wrapped and closed on the inner core insulation board 2, and the inner core insulation board 2 is distributed with cavities 3 , the joint surfaces of the inner core insulation board 2 and the fireproof outer layer body 1 are connected as a whole through a single-directional dovetail groove 4 . The periphery of the hollow fireproof heat preservation board of the present invention is parallel end edges.

[0013] In the above, the combination of the inner core insulation board 2 and the fireproof outer layer body 1 of the present invention can not only adopt the single direction dovetail groove 4, but also adopt vertical and horizontal dovetail grooves on the surface.

[0014] In addition, in practical appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com