Coaxial double-nut coupling mechanism

A coupling mechanism and double nut technology, applied in the mechanical field, can solve the problems of difficult disassembly, incompatibility, large space occupation, etc., and achieve the effects of wide application range, improved service life, and high coupling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in conjunction with accompanying drawing:

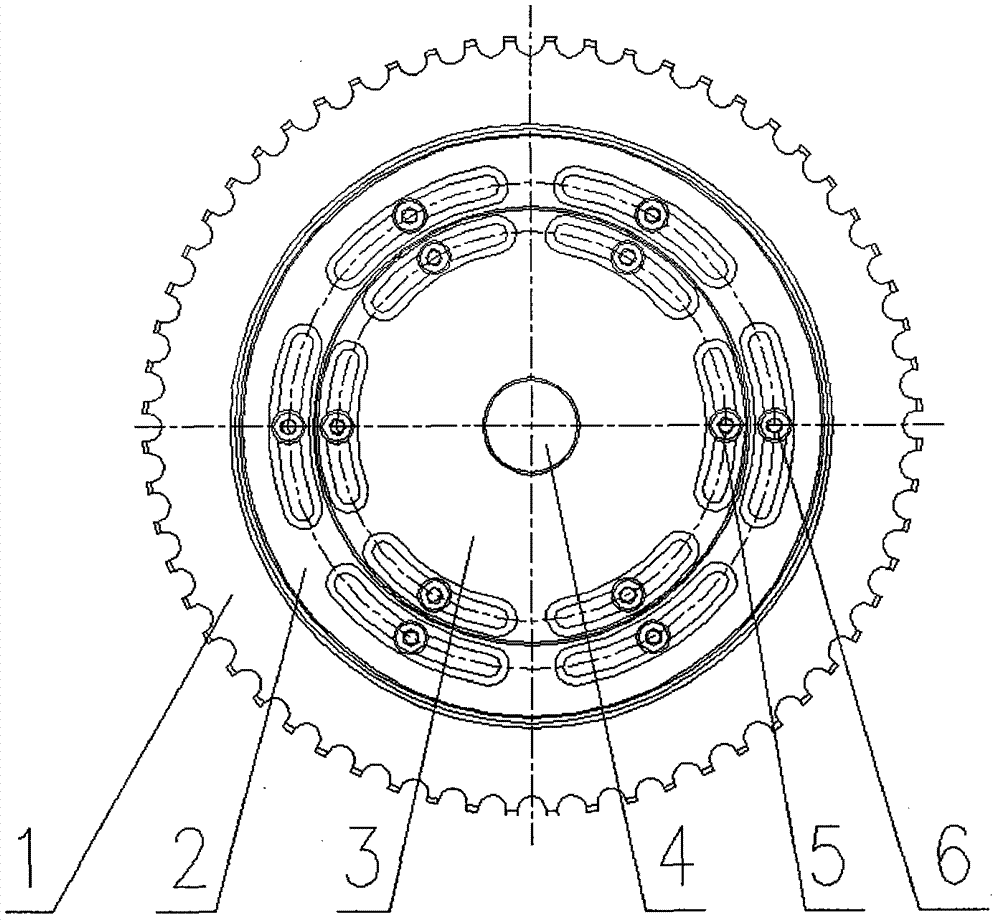

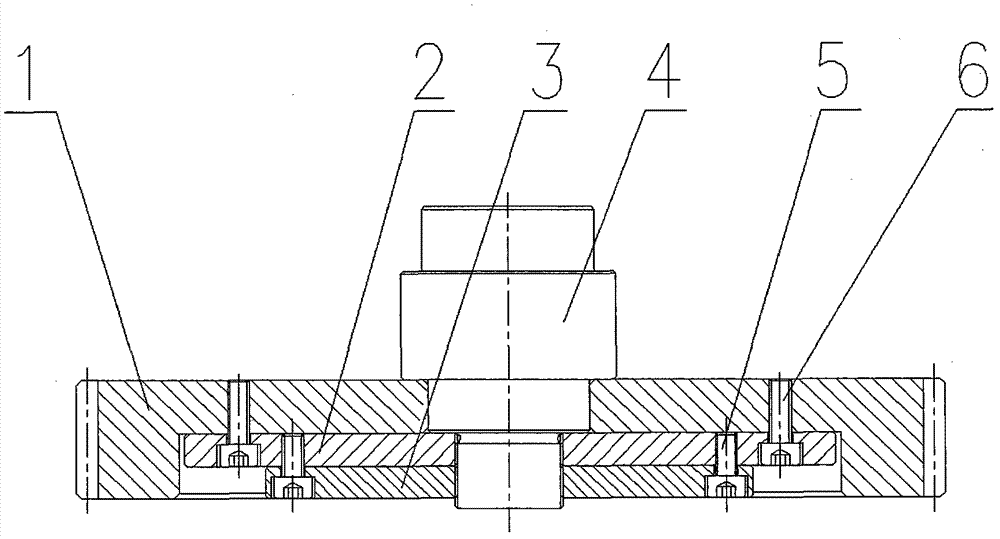

[0017] Shown with reference to accompanying drawing, a kind of novel double-nut coaxial coupling mechanism comprises transmission wheel 1, transmission nut 2, locking nut 3, transmission shaft 4, fastening screw 5, coupling screw 6. Transmission wheel 1 is provided with notch; Transmission shaft 4 is shaped on the screw thread that cooperates with transmission nut 3, locking nut 4; Drive shaft 4 and drive wheel 1 adopt clearance fit. By controlling the machining accuracy of the transmission wheel 1 and the transmission shaft 4, the purpose of controlling the connection accuracy thereof can be achieved. Screw the transmission nut 2 into the threaded part of the transmission shaft 4 until the bottom surface of the transmission nut 2 is close to the bottom surface of the notch of the transmission wheel 1 . Then tighten the connecting screws 6 in the 6 stepped long holes of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com